Material Handling Equipment Market Size, Share & Trends Analysis Report by Offering (Hardware, Software, Services), Package Type, Industry Vertical, End-Use Industry × Application, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

Market Structure & Evolution |

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Material Handling Equipment Market Size, Share, and Growth

The global Material Handling Equipment market is experiencing robust growth, with its estimated value of USD 64.1 billion in the year 2025 and USD 131.8 billion by the period 2035, registering a CAGR of 6.8%. Asia Pacific leads the market with market share of 54.2% with USD 34.7 billion revenue.

"Mercedes-Benz has moved away from traditional forklifts to enhance safety and productivity in its factories and warehouses. The company is adopting safer alternatives such as overhead cranes and autonomous vehicles, aiming to reduce the risk of accidents associated with forklifts."

The material handling equipment market is a highly competitive sector that is growing vigorously due to various factors. With the growing e-commerce popularity, the demand on the efficient logistics solutions is raised considerably. An example would be the successful large-scale contract of Jungheinrich AG in 2025 with Amazon to provide automated guided vehicles (AGVs) that will be sent to their fulfillment centers to maximize efficiency.

There is further automation and robot manufacturing that are changing the material handling. The year 2025 saw the introduction of a new generation of collaborative robots by KUKA AG, which was to be operated by human workers and therefore enhanced safety and output. Market trends are also shifting towards green solutions and Eco Friendly solutions as the focus is on sustainability. In 2025, Daifuku Co., Ltd. released a series of energy-saving conveyors to keep up with the world sustainability plans.

Moreover, system intelligence and predictive maintenance is being advanced with the incorporation of Industry 4.0 technologies, like IoT and AI. In 2025, SSI Schaefer will introduce warehouse management systems with AI usage, which will allow reducing inventories control and downtime. It is projected that the convergence of these factors will drive the MHE market to unprecedented growth in the coming future and organizations are already relying on the use of MHE to propel their growth.

Material Handling Equipment Market Dynamics and Trends

Driver: E-commerce warehouse automation surge driving demand for automated material handling fleets and integrated logistics solutions

-

E-commerce and omni-channel fulfilment are expanding fast, demanding logistics operators to automate manual workflows with automated conveyors and sorters, self-driving forklifts to achieve throughput, accuracy and workforce productivity. The use of pallet trucks in conjunction with automated guided vehicles (AGVs) and warehouse control software in deployments continues to grow as these technologies help to reduce lead times and increase order-pick densities; in May 2025 KION commissioned a highly automated Regional Distribution Centre in Kahl am Main with an investment rate of 90 million in automation of spare parts, indicating the confidence with which OEMs now view the long-term automation of intralogistics.

- ® With retailers shrinking replenishment cycles and SKU assortments expanding, the fleet electrification and modular automation scale economics, mean replacement cycles are shorter and the total contract values are higher to suppliers. Suppliers who package hardware, software and lifecycle services receive recurring revenue in the form of managed-services contracts and spare-parts agreements. Expediting e-commerce transforms replacement and retrofit dollars into superior-valued automated applications, increasing market volume and supplier profitability.

Restraint: Supply chain component shortages and semiconductor constraints delaying equipment production and increasing capital expenditure requirements

-

Long lead times and increased price inputs to global OEMs on semiconductors, power electronics, sensors, and custom gearboxes squeeze margins and lengthen the delivery time to critical verticals including retailing and manufacturing. Hyster-Yale guided its results commentary in 2025 2025 Hyster-Yale, as a procurement volatility restricts fleet turn around and dealer inventories between regions, stated reduced shipments and order pressure due to component and tariffs uncertainty.

- The effects on smaller manufacturers and regional distributors, which do not have the scale to command priority supply, are disproportionate, so many buyers are seeing their options in terms of either tolerating longer delivery time frames or paying premiums. Capital expenditures change focus to replacement and back-up inventories, retarding the rate of authorizing new projects. The long-term ongoing component shortage increases working capital requirements and fleet replacement cadences, dampening short-term market development.

Opportunity: Electrification and lithium-ion battery adoption create market opportunity for electric forklifts and sustainable charging solutions

-

A regulatory push towards decarbonizing operations and the total-cost-of-ownership benefit of lithium-ion batteries are accelerating fleet electrification across warehouse, port, and manufacturing. In May 2025, Mitsubishi Logisnext had expanded the Houston campus to scale up the fabrication of electric forklifts and associated battery systems as part of bets on the traction of EVs in material handling fleets.

- • Adjacent services Electrification will unlock battery-as-a-service use cases, modular fast-charging infrastructure, and energy-management software, enabling OEMs and dealers to provide comprehensive solutions to lower the operational cost and environmental impact. Electrification of the fleet also facilitates smaller and quieter equipment in urban micro-fulfilment centres, which expands the available market. Electrification not only increases revenue streams in products and services but also matches suppliers to the corporate sustainability procurement best interests.

Key Trend: AI-driven predictive maintenance and fleet optimization transforming uptime, utilization, and total cost of ownership equipment

-

High-Level telematics, digital twins, and edge AI are transforming business models to move beyond reactive service to predictive service and result-based SLAs. It is simulating operations, predicting failures, and optimising throughput with AI Control Tower and digital-twin capabilities (March 2025), demonstrating by Dematic/KION Group; tools are increasingly part of the long-term service contracts increasing the service-contract value to the customer.

-

Predictive analytics minimizes unplanned outages, parts longevity, and the ability to dynamically route, increasing utilization rates; OEMs that bundle subscription-based software with their hardware acquire predictable revenue and increased switching costs. Suppliers who validate ROI with analytics attract significantly greater, multi-site deployments in light of customer demands to showcase productivity improvements. AI and digital services morph suppliers of equipment to platform suppliers and boost recurring revenues and customer stickiness.

Material Handling Equipment Market Analysis and Segmental Data

Rising Dominance of AGVs in Hardware Segment of Material Handling Equipment Market

-

The demand for Autonomous Guided Vehicles (AGVs) is highest in the hardware segment due to their capability to reduce operational costs, enhance warehouse automation, and address labour shortages. The use of AGVs in e-commerce facilities, manufacturing facilities and logistics facilities is rife to maintain a steady throughput and optimized movement of materials. Having already showcased robust hardware innovation and market adoption with the introduction of enhanced lithium-ion powered versions of its AGV product offering, Jungheinrich AG announced in May 2025 that it was expanding its AGV product portfolio in attempted increased penetration in the automated intralogistics market.

- The growing requirements of moving materials with scalability, flexibility, and safely is making AGVs a preferred investment over conventional forklifts or conveyors. They are linked further to warehouse management systems (WMS) and IoT, which also contribute to their efficacy, thus providing the guarantee that the hardware sector demand prevails over the software and service sectors. The fast cultivation of AGVs makes hardware the most lucrative segment; this, in turn, transforms the automation priorities in the world as a whole.

Asia Pacific’s Strategic Lead in the Material Handling Equipment Market

-

The demand for material handling equipment is highest in Asia Pacific due to the region’s rapid industrialization, thriving e-commerce growth, and large-scale infrastructure investments. Modernization of the logistics and manufacturing plants in countries such as China, India, and Japan is taking place in a bid to improve efficiency. Another example of the innovative development of regions is the case of Toyota Material Handling which in April 2025 launched a new smart factory dedicated to production of energy-efficient forklifts in Japan, increasing the production capacity of the company.

- Moreover, the Asia Pacific region can enjoy the increase of government-supported efforts to digitalize the supply chains, as well as powerful manufacturing clusters with high demands in modern, sophisticated automation solutions. As more users adopt robotics, AGVs and IoT-enhanced machinery, businesses in the area are transforming warehouses into fully automated centres. Asia Pacific constitutes the market as its scale, investment and innovation merge in the market making it the most profitable as well as fastest growing market to adopt equipment in material handling

Material-Handling-Equipment-Market Ecosystem

The global Material Handling Equipment market reflects a moderately consolidated structure, with Tier 1 players such as Daifuku, Honeywell, Jungheinrich, and KUKA AG holding significant market influence, while Tier 2–3 players including Addverb, Geekplus, and GreyOrange provide niche automation and robotics-based solutions. The ecosystem demonstrates medium-to-high concentration as large players dominate global contracts, while emerging firms drive innovation in robotics and AI. From a Porter’s Five Forces perspective, buyer concentration remains moderate due to the wide customer base across logistics and manufacturing, whereas supplier concentration is relatively high, as advanced component providers and technology innovators retain strong bargaining power in automation integration.

Recent Development and Strategic Overview:

- In April 2025, Daifuku began full operations at its expanded Hyderabad facility. This factory quadruples production capacity for automated storage retrieval systems, sorters, and conveyors, enabling faster delivery and local customization for India's booming logistics market.

- In March 2025, Gather AI launched Material Handling Equipment (MHE) Vision, an AI-driven MHE camera system designed to revolutionize real-time material handling visibility and warehouse efficiency. MHE Vision integrates with Material Handling Equipment, such as forklifts, auto pickers, pallet trucks, etc. It automatically tracks every pallet movement - including loading, unloading, putaway, and replenishment - digitizing workflows and providing AI-powered insights to optimize throughput, productivity, and safety.

Report Scope

|

Attribute |

Detail |

|

Market Size in 2025 |

USD 64.1 Bn |

|

Market Forecast Value in 2035 |

USD 131.8 Bn |

|

Growth Rate (CAGR) |

6.8% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value

|

|

Report Format |

Electronic (PDF) + Excel |

|

Regions and Countries Covered |

|||||

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Material-Handling-Equipment-Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Offering |

|

|

By Package Type |

|

|

By Industry Vertical |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Material Handling Equipment Market Outlook

- 2.1.1. Material Handling Equipment Market Size (Value – US$ Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Material Handling Equipment Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Industrial Machinery Industry Overview, 2025

- 3.1.1. Industry Ecosystem Analysis

- 3.1.2. Key Trends for Industrial Machinery Industry

- 3.1.3. Regional Distribution for Industrial Machinery Industry

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2025

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.1.1. Based on the component & Raw material

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.5.1. Manufacturer

- 3.6. Raw Material Analysis

- 3.1. Global Industrial Machinery Industry Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Rapid growth of e-commerce and automated warehouses increasing demand for efficient material handling solutions

- 4.1.1.2. Rising adoption of robotics and automation in manufacturing and logistics operations

- 4.1.2. Restraints

- 4.1.2.1. High initial investment and maintenance costs for advanced material handling equipment

- 4.1.2.2. Safety concerns and regulatory compliance requirements restricting deployment in certain regions.

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Raw Material & Component Suppliers

- 4.4.2. Material Handling Equipment Manufacturers

- 4.4.3. System Integrators

- 4.4.4. Distributors

- 4.4.5. End-users/ Customers

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Pricing Analysis

- 4.6.1. Regional Pricing Analysis

- 4.6.2. Segmental Pricing Trends

- 4.6.3. Factors Influencing Pricing

- 4.7. Porter’s Five Forces Analysis

- 4.8. PESTEL Analysis

- 4.9. Global Material Handling Equipment Market Demand

- 4.9.1. Historical Market Size - in Value (US$ Bn), 2021-2024

- 4.9.2. Current and Future Market Size - in Value (US$ Bn), 2025–2035

- 4.9.2.1. Y-o-Y Growth Trends

- 4.9.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Material Handling Equipment Market Analysis, by Offering

- 6.1. Key Segment Analysis

- 6.2. Material Handling Equipment Market Size (Value - US$ Bn), Analysis, and Forecasts, by Offering, 2021-2035

- 6.2.1. Hardware

- 6.2.1.1. Automated Conveyors and Sortation Systems

- 6.2.1.2. Belt Conveyors

- 6.2.1.2.1. Roller Conveyors

- 6.2.1.2.2. Overhead Conveyors

- 6.2.1.2.3. Screw Conveyors

- 6.2.1.2.4. Others

- 6.2.1.3. Gantry Robots

- 6.2.1.4. Automated Storage and Retrieval System (ASRS)

- 6.2.1.4.1. 2-Way and 4-Way Shuttle

- 6.2.1.4.2. Unit-load and Mini-load

- 6.2.1.4.3. Carousel

- 6.2.1.4.3.1. Vertical Carousel

- 6.2.1.4.3.2. Horizontal Carousel

- 6.2.1.4.4. Vertical Lift Module

- 6.2.1.5. Palletizing/De-Automated Material Handlings

- 6.2.1.6. Autonomous Guided Vehicles (AGVs)

- 6.2.1.6.1. By Type

- 6.2.1.6.1.1. Tow Vehicles

- 6.2.1.6.1.2. Unit Load Carriers

- 6.2.1.6.1.3. Pallet Trucks

- 6.2.1.6.1.4. Assembly Line Vehicles

- 6.2.1.6.1.5. Forklift Trucks

- 6.2.1.6.1.6. Others

- 6.2.1.6.2. By Navigation Technology

- 6.2.1.6.2.1. Laser Guidance

- 6.2.1.6.2.2. Magnetic Guidance

- 6.2.1.6.2.3. Inductive Guidance

- 6.2.1.6.2.4. Optical Tape Guidance

- 6.2.1.6.2.5. Vision Guidance

- 6.2.1.6.2.6. Other Navigation Technologies

- 6.2.1.6.1. By Type

- 6.2.1.7. Autonomous Mobile Robots (AMR)

- 6.2.1.8. Order and Piece Picking Robots

- 6.2.1.9. Cranes

- 6.2.1.10. Others (RFID Scanners and Readers, etc.)

- 6.2.2. Software

- 6.2.2.1. WMS and WES

- 6.2.2.2. TMS

- 6.2.2.3. Automatic Identification and Data Capture (AIDC)

- 6.2.2.4. Others

- 6.2.3. Services

- 6.2.1. Hardware

- 7. Global Material Handling Equipment Market Analysis, by Package Type

- 7.1. Key Segment Analysis

- 7.2. Material Handling Equipment Market Size (Value - US$ Bn), Analysis, and Forecasts, by Package Type, 2021-2035

- 7.2.1. Pallet

- 7.2.2. Containers

- 7.2.3. Bin

- 7.2.4. Tote

- 7.2.5. Bulk Container

- 7.2.6. Cartons

- 7.2.7. Others (Dunnage, Utilizer, etc.)

- 8. Global Material Handling Equipment Market Analysis, by Industry Vertical

- 8.1. Key Segment Analysis

- 8.2. Material Handling Equipment Market Size (Value - US$ Bn), Analysis, and Forecasts, by Device Type, 2021-2035

- 8.2.1. Food & Beverage

- 8.2.1.1. Bakery

- 8.2.1.2. Food (dry)/Grocery

- 8.2.1.3. Beverage

- 8.2.1.4. Dairy

- 8.2.1.5. Convenience/Confectionary

- 8.2.1.6. Tobacco

- 8.2.1.7. Cold chain

- 8.2.2. Personal Care

- 8.2.3. Non-durable Goods

- 8.2.3.1. Paper

- 8.2.3.2. Tissue

- 8.2.3.3. Chemicals

- 8.2.4. Durable Good

- 8.2.5. Apparel

- 8.2.5.1. E-Commerce

- 8.2.5.2. Offline (Brick-mortar stores)

- 8.2.6. Pharmaceutical

- 8.2.7. Automotive

- 8.2.8. Retail

- 8.2.8.1. E-Commerce

- 8.2.8.2. Offline (Brick-mortar stores)

- 8.2.9. 3PL

- 8.2.10. Courier, Express and Parcel Services

- 8.2.11. Others (Airport Services, Healthcare, etc.)

- 8.2.1. Food & Beverage

- 9. Global Material Handling Equipment Market Analysis and Forecasts, by Region

- 9.1. Key Findings

- 9.2. Material Handling Equipment Market Size (Volume - Mn Units and Value - US$ Mn), Analysis, and Forecasts, by Region, 2021-2035

- 9.2.1. North America

- 9.2.2. Europe

- 9.2.3. Asia Pacific

- 9.2.4. Middle East

- 9.2.5. Africa

- 9.2.6. South America

- 10. North America Material Handling Equipment Market Analysis

- 10.1. Key Segment Analysis

- 10.2. Regional Snapshot

- 10.3. North America Material Handling Equipment Market Size Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 10.3.1. Offering

- 10.3.2. Package Type

- 10.3.3. Industry Vertical

- 10.3.4. Country

- 10.3.4.1. USA

- 10.3.4.2. Canada

- 10.3.4.3. Mexico

- 10.4. USA Material Handling Equipment Market

- 10.4.1. Country Segmental Analysis

- 10.4.2. Offering

- 10.4.3. Package Type

- 10.4.4. Industry Vertical

- 10.5. Canada Material Handling Equipment Market

- 10.5.1. Country Segmental Analysis

- 10.5.2. Offering

- 10.5.3. Package Type

- 10.5.4. Industry Vertical

- 10.6. Mexico Material Handling Equipment Market

- 10.6.1. Country Segmental Analysis

- 10.6.2. Offering

- 10.6.3. Package Type

- 10.6.4. Industry Vertical

- 11. Europe Material Handling Equipment Market Analysis

- 11.1. Key Segment Analysis

- 11.2. Regional Snapshot

- 11.3. Europe Material Handling Equipment Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 11.3.1. Offering

- 11.3.2. Package Type

- 11.3.3. Industry Vertical

- 11.3.4. Country

- 11.3.4.1. Germany

- 11.3.4.2. United Kingdom

- 11.3.4.3. France

- 11.3.4.4. Italy

- 11.3.4.5. Spain

- 11.3.4.6. Netherlands

- 11.3.4.7. Nordic Countries

- 11.3.4.8. Poland

- 11.3.4.9. Russia & CIS

- 11.3.4.10. Rest of Europe

- 11.4. Germany Material Handling Equipment Market

- 11.4.1. Country Segmental Analysis

- 11.4.2. Offering

- 11.4.3. Package Type

- 11.4.4. Industry Vertical

- 11.5. United Kingdom Material Handling Equipment Market

- 11.5.1. Country Segmental Analysis

- 11.5.2. Offering

- 11.5.3. Package Type

- 11.5.4. Industry Vertical

- 11.6. France Material Handling Equipment Market

- 11.6.1. Country Segmental Analysis

- 11.6.2. Offering

- 11.6.3. Package Type

- 11.6.4. Industry Vertical

- 11.7. Italy Material Handling Equipment Market

- 11.7.1. Country Segmental Analysis

- 11.7.2. Offering

- 11.7.3. Package Type

- 11.7.4. Industry Vertical

- 11.8. Spain Material Handling Equipment Market

- 11.8.1. Country Segmental Analysis

- 11.8.2. Offering

- 11.8.3. Package Type

- 11.8.4. Industry Vertical

- 11.9. Netherlands Material Handling Equipment Market

- 11.9.1. Country Segmental Analysis

- 11.9.2. Offering

- 11.9.3. Package Type

- 11.9.4. Industry Vertical

- 11.10. Nordic Countries Material Handling Equipment Market

- 11.10.1. Country Segmental Analysis

- 11.10.2. Offering

- 11.10.3. Package Type

- 11.10.4. Industry Vertical

- 11.11. Poland Material Handling Equipment Market

- 11.11.1. Country Segmental Analysis

- 11.11.2. Offering

- 11.11.3. Package Type

- 11.11.4. Industry Vertical

- 11.12. Russia & CIS Material Handling Equipment Market

- 11.12.1. Country Segmental Analysis

- 11.12.2. Offering

- 11.12.3. Package Type

- 11.12.4. Industry Vertical

- 11.13. Rest of Europe Material Handling Equipment Market

- 11.13.1. Country Segmental Analysis

- 11.13.2. Offering

- 11.13.3. Package Type

- 11.13.4. Industry Vertical

- 12. Asia Pacific Material Handling Equipment Market Analysis

- 12.1. Key Segment Analysis

- 12.2. Regional Snapshot

- 12.3. East Asia Material Handling Equipment Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 12.3.1. Offering

- 12.3.2. Package Type

- 12.3.3. Industry Vertical

- 12.3.4. Country

- 12.3.4.1. China

- 12.3.4.2. India

- 12.3.4.3. Japan

- 12.3.4.4. South Korea

- 12.3.4.5. Australia and New Zealand

- 12.3.4.6. Indonesia

- 12.3.4.7. Malaysia

- 12.3.4.8. Thailand

- 12.3.4.9. Vietnam

- 12.3.4.10. Rest of Asia Pacific

- 12.4. China Material Handling Equipment Market

- 12.4.1. Country Segmental Analysis

- 12.4.2. Offering

- 12.4.3. Package Type

- 12.4.4. Industry Vertical

- 12.5. India Material Handling Equipment Market

- 12.5.1. Country Segmental Analysis

- 12.5.2. Offering

- 12.5.3. Package Type

- 12.5.4. Industry Vertical

- 12.6. Japan Material Handling Equipment Market

- 12.6.1. Country Segmental Analysis

- 12.6.2. Offering

- 12.6.3. Package Type

- 12.6.4. Industry Vertical

- 12.7. South Korea Material Handling Equipment Market

- 12.7.1. Country Segmental Analysis

- 12.7.2. Offering

- 12.7.3. Package Type

- 12.7.4. Industry Vertical

- 12.8. Australia and New Zealand Material Handling Equipment Market

- 12.8.1. Country Segmental Analysis

- 12.8.2. Offering

- 12.8.3. Package Type

- 12.8.4. Industry Vertical

- 12.9. Indonesia Material Handling Equipment Market

- 12.9.1. Country Segmental Analysis

- 12.9.2. Offering

- 12.9.3. Package Type

- 12.9.4. Industry Vertical

- 12.10. Malaysia Material Handling Equipment Market

- 12.10.1. Country Segmental Analysis

- 12.10.2. Offering

- 12.10.3. Package Type

- 12.10.4. Industry Vertical

- 12.11. Thailand Material Handling Equipment Market

- 12.11.1. Country Segmental Analysis

- 12.11.2. Offering

- 12.11.3. Package Type

- 12.11.4. Industry Vertical

- 12.12. Vietnam Material Handling Equipment Market

- 12.12.1. Country Segmental Analysis

- 12.12.2. Offering

- 12.12.3. Package Type

- 12.12.4. Industry Vertical

- 12.13. Rest of Asia Pacific Material Handling Equipment Market

- 12.13.1. Country Segmental Analysis

- 12.13.2. Offering

- 12.13.3. Package Type

- 12.13.4. Industry Vertical

- 13. Middle East Material Handling Equipment Market Analysis

- 13.1. Key Segment Analysis

- 13.2. Regional Snapshot

- 13.3. Middle East Material Handling Equipment Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 13.3.1. Offering

- 13.3.2. Package Type

- 13.3.3. Industry Vertical

- 13.3.4. Country

- 13.3.4.1. Turkey

- 13.3.4.2. UAE

- 13.3.4.3. Saudi Arabia

- 13.3.4.4. Israel

- 13.3.4.5. Rest of Middle East

- 13.4. Turkey Material Handling Equipment Market

- 13.4.1. Country Segmental Analysis

- 13.4.2. Offering

- 13.4.3. Package Type

- 13.4.4. Industry Vertical

- 13.5. UAE Material Handling Equipment Market

- 13.5.1. Country Segmental Analysis

- 13.5.2. Offering

- 13.5.3. Package Type

- 13.5.4. Industry Vertical

- 13.6. Saudi Arabia Material Handling Equipment Market

- 13.6.1. Country Segmental Analysis

- 13.6.2. Offering

- 13.6.3. Package Type

- 13.6.4. Industry Vertical

- 13.7. Israel Material Handling Equipment Market

- 13.7.1. Country Segmental Analysis

- 13.7.2. Offering

- 13.7.3. Package Type

- 13.7.4. Industry Vertical

- 13.8. Rest of Middle East Material Handling Equipment Market

- 13.8.1. Country Segmental Analysis

- 13.8.2. Offering

- 13.8.3. Package Type

- 13.8.4. Industry Vertical

- 14. Africa Material Handling Equipment Market Analysis

- 14.1. Key Segment Analysis

- 14.2. Regional Snapshot

- 14.3. Africa Material Handling Equipment Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 14.3.1. Offering

- 14.3.2. Package Type

- 14.3.3. Industry Vertical

- 14.3.4. Country

- 14.3.4.1. South Africa

- 14.3.4.2. Egypt

- 14.3.4.3. Nigeria

- 14.3.4.4. Algeria

- 14.3.4.5. Rest of Africa

- 14.4. South Africa Material Handling Equipment Market

- 14.4.1. Country Segmental Analysis

- 14.4.2. Offering

- 14.4.3. Package Type

- 14.4.4. Industry Vertical

- 14.5. Egypt Material Handling Equipment Market

- 14.5.1. Country Segmental Analysis

- 14.5.2. Offering

- 14.5.3. Package Type

- 14.5.4. Industry Vertical

- 14.6. Nigeria Material Handling Equipment Market

- 14.6.1. Country Segmental Analysis

- 14.6.2. Offering

- 14.6.3. Package Type

- 14.6.4. Industry Vertical

- 14.7. Algeria Material Handling Equipment Market

- 14.7.1. Country Segmental Analysis

- 14.7.2. Offering

- 14.7.3. Package Type

- 14.7.4. Industry Vertical

- 14.8. Rest of Africa Material Handling Equipment Market

- 14.8.1. Country Segmental Analysis

- 14.8.2. Offering

- 14.8.3. Package Type

- 14.8.4. Industry Vertical

- 15. South America Material Handling Equipment Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. Central and South Africa Material Handling Equipment Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 15.3.1. Offering

- 15.3.2. Package Type

- 15.3.3. Industry Vertical

- 15.3.4. Country

- 15.3.4.1. Brazil

- 15.3.4.2. Argentina

- 15.3.4.3. Rest of South America

- 15.4. Brazil Material Handling Equipment Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Offering

- 15.4.3. Package Type

- 15.4.4. Industry Vertical

- 15.5. Argentina Material Handling Equipment Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Offering

- 15.5.3. Package Type

- 15.5.4. Industry Vertical

- 15.6. Rest of South America Material Handling Equipment Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Offering

- 15.6.3. Package Type

- 15.6.4. Industry Vertical

- 16. Key Players/ Company Profile

- 16.1. Addverb Technologies Private Limited

- 16.1.1. Company Details/ Overview

- 16.1.2. Company Financials

- 16.1.3. Key Customers and Competitors

- 16.1.4. Business/ Industry Portfolio

- 16.1.5. Product Portfolio/ Specification Details

- 16.1.6. Pricing Data

- 16.1.7. Strategic Overview

- 16.1.8. Recent Developments

- 16.2. Berkshire Grey

- 16.3. BEUMER GROUP

- 16.4. Blue Yonder Group, Inc.

- 16.5. Daifuku Co., Ltd.

- 16.6. Datalogic S.p.A.

- 16.7. Dematic

- 16.8. ELETTRIC80 S.P.A.

- 16.9. Fives Group

- 16.10. ForwardX Robotics

- 16.11. Geekplus Technology Co., Ltd.

- 16.12. GreyOrange

- 16.13. Hikrobot Technology Co., Ltd.

- 16.14. Honeywell International Inc.

- 16.15. Infor

- 16.16. inVia Robotics, Inc.

- 16.17. Jungheinrich AG

- 16.18. Kardex

- 16.19. Kindred, Inc.

- 16.20. KNAPP AG

- 16.21. KUKA AG

- 16.22. Manhattan Associates, Inc.

- 16.23. MHS Global

- 16.24. Mobile Industrial Robots

- 16.25. Murata Machinery, Ltd.

- 16.26. Oracle Corporation

- 16.27. plus one robotics

- 16.28. RightHand Robotics, Inc.

- 16.29. SAP

- 16.30. SCHAEFER SYSTEMS INTERNATIONAL PVT LTD

- 16.31. Shanghai Quicktron Intelligent Technology Co., Ltd

- 16.32. System Logistics S.p.A.

- 16.33. TGW Logistics Group

- 16.34. Trimble Inc.

- 16.35. Universal Robots

- 16.36. Vanderlande Industries B.V.

- 16.37. WITRON

- 16.38. Zebra Technologies Corp

- 16.39. Other Key Players

- 16.1. Addverb Technologies Private Limited

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

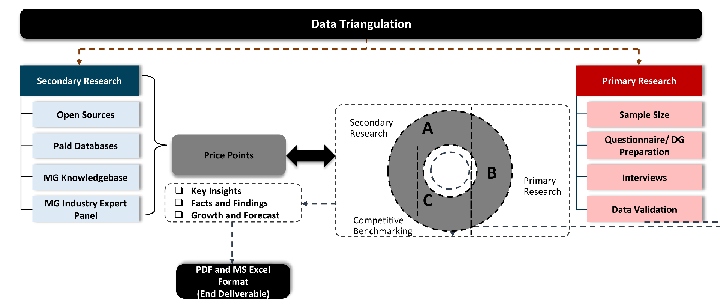

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation