Molded Pulp Packaging Market Size, Share & Trends Analysis Report by Material Type (Recycled Paperboard, Newsprint, Kraft Paper, Others), Molded Type, Product Type, Manufacturing Process, Pulp Type, Distribution Channel, Printing Technology, Capacity/Size, End-use Industry, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Molded Pulp Packaging Market Size, Share, and Growth

The global molded pulp packaging market is experiencing robust growth, with its estimated value of USD 4.9 billion in the year 2025 and USD 8.4 billion by 2035, registering a CAGR of 5.6%, during the forecast period. The molded pulp packaging market is driving due to increasing consumer awareness of environmental issues, government regulations restricting single-use plastics, and the growth of the e-commerce and food service sectors.

Fredrik Davidsson, President, Fiber Foodservice E-A-O, Huhtamaki said,

"We are very excited to start supplying locally made smooth molded fiber lids to our customers also in the UK and Ireland. This investment is a demonstration of our commitment to working with our customers to deliver sustainable packaging solutions from nearby. Our technology provides products with superior quality and competitiveness, backed by a 70-year legacy of paper pulping at Lurgan."

The global molded pulp market is rise because of the strict single-use plastic prohibitions, corporate accountability measures and the innovations in fiber-forming and coating methods to improve product functionality and recyclability. Fiber-based capacity is being rapidly scaled by manufacturers to accommodate the changes towards the circular economy. As an example, in October 2024 Huhtamaki began to make Smooth Molded Fiber (SMF) lids at its Lurgan plant in Northern Ireland in order to provide local foodservice brands with fully compostable alternatives to plastic. Plastic replacement and the transition to fiber-based packaging is increasing in speed, improving sustainability, and positioning the molded pulp in the global foodservice and consumer goods markets.

Moreover, the global molded pulp packaging industry is expanding because strategic alliances of packaging converters and global brand are increasing the use of plastic-free molded fiber solutions across the globe. An example is that in August 2024, Starbucks has collaborated with sustainable packaging firm Huhtamaki to create compostable cold beverage cup lid to minimize plastic waste in the US. These uses make the use of single-use plastics less common and make molded fiber a larger part of the packaging, further accelerating its use in the foodservice and consumer goods industries.

The market regulatory landscape of key economies is boosting the development of the global market of Molded Pulp Packaging through the implementation of the standards of the circular economy, recycling objectives, and the prohibition of single-use plastics. An example, in December 2024, the European Union of the Packaging and Packaging Waste Regulation (PPWR - Regulation (EU) 2025/40), which introduced minimum material recycled fiber content and design-to-recycle requirements of molded fiber and paper-based packaging.

The major market opportunities of the international molded pulp packaging industry are fiber-based barrier coating, compostable biopolymers, recyclable paperboard trays, automation of molded fiber machinery, and eco-friendly packaging solutions through e-commerce. These divisions enjoy comparable sustainability motivators and substance synergies.

Molded Pulp Packaging Market Dynamics and Trends

Driver: Rising Demand for Sustainable Substitutes in Foodservice Packaging

- The global molded pulp packaging market is growing, with the growing awareness of the environment and extensive requirements for plastic reductions, creating the need to find sustainable, recyclable, and compostable packaging. Manufacturers are improving the efficiency of their production processes and are investing in new forming technology to meet brand-owner sustainability promises and the global circular economy objectives.

- As an example, in 2024, Huhtamaki announced that its North America, molded-fiber, plant in Hammond, Indiana, had increased the production of 100% recycled-content egg cartons due to the increased retail demand and changes in regulations. These advancements make the production of packaging with molded pulp more visible and viable and quickly displaces the supply-chains of plastic alternatives.

- Additionally, the increasing pressure to create lightweight and renewable packaging solutions within the FMCG segment remains solidly in support of the place of molded pulp as a mainstream material. As an example, in May 2025, Amcor stated it had entered a partnership with three-dimensional molded fiber packaging solutions with lidding and liner, to be used in numerous food applications. The partnership highlights the practice of sustainability and innovation of the Amcor and Metsa Group in producing recycle-ready packaging solutions.

Restraint: High Production Costs and Complex Mold Design Requirements

- The expenditure on tooling, the energy-consuming drying, and the design of precise molds are still major deterrents to high-volume adoption of molded pulp, especially by small and middle-range suppliers. Differentiated shapes and tailor-made designs can require advanced equipment and capital spending as well as restrict the flexibility of designs. As an example, in August 2025, Fenix Industries described that custom tooling development to create a molded pulp packaging would normally incur a price beginning at around US $4000, and the precision molds would be constructed to survive more than 500,000 production cycles.

- As a result, such cost pressures can hinder competitiveness against low-cost plastic and paperboard alternatives. While technological advancements are gradually addressing these inefficiencies, cost optimization and automation remain critical for widespread adoption.

Opportunity: Advancements in Dry-Forming Technology and High-Speed Fiber Molding

- Rapid development in dry-forming technology is generating revolutionary efficiency, material savings, and macro-commercialization prospect in molded pulp manufacturing. The process removes the forming that consumes water and shortens the cycle times greatly lowering carbon footprint and cutting down operating costs. As an example, in October 2024, Stora Enso declared the launch of its innovative production plant of dry forming in Skene, Sweden. The plant is the biggest and most progressive of its kind, and a major mark in sustainable packaging technology. The development of dry-forming is reducing the cost of production, increasing sustainability, and enhancing the large-scale use of molded pulp packaging as an alternative to plastic.

- Additionally, the implementation of next-generation dry-forming and high-speed fiber-molding technologies is propelling the rapid change of the molded-pulp packaging market. As an example, in December 2024, ANDRITZ Group opened a new pilot line in Montbonnot, France, in cooperation with Pulpac AB, that focused on high-speed production of high-speed “Dry Molded Fiber” and made it possible to test complex 3D fiber packaging.

Key Trend: Growing Integration of Smart Labeling and Traceable Packaging Solutions

- The molded pulp packaging market is witnessing rapid digital transformation as manufacturers integrate smart labeling, QR codes, and NFC-enabled identifiers to improve supply chain transparency and regulatory compliance. This trend supports global digital product passport initiatives, ensuring accurate verification of product origin, recyclability, and compostability across packaging applications. For instance, in August 2025, Identiv, Inc. and IFCO Systems formed a strategic partnership to deploy BLE-enabled smart labels on IFCO’s global reusable packaging pool, enabling real-time monitoring of container usage, temperature and location.

- Moreover, the dynamic development of data-driven material tracking technologies to guarantee the authenticity, safety and sustainability of brands and regulators. As an example, in January 2025, Phenix Label increased manufacturing of specialized UHF-RAIN RFID tags in early 2025 to serve liquid-based consumer goods, allowing item-level tracking even of traditionally difficult to package product packaging types. These developments highlight how the packaging sector is shifting to integrated real-time monitoring, material lifecycle management through data and material authenticity verification across the value chain.

Molded-Pulp-Packaging-Market Analysis and Segmental Data

Trays Dominate Global Molded Pulp Packaging Market

- Trays the global molded pulp packaging market because of its wide use in foodservice, fresh produce and electronic component packaging. The growing need to have sustainable and protective packaging formats that strike a balance between durability and composability is leading to mass adoption in the retail and logistics industries. Producers and retailers of food are moving away towards plastic and foam trays and using fiber-based alternatives to meet changing requirements of sustainability. For instance, in April 2024, Sabert Corporation launched a new line of compostable molded-pulp trays the Pulp 2S Produce Tray (vegetable fresh) and the Pulp 3P Protein Tray (meat/seafood/plant-based protein). The two trays are also commercial certified as being compostable and refrigerator-safe up to 30 days.

- Additionally, innovations in barrier-coated molded pulp trays which lengthen product shelf life and withstand moisture, or grease have been developed and are now being used in frozen and ready-to-eat food segments. As an example, in August 2025, Solenis introduced Contour technology of molded pulp plates, bowls, tubs and trays an oil- and grease-resistant barrier coating that was developed to use in low- to mid-temperature food-service operations, which allows the use of molded pulp trays to operate in challenging environments previously controlled by plastics.

Asia Pacific Leads Global Molded Pulp Packaging Market Demand

- The Asia Pacific region is leading in the world market of the molded pulp packaging, which is influenced by the fast development of industrialization, e-commerce boom, and the rise in environmental standards supporting plastic-free packaging. The increased use of packaged food and takeaway meals in China, India and Indonesia are creating mass market of the molded fiber trays, clamshells, and protective packaging. As an example, in June 2024, Oji Holdings Corporation (Japan) declared a strategic investment in a Taiwanese equipment manufacturer Deluxe Technology Group to purchase global sales rights to high-end Japanese and India molded pulp packaging equipment. This will boost pulp-molding capacity in Asia and respond to increasing demand in electronic, cosmetic and food segments.

- Additionally, the sustainability committed of regional brand owners and manufacturers to develop pulp packaging is also driving the market in Asia Pacific. The higher throughput and cost efficiency of the production of the molded pulp by introduction of the advanced system of forming lines and automation. As an example, in April 2025, Nippon Molding Co., Ltd. in Japan successfully completed a site-acceptance test to a licensed fully automated site of a licensed fully automated production line of a so-called Dry Molded Fiber, making it possible to manufacture high-volume fiber packages using fewer resources.

Molded-Pulp-Packaging-Market Ecosystem

The global molded pulp packaging market is moderately fragmented, with high concentration among key players such as Brodrene Hartmann A/S, Huhtamäki Oyj, Pactiv Evergreen Inc., Sonoco Products Company, and Henry Molded Products, Inc., which are highly concentrated with huge production capacities, vertically integrated operations and strong technological expertise in fiber molding and automation. These businesses use global distribution systems, material development and sustainable product lines to serve foodservice, electronics, and consumer goods markets.

The competitiveness and adulteration to the changing environmental rules are being improved through strategic investments in innovative forming lines, biodegradable, and regional expansion. For instance, in January 2025, Pactiv Evergreen Inc. declared that its 100-percent recycled molded-fiber egg cartons and filler flats have been given complete Forest Stewardship Council (FSC) Recycled certification, which verified that the products were manufactured with 100-percent recycled materials in various plants.

Recent Development and Strategic Overview:

- In May 2025, Amcor declared a partnership to make three-dimensional molded fiber packed containers with liddings and liner in various food purposes. The partnership highlights the sustainability and innovativeness of Amcor and Metsa Group in the development of recycle-acceptable packaging solutions.

- In August 2024, Huhtamaki partnered with Starbucks to launch compostable cold beverage lids leveraging its proprietary pulp molded fiber technology. The lids are made out of plant-based fibers and they mimic the sealing capabilities of the Starbucks traditional lids of hot beverages.

Report Scope

|

Detail |

|

|

Market Size in 2025 |

USD 4.9 Bn |

|

Market Forecast Value in 20255 |

USD 8.4 Bn |

|

Growth Rate (CAGR) |

5.6% |

|

Forecast Period |

2025 – 20255 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value |

|

Report Format |

Electronic (PDF) + Excel |

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Molded Pulp Packaging Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

Molded Pulp Packaging Market By Material Type |

|

|

Molded Pulp Packaging Market By Molded Type |

|

|

Molded Pulp Packaging Market By Product Type

|

|

|

Molded Pulp Packaging Market By Manufacturing Process |

|

|

Molded Pulp Packaging Market By Pulp Type

|

|

|

Molded Pulp Packaging Market By Distribution Channel

|

|

|

Molded Pulp Packaging Market By Printing Technology

|

|

|

Molded Pulp Packaging Market By Capacity/Size |

|

|

Molded Pulp Packaging Market By End-use Industry |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Molded Pulp Packaging Market Outlook

- 2.1.1. Molded Pulp Packaging Market Size (Value - US$ Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Molded Pulp Packaging Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Molded Pulp Packaging Industry Overview, 2025

- 3.1.1. PackagingIndustry Ecosystem Analysis

- 3.1.2. Key Trends for Packaging Industry

- 3.1.3. Regional Distribution for Packaging Industry

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2025

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.1.1. Based on the component & Raw material

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.5.1. Manufacturer

- 3.6. Raw Material Analysis

- 3.1. Global Molded Pulp Packaging Industry Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Rising demand for sustainable and compostable packaging solutions

- 4.1.1.2. Expanding use in electronics and foodservice sectors for protective and eco-friendly packaging

- 4.1.1.3. Government regulations promoting plastic reduction and circular economy practices

- 4.1.2. Restraints

- 4.1.2.1. High production and tooling costs compared to plastic alternatives

- 4.1.2.2. Limited barrier properties restricting application in moisture-sensitive packaging

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Raw Material Suppliers

- 4.4.2. Molded Pulp Packaging Manufacturers

- 4.4.3. Distributors/ Suppliers

- 4.4.4. End-users/ Customers

- 4.5. Porter’s Five Forces Analysis

- 4.6. PESTEL Analysis

- 4.7. Global Molded Pulp Packaging Market Demand

- 4.7.1. Historical Market Size - (Value - US$ Bn), 2020-2024

- 4.7.2. Current and Future Market Size - (Value - US$ Bn), 2025–2035

- 4.7.2.1. Y-o-Y Growth Trends

- 4.7.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Molded Pulp Packaging Market Analysis, by Material Type

- 6.1. Key Segment Analysis

- 6.2. Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, by Material Type, 2021-2035

- 6.2.1. Recycled Paperboard

- 6.2.2. Newsprint

- 6.2.3. Kraft Paper

- 6.2.4. Corrugated Board

- 6.2.5. White Paper

- 6.2.6. Mixed Paper Sources

- 6.2.7. Others

- 7. Global Molded Pulp Packaging Market Analysis, by Molded Type

- 7.1. Key Segment Analysis

- 7.2. Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, by Molded Type, 2021-2035

- 7.2.1. Thick Wall

- 7.2.2. Transfer Molded

- 7.2.3. Thermoformed Fiber

- 7.2.4. Processed Pulp

- 8. Global Molded Pulp Packaging Market Analysis and Forecasts, by Product Type

- 8.1. Key Findings

- 8.2. Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, by Product Type, 2021-2035

- 8.2.1. Trays

- 8.2.1.1. Egg Trays

- 8.2.1.2. Fruit Trays

- 8.2.1.3. Food Service Trays

- 8.2.1.4. Industrial Trays

- 8.2.1.5. Others

- 8.2.2. Clamshells

- 8.2.3. Boxes

- 8.2.4. Plates & Bowls

- 8.2.5. Cup Carriers

- 8.2.6. End Caps

- 8.2.7. Corner Protectors

- 8.2.8. Interior Packaging

- 8.2.1. Trays

- 9. Global Molded Pulp Packaging Market Analysis and Forecasts, by Manufacturing Process

- 9.1. Key Findings

- 9.2. Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, by Manufacturing Process, 2021-2035

- 9.2.1. Thick Wall Process

- 9.2.2. Transfer Molding Process

- 9.2.3. Thermoforming Process

- 9.2.4. Processed Pulp Process

- 10. Global Molded Pulp Packaging Market Analysis and Forecasts, by Pulp Type

- 10.1. Key Findings

- 10.2. Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, by Pulp Type, 2021-2035

- 10.2.1. Virgin Fiber Pulp

- 10.2.2. Recycled Fiber Pulp

- 10.2.3. Bamboo Pulp

- 10.2.4. Bagasse Pulp

- 10.2.5. Wheat Straw Pulp

- 11. Global Molded Pulp Packaging Market Analysis and Forecasts, by Distribution Channel

- 11.1. Key Findings

- 11.2. Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, by Distribution Channel, 2021-2035

- 11.2.1. Direct Sales

- 11.2.2. Distributors

- 11.2.3. Online Channels

- 11.2.4. Retail Channels

- 12. Global Molded Pulp Packaging Market Analysis and Forecasts, by Printing Technology

- 12.1. Key Findings

- 12.2. Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, by Printing Technology, 2021-2035

- 12.2.1. Flexographic Printing

- 12.2.2. Digital Printing

- 12.2.3. Offset Printing

- 12.2.4. Screen Printing

- 12.2.5. Non-Printed

- 13. Global Molded Pulp Packaging Market Analysis and Forecasts, by Capacity/Size

- 13.1. Key Findings

- 13.2. Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, by Capacity/Size, 2021-2035

- 13.2.1. < 500ml

- 13.2.2. 500ml - 1500ml

- 13.2.3. > 1500ml

- 14. Global Molded Pulp Packaging Market Analysis and Forecasts, by End-Use Industry

- 14.1. Key Findings

- 14.2. Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, by End-Use Industry, 2021-2035

- 14.2.1. Food & Beverage

- 14.2.1.1. Fresh Produce Packaging

- 14.2.1.2. Bakery Products Packaging

- 14.2.1.3. Processed Food Packaging

- 14.2.1.4. Beverage Carriers

- 14.2.1.5. Frozen Food Packaging

- 14.2.1.6. Others

- 14.2.2. Electronics & Electrical

- 14.2.2.1. Mobile Phone Packaging

- 14.2.2.2. Laptop & Computer Packaging

- 14.2.2.3. Small Appliance Packaging

- 14.2.2.4. Electronic Component Packaging

- 14.2.2.5. Accessory Packaging

- 14.2.2.6. Others

- 14.2.3. Healthcare & Pharmaceutical

- 14.2.3.1. Medical Device Packaging

- 14.2.3.2. Pharmaceutical Bottle Packaging

- 14.2.3.3. Diagnostic Kit Packaging

- 14.2.3.4. Surgical Instrument Packaging

- 14.2.3.5. Medical Supply Packaging

- 14.2.3.6. Others

- 14.2.4. Personal Care & Cosmetics

- 14.2.4.1. Perfume Packaging

- 14.2.4.2. Skincare Product Packaging

- 14.2.4.3. Cosmetic Jar Packaging

- 14.2.4.4. Bottle Inserts

- 14.2.4.5. Gift Set Packaging

- 14.2.4.6. Others

- 14.2.5. Automotive

- 14.2.5.1. Spare Parts Packaging

- 14.2.5.2. Component Protection

- 14.2.5.3. Aftermarket Product Packaging

- 14.2.5.4. Tool Packaging

- 14.2.5.5. Others

- 14.2.6. Consumer Goods

- 14.2.6.1. Household Product Packaging

- 14.2.6.2. Toy Packaging

- 14.2.6.3. Footwear Packaging

- 14.2.6.4. Textile Packaging

- 14.2.6.5. Appliance Packaging

- 14.2.6.6. Others

- 14.2.7. Industrial & Manufacturing

- 14.2.7.1. Machinery Parts Packaging

- 14.2.7.2. Tool Packaging

- 14.2.7.3. Hardware Packaging

- 14.2.7.4. Protective Cushioning

- 14.2.7.5. Others

- 14.2.8. E-commerce & Logistics

- 14.2.8.1. Protective Inserts

- 14.2.8.2. Void Fill Solutions

- 14.2.8.3. Product Cushioning

- 14.2.8.4. Shipping Trays

- 14.2.8.5. Return Packaging

- 14.2.8.6. Others

- 14.2.9. Food Service

- 14.2.10. Agriculture

- 14.2.11. Other Industries

- 14.2.1. Food & Beverage

- 15. Global Molded Pulp Packaging Market Analysis and Forecasts, by Region

- 15.1. Key Findings

- 15.2. Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, by Region, 2021-2035

- 15.2.1. North America

- 15.2.2. Europe

- 15.2.3. Asia Pacific

- 15.2.4. Middle East

- 15.2.5. Africa

- 15.2.6. South America

- 16. North America Molded Pulp Packaging Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. North America Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 16.3.1. Material Type

- 16.3.2. Molded Type

- 16.3.3. Product Type

- 16.3.4. Manufacturing Process

- 16.3.5. Pulp Type

- 16.3.6. Distribution Channel

- 16.3.7. Printing Technology

- 16.3.8. Capacity/Size

- 16.3.9. End-use Industry

- 16.3.10. Country

- 16.3.10.1. USA

- 16.3.10.2. Canada

- 16.3.10.3. Mexico

- 16.4. USA Molded Pulp Packaging Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Material Type

- 16.4.3. Molded Type

- 16.4.4. Product Type

- 16.4.5. Manufacturing Process

- 16.4.6. Pulp Type

- 16.4.7. Distribution Channel

- 16.4.8. Printing Technology

- 16.4.9. Capacity/Size

- 16.4.10. End-use Industry

- 16.5. Canada Molded Pulp Packaging Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Material Type

- 16.5.3. Molded Type

- 16.5.4. Product Type

- 16.5.5. Manufacturing Process

- 16.5.6. Pulp Type

- 16.5.7. Distribution Channel

- 16.5.8. Printing Technology

- 16.5.9. Capacity/Size

- 16.5.10. End-use Industry

- 16.6. Mexico Molded Pulp Packaging Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Material Type

- 16.6.3. Molded Type

- 16.6.4. Product Type

- 16.6.5. Manufacturing Process

- 16.6.6. Pulp Type

- 16.6.7. Distribution Channel

- 16.6.8. Printing Technology

- 16.6.9. Capacity/Size

- 16.6.10. End-use Industry

- 17. Europe Molded Pulp Packaging Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Europe Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 17.3.1. Material Type

- 17.3.2. Molded Type

- 17.3.3. Product Type

- 17.3.4. Manufacturing Process

- 17.3.5. Pulp Type

- 17.3.6. Distribution Channel

- 17.3.7. Printing Technology

- 17.3.8. Capacity/Size

- 17.3.9. End-use Industry

- 17.3.10. Country

- 17.3.10.1. Germany

- 17.3.10.2. United Kingdom

- 17.3.10.3. France

- 17.3.10.4. Italy

- 17.3.10.5. Spain

- 17.3.10.6. Netherlands

- 17.3.10.7. Nordic Countries

- 17.3.10.8. Poland

- 17.3.10.9. Russia & CIS

- 17.3.10.10. Rest of Europe

- 17.4. Germany Molded Pulp Packaging Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Material Type

- 17.4.3. Molded Type

- 17.4.4. Product Type

- 17.4.5. Manufacturing Process

- 17.4.6. Pulp Type

- 17.4.7. Distribution Channel

- 17.4.8. Printing Technology

- 17.4.9. Capacity/Size

- 17.4.10. End-use Industry

- 17.5. United Kingdom Molded Pulp Packaging Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Material Type

- 17.5.3. Molded Type

- 17.5.4. Product Type

- 17.5.5. Manufacturing Process

- 17.5.6. Pulp Type

- 17.5.7. Distribution Channel

- 17.5.8. Printing Technology

- 17.5.9. Capacity/Size

- 17.5.10. End-use Industry

- 17.6. France Molded Pulp Packaging Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Material Type

- 17.6.3. Molded Type

- 17.6.4. Product Type

- 17.6.5. Manufacturing Process

- 17.6.6. Pulp Type

- 17.6.7. Distribution Channel

- 17.6.8. Printing Technology

- 17.6.9. Capacity/Size

- 17.6.10. End-use Industry

- 17.7. Italy Molded Pulp Packaging Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Material Type

- 17.7.3. Molded Type

- 17.7.4. Product Type

- 17.7.5. Manufacturing Process

- 17.7.6. Pulp Type

- 17.7.7. Distribution Channel

- 17.7.8. Printing Technology

- 17.7.9. Capacity/Size

- 17.7.10. End-use Industry

- 17.8. Spain Molded Pulp Packaging Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Material Type

- 17.8.3. Molded Type

- 17.8.4. Product Type

- 17.8.5. Manufacturing Process

- 17.8.6. Pulp Type

- 17.8.7. Distribution Channel

- 17.8.8. Printing Technology

- 17.8.9. Capacity/Size

- 17.8.10. End-use Industry

- 17.9. Netherlands Molded Pulp Packaging Market

- 17.9.1. Country Segmental Analysis

- 17.9.2. Material Type

- 17.9.3. Molded Type

- 17.9.4. Product Type

- 17.9.5. Manufacturing Process

- 17.9.6. Pulp Type

- 17.9.7. Distribution Channel

- 17.9.8. Printing Technology

- 17.9.9. Capacity/Size

- 17.9.10. End-use Industry

- 17.10. Nordic Countries Molded Pulp Packaging Market

- 17.10.1. Country Segmental Analysis

- 17.10.2. Material Type

- 17.10.3. Molded Type

- 17.10.4. Product Type

- 17.10.5. Manufacturing Process

- 17.10.6. Pulp Type

- 17.10.7. Distribution Channel

- 17.10.8. Printing Technology

- 17.10.9. Capacity/Size

- 17.10.10. End-use Industry

- 17.11. Poland Molded Pulp Packaging Market

- 17.11.1. Country Segmental Analysis

- 17.11.2. Material Type

- 17.11.3. Molded Type

- 17.11.4. Product Type

- 17.11.5. Manufacturing Process

- 17.11.6. Pulp Type

- 17.11.7. Distribution Channel

- 17.11.8. Printing Technology

- 17.11.9. Capacity/Size

- 17.11.10. End-use Industry

- 17.12. Russia & CIS Molded Pulp Packaging Market

- 17.12.1. Country Segmental Analysis

- 17.12.2. Material Type

- 17.12.3. Molded Type

- 17.12.4. Product Type

- 17.12.5. Manufacturing Process

- 17.12.6. Pulp Type

- 17.12.7. Distribution Channel

- 17.12.8. Printing Technology

- 17.12.9. Capacity/Size

- 17.12.10. End-use Industry

- 17.13. Rest of Europe Molded Pulp Packaging Market

- 17.13.1. Country Segmental Analysis

- 17.13.2. Material Type

- 17.13.3. Molded Type

- 17.13.4. Product Type

- 17.13.5. Manufacturing Process

- 17.13.6. Pulp Type

- 17.13.7. Distribution Channel

- 17.13.8. Printing Technology

- 17.13.9. Capacity/Size

- 17.13.10. End-use Industry

- 18. Asia Pacific Molded Pulp Packaging Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. East Asia Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 18.3.1. Material Type

- 18.3.2. Molded Type

- 18.3.3. Product Type

- 18.3.4. Manufacturing Process

- 18.3.5. Pulp Type

- 18.3.6. Distribution Channel

- 18.3.7. Printing Technology

- 18.3.8. Capacity/Size

- 18.3.9. End-use Industry

- 18.3.10. Country

- 18.3.10.1. China

- 18.3.10.2. India

- 18.3.10.3. Japan

- 18.3.10.4. South Korea

- 18.3.10.5. Australia and New Zealand

- 18.3.10.6. Indonesia

- 18.3.10.7. Malaysia

- 18.3.10.8. Thailand

- 18.3.10.9. Vietnam

- 18.3.10.10. Rest of Asia Pacific

- 18.4. China Molded Pulp Packaging Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Material Type

- 18.4.3. Molded Type

- 18.4.4. Product Type

- 18.4.5. Manufacturing Process

- 18.4.6. Pulp Type

- 18.4.7. Distribution Channel

- 18.4.8. Printing Technology

- 18.4.9. Capacity/Size

- 18.4.10. End-use Industry

- 18.5. India Molded Pulp Packaging Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Material Type

- 18.5.3. Molded Type

- 18.5.4. Product Type

- 18.5.5. Manufacturing Process

- 18.5.6. Pulp Type

- 18.5.7. Distribution Channel

- 18.5.8. Printing Technology

- 18.5.9. Capacity/Size

- 18.5.10. End-use Industry

- 18.6. Japan Molded Pulp Packaging Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Material Type

- 18.6.3. Molded Type

- 18.6.4. Product Type

- 18.6.5. Manufacturing Process

- 18.6.6. Pulp Type

- 18.6.7. Distribution Channel

- 18.6.8. Printing Technology

- 18.6.9. Capacity/Size

- 18.6.10. End-use Industry

- 18.7. South Korea Molded Pulp Packaging Market

- 18.7.1. Country Segmental Analysis

- 18.7.2. Material Type

- 18.7.3. Molded Type

- 18.7.4. Product Type

- 18.7.5. Manufacturing Process

- 18.7.6. Pulp Type

- 18.7.7. Distribution Channel

- 18.7.8. Printing Technology

- 18.7.9. Capacity/Size

- 18.7.10. End-use Industry

- 18.8. Australia and New Zealand Molded Pulp Packaging Market

- 18.8.1. Country Segmental Analysis

- 18.8.2. Material Type

- 18.8.3. Molded Type

- 18.8.4. Product Type

- 18.8.5. Manufacturing Process

- 18.8.6. Pulp Type

- 18.8.7. Distribution Channel

- 18.8.8. Printing Technology

- 18.8.9. Capacity/Size

- 18.8.10. End-use Industry

- 18.9. Indonesia Molded Pulp Packaging Market

- 18.9.1. Country Segmental Analysis

- 18.9.2. Material Type

- 18.9.3. Molded Type

- 18.9.4. Product Type

- 18.9.5. Manufacturing Process

- 18.9.6. Pulp Type

- 18.9.7. Distribution Channel

- 18.9.8. Printing Technology

- 18.9.9. Capacity/Size

- 18.9.10. End-use Industry

- 18.10. Malaysia Molded Pulp Packaging Market

- 18.10.1. Country Segmental Analysis

- 18.10.2. Material Type

- 18.10.3. Molded Type

- 18.10.4. Product Type

- 18.10.5. Manufacturing Process

- 18.10.6. Pulp Type

- 18.10.7. Distribution Channel

- 18.10.8. Printing Technology

- 18.10.9. Capacity/Size

- 18.10.10. End-use Industry

- 18.11. Thailand Molded Pulp Packaging Market

- 18.11.1. Country Segmental Analysis

- 18.11.2. Material Type

- 18.11.3. Molded Type

- 18.11.4. Product Type

- 18.11.5. Manufacturing Process

- 18.11.6. Pulp Type

- 18.11.7. Distribution Channel

- 18.11.8. Printing Technology

- 18.11.9. Capacity/Size

- 18.11.10. End-use Industry

- 18.12. Vietnam Molded Pulp Packaging Market

- 18.12.1. Country Segmental Analysis

- 18.12.2. Material Type

- 18.12.3. Molded Type

- 18.12.4. Product Type

- 18.12.5. Manufacturing Process

- 18.12.6. Pulp Type

- 18.12.7. Distribution Channel

- 18.12.8. Printing Technology

- 18.12.9. Capacity/Size

- 18.12.10. End-use Industry

- 18.13. Rest of Asia Pacific Molded Pulp Packaging Market

- 18.13.1. Country Segmental Analysis

- 18.13.2. Material Type

- 18.13.3. Molded Type

- 18.13.4. Product Type

- 18.13.5. Manufacturing Process

- 18.13.6. Pulp Type

- 18.13.7. Distribution Channel

- 18.13.8. Printing Technology

- 18.13.9. Capacity/Size

- 18.13.10. End-use Industry

- 19. Middle East Molded Pulp Packaging Market Analysis

- 19.1. Key Segment Analysis

- 19.2. Regional Snapshot

- 19.3. Middle East Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 19.3.1. Material Type

- 19.3.2. Molded Type

- 19.3.3. Product Type

- 19.3.4. Manufacturing Process

- 19.3.5. Pulp Type

- 19.3.6. Distribution Channel

- 19.3.7. Printing Technology

- 19.3.8. Capacity/Size

- 19.3.9. End-use Industry

- 19.3.10. Country

- 19.3.10.1. Turkey

- 19.3.10.2. UAE

- 19.3.10.3. Saudi Arabia

- 19.3.10.4. Israel

- 19.3.10.5. Rest of Middle East

- 19.4. Turkey Molded Pulp Packaging Market

- 19.4.1. Country Segmental Analysis

- 19.4.2. Material Type

- 19.4.3. Molded Type

- 19.4.4. Product Type

- 19.4.5. Manufacturing Process

- 19.4.6. Pulp Type

- 19.4.7. Distribution Channel

- 19.4.8. Printing Technology

- 19.4.9. Capacity/Size

- 19.4.10. End-use Industry

- 19.5. UAE Molded Pulp Packaging Market

- 19.5.1. Material Type

- 19.5.2. Molded Type

- 19.5.3. Product Type

- 19.5.4. Manufacturing Process

- 19.5.5. Pulp Type

- 19.5.6. Distribution Channel

- 19.5.7. Printing Technology

- 19.5.8. Capacity/Size

- 19.5.9. End-use Industry

- 19.6. Saudi Arabia Molded Pulp Packaging Market

- 19.6.1. Country Segmental Analysis

- 19.6.2. Material Type

- 19.6.3. Molded Type

- 19.6.4. Product Type

- 19.6.5. Manufacturing Process

- 19.6.6. Pulp Type

- 19.6.7. Distribution Channel

- 19.6.8. Printing Technology

- 19.6.9. Capacity/Size

- 19.6.10. End-use Industry

- 19.7. Israel Molded Pulp Packaging Market

- 19.7.1. Country Segmental Analysis

- 19.7.2. Material Type

- 19.7.3. Molded Type

- 19.7.4. Product Type

- 19.7.5. Manufacturing Process

- 19.7.6. Pulp Type

- 19.7.7. Distribution Channel

- 19.7.8. Printing Technology

- 19.7.9. Capacity/Size

- 19.7.10. End-use Industry

- 19.8. Rest of Middle East Molded Pulp Packaging Market

- 19.8.1. Country Segmental Analysis

- 19.8.2. Material Type

- 19.8.3. Molded Type

- 19.8.4. Product Type

- 19.8.5. Manufacturing Process

- 19.8.6. Pulp Type

- 19.8.7. Distribution Channel

- 19.8.8. Printing Technology

- 19.8.9. Capacity/Size

- 19.8.10. End-use Industry

- 20. Africa Molded Pulp Packaging Market Analysis

- 20.1. Key Segment Analysis

- 20.2. Regional Snapshot

- 20.3. Africa Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 20.3.1. Material Type

- 20.3.2. Molded Type

- 20.3.3. Product Type

- 20.3.4. Manufacturing Process

- 20.3.5. Pulp Type

- 20.3.6. Distribution Channel

- 20.3.7. Printing Technology

- 20.3.8. Capacity/Size

- 20.3.9. End-use Industry

- 20.3.10. Country

- 20.3.10.1. South Africa

- 20.3.10.2. Egypt

- 20.3.10.3. Nigeria

- 20.3.10.4. Algeria

- 20.3.10.5. Rest of Africa

- 20.4. South Africa Molded Pulp Packaging Market

- 20.4.1. Country Segmental Analysis

- 20.4.2. Material Type

- 20.4.3. Molded Type

- 20.4.4. Product Type

- 20.4.5. Manufacturing Process

- 20.4.6. Pulp Type

- 20.4.7. Distribution Channel

- 20.4.8. Printing Technology

- 20.4.9. Capacity/Size

- 20.4.10. End-use Industry

- 20.5. Egypt Molded Pulp Packaging Market

- 20.5.1. Country Segmental Analysis

- 20.5.2. Material Type

- 20.5.3. Molded Type

- 20.5.4. Product Type

- 20.5.5. Manufacturing Process

- 20.5.6. Pulp Type

- 20.5.7. Distribution Channel

- 20.5.8. Printing Technology

- 20.5.9. Capacity/Size

- 20.5.10. End-use Industry

- 20.6. Nigeria Molded Pulp Packaging Market

- 20.6.1. Country Segmental Analysis

- 20.6.2. Material Type

- 20.6.3. Molded Type

- 20.6.4. Product Type

- 20.6.5. Manufacturing Process

- 20.6.6. Pulp Type

- 20.6.7. Distribution Channel

- 20.6.8. Printing Technology

- 20.6.9. Capacity/Size

- 20.6.10. End-use Industry

- 20.7. Algeria Molded Pulp Packaging Market

- 20.7.1. Country Segmental Analysis

- 20.7.2. Material Type

- 20.7.3. Molded Type

- 20.7.4. Product Type

- 20.7.5. Manufacturing Process

- 20.7.6. Pulp Type

- 20.7.7. Distribution Channel

- 20.7.8. Printing Technology

- 20.7.9. Capacity/Size

- 20.7.10. End-use Industry

- 20.8. Rest of Africa Molded Pulp Packaging Market

- 20.8.1. Country Segmental Analysis

- 20.8.2. Material Type

- 20.8.3. Molded Type

- 20.8.4. Product Type

- 20.8.5. Manufacturing Process

- 20.8.6. Pulp Type

- 20.8.7. Distribution Channel

- 20.8.8. Printing Technology

- 20.8.9. Capacity/Size

- 20.8.10. End-use Industry

- 21. South America Molded Pulp Packaging Market Analysis

- 21.1. Key Segment Analysis

- 21.2. Regional Snapshot

- 21.3. Central and South Africa Molded Pulp Packaging Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 21.3.1. Material Type

- 21.3.2. Molded Type

- 21.3.3. Product Type

- 21.3.4. Manufacturing Process

- 21.3.5. Pulp Type

- 21.3.6. Distribution Channel

- 21.3.7. Printing Technology

- 21.3.8. Capacity/Size

- 21.3.9. End-use Industry

- 21.3.10. Country

- 21.3.10.1. Brazil

- 21.3.10.2. Argentina

- 21.3.10.3. Rest of South America

- 21.4. Brazil Molded Pulp Packaging Market

- 21.4.1. Country Segmental Analysis

- 21.4.2. Material Type

- 21.4.3. Molded Type

- 21.4.4. Product Type

- 21.4.5. Manufacturing Process

- 21.4.6. Pulp Type

- 21.4.7. Distribution Channel

- 21.4.8. Printing Technology

- 21.4.9. Capacity/Size

- 21.4.10. End-use Industry

- 21.5. Argentina Molded Pulp Packaging Market

- 21.5.1. Country Segmental Analysis

- 21.5.2. Material Type

- 21.5.3. Molded Type

- 21.5.4. Product Type

- 21.5.5. Manufacturing Process

- 21.5.6. Pulp Type

- 21.5.7. Distribution Channel

- 21.5.8. Printing Technology

- 21.5.9. Capacity/Size

- 21.5.10. End-use Industry

- 21.6. Rest of South America Molded Pulp Packaging Market

- 21.6.1. Country Segmental Analysis

- 21.6.2. Material Type

- 21.6.3. Molded Type

- 21.6.4. Product Type

- 21.6.5. Manufacturing Process

- 21.6.6. Pulp Type

- 21.6.7. Distribution Channel

- 21.6.8. Printing Technology

- 21.6.9. Capacity/Size

- 21.6.10. End-use Industry

- 22. Key Players/ Company Profile

- 22.1. Brodrene Hartmann A/S

- 22.1.1. Company Details/ Overview

- 22.1.2. Company Financials

- 22.1.3. Key Customers and Competitors

- 22.1.4. Business/ Industry Portfolio

- 22.1.5. Product Portfolio/ Specification Details

- 22.1.6. Pricing Data

- 22.1.7. Strategic Overview

- 22.1.8. Recent Developments

- 22.2. Celluloses de la Loire (CDL)

- 22.3. Dispak UK Ltd.

- 22.4. Dolco Packaging

- 22.5. EnviroPAK Corporation

- 22.6. Europack S.p.A.

- 22.7. FiberCel Packaging LLC

- 22.8. Guangzhou Nanya Pulp Molding Equipment Co., Ltd.

- 22.9. Henry Molded Products, Inc.

- 22.10. Huhtamaki Oyj

- 22.11. Keiding Inc.

- 22.12. Lihua Group

- 22.13. OrCon Industries Corporation

- 22.14. Pacific Pulp Molding, LLC

- 22.15. Pactiv Evergreen Inc.

- 22.16. Primapack SAE

- 22.17. Sealed Air Corporation

- 22.18. Sonoco Products Company

- 22.19. UFP Technologies, Inc.

- 22.20. Vernacare Limited

- 22.21. Other Key Players

- 22.1. Brodrene Hartmann A/S

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

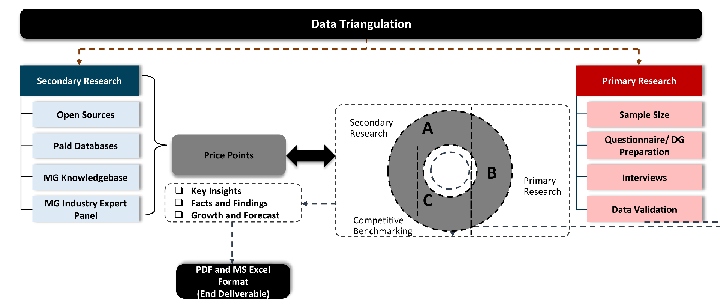

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation