Automotive Lightweight Materials Market Size, Share, Growth Opportunity Analysis Report by Material (Metals, Composites, Plastics, Elastomers and Others), Application, Component, Vehicle Type, Propulsion Type, Sales Channel and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Automotive Lightweight Materials Market Size, Share, and Growth

The global automotive lightweight materials market is projected to grow from USD 79.1 Billion in 2025 to USD 116.9 Billion, with a strong CAGR of 4.0% during the forecasted period. The key driving factors for global automotive lightweight materials market include rising EV adoption demanding improved vehicle range and stringent global emission regulations encouraging lightweighting. For instance, in 2024, Tesla Inc. incorporated a new giga casting aluminum alloy for the Cybertruck's rear underbody, reducing weight and manufacturing complexity.

In April 2024, Zircotec, under the leadership of CTO Peter Whyman, launched the CeraBEV project in collaboration with Cranfield University to develop advanced ceramic thermal coatings. This technology enables the use of lightweight aluminum and composite materials in EV battery enclosures by offering superior flame resistance and dielectric insulation, supporting next-gen EV designs. The strategy reinforces the shift toward safer and lighter EV architectures, boosting demand for lightweight materials across electric mobility platforms.

Furthermore, BMW Group enhanced the application of carbon fiber-reinforced plastics (CFRP) in its i-Series models to satisfy the EU carbon requirements. These developments are growing the OEM investments in the lightweight innovations at a very high rate, which is greatly contributing to the automotive-lightweight-materials market growth.

The major market opportunities to the global automotive lightweight materials market are the advanced composite market aerospace-grade materials, lightweight battery shells to EVs, and high-performance polymer coatings market to increase corrosion resistance. These industries will complete lightweighting strategies in automobiles, and will establish a joint value within mobility ecosystems. This synergy broadens cross industry material innovation and investment resulting in convergence of markets and rapid growth.

Automotive Lightweight Materials Market Dynamics and Trends

Driver: Increasing Demand for Fuel Efficiency and Performance Optimization

- The increasing in growth of automotive lightweight materials market is the continuing need to increase the fuel efficiency and maximum vehicle performance. The internal combustion engine (ICE) automotive and electric vehicle (EV) technology have been forced to move swiftly towards a less-intensive structure, as the recent changes in the automotive OEM industries focus on enhancing the ratio between power and weight.

- High strength steel, aluminum, magnesium alloys, and composite of carbon fiber are lightweight materials that contribute to the minimization of overall vehicle mass without the need to affect the safety or structural integrity of the vehicle. This allows greater acceleration, braking and energy use, which leads to a large part in preventing fuel consumption and emissions.

- As an example, the 2025 model development strategy of the Hyundai Motor Company where the construction of the body and hood of future hybrid and plug-in hybrid SUVs will be made of multi-materials, including lightweight steels and aluminum alloys. The partnership between Hyundai and POSCO (a major steel producer) is aimed at implementing Advanced High-Strength Steel (AHSS) and tailor-welded blanks (TWBs) to help Hyundai decrease the body weight of a vehicle by up to 60 kg.

- This technology adoption and supplier-OEM alliances are driven by this drive towards better fuel economy via lightweighting, which is accelerating automotive-lightweight-materials-market growth throughout the value chain.

Restraint: High Cost and Processing Complexity of Advanced Lightweight Materials

- Although these materials have their benefits, advanced lightweight materials like carbon fiber composite, magnesium alloys and customized aluminum components are extremely expensive. Further, it is likely to hampers the growth of automotive lightweight materials market globally. These materials are usually difficult to manufacture, tools used are specialized and take longer cycles, which cannot be affordable in mass-market vehicles. In addition, the cost of lifecycle such as recyclability, repair and joining between dissimilar materials can make them less popular in other applications, especially in price-sensitive automakers.

- Indicatively, Mazda Motor Corporation has in the recent past reduced its intention to incorporate carbon fiber-reinforced plastics (CFRPs) into its mainstream car models because of the high costs of production and the lack of adequate infrastructure in its supply chain. The company instead concentrated on the optimization of the hot-stamped ultra-high-strength steel to its CX series which offers moderate weight reduction at a lesser cost.

- Costs and production processes are still very high, and it is a major impediment as it reduces the penetration of advanced materials in mid- and low-segment cars.

Opportunity: Growing Shift Toward Lightweighting in Commercial Vehicles and Fleet Electrification

- One of the opportunities of automotive lightweight materials market is the electrification of commercial vehicles fleets. Calculators The use of electric and hybrid means of delivery is becoming increasingly popular among vans, trucks, and logistics vehicles, which need a powerful lightweight solution that would allow reducing the payload capacity and driving distance to the greatest possible. Components of lightweight chassis, cargo enclosures, and battery housing are long-term cost-saving to fleet operators due to greater energy efficiency.

- In 2024, Daimler Truck AG alongside Constellium SE launched lightweight electric Freightliner eCascadia by using lightweight aluminum structural components. The frame and body were made with constellium specially-designed HSA6 aluminum alloy extrusions that allowed up to 8% weight saving over the traditional materials, which increased battery range and load capacity. This alliance reflects the increasing focus on lightweighting not only in the case of passenger cars but also in the commercial vehicle markets, overall economics of the cost-of-ownership, and the ESG objectives.

- The commercial fleet electrification is a promising opportunity to access lucrative markets on lightweight materials, and broaden the automotive lightweight materials market base beyond passenger mobility.

Key Trend: Integration of Multi-Material Architecture in EV Platforms

- One of the automotive lightweight materials market trends is the implementation of multi-material architecture (MMA), where various lightweight materials are used in one vehicle structure, aluminum, steel, composite, and polymers. The strategy strikes a balance between the cost, performance, crash safety, and manufacturability. The MMA is particularly vital in EV platforms where the platforms need to be rigid to carry heavy battery packs and still be efficient.

- In 2024, in its EX30 electric SUV launched, Volvo Cars used a mix of materials based on high-strength steel (used in crash zones), high-strength steel (used in interiors), and thermoplastics (used in closures and chassis). It has led to an overall reduction in the weight of the vehicle by almost twelve percent, which made the battery more efficient and consumed less power per kilometer.

- Vehicle design is changing as MMA is emerging, creativity in joining technology, material science, and weight reduction strategies is being invented.

Automotive Lightweight Materials Market Analysis and Segmental Data

Based on Material, the Metals Segment Retains the Largest Share

- Metals segment has significant market share of the automotive lightweight materials market of ~51% in the globe, owing to its high strength to weight ratio, economic value, recyclability and ability to be integrated into already established manufacturing processes. Structural components, body panels and powertrain systems are highly used in materials such as aluminum, high-strength steel (HSS), and magnesium alloys that allow reducing a significant amount of weight without compromising on crash safety. They are very popular with OEMs due to their ability to be used with the mass production methods.

- Ford Motor Company in 2024 used more aluminum-intensive architecture in its F-150 Lightning EV and reduced body weight by more than 700 pounds, increasing range and payload capacity.

- The viability and scabbiness of lightweight metals is contributing to their dominant automotive lightweight materials market share in the world.

Asia Pacific Dominates Global Automotive Lightweight Materials Market in 2025 and Beyond

- Asia Pacific is the region with the greatest demand of the automotive lightweight materials market because the region is a large-scale automotive manufacturing base, EV penetration is fast, and countries such as China, Japan, South Korea, and India have strict energy efficiency and emission policies. Asia Pacific boasts of large automaker Toyota, Honda, Hyundai, and BYD that are also strongly incorporating lightweight materials to meet the increasingly restrictive carbon standards and improve the performance of their vehicles. Also, the accessibility of cheap raw materials and government policies favoring the green mobility also drive the use of superior materials like automotive aluminum, HSS, and lightweight polymers.

- In 2024, BYD plans to introduce its own "Seal 06 EV" sedan, which will use an aluminum-based body frame and lightweight composite material doors and battery enclosures. It is also aimed at the Chinese and Southeast Asian markets so that the model can comply with local emission regulations and improve the efficiency of the EV.

- The manufacturing leadership of Asia Pacific and the green mobility drive the region much faster in terms of consumption of lightweight materials in the automotive sector.

Automotive-Lightweight-Materials-Market Ecosystem

The automotive lightweight materials market is moderately consolidated globally; Tier 1 suppliers of the market (BASF SE, Novelis, ArcelorMittal, POSCO, and Toray industries) have dominance because the supply chain has been highly integrated, and these companies have invested a lot in R&D. Tier 2 and Tier 3 players have specialized or geographic material content. The level of buyer power is moderate that is influenced by the presence of large OEMs that possess high bargaining power, and the level of supplier power is high, which is determined by the absence of advanced material manufacturers and technology-focused processing in the market.

Recent Development and Strategic Overview:

- In February 2025, Gestamp presented its solutions at the Bharat Mobility Global Expo, which allows large-scale aluminum stamping and tubular high-strength parts, Gestamp introduced its GES-GIGASTAMPING and Highpertubes. These innovations make a big contribution to the efficiency of manufacturing, energy absorption, and reduction of vehicle weight enhancing the sustainability of lightweighting leadership of Gestamp.

- In September 2024, Viva Composite Panel Private Limited, (India) has a new range of aluminum composite panels (ACP) that is specifically designed to be used in bus bodies that were launched. The panels are safer, less structure weight, and more efficient operation to meet the increasing demand of the lightweight public transport market in India.

Report Scope

|

Detail |

|

|

Market Size in 2025 |

USD 79.1 Bn |

|

Market Forecast Value in 2035 |

USD 116.9 Bn |

|

Growth Rate (CAGR) |

4.0% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value Thousand Tons for Volume |

|

Report Format |

Electronic (PDF) + Excel |

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Automotive Lightweight Materials Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Material |

|

|

By Application |

|

|

By Component |

|

|

By Vehicle Type |

|

|

By Propulsion Type |

|

|

By Sales Channel |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Automotive Lightweight Materials Market Outlook

- 2.1.1. Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to-Market Strategy

- 2.5.1. Customer/ Sales Channel Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Automotive Lightweight Materials Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Automotive & Transportation Overview, 2025

- 3.1.1. Industry Ecosystem Analysis

- 3.1.2. Key Trends for Automotive & Transportation Industry

- 3.1.3. Regional Distribution for Automotive & Transportation

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.1. Global Automotive & Transportation Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Increasing adoption of electric vehicles (EVs) requiring lightweight components to improve battery efficiency and driving range.

- 4.1.1.2. Stringent global fuel efficiency and CO₂ emission regulations pushing automakers to reduce vehicle weight.

- 4.1.1.3. Growing demand for high-perApplicationance materials like aluminum, magnesium, and carbon fiber for enhanced safety and durability.

- 4.1.2. Restraints

- 4.1.2.1. High production and material costs of advanced lightweight materials limiting widespread adoption

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis/ Ecosystem Analysis

- 4.4.1. Raw Material Suppliers

- 4.4.2. Material Processing & Component Manufacturers

- 4.4.3. Distributors

- 4.4.4. Vehicle Manufacturers/ OEM

- 4.4.5. Sales Channelrs/ Customers

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Porter’s Five Forces Analysis

- 4.7. PESTEL Analysis

- 4.8. Global Automotive Lightweight Materials Market Demand

- 4.8.1. Historical Market Size - in Value (Volume - Thousand Tons & Value - US$ Billion), 2021-2024

- 4.8.2. Current and Future Market Size - in Value (Volume - Thousand Tons & Value - US$ Billion), 2025–2035

- 4.8.2.1. Y-o-Y Growth Trends

- 4.8.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Automotive Lightweight Materials Market Analysis, by Material

- 6.1. Key Segment Analysis

- 6.2. Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, by Material, 2021-2035

- 6.2.1. Metals

- 6.2.1.1. High Strength Steel (HSS)

- 6.2.1.2. Aluminum

- 6.2.1.3. Magnesium and Titanium

- 6.2.2. Composites

- 6.2.2.1. Carbon Fiber Reinforced Polymers (CFRP)

- 6.2.2.2. Glass Fiber Reinforced Polymers (GFRP)

- 6.2.2.3. Natural Fiber Reinforced Polymers (NFRP)

- 6.2.3. Plastics

- 6.2.4. Elastomers

- 6.2.5. Others

- 6.2.1. Metals

- 7. Global Automotive Lightweight Materials Market Analysis, by Application

- 7.1. Key Segment Analysis

- 7.2. Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, by Application, 2021-2035

- 7.2.1. Body-in-White

- 7.2.2. Chassis and Suspensions

- 7.2.3. Powertrains

- 7.2.4. Closures

- 7.2.5. Interiors

- 7.2.6. Others

- 8. Global Automotive Lightweight Materials Market Analysis, by Component

- 8.1. Key Segment Analysis

- 8.2. Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, by Component, 2021-2035

- 8.2.1. Frames

- 8.2.2. Wheels

- 8.2.3. Bumpers and Fenders

- 8.2.4. Engines and Exhausts

- 8.2.5. Transmissions

- 8.2.6. Doors

- 8.2.7. Hoods and Trunks

- 8.2.8. Seats

- 8.2.9. Instrument Panels

- 8.2.10. Fuel Tanks

- 8.2.11. Others

- 9. Global Automotive Lightweight Materials Market Analysis, by Vehicle Type

- 9.1. Key Segment Analysis

- 9.2. Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, by Vehicle Type, 2021-2035

- 9.2.1. Two Wheelers

- 9.2.2. Three Wheelers

- 9.2.3. Passenger Vehicles

- 9.2.3.1. Hatchback

- 9.2.3.2. Sedan

- 9.2.3.3. SUVs

- 9.2.4. Light Commercial Vehicles

- 9.2.5. Heavy Duty Trucks

- 9.2.6. Buses & Coaches

- 9.2.7. Off-road Vehicles

- 9.2.7.1. Agriculture Tractors & Equipment

- 9.2.7.2. Construction & Mining Equipment

- 10. Global Automotive Lightweight Materials Market Analysis, by Propulsion Type

- 10.1. Key Segment Analysis

- 10.2. Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, by Propulsion Type, 2021-2035

- 10.2.1. ICE Vehicles

- 10.2.1.1. Gasoline

- 10.2.1.2. Diesel

- 10.2.2. Electric

- 10.2.2.1. Battery Electric Vehicles

- 10.2.2.2. Hybrid/ Plug-in Hybrid Electric Vehicles

- 10.2.2.3. Fuel Cell Electric Vehicles

- 10.2.1. ICE Vehicles

- 11. Global Automotive Lightweight Materials Market Analysis, by Sales Channel

- 11.1. Key Segment Analysis

- 11.2. Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, by Sales Channel, 2021-2035

- 11.2.1. OEM

- 11.2.2. Aftermarket

- 12. Global Automotive Lightweight Materials Market Analysis and Forecasts, by Region

- 12.1. Key Findings

- 12.2. Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, by Region, 2021-2035

- 12.2.1. North America

- 12.2.2. Europe

- 12.2.3. Asia Pacific

- 12.2.4. Middle East

- 12.2.5. Africa

- 12.2.6. South America

- 13. North America Automotive Lightweight Materials Market Analysis

- 13.1. Key Segment Analysis

- 13.2. Regional Snapshot

- 13.3. North America Automotive Lightweight Materials Market Size Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 13.3.1. Material

- 13.3.2. Application

- 13.3.3. Component

- 13.3.4. Vehicle Type

- 13.3.5. Propulsion Type

- 13.3.6. Sales Channel

- 13.3.7. Country

- 13.3.7.1. USA

- 13.3.7.2. Canada

- 13.3.7.3. Mexico

- 13.4. USA Automotive Lightweight Materials Market

- 13.4.1. Country Segmental Analysis

- 13.4.2. Material

- 13.4.3. Application

- 13.4.4. Component

- 13.4.5. Vehicle Type

- 13.4.6. Propulsion Type

- 13.4.7. Sales Channel

- 13.5. Canada Automotive Lightweight Materials Market

- 13.5.1. Country Segmental Analysis

- 13.5.2. Material

- 13.5.3. Application

- 13.5.4. Component

- 13.5.5. Vehicle Type

- 13.5.6. Propulsion Type

- 13.5.7. Sales Channel

- 13.6. Mexico Automotive Lightweight Materials Market

- 13.6.1. Country Segmental Analysis

- 13.6.2. Material

- 13.6.3. Application

- 13.6.4. Component

- 13.6.5. Vehicle Type

- 13.6.6. Propulsion Type

- 13.6.7. Sales Channel

- 14. Europe Automotive Lightweight Materials Market Analysis

- 14.1. Key Segment Analysis

- 14.2. Regional Snapshot

- 14.3. Europe Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 14.3.1. Material

- 14.3.2. Application

- 14.3.3. Component

- 14.3.4. Vehicle Type

- 14.3.5. Propulsion Type

- 14.3.6. Sales Channel

- 14.3.7. Country

- 14.3.7.1. Germany

- 14.3.7.2. United Kingdom

- 14.3.7.3. France

- 14.3.7.4. Italy

- 14.3.7.5. Spain

- 14.3.7.6. Netherlands

- 14.3.7.7. Nordic Countries

- 14.3.7.8. Poland

- 14.3.7.9. Russia & CIS

- 14.3.7.10. Rest of Europe

- 14.4. Germany Automotive Lightweight Materials Market

- 14.4.1. Country Segmental Analysis

- 14.4.2. Material

- 14.4.3. Application

- 14.4.4. Component

- 14.4.5. Vehicle Type

- 14.4.6. Propulsion Type

- 14.4.7. Sales Channel

- 14.5. United Kingdom Automotive Lightweight Materials Market

- 14.5.1. Country Segmental Analysis

- 14.5.2. Material

- 14.5.3. Application

- 14.5.4. Component

- 14.5.5. Vehicle Type

- 14.5.6. Propulsion Type

- 14.5.7. Sales Channel

- 14.6. France Automotive Lightweight Materials Market

- 14.6.1. Country Segmental Analysis

- 14.6.2. Material

- 14.6.3. Application

- 14.6.4. Component

- 14.6.5. Vehicle Type

- 14.6.6. Propulsion Type

- 14.6.7. Sales Channel

- 14.7. Italy Automotive Lightweight Materials Market

- 14.7.1. Country Segmental Analysis

- 14.7.2. Material

- 14.7.3. Application

- 14.7.4. Component

- 14.7.5. Vehicle Type

- 14.7.6. Propulsion Type

- 14.7.7. Sales Channel

- 14.8. Spain Automotive Lightweight Materials Market

- 14.8.1. Country Segmental Analysis

- 14.8.2. Material

- 14.8.3. Application

- 14.8.4. Component

- 14.8.5. Vehicle Type

- 14.8.6. Propulsion Type

- 14.8.7. Sales Channel

- 14.9. Netherlands Automotive Lightweight Materials Market

- 14.9.1. Country Segmental Analysis

- 14.9.2. Material

- 14.9.3. Application

- 14.9.4. Component

- 14.9.5. Vehicle Type

- 14.9.6. Propulsion Type

- 14.9.7. Sales Channel

- 14.10. Nordic Countries Automotive Lightweight Materials Market

- 14.10.1. Country Segmental Analysis

- 14.10.2. Material

- 14.10.3. Application

- 14.10.4. Component

- 14.10.5. Vehicle Type

- 14.10.6. Propulsion Type

- 14.10.7. Sales Channel

- 14.11. Poland Automotive Lightweight Materials Market

- 14.11.1. Country Segmental Analysis

- 14.11.2. Material

- 14.11.3. Application

- 14.11.4. Component

- 14.11.5. Vehicle Type

- 14.11.6. Propulsion Type

- 14.11.7. Sales Channel

- 14.12. Russia & CIS Automotive Lightweight Materials Market

- 14.12.1. Country Segmental Analysis

- 14.12.2. Material

- 14.12.3. Application

- 14.12.4. Component

- 14.12.5. Vehicle Type

- 14.12.6. Propulsion Type

- 14.12.7. Sales Channel

- 14.13. Rest of Europe Automotive Lightweight Materials Market

- 14.13.1. Country Segmental Analysis

- 14.13.2. Material

- 14.13.3. Application

- 14.13.4. Component

- 14.13.5. Vehicle Type

- 14.13.6. Propulsion Type

- 14.13.7. Sales Channel

- 15. Asia Pacific Automotive Lightweight Materials Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. East Asia Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 15.3.1. Material

- 15.3.2. Application

- 15.3.3. Component

- 15.3.4. Vehicle Type

- 15.3.5. Propulsion Type

- 15.3.6. Sales Channel

- 15.3.7. Country

- 15.3.7.1. China

- 15.3.7.2. India

- 15.3.7.3. Japan

- 15.3.7.4. South Korea

- 15.3.7.5. Australia and New Zealand

- 15.3.7.6. Indonesia

- 15.3.7.7. Malaysia

- 15.3.7.8. Thailand

- 15.3.7.9. Vietnam

- 15.3.7.10. Rest of Asia Pacific

- 15.4. China Automotive Lightweight Materials Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Material

- 15.4.3. Application

- 15.4.4. Component

- 15.4.5. Vehicle Type

- 15.4.6. Propulsion Type

- 15.4.7. Sales Channel

- 15.5. India Automotive Lightweight Materials Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Material

- 15.5.3. Application

- 15.5.4. Component

- 15.5.5. Vehicle Type

- 15.5.6. Propulsion Type

- 15.5.7. Sales Channel

- 15.6. Japan Automotive Lightweight Materials Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Material

- 15.6.3. Application

- 15.6.4. Component

- 15.6.5. Vehicle Type

- 15.6.6. Propulsion Type

- 15.6.7. Sales Channel

- 15.7. South Korea Automotive Lightweight Materials Market

- 15.7.1. Country Segmental Analysis

- 15.7.2. Material

- 15.7.3. Application

- 15.7.4. Component

- 15.7.5. Vehicle Type

- 15.7.6. Propulsion Type

- 15.7.7. Sales Channel

- 15.8. Australia and New Zealand Automotive Lightweight Materials Market

- 15.8.1. Country Segmental Analysis

- 15.8.2. Material

- 15.8.3. Application

- 15.8.4. Component

- 15.8.5. Vehicle Type

- 15.8.6. Propulsion Type

- 15.8.7. Sales Channel

- 15.9. Indonesia Automotive Lightweight Materials Market

- 15.9.1. Country Segmental Analysis

- 15.9.2. Material

- 15.9.3. Application

- 15.9.4. Component

- 15.9.5. Vehicle Type

- 15.9.6. Propulsion Type

- 15.9.7. Sales Channel

- 15.10. Malaysia Automotive Lightweight Materials Market

- 15.10.1. Country Segmental Analysis

- 15.10.2. Material

- 15.10.3. Application

- 15.10.4. Component

- 15.10.5. Vehicle Type

- 15.10.6. Propulsion Type

- 15.10.7. Sales Channel

- 15.11. Thailand Automotive Lightweight Materials Market

- 15.11.1. Country Segmental Analysis

- 15.11.2. Material

- 15.11.3. Application

- 15.11.4. Component

- 15.11.5. Vehicle Type

- 15.11.6. Propulsion Type

- 15.11.7. Sales Channel

- 15.12. Vietnam Automotive Lightweight Materials Market

- 15.12.1. Country Segmental Analysis

- 15.12.2. Material

- 15.12.3. Application

- 15.12.4. Component

- 15.12.5. Vehicle Type

- 15.12.6. Propulsion Type

- 15.12.7. Sales Channel

- 15.13. Rest of Asia Pacific Automotive Lightweight Materials Market

- 15.13.1. Country Segmental Analysis

- 15.13.2. Material

- 15.13.3. Application

- 15.13.4. Component

- 15.13.5. Vehicle Type

- 15.13.6. Propulsion Type

- 15.13.7. Sales Channel

- 16. Middle East Automotive Lightweight Materials Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Middle East Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 16.3.1. Material

- 16.3.2. Application

- 16.3.3. Component

- 16.3.4. Vehicle Type

- 16.3.5. Propulsion Type

- 16.3.6. Sales Channel

- 16.3.7. Country

- 16.3.7.1. Turkey

- 16.3.7.2. UAE

- 16.3.7.3. Saudi Arabia

- 16.3.7.4. Israel

- 16.3.7.5. Rest of Middle East

- 16.4. Turkey Automotive Lightweight Materials Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Material

- 16.4.3. Application

- 16.4.4. Component

- 16.4.5. Vehicle Type

- 16.4.6. Propulsion Type

- 16.4.7. Sales Channel

- 16.5. UAE Automotive Lightweight Materials Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Material

- 16.5.3. Application

- 16.5.4. Component

- 16.5.5. Vehicle Type

- 16.5.6. Propulsion Type

- 16.5.7. Sales Channel

- 16.6. Saudi Arabia Automotive Lightweight Materials Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Material

- 16.6.3. Application

- 16.6.4. Component

- 16.6.5. Vehicle Type

- 16.6.6. Propulsion Type

- 16.6.7. Sales Channel

- 16.7. Israel Automotive Lightweight Materials Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Material

- 16.7.3. Application

- 16.7.4. Component

- 16.7.5. Vehicle Type

- 16.7.6. Propulsion Type

- 16.7.7. Sales Channel

- 16.8. Rest of Middle East Automotive Lightweight Materials Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Material

- 16.8.3. Application

- 16.8.4. Component

- 16.8.5. Vehicle Type

- 16.8.6. Propulsion Type

- 16.8.7. Sales Channel

- 17. Africa Automotive Lightweight Materials Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Africa Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 17.3.1. Material

- 17.3.2. Application

- 17.3.3. Component

- 17.3.4. Vehicle Type

- 17.3.5. Propulsion Type

- 17.3.6. Sales Channel

- 17.3.7. Country

- 17.3.7.1. South Africa

- 17.3.7.2. Egypt

- 17.3.7.3. Nigeria

- 17.3.7.4. Algeria

- 17.3.7.5. Rest of Africa

- 17.4. South Africa Automotive Lightweight Materials Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Material

- 17.4.3. Application

- 17.4.4. Component

- 17.4.5. Vehicle Type

- 17.4.6. Propulsion Type

- 17.4.7. Sales Channel

- 17.5. Egypt Automotive Lightweight Materials Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Material

- 17.5.3. Application

- 17.5.4. Component

- 17.5.5. Vehicle Type

- 17.5.6. Propulsion Type

- 17.5.7. Sales Channel

- 17.6. Nigeria Automotive Lightweight Materials Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Material

- 17.6.3. Application

- 17.6.4. Component

- 17.6.5. Vehicle Type

- 17.6.6. Propulsion Type

- 17.6.7. Sales Channel

- 17.7. Algeria Automotive Lightweight Materials Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Material

- 17.7.3. Application

- 17.7.4. Component

- 17.7.5. Vehicle Type

- 17.7.6. Propulsion Type

- 17.7.7. Sales Channel

- 17.8. Rest of Africa Automotive Lightweight Materials Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Material

- 17.8.3. Application

- 17.8.4. Component

- 17.8.5. Vehicle Type

- 17.8.6. Propulsion Type

- 17.8.7. Sales Channel

- 18. South America Automotive Lightweight Materials Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Central and South Africa Automotive Lightweight Materials Market Size (Volume - Thousand Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 18.3.1. Material

- 18.3.2. Application

- 18.3.3. Component

- 18.3.4. Vehicle Type

- 18.3.5. Propulsion Type

- 18.3.6. Sales Channel

- 18.3.7. Country

- 18.3.7.1. Brazil

- 18.3.7.2. Argentina

- 18.3.7.3. Rest of South America

- 18.4. Brazil Automotive Lightweight Materials Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Material

- 18.4.3. Application

- 18.4.4. Component

- 18.4.5. Vehicle Type

- 18.4.6. Propulsion Type

- 18.4.7. Sales Channel

- 18.5. Argentina Automotive Lightweight Materials Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Material

- 18.5.3. Application

- 18.5.4. Component

- 18.5.5. Vehicle Type

- 18.5.6. Propulsion Type

- 18.5.7. Sales Channel

- 18.6. Rest of South America Automotive Lightweight Materials Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Material

- 18.6.3. Application

- 18.6.4. Component

- 18.6.5. Vehicle Type

- 18.6.6. Propulsion Type

- 18.6.7. Sales Channel

- 19. Key Players/ Company Profile

- 19.1. BASF SE

- 19.1.1. Company Details/ Overview

- 19.1.2. Company Financials

- 19.1.3. Key Customers and Competitors

- 19.1.4. Business/ Industry Portfolio

- 19.1.5. Product Portfolio/ Specification Details

- 19.1.6. Pricing Data

- 19.1.7. Strategic Overview

- 19.1.8. Recent Developments

- 19.2. Alcoa Corporation

- 19.3. ArcelorMittal

- 19.4. Covestro AG

- 19.5. LANXESS

- 19.6. LyondellBasell Industries Holdings B.V.

- 19.7. Mitsubishi Chemical Corporation

- 19.8. Novelis

- 19.9. Owens Corning

- 19.10. POSCO

- 19.11. SGL Carbon

- 19.12. Stratasys

- 19.13. Tata Steel

- 19.14. TEIJIN LIMITED

- 19.15. Thyssenkrupp AG

- 19.16. Toray Industries, Inc.

- 19.17. Other Key Players

- 19.1. BASF SE

Note* - This is just tentative list of players. While providing the report, we will cover a greater number of players based on their revenue and share for each geography

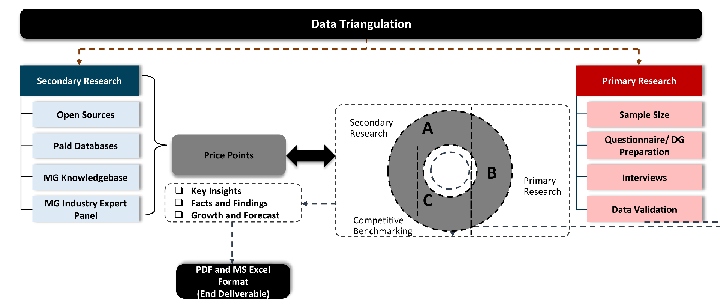

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation