Battery Recycling Market Size, Share & Trends Analysis Report by Recycling Process/ Technology (Mechanical/ Physical Recycling, Pyrometallurgical Recycling, Hydrometallurgical Recycling, Direct/Closed-loop Recycling, Hybrid Recycling Techniques, Others), by Material Recovered (Lead, Lithium, Cobalt, Nickel, Graphite, Manganese, Plastic and Electrolyte Fluids, and Others), Battery Type, Chemistry, Source, End-use Industry, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035.

|

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Battery Recycling Market Size, Share, and Growth

The global battery recycling market is experiencing robust growth, with its estimated value of USD 27.1 billion in the year 2025 and USD 71.3 billion by the period 2035, registering a CAGR of 9.2%. Asia Pacific leads the market with market share of 58.2% with USD 15.8 billion revenue.

In July 2025 Dr. Avishek Kumar, CEO of BatX Energies, led a joint initiative with Germany’s Rocklink GmbH to launch India’s first integrated rare-earth magnet recycling and refining hub. This move under the EU‑India Trade & Technology Council expands recycling scope beyond lithium-ion materials.

Increasing interest in a low-carbon future, the proliferation of batteries, particularly Li-ion batteries in electric vehicles (EVs) and energy storage, and portable electronics, has necessitated the construction of an efficacious battery recycling infrastructure. The need to recoup demand in the form of the extraction of valuable raw materials, such as lithium, cobalt, nickel, and manganese, whose production is fraught with severe environmental and geopolitical consequences, is also a factor in this perseverance.

Moreover, increasing state regulation in recycling on governments in most large economies. As an example, European Union, the new Batteries Regulation (EU) 2023/1542, effective since August 2023, supersedes Battery Directive of 2006 and entails high recycling rates and extraction of materials. In 2027, battery manufacturers have to recycle 90 percent of cobalt, copper, and nickel and 50 percent of lithium used in waste batteries and it shall be required to recycle 80 percent of them by 2031.

In boasting of the environmental and economic advantages of recycling, automotive OEMs are actively joining the recycling system, either through partnerships with strategic actors or internally. As an example, in April 2024, General Motors and Lithium Americas issued a statement that they would consider together the battery recycling matters through the United States, with a focus on closed-loop production in the home country.

Additionally, artificial intelligence and robotics are now used more frequently in a bid to enhance battery sorting and breakdown. Through AI-based detection systems, battery chemistries and states-of-health can be detected, thus, allowing downstream processing to be inherently optimized. In India, sensor-based sorting lines are being tested by the Centre for Materials for Electronics Technology (C-MET) efforts led to making the process of lithium-ion battery recovery more efficient.

Battery-Recycling-Market Dynamics and Trends

Driver: Rising EV Battery Decommissioning Leading to Accelerated Recycling Infrastructure Development

- The rapid deterioration of the battery of electric vehicles (EVs) is also pushing manufacturers to develop more recycling facilities worldwide. As EV use grows, particularly in North America, Europe and China, the battery life cycle of lithium-ion batteries is starting to end in a flood of lithium-ion batteries reaching end of life in their pioneering models.

- Even major producers like Tesla and BYD are engaging in greater vertical integration of recycling processes in an effort to maintain control over the access of key raw materials like lithium, cobalt, and nickel. As an example, in June 2024, Tesla reported the expansion of its battery recycling plant in Nevada run by Redwood Materials that was reported to recover more than 90 per cent of raw materials of its discarded battery packs.

- This goes hand in hand with the goals of circular economy and provides a stable low-cost domestic supply of rare metals. The sharp increase in used batteries is transforming into a catalyst of innovations and infrastructure roll-outs throughout the recycling value chain.

Restraint: Technological Complexity and Cost Barriers in Recycling Advanced Battery Chemistries

- Although the demand of battery recycling industry is rising, currently there lies a major technological and economic barrier to recycle next-generation chemistries. An important factor to take note of is that the compositions of lithium-ion batteries are evolving, e.g., with lithium iron phosphate (LFP) and solid-state technologies, and this needs special recycling methods not yet widespread or economically efficient.

- In addition, the commercial recycling of LFP batteries is less economical because they contain less cobalt and nickel than other kinds of battery and commercial recycling is not a financially-positive option. For instance, in April 2025, when the battery recycling business unit of Umicore reported a delay in ramping a pilot recycling line developed with LFP-based battery chemistries due to the high cost of energy and reduced material recovery margins. These challenges make the recycling facilities have a larger payback period and are preventing investments into newer technologies.

- These limitations act as a barrier to growth in capacity in a short duration, particularly in markets which already do not have great margins because of regulatory pressure and the fluctuating prices of raw materials.

Opportunity: Strategic Collaboration Between Automakers and Recyclers to Secure Critical Material Supply Chains

- The increased need to access supply of decisive battery raw materials is creating new vistas on alliance strategy between car makers and expert recyclers. The scope of these cooperatives is to ensure closed-loop supply of materials, minimize their reliance on unstable mining industries, and be in compliance with regulations on Extended Producer Responsibility (EPR).

- In March 2025, Ford Motor Company has signed a multi-year contract with Li-Cycle Holdings to recycle the manufacturing scrap of the EV battery at its BlueOval Battery Park in Tennessee. The partnership entails on-site material recovery and transportation to Li-Cycle hub at Rochester site whereby the firm obtains high-purity lithium carbonate, cobalt sulfate, and nickel sulfate. Not only can this model guarantee traceability and sustainability, but it will also help achieve the objective of Ford to manufacture net-zero carbon cars.

- These collaborations are becoming an essential tool that car manufacturers can use in order to be both economically and environmentally competitive.

Key Trend: Increasing Regulatory Enforcements Pushing Manufacturers Toward Sustainable Battery Lifecycle Management

- Governments have been establishing strict regulations across the globe that ensure that recycling of batteries is not merely optional but a necessity in operations. Such rules are aimed at enhancing the effects of recycling, mandatory recycling collection rates, and environmentally friendly sources of materials.

- As of February 2025, the Battery Regulation of the European Union will finalise its recycled content standards on the new batteries production requirement, and implement strict labelling requirements to aid traceability. German-based battery maker VARTA AG has responded by starting to rework its battery lifecycle strategy to comply with these laws such as the opening of an internal recycling division in Q2 2025. By 2027, the company is going to recycle at least 65 percent of up to lithium found in its consumer batteries.

- Such changing policy environments are also compelling manufacturers to put money in end of life, traceable supply chain, and cleaner processes of production, creating a sustainable pattern all over the industry.

Battery Recycling Market Analysis and Segmental Data

Automotive Batteries as the Dominant Source Driving Global Battery Recycling Demand

- The automotive battery segment has the largest market globally in battery recycling mainly because of the continuous exponential growth in adoption of the electric vehicles (EV) and the consequential growth in end-of-life automotive batteries that reach the waste steam. The source that is given the highest priority is EV batteries because they are bigger, more precious metals are contained in them, and simpler recycling requirements apply to them.

- LG Energy Solution Inc., a South Korean battery company that currently ranks third in the world with a market share of 4% reported in April 2025 a strategic partnership with RecycLiCo Battery Materials Inc. to recover cathode materials out of retired EV battery packs which revealed the industry-wide appreciation of the segment recycling capabilities.

- In addition to this, automotive batteries add the greatest volume of end-of-life batteries worldwide because on an average an automotive battery weighs hundreds of kilograms and contains substantial amount of lithium, cobalt and nickel that makes their recovery economic.

- Compared to smaller consumer batteries, it is easier to identify, collect, and recycle automotive batteries, as it is provided by the integrated recycling requirements set under EV manufacturers.

Asia Pacific’s Manufacturing and Scrap Volume Propel Battery Recycling Dominance

- The Asia Pacific region leads in battery recycling demand due to its dominance in battery production and growing accumulation of manufacturing scrap and defective cells. As the region is home to the world market leaders in battery manufacturing, such as CATL, Panasonic, and Samsung SDI, a huge amount of scrap is produced in the process of cell assembly. In March 2025, Panasonic Energy also started to expand its battery scrap recycling operation, in its Osaka factory, to recover lithium and cobalt, within the waste of its gigafactory production, to support regional recycling activity.

- Besides the production of waste, Asia Pacific is also subject to growing import of used EV and consumer batteries considering previous cycles of EV adoption in China, Japan and South Korea. This demand has further been crowded by the introduction of regulative backed collection networks and recycling parks in the region in a very short time.

- All these help Asia Pacific to maintain its authority in terms of the availability of feedstocks as well as processing facilities. Asia Pacific’s recycling demand is driven by a dual supply of manufacturing scrap and retired batteries.

Battery Recycling Market Ecosystem

Key players in the global battery-recycling-market include prominent companies such as Umicore, Glencore, Redwood Materials, Li-Cycle Holdings Corp., American Battery Technology Company and Other Key Players.

The global battery recycling market exhibits a moderately fragmented structure, with a medium to low level of market consolidation. The ecosystem comprises a balanced mix of Tier 1 players like Umicore, Glencore, and Redwood Materials with vertically integrated operations and global presence, Tier 2 firms such as Li-Cycle, Fortum, and GEM Co. with regional dominance and advancing technology platforms, and Tier 3 participants like Envirostream, Raw Materials Company, and Battery Solutions focusing on niche or local markets. In terms of Porter’s Five Forces, buyer concentration is low, as recyclers serve a wide variety of battery producers, OEMs, and government agencies, resulting in limited buyer dominance.

Recent Development and Strategic Overview:

- In July 2025, India’s BatX Energies partnered with Germany’s Rocklink GmbH to establish India’s first fully integrated rare‑earth magnet recycling hub under the EU‑India Trade & Technology Council framework, expanding battery recycling scope beyond Li‑ion chemistries.

- In June 2025, Redwood Materials introduced Redwood Energy, a new division repurposing retired EV batteries for stationary energy storage. Its first deployment a 12 MW/63 MWh microgrid powering Crusoe’s AI data centre is the world’s largest second-life battery installation, marking a strategic pivot toward value-adding reuse before recycling.

- In February 2025, UK‑based Altilium commenced operations of its EcoCathode recycling facility in Devon, achieving up to 97% lithium and 99% graphite recovery from LFP and NMC batteries. The plant is designed to process 150,000 EV-equivalent battery scrap annually.

Report Scope

|

Attribute |

Detail |

|

Market Size in 2024 |

USD 27.1 Bn |

|

Market Forecast Value in 2035 |

USD 71.3 Bn |

|

Growth Rate (CAGR) |

9.2% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2020 – 2024 |

|

Market Size Units |

US$ Billion for Value |

|

Report Format |

Electronic (PDF) + Excel |

|

Regions Covered |

|

|

Countries Covered |

|

|

Companies Profiled |

|

Battery Recycling Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Battery Type |

|

|

By Chemistry |

|

|

By Source |

|

|

By Recycling Process/ Technology |

|

|

By Material Recovered |

|

|

By End-Use Industry |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Battery Recycling Market Outlook

- 2.1.1. Battery Recycling Market Size (Value - US$ Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Battery Recycling Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Automotive Industry Overview, 2025

- 3.1.1. Industry Ecosystem Analysis

- 3.1.2. Key Trends for Automotive Industry

- 3.1.3. Regional Distribution for Automotive Industry

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2025

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.1.1. Based on the component & Raw material

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.5.1. Manufacturer

- 3.6. Raw Material Analysis

- 3.1. Global Automotive Industry Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Surge in electric vehicle (EV) adoption leading to higher volumes of end-of-life lithium-ion batteries

- 4.1.1.2. Regulatory mandates enforcing Extended Producer Responsibility (EPR) and recycling quotas

- 4.1.1.3. Rising demand for critical minerals like lithium, cobalt, and nickel amid limited mining output

- 4.1.2. Restraints

- 4.1.2.1. High capital investment and operational costs for setting up advanced recycling facilities.

- 4.1.2.2. Lack of standardized collection infrastructure and consumer awareness in developing regions

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Raw Material Suppliers

- 4.4.2. Battery Recycling Companies

- 4.4.3. End-users/ Customers

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Pricing Analysis

- 4.6.1. Regional Pricing Analysis

- 4.6.2. Segmental Pricing Trends

- 4.6.3. Factors Influencing Pricing

- 4.7. Porter’s Five Forces Analysis

- 4.8. PESTEL Analysis

- 4.9. Global Battery Recycling Market Demand

- 4.9.1. Historical Market Size - in Value (US$ Bn), 2020-2024

- 4.9.2. Current and Future Market Size - in Value (US$ Bn), 2025–2035

- 4.9.2.1. Y-o-Y Growth Trends

- 4.9.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Battery Recycling Market Analysis, by Battery Type

- 6.1. Key Segment Analysis

- 6.2. Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, by Battery Type, 2021-2035

- 6.2.1. Lead-Acid Batteries

- 6.2.2. Lithium-ion Batteries

- 6.2.3. Nickel-Cadmium Batteries

- 6.2.4. Nickel-Metal Hydride Batteries

- 6.2.5. Alkaline Batteries

- 6.2.6. Other Batteries (e.g., Zinc-carbon, Silver-oxide)

- 7. Global Battery Recycling Market Analysis, by Chemistry

- 7.1. Key Segment Analysis

- 7.2. Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, by Chemistry, 2021-2035

- 7.2.1. Lithium-Nickel-Manganese-Cobalt Oxide (NMC)

- 7.2.2. Lithium-Iron-Phosphate (LFP)

- 7.2.3. Lithium-Cobalt Oxide (LCO)

- 7.2.4. Lithium-Nickel-Cobalt-Aluminum Oxide (NCA)

- 7.2.5. Lithium-Titanate (LTO)

- 7.2.6. Lead-based

- 7.2.7. Nickel-based

- 7.2.8. Others

- 8. Global Battery Recycling Market Analysis, by Source

- 8.1. Key Segment Analysis

- 8.2. Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, by Source, 2021-2035

- 8.2.1. Automotive Batteries

- 8.2.1.1. Electric Vehicles (EVs)

- 8.2.1.2. Internal Combustion Engine (ICE) vehicles

- 8.2.2. Industrial Batteries

- 8.2.2.1. Uninterruptible Power Supplies (UPS)

- 8.2.2.2. Machinery & Equipment

- 8.2.2.3. Grid Energy Storage

- 8.2.2.4. Others

- 8.2.3. Consumer & Electronic Device Batteries

- 8.2.3.1. Smartphones

- 8.2.3.2. Laptops

- 8.2.3.3. Wearables

- 8.2.3.4. Others

- 8.2.4. Others (Marine, Railway, Military, etc.)

- 8.2.1. Automotive Batteries

- 9. Global Battery Recycling Market Analysis, by Recycling Process/ Technology

- 9.1. Key Segment Analysis

- 9.2. Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, by Recycling Process/ Technology, 2021-2035

- 9.2.1. Mechanical/Physical Recycling

- 9.2.2. Pyrometallurgical Recycling (smelting)

- 9.2.3. Hydrometallurgical Recycling (leaching)

- 9.2.4. Direct/Closed-loop Recycling

- 9.2.5. Hybrid Recycling Techniques

- 9.2.6. Others

- 10. Global Battery Recycling Market Analysis, by Material Recovered

- 10.1. Key Segment Analysis

- 10.2. Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, by Material Recovered, 2021-2035

- 10.2.1. Lead

- 10.2.2. Lithium

- 10.2.3. Cobalt

- 10.2.4. Nickel

- 10.2.5. Graphite

- 10.2.6. Manganese

- 10.2.7. Plastic and Electrolyte Fluids

- 10.2.8. Others

- 11. Global Battery Recycling Market Analysis, by End-Use Industry

- 11.1. Key Segment Analysis

- 11.2. Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, by End-Use Industry, 2021-2035

- 11.2.1. Automotive

- 11.2.2. Consumer Electronics

- 11.2.3. Industrial

- 11.2.4. Energy & Utilities (Energy Storage Systems)

- 11.2.5. Defense

- 11.2.6. Others (Telecom, Marine, Aviation, etc.)

- 12. Global Battery Recycling Market Analysis and Forecasts, by Region

- 12.1. Key Findings

- 12.2. Battery Recycling Market Size (Volume - Mn Units and Value - US$ Mn), Analysis, and Forecasts, by Region, 2021-2035

- 12.2.1. North America

- 12.2.2. Europe

- 12.2.3. Asia Pacific

- 12.2.4. Middle East

- 12.2.5. Africa

- 12.2.6. South America

- 13. North America Battery Recycling Market Analysis

- 13.1. Key Segment Analysis

- 13.2. Regional Snapshot

- 13.3. North America Battery Recycling Market Size Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 13.3.1. Battery Type

- 13.3.2. Chemistry

- 13.3.3. Source

- 13.3.4. Recycling Process/ Technology

- 13.3.5. Material Recovered

- 13.3.6. End-Use Industry

- 13.3.7. Country

- 13.3.7.1. USA

- 13.3.7.2. Canada

- 13.3.7.3. Mexico

- 13.4. USA Battery Recycling Market

- 13.4.1. Country Segmental Analysis

- 13.4.2. Battery Type

- 13.4.3. Chemistry

- 13.4.4. Source

- 13.4.5. Recycling Process/ Technology

- 13.4.6. Material Recovered

- 13.4.7. End-Use Industry

- 13.5. Canada Battery Recycling Market

- 13.5.1. Country Segmental Analysis

- 13.5.2. Battery Type

- 13.5.3. Chemistry

- 13.5.4. Source

- 13.5.5. Recycling Process/ Technology

- 13.5.6. Material Recovered

- 13.5.7. End-Use Industry

- 13.6. Mexico Battery Recycling Market

- 13.6.1. Country Segmental Analysis

- 13.6.2. Battery Type

- 13.6.3. Chemistry

- 13.6.4. Source

- 13.6.5. Recycling Process/ Technology

- 13.6.6. Material Recovered

- 13.6.7. End-Use Industry

- 14. Europe Battery Recycling Market Analysis

- 14.1. Key Segment Analysis

- 14.2. Regional Snapshot

- 14.3. Europe Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 14.3.1. Battery Type

- 14.3.2. Chemistry

- 14.3.3. Source

- 14.3.4. Recycling Process/ Technology

- 14.3.5. Material Recovered

- 14.3.6. End-Use Industry

- 14.3.7. Country

- 14.3.7.1. Germany

- 14.3.7.2. United Kingdom

- 14.3.7.3. France

- 14.3.7.4. Italy

- 14.3.7.5. Spain

- 14.3.7.6. Netherlands

- 14.3.7.7. Nordic Countries

- 14.3.7.8. Poland

- 14.3.7.9. Russia & CIS

- 14.3.7.10. Rest of Europe

- 14.4. Germany Battery Recycling Market

- 14.4.1. Country Segmental Analysis

- 14.4.2. Battery Type

- 14.4.3. Chemistry

- 14.4.4. Source

- 14.4.5. Recycling Process/ Technology

- 14.4.6. Material Recovered

- 14.4.7. End-Use Industry

- 14.5. United Kingdom Battery Recycling Market

- 14.5.1. Country Segmental Analysis

- 14.5.2. Battery Type

- 14.5.3. Chemistry

- 14.5.4. Source

- 14.5.5. Recycling Process/ Technology

- 14.5.6. Material Recovered

- 14.5.7. End-Use Industry

- 14.6. France Battery Recycling Market

- 14.6.1. Country Segmental Analysis

- 14.6.2. Battery Type

- 14.6.3. Chemistry

- 14.6.4. Source

- 14.6.5. Recycling Process/ Technology

- 14.6.6. Material Recovered

- 14.6.7. End-Use Industry

- 14.7. Italy Battery Recycling Market

- 14.7.1. Country Segmental Analysis

- 14.7.2. Battery Type

- 14.7.3. Chemistry

- 14.7.4. Source

- 14.7.5. Recycling Process/ Technology

- 14.7.6. Material Recovered

- 14.7.7. End-Use Industry

- 14.8. Spain Battery Recycling Market

- 14.8.1. Country Segmental Analysis

- 14.8.2. Battery Type

- 14.8.3. Chemistry

- 14.8.4. Source

- 14.8.5. Recycling Process/ Technology

- 14.8.6. Material Recovered

- 14.8.7. End-Use Industry

- 14.9. Netherlands Battery Recycling Market

- 14.9.1. Country Segmental Analysis

- 14.9.2. Battery Type

- 14.9.3. Chemistry

- 14.9.4. Source

- 14.9.5. Recycling Process/ Technology

- 14.9.6. Material Recovered

- 14.9.7. End-Use Industry

- 14.10. Nordic Countries Battery Recycling Market

- 14.10.1. Country Segmental Analysis

- 14.10.2. Battery Type

- 14.10.3. Chemistry

- 14.10.4. Source

- 14.10.5. Recycling Process/ Technology

- 14.10.6. Material Recovered

- 14.10.7. End-Use Industry

- 14.11. Poland Battery Recycling Market

- 14.11.1. Country Segmental Analysis

- 14.11.2. Battery Type

- 14.11.3. Chemistry

- 14.11.4. Source

- 14.11.5. Recycling Process/ Technology

- 14.11.6. Material Recovered

- 14.11.7. End-Use Industry

- 14.12. Russia & CIS Battery Recycling Market

- 14.12.1. Country Segmental Analysis

- 14.12.2. Battery Type

- 14.12.3. Chemistry

- 14.12.4. Source

- 14.12.5. Recycling Process/ Technology

- 14.12.6. Material Recovered

- 14.12.7. End-Use Industry

- 14.13. Rest of Europe Battery Recycling Market

- 14.13.1. Country Segmental Analysis

- 14.13.2. Battery Type

- 14.13.3. Chemistry

- 14.13.4. Source

- 14.13.5. Recycling Process/ Technology

- 14.13.6. Material Recovered

- 14.13.7. End-Use Industry

- 15. Asia Pacific Battery Recycling Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. East Asia Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 15.3.1. Battery Type

- 15.3.2. Chemistry

- 15.3.3. Source

- 15.3.4. Recycling Process/ Technology

- 15.3.5. Material Recovered

- 15.3.6. End-Use Industry

- 15.3.7. Country

- 15.3.7.1. China

- 15.3.7.2. India

- 15.3.7.3. Japan

- 15.3.7.4. South Korea

- 15.3.7.5. Australia and New Zealand

- 15.3.7.6. Indonesia

- 15.3.7.7. Malaysia

- 15.3.7.8. Thailand

- 15.3.7.9. Vietnam

- 15.3.7.10. Rest of Asia Pacific

- 15.4. China Battery Recycling Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Battery Type

- 15.4.3. Chemistry

- 15.4.4. Source

- 15.4.5. Recycling Process/ Technology

- 15.4.6. Material Recovered

- 15.4.7. End-Use Industry

- 15.5. India Battery Recycling Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Battery Type

- 15.5.3. Chemistry

- 15.5.4. Source

- 15.5.5. Recycling Process/ Technology

- 15.5.6. Material Recovered

- 15.5.7. End-Use Industry

- 15.6. Japan Battery Recycling Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Battery Type

- 15.6.3. Chemistry

- 15.6.4. Source

- 15.6.5. Recycling Process/ Technology

- 15.6.6. Material Recovered

- 15.6.7. End-Use Industry

- 15.7. South Korea Battery Recycling Market

- 15.7.1. Country Segmental Analysis

- 15.7.2. Battery Type

- 15.7.3. Chemistry

- 15.7.4. Source

- 15.7.5. Recycling Process/ Technology

- 15.7.6. Material Recovered

- 15.7.7. End-Use Industry

- 15.8. Australia and New Zealand Battery Recycling Market

- 15.8.1. Country Segmental Analysis

- 15.8.2. Battery Type

- 15.8.3. Chemistry

- 15.8.4. Source

- 15.8.5. Recycling Process/ Technology

- 15.8.6. Material Recovered

- 15.8.7. End-Use Industry

- 15.9. Indonesia Battery Recycling Market

- 15.9.1. Country Segmental Analysis

- 15.9.2. Battery Type

- 15.9.3. Chemistry

- 15.9.4. Source

- 15.9.5. Recycling Process/ Technology

- 15.9.6. Material Recovered

- 15.9.7. End-Use Industry

- 15.10. Malaysia Battery Recycling Market

- 15.10.1. Country Segmental Analysis

- 15.10.2. Battery Type

- 15.10.3. Chemistry

- 15.10.4. Source

- 15.10.5. Recycling Process/ Technology

- 15.10.6. Material Recovered

- 15.10.7. End-Use Industry

- 15.11. Thailand Battery Recycling Market

- 15.11.1. Country Segmental Analysis

- 15.11.2. Battery Type

- 15.11.3. Chemistry

- 15.11.4. Source

- 15.11.5. Recycling Process/ Technology

- 15.11.6. Material Recovered

- 15.11.7. End-Use Industry

- 15.12. Vietnam Battery Recycling Market

- 15.12.1. Country Segmental Analysis

- 15.12.2. Battery Type

- 15.12.3. Chemistry

- 15.12.4. Source

- 15.12.5. Recycling Process/ Technology

- 15.12.6. Material Recovered

- 15.12.7. End-Use Industry

- 15.13. Rest of Asia Pacific Battery Recycling Market

- 15.13.1. Country Segmental Analysis

- 15.13.2. Battery Type

- 15.13.3. Chemistry

- 15.13.4. Source

- 15.13.5. Recycling Process/ Technology

- 15.13.6. Material Recovered

- 15.13.7. End-Use Industry

- 16. Middle East Battery Recycling Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Middle East Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 16.3.1. Battery Type

- 16.3.2. Chemistry

- 16.3.3. Source

- 16.3.4. Recycling Process/ Technology

- 16.3.5. Material Recovered

- 16.3.6. End-Use Industry

- 16.3.7. Country

- 16.3.7.1. Turkey

- 16.3.7.2. UAE

- 16.3.7.3. Saudi Arabia

- 16.3.7.4. Israel

- 16.3.7.5. Rest of Middle East

- 16.4. Turkey Battery Recycling Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Battery Type

- 16.4.3. Chemistry

- 16.4.4. Source

- 16.4.5. Recycling Process/ Technology

- 16.4.6. Material Recovered

- 16.4.7. End-Use Industry

- 16.5. UAE Battery Recycling Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Battery Type

- 16.5.3. Chemistry

- 16.5.4. Source

- 16.5.5. Recycling Process/ Technology

- 16.5.6. Material Recovered

- 16.5.7. End-Use Industry

- 16.6. Saudi Arabia Battery Recycling Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Battery Type

- 16.6.3. Chemistry

- 16.6.4. Source

- 16.6.5. Recycling Process/ Technology

- 16.6.6. Material Recovered

- 16.6.7. End-Use Industry

- 16.7. Israel Battery Recycling Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Battery Type

- 16.7.3. Chemistry

- 16.7.4. Source

- 16.7.5. Recycling Process/ Technology

- 16.7.6. Material Recovered

- 16.7.7. End-Use Industry

- 16.8. Rest of Middle East Battery Recycling Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Battery Type

- 16.8.3. Chemistry

- 16.8.4. Source

- 16.8.5. Recycling Process/ Technology

- 16.8.6. Material Recovered

- 16.8.7. End-Use Industry

- 17. Africa Battery Recycling Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Africa Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 17.3.1. Battery Type

- 17.3.2. Chemistry

- 17.3.3. Source

- 17.3.4. Recycling Process/ Technology

- 17.3.5. Material Recovered

- 17.3.6. End-Use Industry

- 17.3.7. Country

- 17.3.7.1. South Africa

- 17.3.7.2. Egypt

- 17.3.7.3. Nigeria

- 17.3.7.4. Algeria

- 17.3.7.5. Rest of Africa

- 17.4. South Africa Battery Recycling Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Battery Type

- 17.4.3. Chemistry

- 17.4.4. Source

- 17.4.5. Recycling Process/ Technology

- 17.4.6. Material Recovered

- 17.4.7. End-Use Industry

- 17.5. Egypt Battery Recycling Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Battery Type

- 17.5.3. Chemistry

- 17.5.4. Source

- 17.5.5. Recycling Process/ Technology

- 17.5.6. Material Recovered

- 17.5.7. End-Use Industry

- 17.6. Nigeria Battery Recycling Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Battery Type

- 17.6.3. Chemistry

- 17.6.4. Source

- 17.6.5. Recycling Process/ Technology

- 17.6.6. Material Recovered

- 17.6.7. End-Use Industry

- 17.7. Algeria Battery Recycling Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Battery Type

- 17.7.3. Chemistry

- 17.7.4. Source

- 17.7.5. Recycling Process/ Technology

- 17.7.6. Material Recovered

- 17.7.7. End-Use Industry

- 17.8. Rest of Africa Battery Recycling Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Battery Type

- 17.8.3. Chemistry

- 17.8.4. Source

- 17.8.5. Recycling Process/ Technology

- 17.8.6. Material Recovered

- 17.8.7. End-Use Industry

- 18. South America Battery Recycling Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Central and South Africa Battery Recycling Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 18.3.1. Battery Type

- 18.3.2. Chemistry

- 18.3.3. Source

- 18.3.4. Recycling Process/ Technology

- 18.3.5. Material Recovered

- 18.3.6. End-Use Industry

- 18.3.7. Country

- 18.3.7.1. Brazil

- 18.3.7.2. Argentina

- 18.3.7.3. Rest of South America

- 18.4. Brazil Battery Recycling Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Battery Type

- 18.4.3. Chemistry

- 18.4.4. Source

- 18.4.5. Recycling Process/ Technology

- 18.4.6. Material Recovered

- 18.4.7. End-Use Industry

- 18.5. Argentina Battery Recycling Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Battery Type

- 18.5.3. Chemistry

- 18.5.4. Source

- 18.5.5. Recycling Process/ Technology

- 18.5.6. Material Recovered

- 18.5.7. End-Use Industry

- 18.6. Rest of South America Battery Recycling Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Battery Type

- 18.6.3. Chemistry

- 18.6.4. Source

- 18.6.5. Recycling Process/ Technology

- 18.6.6. Material Recovered

- 18.6.7. End-Use Industry

- 19. Key Players/ Company Profile

- 19.1. Accurec Recycling GmbH

- 19.1.1. Company Details/ Overview

- 19.1.2. Company Financials

- 19.1.3. Key Customers and Competitors

- 19.1.4. Business/ Industry Portfolio

- 19.1.5. Product Portfolio/ Specification Details

- 19.1.6. Pricing Data

- 19.1.7. Strategic Overview

- 19.1.8. Recent Developments

- 19.2. American Battery Technology Company (ABTC)

- 19.3. Aqua Metals, Inc.

- 19.4. Batrec Industrie AG

- 19.5. Battery Solutions LLC

- 19.6. Call2Recycle, Inc.

- 19.7. Duesenfeld GmbH

- 19.8. Ecobat

- 19.9. Envirostream Australia Pty Ltd.

- 19.10. Fortum Oyj

- 19.11. GEM Co., Ltd.

- 19.12. Glencore plc

- 19.13. Li-Cycle Holdings Corp.

- 19.14. Neometals Ltd.

- 19.15. Raw Materials Company Inc. (RMC)

- 19.16. Redwood Materials, Inc.

- 19.17. Retriev Technologies Inc.

- 19.18. SungEel HiTech Co., Ltd.

- 19.19. TES – Sustainable Technology Solutions

- 19.20. Umicore

- 19.21. Other Key players

- 19.1. Accurec Recycling GmbH

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

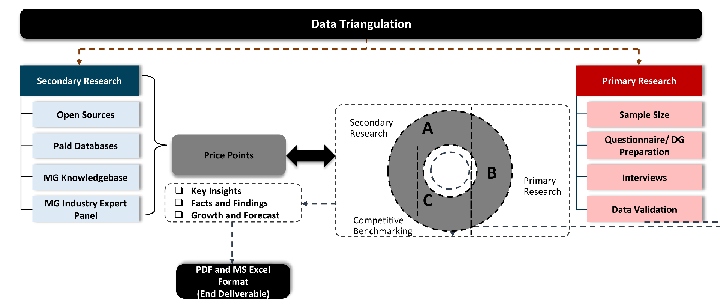

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation