Metal Cutting Tools Market Size, Share, Growth Opportunity Analysis Report by Product Type (Milling Tools, Drilling Tools, Turning Tools, Boring Tools, Broaching Tools, Reaming Tools, Threading Tools and Others (Sawing, Tapping, and Gear Cutting Tools)), Material Type, Tool Type, Machine Type, Coating Type, End Use Industry and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Metal Cutting Tools Market Size, Share, and Growth

The global metal cutting tools market is projected to grow from USD 58.1 Billion in 2025 to USD 85.3 Billion in 2035, with a strong CAGR of 3.9% during the forecasted period. Asia Pacific leads the metal cutting tools market with market share of 48.1% with USD 28.0 billion revenue.

In June 2024, Kennametal Inc., under CEO Sanjay Chowbey, launched an AI-driven Computer-Aided Manufacturing (CAM) integration initiative to enhance toolpath optimization and machining accuracy. The strategy focuses on boosting productivity through real-time data analytics, predictive maintenance, and digital workflow automation, reinforcing Kennametal’s leadership in precision metal cutting tools.

The increasing automation of industries and the booming demand in aerospace and auto industry are the global drivers of the metal cutting tools market. It is true that manufacturers are becoming more and more inclined towards CNC and smart machining tools to improve precision and efficiency. For instance, in July 2024, Sandvik AB cut its new CoroPlus ToolGuide platform with an enhanced tool selection that can be used automatically to enhance machining performance.

Moreover, Mitsubishi Materials introduced its MP9005 carbide inserts that are geared towards high-speed production of automotive components. These developments are increasing the speed of productivity and spreading the use of intelligent and high-performance cutting tools worldwide.

The major market opportunities to the global metal cutting tools market entail advancement in additive manufacturing equipment, precision measuring tools, and automation systems in the industry. These industries enjoy the advantages of increased demand of machining and digitalizing production facilities with high precision. Impact: The expansion into those areas increases the value chain integration and increases the long-term competitiveness in the metal cutting tools market.

Metal Cutting Tools Market Dynamics and Trends

Driver: Materials & Grade Innovation (Advanced Coatings and Carbide Substrates)

- The global metal cutting tools market experiences a significant change due to the innovations in the field of materials science, in particular, in the field of their coatings, substrates, and composite tool grades. Manufacturers are coming up with tools that can perform high-speed machining of hard to cut materials such as titanium, Inconel, and hardened steels that have been used in the aerospace, defense, and automotive components. Developed coatings like AlTiN, TiAlN and nanocomposites layers increase resistance to oxidation, friction and the life of cutting edge. In addition, ultra-fine carbide substrates that have been combined with optimized binder compositions also increase tool toughness and wear resistance.

- Sumitomo Electric Industries, Ltd. that launched its AC8115P grade coated carbide in 2025. Incidences of continuous machining cycles are made in this new grade, which was designed to meet the requirements of dry and high-speed turning of nickel-based alloys and increased the tool life by more than 30 percent and decreased chipping. These innovations are allowing manufacturers to be more productive, reduce tooling costs and precision.

- The ever-increasing improvements in the materials and finishes on the tools are increasing the productivity and quality of machining operations, leading to a high demand on the next-generation high-quality cutting tools in the global metal cutting tools market.

Restraint: Raw Material Volatility and Supply Chain Dependencies

- The global metal cutting tools market has been experiencing threats of the fluctuation in price of raw materials and the intricate supply web. The elements such as tungsten, cobalt, and tantalum used in the production of carbide tools are concentrated in areas with unstable geopolitical and environmental factors such as the Democratic Republic of Congo and China. This reliance exposes one to trade barriers and inflated prices. In addition, enhanced sustainability standards in the EU and North America have created compliance expenses, especially in mining-based materials and the coating process of hazardous chemicals.

- For instance, in 2025, Ceratizit S.A. reorganized its procurement network, which concentrated on long-term sourcing agreements with certified suppliers and introduced closed-loop recycling of tungsten and cobalt to maintain continuity in supply. Smaller and mid-tier toolmakers are however under more financial pressure because they are directly affected by the varying material costs and hence manufacturing margins.

- The continued uncertainty in the price of raw materials and the shortage of supply in the region limit the competitiveness of smaller players and increases the cost of manufacturing, reducing the market growth momentum.

Opportunity: Sustainable Tool Manufacturing and Circular Economy Integration

- Green sustainability is fast becoming a profitable expansion form in the metal cutting tools market. OEMs and tier-one suppliers are also requiring a greener production process, which emphasizes energy-efficient production, recyclability, and optimization of the life-cycle of the tooling systems. Manufacturers are reacting to it by embracing reconditioning, recycling and take-back initiatives, where old one-time sales are being changed to recurring service-based revenue schemes. Moreover, the carbon footprint tracking and life-cycle assessment (LCA) data also add to the list of primary distinguishing characteristics when choosing suppliers in big industrial clients.

- For instance, Seco Tools AB has introduced its Circularity Program in the first half of 2025, allowing its customers to recycle and reuse used inserts and decrease waste of materials by up to 70. This project will contribute to EU Green Deal targets and help to create long-term customer relations. These sustainability-oriented services are becoming economical and environmentally beneficial that they are winning contracts with large aerospace and automotive companies over a period of years.

- The transition to the circular manufacturing and sustainability practice has a positive impact on brand recognition, regulatory adherence, and the development of a stable and high-margin service opportunity in the tooling ecosystem.

Key Trend: Modular, Smart, and Hybrid Tooling Systems

- The emergence of intelligent manufacturing and digital machining has enhanced the rise of modular and hybrid cutting tool systems which are flexible, precise and cost effective. The systems enable the manufactures to swap tool heads rapidly, optimize the geometry of the tool and incorporate sensors to monitor real-time performance. In addition to minimizing downtime, modular tooling facilitates lean manufacturing by minimizing the variety of types of tools that are needed to perform different machining operations. Predictive maintenance and optimization of the processes are made even more effective with the combination of embedded IoT and AI-based analytics.

- In 2025, Walter AG also offered its D4120 double-sided insert drill system, which has replaceable heads, two cutting edges on each insert, which provides 25 percent higher productivity and considerable carbide savings. On the same note, Kennametal Inc. also revealed intelligent modular milling systems that worked with online machine interfaces, improving precision as well as traceability in automated machining.

- The transformation to modular, intelligent and hybrid tool platforms is transforming how operational efficiency and sustainability is achieved, pushing modernization of the old machining systems and increasing demand of the tools in the global metal cutting tools market.

Metal Cutting Tools Market Analysis and Segmental Data

Based on Product Type, the Milling Tools Segment Retains the Largest Share

- The milling tools segment holds major share ~33% in the global metal cutting tools market, because it is widely used in the industry of precision manufacturing and component machining of major industries including automotive, aerospace, energy and general engineering. Milling tools are extremely multifunctional to the extent of contouring, slotting, drilling, and surface finishing, and thus are inseparable in high-performance manufacturing lines.

- The electrification of the world with lightweight alloys, hardened steels and composite materials in aircraft structure and automobiles; has contributed to the use of the newer and more advanced carbide and coated milling tools that can maintain higher temperatures and high speed. Moreover, the optimization of tool paths has been advanced due to the digitalization and the integration of CNC systems, which made the tool use more productive and consuming less material.

- In April 2025, Kyocera Corporation launched its MEV end mill series, which was optimized to have multi-edge geometry and PVD coating that had been developed in the past. The tools provide as much as 20 percent greater feed rates and longer tool life in high-speed machining of aluminum and stainless-steel parts, especially in the the manufacture of EV parts and aerospace parts. The automation trends in machining centers that are intensive on precision milling solutions also support the demand surge of achieving tighter tolerances and faster cycle times.

- The use of tools materials, coating, and integration of CNCs is still improving the dominance of milling tools to generate a continuous growth in the market across the world.

Asia Pacific Dominates Global Metal Cutting Tools Market in 2025 and Beyond

- In the Asia Pacific region, the metal cutting tools are demanded the most because of the high rate of industrialization, growth of automotive and electronics production, and implementation of new CNC and smart machining products. The key nations such as China, India and Japan are spending massively on production of high preciseness manufacturing establishments thereby generating high demand on carbide, coated and modular cutting tools.

- Sandvik AB increased its production of high-performance milling tools in Suzhou, China in 2025 to cater to the automotive and EV component manufacturing industry, which was rising in the region, to satisfy the increased demand of precision and efficiency in the region.

- Moreover, more investments in infrastructure, aerospace, and renewable energy ventures in Asia Pacific are enhancing the consumption of metal cutting tools. In early 2025, Kyocera Corporation also introduced localized high-speed mills in India to serve local aerospace and industrial manufacturers to minimize lead times and enhance availability. Vibrant local production system, the affordability of labor and easy access to raw material sources also contribute to the high attractiveness of Asia Pacific as the largest consumption center of cutting tools.

- The industrial development and investment in manufacturing in Asia Pacific has remained to make the Asia Pacific region the largest and fastest growing metal cutting tools market in the globe.

Metal-Cutting-Tools-Market Ecosystem

The global metal cutting tools market is a moderately consolidated, with Tier 1 companies, like Sandvik AB, Kennametal Inc., Ceratizit S.A. and Kyocera Corporation, and Mitsubishi Materials Corporation, having an overall control over the large segments of high-performance and premium tooling. The companies of tier 2 and 3, such as Taegutec Ltd., Tivoly S.A., and Union Tool Co., are mostly regional and mid-range competitors, which help to create a fairly fragmented lower-tier environment.

The ecosystem has been shown to concentrate highly on the premium and technologically advanced segment, and general-purpose tools are more competitive and price-sensitive. Major points in the value chain are sourcing of raw materials to make carbide and high-speed steel and precision tool production and coating, which are essential in quality and differentiation of the product.

For instance, Ceratizit S.A. has recently increased its carbide blank manufacturing plant in Luxembourg, which reinforced the upstream integration and gave the company high-quality feedstock to manufacture high-end cutting inserts, which proves the strategic role of value chain control in sustaining its competitiveness in the world markets.

Metal Cutting Tools Market Recent Development and Strategic Overview:

- In August 2025, Ceratizit S.A. reported that it was developing its manufacturing capacities in Uluberia (West Bengal) and Bommasandra (Bengaluru) in India to respond to the rising demand of cutting tool solutions in the area. This tactical step highlights the fact that the company is determined to grow, innovate and invest in India as a critical market and manufacturing center.

- In August 2025, Sandvik launched the Osprey MAR 55 which is an all-purpose tool steel powder that fills the gap in between maraging and carbon-bearing tool steels. The new alloy has a high weldability and high fracture toughness which makes it suitable in tooling where hardness of over 50 HRC and wear resistance is needed even higher than the 18-Ni group of maraging steels.

Metal-Cutting-Tools-Market Report Scope

|

Detail |

|

|

Market Size in 2025 |

USD 58.1 Bn |

|

Market Forecast Value in 2035 |

USD 85.3 Bn |

|

Growth Rate (CAGR) |

3.9% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value Million Units for Volume |

|

Report Format |

Electronic (PDF) + Excel |

|

Regions and Countries Covered for Metal Cutting Tools Market |

|||||

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered for Metal Cutting Tools Market |

|||||

|

|

|

|

|

|

Metal Cutting Tools Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

Metal Cutting Tools Market, By Product Type |

|

|

Metal Cutting Tools Market, By Material Type |

|

|

Metal Cutting Tools Market, By Tool Type |

|

|

Metal Cutting Tools Market, By Machine Type |

|

|

Metal Cutting Tools Market, By Coating Type |

|

|

Metal Cutting Tools Market, By End Use Industry |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Metal Cutting Tools Market Outlook

- 2.1.1. Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to-Market Strategy

- 2.5.1. Customer/ End Use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Metal Cutting Tools Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Industrial Machinery Overview, 2025

- 3.1.1. Industry Ecosystem Analysis

- 3.1.2. Key Trends for Industrial Machinery Industry

- 3.1.3. Regional Distribution for Industrial Machinery

- 3.2. Supplier Customer Data

- 3.3. Technology and Developments

- 3.1. Global Industrial Machinery Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Rapid industrial automation and adoption of CNC machining technologies.

- 4.1.1.2. Rising demand from automotive, aerospace, and precision engineering industries.

- 4.1.1.3. Increasing infrastructure development and expansion of manufacturing facilities in emerging economies.

- 4.1.2. Restraints

- 4.1.2.1. High initial investment and maintenance costs associated with advanced cutting tool systems.

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis/ Ecosystem Analysis

- 4.4.1. Component Suppliers

- 4.4.2. Metal Cutting Tools Manufacturers

- 4.4.3. Dealers and Distributors

- 4.4.4. End-users/ Customers

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Porter’s Five Forces Analysis

- 4.7. PESTEL Analysis

- 4.8. Global Metal Cutting Tools Market Demand

- 4.8.1. Historical Market Size - in Value (Volume - Million Units & Value - US$ Billion), 2021-2024

- 4.8.2. Current and Future Market Size - in Value (Volume - Million Units & Value - US$ Billion), 2025–2035

- 4.8.2.1. Y-o-Y Growth Trends

- 4.8.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Metal Cutting Tools Market Analysis, by Product Type

- 6.1. Key Segment Analysis

- 6.2. Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, by Product Type, 2021-2035

- 6.2.1. Milling Tools

- 6.2.2. Drilling Tools

- 6.2.3. Turning Tools

- 6.2.4. Boring Tools

- 6.2.5. Broaching Tools

- 6.2.6. Reaming Tools

- 6.2.7. Threading Tools

- 6.2.8. Others (Sawing, Tapping, and Gear Cutting Tools)

- 7. Global Metal Cutting Tools Market Analysis, by Material Type

- 7.1. Key Segment Analysis

- 7.2. Metal Cutting Tools Market Size (Value - US$ Billion), Analysis, and Forecasts, by Material Type, 2021-2035

- 7.2.1. High-Speed Steel (HSS)

- 7.2.2. Carbide

- 7.2.3. Ceramics

- 7.2.4. Cubic Boron Nitride (CBN)

- 7.2.5. Polycrystalline Diamond (PCD)

- 7.2.6. Coated Tools

- 7.2.7. Others

- 8. Global Metal Cutting Tools Market Analysis, by Tool Type

- 8.1. Key Segment Analysis

- 8.2. Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, by Tool Type, 2021-2035

- 8.2.1. Solid Tools

- 8.2.2. Indexable Inserts

- 9. Global Metal Cutting Tools Market Analysis, by Machine Type

- 9.1. Key Segment Analysis

- 9.2. Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, by Machine Type, 2021-2035

- 9.2.1. CNC Machines

- 9.2.2. Conventional Machines

- 10. Global Metal Cutting Tools Market Analysis, by Coating Type

- 10.1. Key Segment Analysis

- 10.2. Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, by Coating Type, 2021-2035

- 10.2.1. Titanium Nitride (TiN)

- 10.2.2. Titanium Aluminum Nitride (TiAlN)

- 10.2.3. Aluminum Titanium Nitride (AlTiN)

- 10.2.4. Diamond Coating

- 10.2.5. Others

- 11. Global Metal Cutting Tools Market Analysis and Forecasts, by End Use Industry

- 11.1. Key Findings

- 11.2. Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, by End Use Industry, 2021-2035

- 11.2.1. Automotive

- 11.2.2. Aerospace & Defense

- 11.2.3. Oil & Gas

- 11.2.4. Construction Equipment

- 11.2.5. Industrial Machinery

- 11.2.6. Energy & Power

- 11.2.7. Medical Devices

- 11.2.8. Others (Marine, Electrical & Electronics)

- 12. Global Metal Cutting Tools Market Analysis and Forecasts, by Region

- 12.1. Key Findings

- 12.2. Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, by Region, 2021-2035

- 12.2.1. North America

- 12.2.2. Europe

- 12.2.3. Asia Pacific

- 12.2.4. Middle East

- 12.2.5. Africa

- 12.2.6. South America

- 13. North America Metal Cutting Tools Market Analysis

- 13.1. Key Segment Analysis

- 13.2. Regional Snapshot

- 13.3. North America Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 13.3.1. Product Type

- 13.3.2. Material Type

- 13.3.3. Tool Type

- 13.3.4. Machine Type

- 13.3.5. Coating Type

- 13.3.6. End Use Industry

- 13.3.7. Country

- 13.3.7.1. USA

- 13.3.7.2. Canada

- 13.3.7.3. Mexico

- 13.4. USA Metal Cutting Tools Market

- 13.4.1. Country Segmental Analysis

- 13.4.2. Product Type

- 13.4.3. Material Type

- 13.4.4. Tool Type

- 13.4.5. Machine Type

- 13.4.6. Coating Type

- 13.4.7. End Use Industry

- 13.5. Canada Metal Cutting Tools Market

- 13.5.1. Country Segmental Analysis

- 13.5.2. Product Type

- 13.5.3. Material Type

- 13.5.4. Tool Type

- 13.5.5. Machine Type

- 13.5.6. Coating Type

- 13.5.7. End Use Industry

- 13.6. Mexico Metal Cutting Tools Market

- 13.6.1. Country Segmental Analysis

- 13.6.2. Product Type

- 13.6.3. Material Type

- 13.6.4. Tool Type

- 13.6.5. Machine Type

- 13.6.6. Coating Type

- 13.6.7. End Use Industry

- 14. Europe Metal Cutting Tools Market Analysis

- 14.1. Key Segment Analysis

- 14.2. Regional Snapshot

- 14.3. Europe Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 14.3.1. Product Type

- 14.3.2. Material Type

- 14.3.3. Tool Type

- 14.3.4. Machine Type

- 14.3.5. Coating Type

- 14.3.6. End Use Industry

- 14.3.7. Country

- 14.3.7.1. Germany

- 14.3.7.2. United Kingdom

- 14.3.7.3. France

- 14.3.7.4. Italy

- 14.3.7.5. Spain

- 14.3.7.6. Netherlands

- 14.3.7.7. Nordic Countries

- 14.3.7.8. Poland

- 14.3.7.9. Russia & CIS

- 14.3.7.10. Rest of Europe

- 14.4. Germany Metal Cutting Tools Market

- 14.4.1. Country Segmental Analysis

- 14.4.2. Product Type

- 14.4.3. Material Type

- 14.4.4. Tool Type

- 14.4.5. Machine Type

- 14.4.6. Coating Type

- 14.4.7. End Use Industry

- 14.5. United Kingdom Metal Cutting Tools Market

- 14.5.1. Country Segmental Analysis

- 14.5.2. Product Type

- 14.5.3. Material Type

- 14.5.4. Tool Type

- 14.5.5. Machine Type

- 14.5.6. Coating Type

- 14.5.7. End Use Industry

- 14.6. France Metal Cutting Tools Market

- 14.6.1. Country Segmental Analysis

- 14.6.2. Product Type

- 14.6.3. Material Type

- 14.6.4. Tool Type

- 14.6.5. Machine Type

- 14.6.6. Coating Type

- 14.6.7. End Use Industry

- 14.7. Italy Metal Cutting Tools Market

- 14.7.1. Country Segmental Analysis

- 14.7.2. Product Type

- 14.7.3. Material Type

- 14.7.4. Tool Type

- 14.7.5. Machine Type

- 14.7.6. Coating Type

- 14.7.7. End Use Industry

- 14.8. Spain Metal Cutting Tools Market

- 14.8.1. Country Segmental Analysis

- 14.8.2. Product Type

- 14.8.3. Material Type

- 14.8.4. Tool Type

- 14.8.5. Machine Type

- 14.8.6. Coating Type

- 14.8.7. End Use Industry

- 14.9. Netherlands Metal Cutting Tools Market

- 14.9.1. Country Segmental Analysis

- 14.9.2. Product Type

- 14.9.3. Material Type

- 14.9.4. Tool Type

- 14.9.5. Machine Type

- 14.9.6. Coating Type

- 14.9.7. End Use Industry

- 14.10. Nordic Countries Metal Cutting Tools Market

- 14.10.1. Country Segmental Analysis

- 14.10.2. Product Type

- 14.10.3. Material Type

- 14.10.4. Tool Type

- 14.10.5. Machine Type

- 14.10.6. Coating Type

- 14.10.7. End Use Industry

- 14.11. Poland Metal Cutting Tools Market

- 14.11.1. Country Segmental Analysis

- 14.11.2. Product Type

- 14.11.3. Material Type

- 14.11.4. Tool Type

- 14.11.5. Machine Type

- 14.11.6. Coating Type

- 14.11.7. End Use Industry

- 14.12. Russia & CIS Metal Cutting Tools Market

- 14.12.1. Country Segmental Analysis

- 14.12.2. Product Type

- 14.12.3. Material Type

- 14.12.4. Tool Type

- 14.12.5. Machine Type

- 14.12.6. Coating Type

- 14.12.7. End Use Industry

- 14.13. Rest of Europe Metal Cutting Tools Market

- 14.13.1. Country Segmental Analysis

- 14.13.2. Product Type

- 14.13.3. Material Type

- 14.13.4. Tool Type

- 14.13.5. Machine Type

- 14.13.6. Coating Type

- 14.13.7. End Use Industry

- 15. Asia Pacific Metal Cutting Tools Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. East Asia Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 15.3.1. Product Type

- 15.3.2. Material Type

- 15.3.3. Tool Type

- 15.3.4. Machine Type

- 15.3.5. Coating Type

- 15.3.6. End Use Industry

- 15.3.7. Country

- 15.3.7.1. China

- 15.3.7.2. India

- 15.3.7.3. Japan

- 15.3.7.4. South Korea

- 15.3.7.5. Australia and New Zealand

- 15.3.7.6. Indonesia

- 15.3.7.7. Malaysia

- 15.3.7.8. Thailand

- 15.3.7.9. Vietnam

- 15.3.7.10. Rest of Asia Pacific

- 15.4. China Metal Cutting Tools Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Product Type

- 15.4.3. Material Type

- 15.4.4. Tool Type

- 15.4.5. Machine Type

- 15.4.6. Coating Type

- 15.4.7. End Use Industry

- 15.5. India Metal Cutting Tools Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Product Type

- 15.5.3. Material Type

- 15.5.4. Tool Type

- 15.5.5. Machine Type

- 15.5.6. Coating Type

- 15.5.7. End Use Industry

- 15.6. Japan Metal Cutting Tools Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Product Type

- 15.6.3. Material Type

- 15.6.4. Tool Type

- 15.6.5. Machine Type

- 15.6.6. Coating Type

- 15.6.7. End Use Industry

- 15.7. South Korea Metal Cutting Tools Market

- 15.7.1. Country Segmental Analysis

- 15.7.2. Product Type

- 15.7.3. Material Type

- 15.7.4. Tool Type

- 15.7.5. Machine Type

- 15.7.6. Coating Type

- 15.7.7. End Use Industry

- 15.8. Australia and New Zealand Metal Cutting Tools Market

- 15.8.1. Country Segmental Analysis

- 15.8.2. Product Type

- 15.8.3. Material Type

- 15.8.4. Tool Type

- 15.8.5. Machine Type

- 15.8.6. Coating Type

- 15.8.7. End Use Industry

- 15.9. Indonesia Metal Cutting Tools Market

- 15.9.1. Country Segmental Analysis

- 15.9.2. Product Type

- 15.9.3. Material Type

- 15.9.4. Tool Type

- 15.9.5. Machine Type

- 15.9.6. Coating Type

- 15.9.7. End Use Industry

- 15.10. Malaysia Metal Cutting Tools Market

- 15.10.1. Country Segmental Analysis

- 15.10.2. Product Type

- 15.10.3. Material Type

- 15.10.4. Tool Type

- 15.10.5. Machine Type

- 15.10.6. Coating Type

- 15.10.7. End Use Industry

- 15.11. Thailand Metal Cutting Tools Market

- 15.11.1. Country Segmental Analysis

- 15.11.2. Product Type

- 15.11.3. Material Type

- 15.11.4. Tool Type

- 15.11.5. Machine Type

- 15.11.6. Coating Type

- 15.11.7. End Use Industry

- 15.12. Vietnam Metal Cutting Tools Market

- 15.12.1. Country Segmental Analysis

- 15.12.2. Product Type

- 15.12.3. Material Type

- 15.12.4. Tool Type

- 15.12.5. Machine Type

- 15.12.6. Coating Type

- 15.12.7. End Use Industry

- 15.13. Rest of Asia Pacific Metal Cutting Tools Market

- 15.13.1. Country Segmental Analysis

- 15.13.2. Product Type

- 15.13.3. Material Type

- 15.13.4. Tool Type

- 15.13.5. Machine Type

- 15.13.6. Coating Type

- 15.13.7. End Use Industry

- 16. Middle East Metal Cutting Tools Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Middle East Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 16.3.1. Product Type

- 16.3.2. Material Type

- 16.3.3. Tool Type

- 16.3.4. Machine Type

- 16.3.5. Coating Type

- 16.3.6. End Use Industry

- 16.3.7. Country

- 16.3.7.1. Turkey

- 16.3.7.2. UAE

- 16.3.7.3. Saudi Arabia

- 16.3.7.4. Israel

- 16.3.7.5. Rest of Middle East

- 16.4. Turkey Metal Cutting Tools Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Product Type

- 16.4.3. Material Type

- 16.4.4. Tool Type

- 16.4.5. Machine Type

- 16.4.6. Coating Type

- 16.4.7. End Use Industry

- 16.5. UAE Metal Cutting Tools Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Product Type

- 16.5.3. Material Type

- 16.5.4. Tool Type

- 16.5.5. Machine Type

- 16.5.6. Coating Type

- 16.5.7. End Use Industry

- 16.6. Saudi Arabia Metal Cutting Tools Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Product Type

- 16.6.3. Material Type

- 16.6.4. Tool Type

- 16.6.5. Machine Type

- 16.6.6. Coating Type

- 16.6.7. End Use Industry

- 16.7. Israel Metal Cutting Tools Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Product Type

- 16.7.3. Material Type

- 16.7.4. Tool Type

- 16.7.5. Machine Type

- 16.7.6. Coating Type

- 16.7.7. End Use Industry

- 16.8. Rest of Middle East Metal Cutting Tools Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Product Type

- 16.8.3. Material Type

- 16.8.4. Tool Type

- 16.8.5. Machine Type

- 16.8.6. Coating Type

- 16.8.7. End Use Industry

- 17. Africa Metal Cutting Tools Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Africa Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 17.3.1. Product Type

- 17.3.2. Material Type

- 17.3.3. Tool Type

- 17.3.4. Machine Type

- 17.3.5. Coating Type

- 17.3.6. End Use Industry

- 17.3.7. Country

- 17.3.7.1. South Africa

- 17.3.7.2. Egypt

- 17.3.7.3. Nigeria

- 17.3.7.4. Algeria

- 17.3.7.5. Rest of Africa

- 17.4. South Africa Metal Cutting Tools Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Product Type

- 17.4.3. Material Type

- 17.4.4. Tool Type

- 17.4.5. Machine Type

- 17.4.6. Coating Type

- 17.4.7. End Use Industry

- 17.5. Egypt Metal Cutting Tools Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Product Type

- 17.5.3. Material Type

- 17.5.4. Tool Type

- 17.5.5. Machine Type

- 17.5.6. Coating Type

- 17.5.7. End Use Industry

- 17.6. Nigeria Metal Cutting Tools Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Product Type

- 17.6.3. Material Type

- 17.6.4. Tool Type

- 17.6.5. Machine Type

- 17.6.6. Coating Type

- 17.6.7. End Use Industry

- 17.7. Algeria Metal Cutting Tools Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Product Type

- 17.7.3. Material Type

- 17.7.4. Tool Type

- 17.7.5. Machine Type

- 17.7.6. Coating Type

- 17.7.7. End Use Industry

- 17.8. Rest of Africa Metal Cutting Tools Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Product Type

- 17.8.3. Material Type

- 17.8.4. Tool Type

- 17.8.5. Machine Type

- 17.8.6. Coating Type

- 17.8.7. End Use Industry

- 18. South America Metal Cutting Tools Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Central and South Africa Metal Cutting Tools Market Size (Volume - Million Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 18.3.1. Product Type

- 18.3.2. Material Type

- 18.3.3. Tool Type

- 18.3.4. Machine Type

- 18.3.5. Coating Type

- 18.3.6. End Use Industry

- 18.3.7. Country

- 18.3.7.1. Brazil

- 18.3.7.2. Argentina

- 18.3.7.3. Rest of South America

- 18.4. Brazil Metal Cutting Tools Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Product Type

- 18.4.3. Material Type

- 18.4.4. Tool Type

- 18.4.5. Machine Type

- 18.4.6. Coating Type

- 18.4.7. End Use Industry

- 18.5. Argentina Metal Cutting Tools Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Product Type

- 18.5.3. Material Type

- 18.5.4. Tool Type

- 18.5.5. Machine Type

- 18.5.6. Coating Type

- 18.5.7. End Use Industry

- 18.6. Rest of South America Metal Cutting Tools Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Product Type

- 18.6.3. Material Type

- 18.6.4. Tool Type

- 18.6.5. Machine Type

- 18.6.6. Coating Type

- 18.6.7. End Use Industry

- 19. Key Players/ Company Profile

- 19.1. Ceratizit S.A.

- 19.1.1. Company Details/ Overview

- 19.1.2. Company Financials

- 19.1.3. Key Customers and Competitors

- 19.1.4. Business/ Industry Portfolio

- 19.1.5. Product Portfolio/ Specification Details

- 19.1.6. Pricing Data

- 19.1.7. Strategic Overview

- 19.1.8. Recent Developments

- 19.2. Dormer Pramet (Sandvik Group)

- 19.3. Guhring KG

- 19.4. Ingersoll Cutting Tools (IMC Group)

- 19.5. ISCAR Ltd. (IMC Group)

- 19.6. Kennametal Inc.

- 19.7. Korloy Inc.

- 19.8. Kyocera Corporation

- 19.9. Mapal Dr. Kress KG

- 19.10. Mitsubishi Materials Corporation

- 19.11. Nachi-Fujikoshi Corp.

- 19.12. OSG Corporation

- 19.13. Sandvik AB

- 19.14. Seco Tools AB

- 19.15. Sumitomo Electric Industries, Ltd.

- 19.16. Taegutec Ltd.

- 19.17. Tivoly S.A.

- 19.18. Union Tool Co.

- 19.19. Walter AG

- 19.20. YG-1 Co., Ltd.

- 19.21. Other Key Players

- 19.1. Ceratizit S.A.

Note* - This is just tentative list of players. While providing the report, we will cover a greater number of players based on their revenue and share for each geography

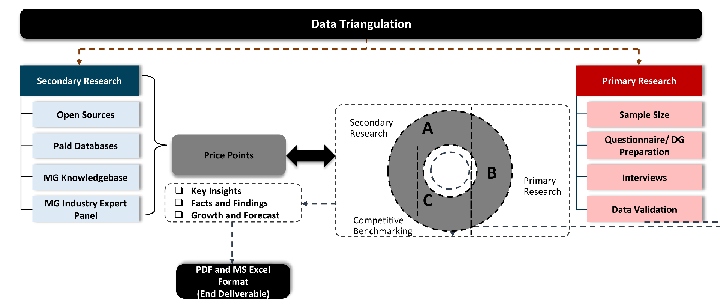

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation