Automotive Aluminum Market Size, Share, Growth Opportunity Analysis Report by Product Type (Cast Aluminum, Rolled Aluminum, Extruded Aluminum, Forged Aluminum, Powdered Aluminum and Others (e.g., Aluminum Composites)), Form, Application, Propulsion Type, Vehicle Type, Sales Channel and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Automotive Aluminum Market Size, Share, and Growth

The global automotive aluminum market is expanding from USD 19.2 Billion in 2024 to USD 32.1 Billion by the year 2035, showing a CAGR of 5.3% over the forecast period. The global automotive aluminum market is the increasing demand for lightweight vehicles to meet fuel efficiency and emission norms. For instance, Novelis Inc. announced in 2024 its expanded aluminum sheet supply agreement with BMW Group to support lightweight electric vehicle production in Europe, highlighting automakers’ shift toward aluminum-intensive platforms.

In January 2025, Magna International Inc. announced the launch of its new aluminum structural battery enclosure facility in Ontario, Canada, aimed at supplying next-generation EV platforms. The strategy aligns with Magna’s focus on lightweight, scalable aluminum solutions for global automakers. According to Swamy Kotagiri, CEO of Magna, this expansion supports OEMs’ evolving EV needs while reinforcing sustainable manufacturing practices. This development strengthens Magna’s footprint in structural aluminum components and caters to growing EV demand globally.

The increasing EV manufacture which needs high thermal management and crash safety. The use of aluminum, such as crash management systems and battery containers, in the Hyundai IONIQ 6 was provided by Constellium SE in 2023, to meet the performance and safety requirements in EVs. These drivers are increasing the rate of aluminum adoption in all vehicle platforms, enhancing world market demand.

The global automotive aluminum market comprises recycling technologies of aluminum, which is guided by the sustainability concerns; production of lightweight components such as battery enclosures in EVs; production of additive manufacturing using aluminum, to aid in the rapid prototyping in the designing of an auto. These territories provide synergistic development opportunities as car manufacturers are seeking efficiency, personalization and circular economy designs. These neighboring markets are strengthening demand and innovation on automotive aluminum.

Automotive Aluminum Market Dynamics and Trends

Driver: Surge in SUV and Pickup Truck Demand Boosting Aluminum Use

-

The going popularity of SUVs and pickup trucks in the automotive industries around the world has become a powerful force that is fueling the automotive aluminum market. These automobiles are heavier in nature and thus this makes them take advantage of the light weight properties of aluminum which is useful in increasing the fuel efficiency, less CO2 emissions, and also increase the towing performance. Makers of automobiles are moving to aluminum and making use of it in all body panels, chassis, engine blocks and parts of the suspensions to counter the extra weight without affecting the durability. Such a move is further encouraged by the government policies that have strict emission regulations in Europe, North America and sections of Asia-Pacific. With the recent trend among customers to use bigger cars as a utility and road presence, aluminum is now a key to sustainable SUV design.

- As an example, the growth of the use of aluminum in manufacturing its top-selling F-Series trucks by Ford Motor Company. Ford started using over 90 percent aluminum in the body structure of its new F-150 Lightning EV and hybrid models in 2023, as it strived to lower the weight (up to 700 pounds) and increase energy efficiency and payload ability. This action comes after the firm has had a long-term aluminum integration plan, which began in 2015, but the new initiative is the final step toward electrification as well as fuel economy. This is because of the high-volume applications that aluminum has played in the redesign of modern trucks and SUVs.

- The increased utility car demand in the world is driving the urgency to manufacture vehicles based on aluminum which should further boost the growth in the automotive aluminum market.

Restraint: High Initial Capital and Retooling Costs for Manufacturers

-

The greatest constraint to its further implementation is the large upfront cost of re-tooling and restructuring manufacturing processes. Various welding, stamping and machining technologies are needed to work on aluminum than on traditional steel, and this results in huge initial cost to automakers and the suppliers who will switch to aluminum parts.

- Besides, the necessity of special labor, quality control systems, and supply chain changes also contributes to the financial load. This is especially hard when small and mid-sized car makers or even emerging market car makers have to contend with, and profit margins are small and the investment capital is low.

- As an example, Mazda Motor Corporation that in 2024 postponed the decision to switch a number of its ICE vehicles to aluminum body frames because it is too expensive to retool its plant in Hiroshima. In its turn, Mazda chose mixed-material designs whereby high-tensile steel was used and the use of aluminum was limited due to the limitation of justifying the investment payback in its existing production volumes. This conservative stance is indicative of a larger nervousness in the tier 2 automotive players that although the technical benefits of aluminum exist the cost factor can reduce its rapid adoption beyond the high value or high-volume models.

- The cost of high infrastructure and process modification are taming the rate of adoption of aluminum in diverse segments of the auto industry across the globe.

Opportunity: Expansion of Aluminum Battery Enclosures in EVs

-

The shift to electric cars (EVs) offers the automotive aluminum industry a high-growth potential particularly in the formulation of battery casings and thermoregulation systems. Aluminum is a great thermal conductor, resistant to corrosion, and crash absorber; hence, it is a perfect material to absorb heat in EV batteries and control them. As the size of batteries and battery safety standards are growing in the world, OEMs and EV startups are rushing to aluminum-based enclosures. Moreover, as part of EVs, automakers are focusing on making them lightweight to increase their driving range and reduce weight-to-energy ratios, which further makes aluminum a material of choice.

- For example, the 2024 supply contract between Hydro Extrusion and Rivian Automotive Inc., pursuant to which Hydro will provide Rivian with custom aluminum battery enclosure and structural parts to be used in Rivian R2 platform. That will involve the next-generation extrusion profiles designed to be produced in modular assembly and improved thermal performance, which will be starting production in 2025. Such strategic engagement is consistent with the idea of Rivian to make vehicles more affordable and keep their safety intact, and the innovations of Hydro are assisting in bringing a new degree of flexibility in terms of design. OEM sourcing strategies are increasingly based on such aluminum-intensive alliances with increased EV manufacturing in different locations.

- An application area is seen in battery enclosure that is generating a new and quickly expanding revenue stream by the aluminum producers to the EV ecosystem.

Key Trend: Growth in Closed-Loop Recycling Systems for Aluminum Components

-

One of the trends that are transforming the automotive aluminum market is the emergence of closed loop recycling processes where producers use scrap aluminum that is produced in the process making of new parts. Such systems save a lot of raw material expenses, decrease carbon footprints, and enhance resiliency of the supply chain. Circularity is a material sourcing strategy that increasingly is being integrated by automakers to achieve their environmental, social, and governance (ESG) goals and attract environmentally conscious buyers. Due to the opportunity to recycle it and still have it with the same quality, aluminum has become a staple of environmentally-friendly vehicle design and production.

- For instance, in 2024, Stellantis N.V. announced a collaboration with Novelis Inc. to introduce a closed-loop recycling program in all its manufacturing facilities in Europe, producing Peugeot, Citroen, and Fiat brands. In this program, Novelis will take on the scrap of aluminum production at Stellantis plants and give back a refined scrap or recycled sheets of aluminum that will be utilized in the creation of other vehicles. The program will result in a reduction of the emission during the lifecycle by more than 30 percent than the conventional sourcing of aluminum, and will help Stellantis to reach its target of carbon net-zero by 2038. This type of circular collaboration is gaining momentum and is an indication of a strategic change towards sustainability-oriented supply chains.

- Recycling models that are circular using aluminum are transforming the production economics, and promoting long-term sustainability in the automotive industry.

Automotive Aluminum Market Analysis and Segmental Data

Based on Application, the Body-in-White Segment Retains the Largest Share

Based on Application, the Body-in-White Segment Retains the Largest Share

- Body-in-white segment holds major share of the global automotive aluminum market of 36% in the industry requires producing lightweight structures of their vehicles to achieve fuel efficiency and meet the global emissions standards. Frames, cross-members, and panels are all components of BIW, which leads to significant weight increase to the car, and so the impact of the substituent of aluminum is enormous. Its weight-to-strength ratio and crashworthiness also proves the safety without the cost of design flexibility.

- In 2024, GM increased the volume of aluminum in the BIW of the Chevrolet Silverado EV, with more than 400 kg of mass reduction and structural rigidity, demonstrating the willingness of OEMs to use aluminum-intensive designs.

- The leadership of the BIW segment is hastening to structural integration of aluminum in both ICE and EVs.

Asia Pacific Dominates Global Automotive Aluminum Market in 2025 and Beyond

-

Asia Pacific region is the most popular automotive demand in terms of high volume of vehicle production, high visibility of EV, and the governmental policies favoring a lightweight and fuel efficiency vehicle. The region is home to top OEMs and aluminum producers such as China, Japan, and South Korea, and it is an innovation and consumption region. Increased urbanization and consumer preference towards high performance vehicles which are economical also increase the use of aluminum in the structural and functional components.

- In 2024, BYD incorporated high-strength aluminum frames and battery enclosures into its latest Seal U DM-i plug-in hybrid SUV, which conforms to the dual carbon targets in China and its EV range.

- With this kind of dominance, Asia Pacific secures further innovation and volume-based expansion of the automotive aluminum market globally.

Automotive Aluminum Market Ecosystem

The global automotive aluminum market is moderately consolidated, with Tier 1 players including Novelis Inc., Constellium SE and Norsk Hydro ASA having a wide technological base, vertical supply chain, and integrated operations. Tier 2 and Tier 3 players, such as Jindal Aluminium and Shiloh Industries are in utilization on regional or specialized levels. The market is medium-high in terms of concentration since it has a high degree of established manufacturers. Porters Five Forces state that the concentration of buyers is medium, with the leading automakers having a fragment of bargaining power, whereas the concentration of suppliers is great, with a few global manufacturers dominating the supply-and-price interactions.

Recent Development and Strategic Overview:

-

In March 2025, Novelis Inc. made a breakthrough in automotive aluminum development by introducing the first in the world recycled end-of- life (EOL) auto coil which is composed of 100 percent recycled material. The innovation is aimed at the automotive body and structural markets, mainly in the case of European original equipment manufacturer (OEM) in an attempt to achieve high EU sustainability targets and net-zero objectives. The recycled aluminum coil is projected to contain the same strength, formability and resistance to corrosions with primary aluminum, but cut down carbon emissions by up to 90 percent of what traditional production processes bring.

- In April 2025, the company that signed a Letter of Intent (LoI) to collaborate in the development and distribution of low-carbon aluminum castings to the automotive industry is Hydro (a large aluminum and electricity producer) and Nemak (one of the largest suppliers of automotive structural and powertrain components in the world). This business partnership will see Hydro merge its knowledge in post-consumer scrap recycling and renewable-based smelting with the qualified expertise of Nemak in casting and machining. The production is targeted at manufacturing structural and engine parts including e-motor housings, battery tray parts, and parts of the chassis with much fewer embedded carbon.

Report Scope

|

Detail |

|

|

Market Size in 2025 |

USD 19.2 Bn |

|

Market Forecast Value in 2035 |

USD 32.1 Bn |

|

Growth Rate (CAGR) |

5.3% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value Million Tons for Volume |

|

Report Format |

Electronic (PDF) + Excel |

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Automotive Aluminum Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Product Type |

|

|

By Form |

|

|

By Application |

|

|

By Propulsion Type |

|

|

By Vehicle Type |

|

|

By Sales Channel |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Automotive Aluminum Market Outlook

- 2.1.1. Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to-Market Strategy

- 2.5.1. Customer/ End Use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Automotive Aluminum Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Automotive & Transportation Overview, 2025

- 3.1.1. Industry Ecosystem Analysis

- 3.1.2. Key Trends for Automotive & Transportation Industry

- 3.1.3. Regional Distribution for Automotive & Transportation

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.1. Global Automotive & Transportation Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Automakers are using aluminum to reduce vehicle weight, improve fuel efficiency, and comply with stringent emissions regulations

- 4.1.1.2. Rising EV production boosts aluminum demand for battery packs, chassis, and body structural components.

- 4.1.1.3. Advances in aluminum recycling and global green manufacturing policies support automotive aluminum adoption.

- 4.1.2. Restraints

- 4.1.2.1. Aluminum remains significantly more expensive than traditional steel, increasing barriers for cost-sensitive OEMs.

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis/ Ecosystem Analysis

- 4.4.1. Raw Material Suppliers

- 4.4.2. Aluminum Producers & Alloy Manufacturers

- 4.4.3. Component Manufacturers & Tier-1 Suppliers

- 4.4.4. Vehicle Manufacturers & OEM

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Porter’s Five Forces Analysis

- 4.7. PESTEL Analysis

- 4.8. Global Automotive Aluminum Market Demand

- 4.8.1. Historical Market Size - in Value (Volume - Million Tons & Value - US$ Billion), 2021-2024

- 4.8.2. Current and Future Market Size - in Value (Volume - Million Tons & Value - US$ Billion), 2025–2035

- 4.8.2.1. Y-o-Y Growth Trends

- 4.8.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Automotive Aluminum Market Analysis, by Product Type

- 6.1. Key Segment Analysis

- 6.2. Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, by Product Type, 2021-2035

- 6.2.1. Cast Aluminum

- 6.2.2. Rolled Aluminum

- 6.2.3. Extruded Aluminum

- 6.2.4. Forged Aluminum

- 6.2.5. Powdered Aluminum

- 6.2.6. Others (e.g., aluminum composites)

- 7. Global Automotive Aluminum Market Analysis, by Form

- 7.1. Key Segment Analysis

- 7.2. Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, by Form, 2021-2035

- 7.2.1. Aluminum Sheets

- 7.2.2. Aluminum Ingots

- 7.2.3. Aluminum Foils

- 7.2.4. Aluminum Wires

- 7.2.5. Aluminum Plates

- 7.2.6. Aluminum Alloys (e.g., 6000 & 7000 series)

- 8. Global Automotive Aluminum Market Analysis, by Application

- 8.1. Key Segment Analysis

- 8.2. Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, by Application, 2021-2035

- 8.2.1. Powertrain

- 8.2.1.1. Engine Blocks

- 8.2.1.2. Cylinder Heads

- 8.2.1.3. Pistons

- 8.2.1.4. Others

- 8.2.2. Chassis & Suspension

- 8.2.2.1. Control Arms

- 8.2.2.2. Subframes

- 8.2.2.3. Others

- 8.2.3. Body-in-White

- 8.2.3.1. Doors

- 8.2.3.2. Hoods

- 8.2.3.3. Roofs

- 8.2.3.4. Panels

- 8.2.3.5. Others

- 8.2.4. Wheels & Brakes

- 8.2.4.1. Rims

- 8.2.4.2. Brake Calipers

- 8.2.4.3. Others

- 8.2.5. Heat Exchangers

- 8.2.5.1. Radiators

- 8.2.5.2. Condensers

- 8.2.5.3. Others

- 8.2.6. Transmission Systems

- 8.2.7. Battery Housing (for EVs)

- 8.2.8. Interior & Trim Components

- 8.2.9. Others

- 8.2.1. Powertrain

- 9. Global Automotive Aluminum Market Analysis, by Propulsion Type

- 9.1. Key Segment Analysis

- 9.2. Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, by Propulsion Type, 2021-2035

- 9.2.1. ICE Vehicles

- 9.2.1.1. Gasoline

- 9.2.1.2. Diesel

- 9.2.2. Electric

- 9.2.2.1. Battery Electric Vehicles

- 9.2.2.2. Hybrid/ Plug-in Hybrid Electric Vehicles

- 9.2.2.3. Fuel Cell Electric Vehicles

- 9.2.1. ICE Vehicles

- 10. Global Automotive Aluminum Market Analysis, by Vehicle Type

- 10.1. Key Segment Analysis

- 10.2. Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, by Vehicle Type, 2021-2035

- 10.2.1. Two Wheelers

- 10.2.2. Three Wheelers

- 10.2.3. Passenger Vehicles

- 10.2.3.1. Hatchback

- 10.2.3.2. Sedan

- 10.2.3.3. SUVs

- 10.2.4. Light Commercial Vehicles

- 10.2.5. Heavy Duty Trucks

- 10.2.6. Buses & Coaches

- 10.2.7. Off-road Vehicles

- 10.2.7.1. Agriculture Tractors & Equipment

- 10.2.7.2. Construction & Mining Equipment

- 11. Global Automotive Aluminum Market Analysis, by Sales Channel

- 11.1. Key Segment Analysis

- 11.2. Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, by Sales Channel, 2021-2035

- 11.2.1. OEM

- 11.2.2. Aftermarket

- 12. Global Automotive Aluminum Market Analysis and Forecasts, by Region

- 12.1. Key Findings

- 12.2. Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, by Region, 2021-2035

- 12.2.1. North America

- 12.2.2. Europe

- 12.2.3. Asia Pacific

- 12.2.4. Middle East

- 12.2.5. Africa

- 12.2.6. South America

- 13. North America Automotive Aluminum Market Analysis

- 13.1. Key Segment Analysis

- 13.2. Regional Snapshot

- 13.3. North America Automotive Aluminum Market Size Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 13.3.1. Product Type

- 13.3.2. Form

- 13.3.3. Application

- 13.3.4. Propulsion Type

- 13.3.5. Vehicle Type

- 13.3.6. Sales Channel

- 13.3.7. Country

- 13.3.7.1. USA

- 13.3.7.2. Canada

- 13.3.7.3. Mexico

- 13.4. USA Automotive Aluminum Market

- 13.4.1. Country Segmental Analysis

- 13.4.2. Product Type

- 13.4.3. Form

- 13.4.4. Application

- 13.4.5. Propulsion Type

- 13.4.6. Vehicle Type

- 13.4.7. Sales Channel

- 13.5. Canada Automotive Aluminum Market

- 13.5.1. Country Segmental Analysis

- 13.5.2. Product Type

- 13.5.3. Form

- 13.5.4. Application

- 13.5.5. Propulsion Type

- 13.5.6. Vehicle Type

- 13.5.7. Sales Channel

- 13.6. Mexico Automotive Aluminum Market

- 13.6.1. Country Segmental Analysis

- 13.6.2. Product Type

- 13.6.3. Form

- 13.6.4. Application

- 13.6.5. Propulsion Type

- 13.6.6. Vehicle Type

- 13.6.7. Sales Channel

- 14. Europe Automotive Aluminum Market Analysis

- 14.1. Key Segment Analysis

- 14.2. Regional Snapshot

- 14.3. Europe Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 14.3.1. Product Type

- 14.3.2. Form

- 14.3.3. Application

- 14.3.4. Propulsion Type

- 14.3.5. Vehicle Type

- 14.3.6. Sales Channel

- 14.3.7. Country

- 14.3.7.1. Germany

- 14.3.7.2. United Kingdom

- 14.3.7.3. France

- 14.3.7.4. Italy

- 14.3.7.5. Spain

- 14.3.7.6. Netherlands

- 14.3.7.7. Nordic Countries

- 14.3.7.8. Poland

- 14.3.7.9. Russia & CIS

- 14.3.7.10. Rest of Europe

- 14.4. Germany Automotive Aluminum Market

- 14.4.1. Country Segmental Analysis

- 14.4.2. Product Type

- 14.4.3. Form

- 14.4.4. Application

- 14.4.5. Propulsion Type

- 14.4.6. Vehicle Type

- 14.4.7. Sales Channel

- 14.5. United Kingdom Automotive Aluminum Market

- 14.5.1. Country Segmental Analysis

- 14.5.2. Product Type

- 14.5.3. Form

- 14.5.4. Application

- 14.5.5. Propulsion Type

- 14.5.6. Vehicle Type

- 14.5.7. Sales Channel

- 14.6. France Automotive Aluminum Market

- 14.6.1. Country Segmental Analysis

- 14.6.2. Product Type

- 14.6.3. Form

- 14.6.4. Application

- 14.6.5. Propulsion Type

- 14.6.6. Vehicle Type

- 14.6.7. Sales Channel

- 14.7. Italy Automotive Aluminum Market

- 14.7.1. Country Segmental Analysis

- 14.7.2. Product Type

- 14.7.3. Form

- 14.7.4. Application

- 14.7.5. Propulsion Type

- 14.7.6. Vehicle Type

- 14.7.7. Sales Channel

- 14.8. Spain Automotive Aluminum Market

- 14.8.1. Country Segmental Analysis

- 14.8.2. Product Type

- 14.8.3. Form

- 14.8.4. Application

- 14.8.5. Propulsion Type

- 14.8.6. Vehicle Type

- 14.8.7. Sales Channel

- 14.9. Netherlands Automotive Aluminum Market

- 14.9.1. Country Segmental Analysis

- 14.9.2. Product Type

- 14.9.3. Form

- 14.9.4. Application

- 14.9.5. Propulsion Type

- 14.9.6. Vehicle Type

- 14.9.7. Sales Channel

- 14.10. Nordic Countries Automotive Aluminum Market

- 14.10.1. Country Segmental Analysis

- 14.10.2. Product Type

- 14.10.3. Form

- 14.10.4. Application

- 14.10.5. Propulsion Type

- 14.10.6. Vehicle Type

- 14.10.7. Sales Channel

- 14.11. Poland Automotive Aluminum Market

- 14.11.1. Country Segmental Analysis

- 14.11.2. Product Type

- 14.11.3. Form

- 14.11.4. Application

- 14.11.5. Propulsion Type

- 14.11.6. Vehicle Type

- 14.11.7. Sales Channel

- 14.12. Russia & CIS Automotive Aluminum Market

- 14.12.1. Country Segmental Analysis

- 14.12.2. Product Type

- 14.12.3. Form

- 14.12.4. Application

- 14.12.5. Propulsion Type

- 14.12.6. Vehicle Type

- 14.12.7. Sales Channel

- 14.13. Rest of Europe Automotive Aluminum Market

- 14.13.1. Country Segmental Analysis

- 14.13.2. Product Type

- 14.13.3. Form

- 14.13.4. Application

- 14.13.5. Propulsion Type

- 14.13.6. Vehicle Type

- 14.13.7. Sales Channel

- 15. Asia Pacific Automotive Aluminum Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. East Asia Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 15.3.1. Product Type

- 15.3.2. Form

- 15.3.3. Application

- 15.3.4. Propulsion Type

- 15.3.5. Vehicle Type

- 15.3.6. Sales Channel

- 15.3.7. Country

- 15.3.7.1. China

- 15.3.7.2. India

- 15.3.7.3. Japan

- 15.3.7.4. South Korea

- 15.3.7.5. Australia and New Zealand

- 15.3.7.6. Indonesia

- 15.3.7.7. Malaysia

- 15.3.7.8. Thailand

- 15.3.7.9. Vietnam

- 15.3.7.10. Rest of Asia Pacific

- 15.4. China Automotive Aluminum Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Product Type

- 15.4.3. Form

- 15.4.4. Application

- 15.4.5. Propulsion Type

- 15.4.6. Vehicle Type

- 15.4.7. Sales Channel

- 15.5. India Automotive Aluminum Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Product Type

- 15.5.3. Form

- 15.5.4. Application

- 15.5.5. Propulsion Type

- 15.5.6. Vehicle Type

- 15.5.7. Sales Channel

- 15.6. Japan Automotive Aluminum Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Product Type

- 15.6.3. Form

- 15.6.4. Application

- 15.6.5. Propulsion Type

- 15.6.6. Vehicle Type

- 15.6.7. Sales Channel

- 15.7. South Korea Automotive Aluminum Market

- 15.7.1. Country Segmental Analysis

- 15.7.2. Product Type

- 15.7.3. Form

- 15.7.4. Application

- 15.7.5. Propulsion Type

- 15.7.6. Vehicle Type

- 15.7.7. Sales Channel

- 15.8. Australia and New Zealand Automotive Aluminum Market

- 15.8.1. Country Segmental Analysis

- 15.8.2. Product Type

- 15.8.3. Form

- 15.8.4. Application

- 15.8.5. Propulsion Type

- 15.8.6. Vehicle Type

- 15.8.7. Sales Channel

- 15.9. Indonesia Automotive Aluminum Market

- 15.9.1. Country Segmental Analysis

- 15.9.2. Product Type

- 15.9.3. Form

- 15.9.4. Application

- 15.9.5. Propulsion Type

- 15.9.6. Vehicle Type

- 15.9.7. Sales Channel

- 15.10. Malaysia Automotive Aluminum Market

- 15.10.1. Country Segmental Analysis

- 15.10.2. Product Type

- 15.10.3. Form

- 15.10.4. Application

- 15.10.5. Propulsion Type

- 15.10.6. Vehicle Type

- 15.10.7. Sales Channel

- 15.11. Thailand Automotive Aluminum Market

- 15.11.1. Country Segmental Analysis

- 15.11.2. Product Type

- 15.11.3. Form

- 15.11.4. Application

- 15.11.5. Propulsion Type

- 15.11.6. Vehicle Type

- 15.11.7. Sales Channel

- 15.12. Vietnam Automotive Aluminum Market

- 15.12.1. Country Segmental Analysis

- 15.12.2. Product Type

- 15.12.3. Form

- 15.12.4. Application

- 15.12.5. Propulsion Type

- 15.12.6. Vehicle Type

- 15.12.7. Sales Channel

- 15.13. Rest of Asia Pacific Automotive Aluminum Market

- 15.13.1. Country Segmental Analysis

- 15.13.2. Product Type

- 15.13.3. Form

- 15.13.4. Application

- 15.13.5. Propulsion Type

- 15.13.6. Vehicle Type

- 15.13.7. Sales Channel

- 16. Middle East Automotive Aluminum Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Middle East Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 16.3.1. Product Type

- 16.3.2. Form

- 16.3.3. Application

- 16.3.4. Propulsion Type

- 16.3.5. Vehicle Type

- 16.3.6. Sales Channel

- 16.3.7. Country

- 16.3.7.1. Turkey

- 16.3.7.2. UAE

- 16.3.7.3. Saudi Arabia

- 16.3.7.4. Israel

- 16.3.7.5. Rest of Middle East

- 16.4. Turkey Automotive Aluminum Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Product Type

- 16.4.3. Form

- 16.4.4. Application

- 16.4.5. Propulsion Type

- 16.4.6. Vehicle Type

- 16.4.7. Sales Channel

- 16.5. UAE Automotive Aluminum Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Product Type

- 16.5.3. Form

- 16.5.4. Application

- 16.5.5. Propulsion Type

- 16.5.6. Vehicle Type

- 16.5.7. Sales Channel

- 16.6. Saudi Arabia Automotive Aluminum Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Product Type

- 16.6.3. Form

- 16.6.4. Application

- 16.6.5. Propulsion Type

- 16.6.6. Vehicle Type

- 16.6.7. Sales Channel

- 16.7. Israel Automotive Aluminum Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Product Type

- 16.7.3. Form

- 16.7.4. Application

- 16.7.5. Propulsion Type

- 16.7.6. Vehicle Type

- 16.7.7. Sales Channel

- 16.8. Rest of Middle East Automotive Aluminum Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Product Type

- 16.8.3. Form

- 16.8.4. Application

- 16.8.5. Propulsion Type

- 16.8.6. Vehicle Type

- 16.8.7. Sales Channel

- 17. Africa Automotive Aluminum Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Africa Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 17.3.1. Product Type

- 17.3.2. Form

- 17.3.3. Application

- 17.3.4. Propulsion Type

- 17.3.5. Vehicle Type

- 17.3.6. Sales Channel

- 17.3.7. Country

- 17.3.7.1. South Africa

- 17.3.7.2. Egypt

- 17.3.7.3. Nigeria

- 17.3.7.4. Algeria

- 17.3.7.5. Rest of Africa

- 17.4. South Africa Automotive Aluminum Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Product Type

- 17.4.3. Form

- 17.4.4. Application

- 17.4.5. Propulsion Type

- 17.4.6. Vehicle Type

- 17.4.7. Sales Channel

- 17.5. Egypt Automotive Aluminum Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Product Type

- 17.5.3. Form

- 17.5.4. Application

- 17.5.5. Propulsion Type

- 17.5.6. Vehicle Type

- 17.5.7. Sales Channel

- 17.6. Nigeria Automotive Aluminum Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Product Type

- 17.6.3. Form

- 17.6.4. Application

- 17.6.5. Propulsion Type

- 17.6.6. Vehicle Type

- 17.6.7. Sales Channel

- 17.7. Algeria Automotive Aluminum Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Product Type

- 17.7.3. Form

- 17.7.4. Application

- 17.7.5. Propulsion Type

- 17.7.6. Vehicle Type

- 17.7.7. Sales Channel

- 17.8. Rest of Africa Automotive Aluminum Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Product Type

- 17.8.3. Form

- 17.8.4. Application

- 17.8.5. Propulsion Type

- 17.8.6. Vehicle Type

- 17.8.7. Sales Channel

- 18. South America Automotive Aluminum Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Central and South Africa Automotive Aluminum Market Size (Volume - Million Tons & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 18.3.1. Product Type

- 18.3.2. Form

- 18.3.3. Application

- 18.3.4. Propulsion Type

- 18.3.5. Vehicle Type

- 18.3.6. Sales Channel

- 18.3.7. Country

- 18.3.7.1. Brazil

- 18.3.7.2. Argentina

- 18.3.7.3. Rest of South America

- 18.4. Brazil Automotive Aluminum Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Product Type

- 18.4.3. Form

- 18.4.4. Application

- 18.4.5. Propulsion Type

- 18.4.6. Vehicle Type

- 18.4.7. Sales Channel

- 18.5. Argentina Automotive Aluminum Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Product Type

- 18.5.3. Form

- 18.5.4. Application

- 18.5.5. Propulsion Type

- 18.5.6. Vehicle Type

- 18.5.7. Sales Channel

- 18.6. Rest of South America Automotive Aluminum Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Product Type

- 18.6.3. Form

- 18.6.4. Application

- 18.6.5. Propulsion Type

- 18.6.6. Vehicle Type

- 18.6.7. Sales Channel

- 19. Key Players/ Company Profile

- 19.1. Alcoa Corporation

- 19.1.1. Company Details/ Overview

- 19.1.2. Company Financials

- 19.1.3. Key Customers and Competitors

- 19.1.4. Business/ Industry Portfolio

- 19.1.5. Product Portfolio/ Specification Details

- 19.1.6. Pricing Data

- 19.1.7. Strategic Overview

- 19.1.8. Recent Developments

- 19.2. Aleris International, Inc. (part of Novelis)

- 19.3. Aluminum Corporation of China Limited (CHALCO)

- 19.4. Arconic Corporation

- 19.5. China Zhongwang Holdings Limited

- 19.6. Constellium Automotive Structures

- 19.7. Constellium SE

- 19.8. Hindalco Industries Limited

- 19.9. Jindal Aluminium Limited

- 19.10. Kaiser Aluminum Corporation

- 19.11. Kobe Steel, Ltd.

- 19.12. Linamar Corporation

- 19.13. Magna International Inc.

- 19.14. Nemak S.A.B. de C.V.

- 19.15. Norsk Hydro ASA

- 19.16. Novelis Inc.

- 19.17. Rio Tinto Group

- 19.18. Shiloh Industries, Inc.

- 19.19. Thyssenkrupp AG

- 19.20. UACJ Corporation

- 19.21. Other Key Players

- 19.1. Alcoa Corporation

Note* - This is just tentative list of players. While providing the report, we will cover a greater number of players based on their revenue and share for each geography

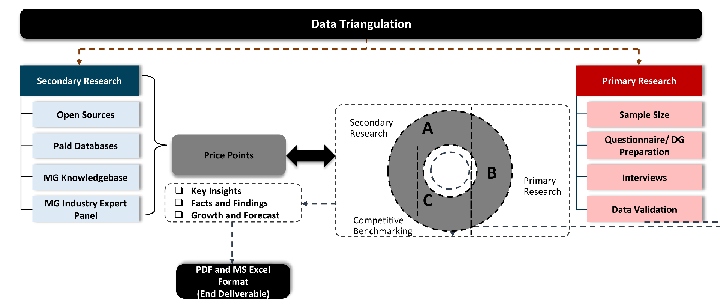

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation