Cargo Container X-ray Inspection Systems Market Size, Share & Trends Analysis Report by Technology Type (Single Energy X-ray Systems, Multi-Energy X-ray Systems, Computed Tomography (CT) Based Systems, Backscatter X-ray Technology, Transmission X-ray Technology, Others), Product Type, Scanning Mode, Energy Level, Throughput Capacity, Container Size Compatibility, Detection Capability, Integration Level, Deployment Model, Automation Level, Image Processing Capability, End-users, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025 – 2035

|

Market Structure & Evolution |

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Cargo Container X-ray Inspection Systems Market Size, Share, and Growth

The global cargo container X-ray inspection systems market is experiencing robust growth, with its estimated value of ~USD 2 billion in the year 2025 and USD 3.7 billion by the period 2035, registering a CAGR of 6.5% during the forecast period.

Varex Imaging CEO, Sunny Sanyal, stated “As a leader in high energy Linear Accelerator based imaging, we are pleased to see that our technology, and track record for quality and excellence is enabling us to win new business in Cargo Systems. We are glad to partner with our customers and end users to help secure ports and borders globally.”

Rising security concerns, growing regulation requirements, and escalating trade levels in the international market are major drivers fueling the global cargo container X-ray inspection systems market, which demand faster and more accurate cargo scanning in ports, airports, and along the borders. Governments and operators are looking after enhanced imaging solutions to identify contraband, explosives, and dangerous materials at the same time keeping the cargo movement efficient.

An example that can be provided is a case of Smiths Detection, which installed the high-throughput system of HI-SCAN 180180-2is at the Port of Rotterdam that meant that the large shipping containers could be scanned automatically with increased capabilities of detecting threats. Likewise, Rapiscan Systems launched its 920XR high-energy X-ray inspection system in the Los Angeles International Airport and it enhanced the precision of container screening and the time taken during the inspection process.

The use of advanced capabilities, such as threat recognition using AI, auto-image analysis, and built-in data analytics, will help the operators to process larger volumes of cargo without putting the safety of the cargo at risk. The increasing security requirements and the expansion of trade are creating the interest in adopting high-performance and automated X-ray inspection systems around the world to protect cargo safety and streamline operations.

The opportunities adjacent to the global cargo container X-ray inspection systems market are the AI-based threat detection software, conveyor-based scanning solutions (automated option), IoT-based cargo tracking, mobile X-ray devices, and connectivity with the customs and logistics management systems. These adjacent markets contribute to security, efficiency, and visibility of operations, create innovation, and implementation in cargo inspection systems.

Cargo Container X-ray Inspection Systems Market Dynamics and Trends

Driver: Surge in International Trade Boosts Demand for Cargo Inspection Services

- The global cargo container X-ray inspection systems market is under a tremendous growth owing to the expansion of international trade. Due to the rise in the volume of international merchandise trading, the importance of an effective and safe cargo check grows.

- As an example, the World Trade Organization estimated a 2.6 percent growth of merchandise trade in the world in 2024, which implies the growing trade operations that require modern inspection technologies to comply with safety and security measures. This trade expansion is directly connected to the rise in the demand of cargo inspection technologies such as X-ray systems to address the rise in volume and sophistication of shipments.

- The increase in international trade is the direct contributor to the need in the development of the advanced cargo inspection system which leads to the Markets development.

Restraint: High Initial Investment and Maintenance Costs Limit Adoption

- One of the limitations to the use of cargo container X-ray inspection systems is that it is expensive and also requires subsequent maintenance. The cost of purchase and installation of these systems is capital-intensive, and a small port and logistics center may be unable to afford it.

- Also, the costs of maintenance and operation of these systems may be cumbersome. Indicatively, in 2024, medium-sized ports in Europe indicated that they had difficulties in justifying the pay-off of new X-ray inspections systems because the cost of acquiring these systems was high. This is a financial constraint that restricts the use of such technologies especially in areas that have financial constraints.

- The adopted cost of acquisition and maintenance of cargo X-ray inspection hinders the implementation of such systems, particularly in the limited resource areas.

Opportunity: Integration of Artificial Intelligence Enhances Detection Capabilities

- The adoption of the Artificial Intelligence (AI) into the cargo containers X-ray inspection systems is an opportunity to increase the detection abilities. The X-ray images can be more effectively analyzed by AI algorithms and potentially dangerous objects can be identified more accurately and quickly.

- In 2024, one of the major manufacturers, Smiths Detection, launched an AI-based X-ray Lid that increased the detection rate of threats by 30 percent over the former. This development in technology will not only enhance security but simplify the operations, whereby manual intervention will be minimized and also the process of inspection will be faster.

- The introduction of AI to X-ray systems makes them more accurate in detection and efficient in their work, which leads to the development of the market.

Key Trend: Shift Towards Mobile and Modular Inspection Solutions

- Adoption of mobile and modular cargo container X-ray inspection systems is on an increasing trend. Such solutions are flexible and can be implemented anywhere on demand to offer scalability and adaptability to dynamic security demands. As an example, the purchase of a mobile X-ray van by Australia Border Force supplements the permanent facility in Townsville, to enable it to respond dynamically to the inspection requirements in various locations.

- Likewise, in 2024 the U.S. Customs and Border Protection agency introduced mobile X-ray equipment to various points of checkpoints to speed up the inspection process and alleviate congestion. This trend is indicative of a move towards more flexible and interchangeable inspection solutions in order to match up to dynamic security requirements.

- The emergence of mobile X-ray systems offers flexible and variable inspection services, to meet the changing security need.

Cargo Container X-ray Inspection Systems Market Analysis and Segmental Data

Fixed X-ray Systems Lead Global Cargo Inspection Demand

- The product type segment offers the highest demand in the fixed or stationary X-ray inspection systems because they can handle the high volume cargo with a high degree of consistency in accuracy. These systems are needed at the airports, seaports, and logistics hubs to screen the large container shipments continuously. In 2024, at the Port of Rotterdam, Smiths Detection set up a stationary high-energy X-ray system, with a capacity of 600 containers per hour, which has radically decreased bottlenecks in the inspection process.

- Their pre-determined design makes them be compatible with automated conveyor systems and advanced imaging software so that they do not involve many people and are more effective in operation. These systems are the most preferred in large trading centres because of their reliability, throughput capacity and precision as compared to the mobile ones.

- The fixed X-ray systems are the keystones of the global cargo security operation due to high volume handling and consistent precision.

North America Dominates Cargo Container X-ray Inspection System Demand

- The North American market observes the highest demand of cargo container X-ray inspection systems in the market because of the strict security requirements, large volume of trade and the modern port infrastructure. In 2024, the Port of Los Angeles modernized its inspection area with high-energy X-ray equipment by Rapiscan Systems, which allows screening import and export boxes much faster and more efficiently. This implementation signifies how the region is keen on ensuring safety of supply chains as well as on reducing delays in operations.

- The availability of such key players as Smiths Detection, Rapiscan Systems, and Nuctech, together with the government efforts to improve border security only solidifies market growth. The technological preparedness and investment capabilities of North America make it one of the leading countries in the implementation of cargo inspection in the world.

Cargo Container X-ray Inspection Systems Market Ecosystem

Global cargo container X-ray inspection systems market is moderately consolidated with the major players in the market including Smiths Detection, Rapiscan Systems, Nuctech Company Limited, Leidos, and Astrophysics Inc. controlling the industry. These enterprises make use of the newest technologies such as dual-energy X-ray imaging, calculated tomography (CT) and artificial intelligence (AI) to increase the detection rates, enhance the throughput, and guarantee the strict security policies. Their international nature and innovation are some of the factors that allow them to stay competitive in the market.

To foster innovation and development, key players focus on specialized solutions tailored to specific applications and regions. For instance, Rapiscan Systems offers the Eagle M60, a mobile X-ray inspection system designed for rapid deployment at temporary checkpoints. Similarly, Nuctech Company Limited provides the Nuctech CX180100, a high-energy X-ray inspection system capable of scanning large cargo containers, addressing the need for efficient screening at major ports and logistics hubs.

Government bodies, institutions, and R&D organizations play a crucial role in enhancing current technologies in the market. In September 2024, the U.S. Department of Homeland Security awarded a contract to Leidos to develop an advanced cargo screening system incorporating AI and machine learning algorithms. This initiative aims to improve threat detection accuracy and reduce inspection times, thereby enhancing border security and facilitating smoother trade operations.

Recent Development and Strategic Overview:

- In July 2025, Varex Imaging Corporation announced receiving orders valued at approximately $17 million for its high-energy non-intrusive cargo and vehicle inspection systems. These systems are set to be deployed at strategic sea and land ports to enhance security measures.

- In May 2025, Leidos and LINEV Systems collaborated to develop advanced X-ray scanning solutions aimed at enhancing security in ground transportation. These systems facilitate the inspection of ground vehicles and shipping containers, aiding customs and security officials in identifying potential threats.

Report Scope

|

Attribute |

Detail |

|

Market Size in 2025 |

~USD 2 Bn |

|

Market Forecast Value in 2035 |

USD 3.7 Bn |

|

Growth Rate (CAGR) |

6.5% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value Thousand Units for Volume |

|

Report Format |

Electronic (PDF) + Excel |

|

Regions and Countries Covered |

|||||

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Cargo Container X-ray Inspection Systems Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Technology Type |

|

|

By Product Type |

|

|

By Scanning Mode |

|

|

By Energy Level |

|

|

By Throughput Capacity |

|

|

By Container Size Compatibility |

|

|

By Detection Capability |

|

|

By Integration Level |

|

|

By Deployment Model |

|

|

By Automation Level |

|

|

By Image Processing Capability |

|

|

By End-users |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Cargo Container X-ray Inspection Systems Market Outlook

- 2.1.1. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Cargo Container X-ray Inspection Systems Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Cargo Container X-ray Inspection Systems Industry Overview, 2025

- 3.1.1. Automation & Process Control Industry Ecosystem Analysis

- 3.1.2. Key Trends for Automation & Process Control Industry

- 3.1.3. Regional Distribution for Automation & Process Control Industry

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2025

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.1.1. Based on the component & Raw material

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.5.1. Manufacturer

- 3.6. Raw Material Analysis

- 3.1. Global Cargo Container X-ray Inspection Systems Industry Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Rising demand for sustainable and bio-based materials across manufacturing sectors.

- 4.1.1.2. Expanding industrial applications in construction, automotive, and packaging industries.

- 4.1.2. Restraints

- 4.1.2.1. Volatility in raw material prices affecting production stability.

- 4.1.2.2. Stringent environmental and chemical safety regulations limiting product innovation.

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Pricing Analysis

- 4.6.1. Regional Pricing Analysis

- 4.6.2. Segmental Pricing Trends

- 4.6.3. Factors Influencing Pricing

- 4.7. Porter’s Five Forces Analysis

- 4.8. PESTEL Analysis

- 4.9. Global Cargo Container X-ray Inspection Systems Market Demand

- 4.9.1. Historical Market Size – in Volume (Thousand Units) and Value (US$ Bn), 2020-2024

- 4.9.2. Current and Future Market Size - in Volume (Thousand Units) and Value (US$ Bn), 2025–2035

- 4.9.2.1. Y-o-Y Growth Trends

- 4.9.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Cargo Container X-ray Inspection Systems Market Analysis, by Technology Type

- 6.1. Key Segment Analysis

- 6.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, by Technology Type, 2021-2035

- 6.2.1. Single Energy X-ray Systems

- 6.2.2. Multi-Energy X-ray Systems

- 6.2.3. Computed Tomography (CT) Based Systems

- 6.2.4. Backscatter X-ray Technology

- 6.2.5. Transmission X-ray Technology

- 6.2.6. Others

- 7. Global Cargo Container X-ray Inspection Systems Market Analysis, by Product Type

- 7.1. Key Segment Analysis

- 7.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, by Product Type, 2021-2035

- 7.2.1. Fixed/Stationary X-ray Inspection Systems

- 7.2.2. Mobile X-ray Inspection Systems

- 7.2.3. Relocatable X-ray Inspection Systems

- 7.2.4. Drive-Through X-ray Systems

- 7.2.5. Rail-Mounted X-ray Systems

- 7.2.6. Others

- 8. Global Cargo Container X-ray Inspection Systems Market Analysis, by Scanning Mode

- 8.1. Key Segment Analysis

- 8.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, by Scanning Mode, 2021-2035

- 8.2.1. Full Scan

- 8.2.2. Partial Scan

- 9. Global Cargo Container X-ray Inspection Systems Market Analysis, by Energy Level

- 9.1. Key Segment Analysis

- 9.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, by Energy Level, 2021-2035

- 9.2.1. Low Energy Systems (<1 MeV)

- 9.2.2. Medium Energy Systems (1-3 MeV)

- 9.2.3. High Energy Systems (3-6 MeV)

- 9.2.4. Very High Energy Systems (>6 MeV)

- 10. Global Cargo Container X-ray Inspection Systems Market Analysis, by Throughput Capacity

- 10.1. Key Segment Analysis

- 10.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, by Throughput Capacity, 2021-2035

- 10.2.1. Up to 30 containers/hour

- 10.2.2. 30-60 containers/hour

- 10.2.3. 60-100 containers/hour

- 10.2.4. Above 100 containers/hour

- 11. Global Cargo Container X-ray Inspection Systems Market Analysis, by Container Size Compatibility

- 11.1. Key Segment Analysis

- 11.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, by Container Size Compatibility, 2021-2035

- 11.2.1. 20-foot Container

- 11.2.2. 40-foot Container

- 11.2.3. 45-foot Container

- 11.2.4. Universal/Multi-size Container

- 12. Global Cargo Container X-ray Inspection Systems Market Analysis, by Detection Capability

- 12.1. Key Segment Analysis

- 12.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, by Detection Capability, 2021-2035

- 12.2.1. Organic Material Detection Systems

- 12.2.2. Inorganic Material Detection Systems

- 12.2.3. Explosives Detection Systems

- 12.2.4. Narcotics Detection Systems

- 12.2.5. Weapons & Ammunition Detection Systems

- 12.2.6. Nuclear/Radiological Material Detection Systems

- 12.2.7. Multi-Threat Detection Systems

- 13. Global Cargo Container X-ray Inspection Systems Market Analysis, by Integration Level

- 13.1. Key Segment Analysis

- 13.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, by Integration Level, 2021-2035

- 13.2.1. Standalone Systems

- 13.2.2. Integrated Border Control Systems

- 13.2.3. Network-Connected Systems

- 14. Global Cargo Container X-ray Inspection Systems Market Analysis, by Deployment Model

- 14.1. Key Findings

- 14.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Mn), Analysis, and Forecasts, by Deployment Model, 2021-2035

- 14.2.1. New Installation

- 14.2.2. Upgrade/Retrofit Solutions

- 14.2.3. Rental/Leasing Systems

- 15. Global Cargo Container X-ray Inspection Systems Market Analysis, by Automation Level

- 15.1. Key Findings

- 15.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Mn), Analysis, and Forecasts, by Automation Level, 2021-2035

- 15.2.1. Manual Operation Systems

- 15.2.2. Semi-Automated Systems

- 15.2.3. Fully Automated Systems

- 16. Global Cargo Container X-ray Inspection Systems Market Analysis, by Image Processing Capability

- 16.1. Key Findings

- 16.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Mn), Analysis, and Forecasts, by Image Processing Capability, 2021-2035

- 16.2.1. 2D Imaging Systems

- 16.2.2. 3D Imaging Systems

- 16.2.3. Real-time Image Processing

- 16.2.4. Advanced Material Discrimination (AMD)

- 16.2.5. Automatic Threat Recognition (ATR)

- 17. Global Cargo Container X-ray Inspection Systems Market Analysis, by End-users

- 17.1. Key Findings

- 17.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Mn), Analysis, and Forecasts, by End-users, 2021-2035

- 17.2.1. Ports & Maritime Facilities

- 17.2.1.1. Import Cargo Screening

- 17.2.1.2. Export Cargo Screening

- 17.2.1.3. Transshipment Cargo Inspection

- 17.2.1.4. Suspicious Cargo Investigation

- 17.2.1.5. Random Cargo Verification

- 17.2.1.6. Others

- 17.2.2. Customs & Border Protection

- 17.2.2.1. Border Security Checkpoints

- 17.2.2.2. Land Border Crossings

- 17.2.2.3. International Trade Compliance

- 17.2.2.4. Anti-Smuggling Operations

- 17.2.2.5. Trade Facilitation Programs

- 17.2.2.6. Others

- 17.2.3. Railways & Intermodal Terminals

- 17.2.3.1. Rail Container Inspection

- 17.2.3.2. Intermodal Transfer Point Screening

- 17.2.3.3. Cross-Border Rail Cargo Inspection

- 17.2.3.4. Freight Train Security

- 17.2.3.5. Others

- 17.2.4. Private Security & Logistics

- 17.2.4.1. Third-Party Logistics Screening

- 17.2.4.2. Private Port Operations

- 17.2.4.3. Warehouse Security

- 17.2.4.4. Supply Chain Integrity

- 17.2.4.5. Others

- 17.2.5. Critical Infrastructure Protection

- 17.2.6. Other End-users

- 17.2.1. Ports & Maritime Facilities

- 18. Global Cargo Container X-ray Inspection Systems Market Analysis, by Region

- 18.1. Key Findings

- 18.2. Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Mn), Analysis, and Forecasts, by Region, 2021-2035

- 18.2.1. North America

- 18.2.2. Europe

- 18.2.3. Asia Pacific

- 18.2.4. Middle East

- 18.2.5. Africa

- 18.2.6. South America

- 19. North America Cargo Container X-ray Inspection Systems Market Analysis

- 19.1. Key Segment Analysis

- 19.2. Regional Snapshot

- 19.3. North America Cargo Container X-ray Inspection Systems Market Size Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 19.3.1. Technology Type

- 19.3.2. Product Type

- 19.3.3. Scanning Mode

- 19.3.4. Energy Level

- 19.3.5. Throughput Capacity

- 19.3.6. Container Size Compatibility

- 19.3.7. Detection Capability

- 19.3.8. Integration Level

- 19.3.9. Deployment Model

- 19.3.10. Automation Level

- 19.3.11. Image Processing Capability

- 19.3.12. End-users

- 19.3.13. Country

- 19.3.13.1. USA

- 19.3.13.2. Canada

- 19.3.13.3. Mexico

- 19.4. USA Cargo Container X-ray Inspection Systems Market

- 19.4.1. Country Segmental Analysis

- 19.4.2. Technology Type

- 19.4.3. Product Type

- 19.4.4. Scanning Mode

- 19.4.5. Energy Level

- 19.4.6. Throughput Capacity

- 19.4.7. Container Size Compatibility

- 19.4.8. Detection Capability

- 19.4.9. Integration Level

- 19.4.10. Deployment Model

- 19.4.11. Automation Level

- 19.4.12. Image Processing Capability

- 19.4.13. End-users

- 19.5. Canada Cargo Container X-ray Inspection Systems Market

- 19.5.1. Country Segmental Analysis

- 19.5.2. Technology Type

- 19.5.3. Product Type

- 19.5.4. Scanning Mode

- 19.5.5. Energy Level

- 19.5.6. Throughput Capacity

- 19.5.7. Container Size Compatibility

- 19.5.8. Detection Capability

- 19.5.9. Integration Level

- 19.5.10. Deployment Model

- 19.5.11. Automation Level

- 19.5.12. Image Processing Capability

- 19.5.13. End-users

- 19.6. Mexico Cargo Container X-ray Inspection Systems Market

- 19.6.1. Country Segmental Analysis

- 19.6.2. Technology Type

- 19.6.3. Product Type

- 19.6.4. Scanning Mode

- 19.6.5. Energy Level

- 19.6.6. Throughput Capacity

- 19.6.7. Container Size Compatibility

- 19.6.8. Detection Capability

- 19.6.9. Integration Level

- 19.6.10. Deployment Model

- 19.6.11. Automation Level

- 19.6.12. Image Processing Capability

- 19.6.13. End-users

- 20. Europe Cargo Container X-ray Inspection Systems Market Analysis

- 20.1. Key Segment Analysis

- 20.2. Regional Snapshot

- 20.3. Europe Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 20.3.1. Technology Type

- 20.3.2. Product Type

- 20.3.3. Scanning Mode

- 20.3.4. Energy Level

- 20.3.5. Throughput Capacity

- 20.3.6. Container Size Compatibility

- 20.3.7. Detection Capability

- 20.3.8. Integration Level

- 20.3.9. Deployment Model

- 20.3.10. Automation Level

- 20.3.11. Image Processing Capability

- 20.3.12. End-users

- 20.3.13. Country

- 20.3.13.1. Germany

- 20.3.13.2. United Kingdom

- 20.3.13.3. France

- 20.3.13.4. Italy

- 20.3.13.5. Spain

- 20.3.13.6. Netherlands

- 20.3.13.7. Nordic Countries

- 20.3.13.8. Poland

- 20.3.13.9. Russia & CIS

- 20.3.13.10. Rest of Europe

- 20.4. Germany Cargo Container X-ray Inspection Systems Market

- 20.4.1. Country Segmental Analysis

- 20.4.2. Technology Type

- 20.4.3. Product Type

- 20.4.4. Scanning Mode

- 20.4.5. Energy Level

- 20.4.6. Throughput Capacity

- 20.4.7. Container Size Compatibility

- 20.4.8. Detection Capability

- 20.4.9. Integration Level

- 20.4.10. Deployment Model

- 20.4.11. Automation Level

- 20.4.12. Image Processing Capability

- 20.4.13. End-users

- 20.5. United Kingdom Cargo Container X-ray Inspection Systems Market

- 20.5.1. Country Segmental Analysis

- 20.5.2. Technology Type

- 20.5.3. Product Type

- 20.5.4. Scanning Mode

- 20.5.5. Energy Level

- 20.5.6. Throughput Capacity

- 20.5.7. Container Size Compatibility

- 20.5.8. Detection Capability

- 20.5.9. Integration Level

- 20.5.10. Deployment Model

- 20.5.11. Automation Level

- 20.5.12. Image Processing Capability

- 20.5.13. End-users

- 20.6. France Cargo Container X-ray Inspection Systems Market

- 20.6.1. Country Segmental Analysis

- 20.6.2. Technology Type

- 20.6.3. Product Type

- 20.6.4. Scanning Mode

- 20.6.5. Energy Level

- 20.6.6. Throughput Capacity

- 20.6.7. Container Size Compatibility

- 20.6.8. Detection Capability

- 20.6.9. Integration Level

- 20.6.10. Deployment Model

- 20.6.11. Automation Level

- 20.6.12. Image Processing Capability

- 20.6.13. End-users

- 20.7. Italy Cargo Container X-ray Inspection Systems Market

- 20.7.1. Country Segmental Analysis

- 20.7.2. Technology Type

- 20.7.3. Product Type

- 20.7.4. Scanning Mode

- 20.7.5. Energy Level

- 20.7.6. Throughput Capacity

- 20.7.7. Container Size Compatibility

- 20.7.8. Detection Capability

- 20.7.9. Integration Level

- 20.7.10. Deployment Model

- 20.7.11. Automation Level

- 20.7.12. Image Processing Capability

- 20.7.13. End-users

- 20.8. Spain Cargo Container X-ray Inspection Systems Market

- 20.8.1. Country Segmental Analysis

- 20.8.2. Technology Type

- 20.8.3. Product Type

- 20.8.4. Scanning Mode

- 20.8.5. Energy Level

- 20.8.6. Throughput Capacity

- 20.8.7. Container Size Compatibility

- 20.8.8. Detection Capability

- 20.8.9. Integration Level

- 20.8.10. Deployment Model

- 20.8.11. Automation Level

- 20.8.12. Image Processing Capability

- 20.8.13. End-users

- 20.9. Netherlands Cargo Container X-ray Inspection Systems Market

- 20.9.1. Country Segmental Analysis

- 20.9.2. Technology Type

- 20.9.3. Product Type

- 20.9.4. Scanning Mode

- 20.9.5. Energy Level

- 20.9.6. Throughput Capacity

- 20.9.7. Container Size Compatibility

- 20.9.8. Detection Capability

- 20.9.9. Integration Level

- 20.9.10. Deployment Model

- 20.9.11. Automation Level

- 20.9.12. Image Processing Capability

- 20.9.13. End-users

- 20.10. Nordic Countries Cargo Container X-ray Inspection Systems Market

- 20.10.1. Country Segmental Analysis

- 20.10.2. Technology Type

- 20.10.3. Product Type

- 20.10.4. Scanning Mode

- 20.10.5. Energy Level

- 20.10.6. Throughput Capacity

- 20.10.7. Container Size Compatibility

- 20.10.8. Detection Capability

- 20.10.9. Integration Level

- 20.10.10. Deployment Model

- 20.10.11. Automation Level

- 20.10.12. Image Processing Capability

- 20.10.13. End-users

- 20.11. Poland Cargo Container X-ray Inspection Systems Market

- 20.11.1. Country Segmental Analysis

- 20.11.2. Technology Type

- 20.11.3. Product Type

- 20.11.4. Scanning Mode

- 20.11.5. Energy Level

- 20.11.6. Throughput Capacity

- 20.11.7. Container Size Compatibility

- 20.11.8. Detection Capability

- 20.11.9. Integration Level

- 20.11.10. Deployment Model

- 20.11.11. Automation Level

- 20.11.12. Image Processing Capability

- 20.11.13. End-users

- 20.12. Russia & CIS Cargo Container X-ray Inspection Systems Market

- 20.12.1. Country Segmental Analysis

- 20.12.2. Technology Type

- 20.12.3. Product Type

- 20.12.4. Scanning Mode

- 20.12.5. Energy Level

- 20.12.6. Throughput Capacity

- 20.12.7. Container Size Compatibility

- 20.12.8. Detection Capability

- 20.12.9. Integration Level

- 20.12.10. Deployment Model

- 20.12.11. Automation Level

- 20.12.12. Image Processing Capability

- 20.12.13. End-users

- 20.13. Rest of Europe Cargo Container X-ray Inspection Systems Market

- 20.13.1. Country Segmental Analysis

- 20.13.2. Technology Type

- 20.13.3. Product Type

- 20.13.4. Scanning Mode

- 20.13.5. Energy Level

- 20.13.6. Throughput Capacity

- 20.13.7. Container Size Compatibility

- 20.13.8. Detection Capability

- 20.13.9. Integration Level

- 20.13.10. Deployment Model

- 20.13.11. Automation Level

- 20.13.12. Image Processing Capability

- 20.13.13. End-users

- 21. Asia Pacific Cargo Container X-ray Inspection Systems Market Analysis

- 21.1. Key Segment Analysis

- 21.2. Regional Snapshot

- 21.3. East Asia Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 21.3.1. Technology Type

- 21.3.2. Product Type

- 21.3.3. Scanning Mode

- 21.3.4. Energy Level

- 21.3.5. Throughput Capacity

- 21.3.6. Container Size Compatibility

- 21.3.7. Detection Capability

- 21.3.8. Integration Level

- 21.3.9. Deployment Model

- 21.3.10. Automation Level

- 21.3.11. Image Processing Capability

- 21.3.12. End-users

- 21.3.13. Country

- 21.3.13.1. China

- 21.3.13.2. India

- 21.3.13.3. Japan

- 21.3.13.4. South Korea

- 21.3.13.5. Australia and New Zealand

- 21.3.13.6. Indonesia

- 21.3.13.7. Malaysia

- 21.3.13.8. Thailand

- 21.3.13.9. Vietnam

- 21.3.13.10. Rest of Asia Pacific

- 21.4. China Cargo Container X-ray Inspection Systems Market

- 21.4.1. Country Segmental Analysis

- 21.4.2. Technology Type

- 21.4.3. Product Type

- 21.4.4. Scanning Mode

- 21.4.5. Energy Level

- 21.4.6. Throughput Capacity

- 21.4.7. Container Size Compatibility

- 21.4.8. Detection Capability

- 21.4.9. Integration Level

- 21.4.10. Deployment Model

- 21.4.11. Automation Level

- 21.4.12. Image Processing Capability

- 21.4.13. End-users

- 21.5. India Cargo Container X-ray Inspection Systems Market

- 21.5.1. Country Segmental Analysis

- 21.5.2. Technology Type

- 21.5.3. Product Type

- 21.5.4. Scanning Mode

- 21.5.5. Energy Level

- 21.5.6. Throughput Capacity

- 21.5.7. Container Size Compatibility

- 21.5.8. Detection Capability

- 21.5.9. Integration Level

- 21.5.10. Deployment Model

- 21.5.11. Automation Level

- 21.5.12. Image Processing Capability

- 21.5.13. End-users

- 21.6. Japan Cargo Container X-ray Inspection Systems Market

- 21.6.1. Country Segmental Analysis

- 21.6.2. Technology Type

- 21.6.3. Product Type

- 21.6.4. Scanning Mode

- 21.6.5. Energy Level

- 21.6.6. Throughput Capacity

- 21.6.7. Container Size Compatibility

- 21.6.8. Detection Capability

- 21.6.9. Integration Level

- 21.6.10. Deployment Model

- 21.6.11. Automation Level

- 21.6.12. Image Processing Capability

- 21.6.13. End-users

- 21.7. South Korea Cargo Container X-ray Inspection Systems Market

- 21.7.1. Country Segmental Analysis

- 21.7.2. Technology Type

- 21.7.3. Product Type

- 21.7.4. Scanning Mode

- 21.7.5. Energy Level

- 21.7.6. Throughput Capacity

- 21.7.7. Container Size Compatibility

- 21.7.8. Detection Capability

- 21.7.9. Integration Level

- 21.7.10. Deployment Model

- 21.7.11. Automation Level

- 21.7.12. Image Processing Capability

- 21.7.13. End-users

- 21.8. Australia and New Zealand Cargo Container X-ray Inspection Systems Market

- 21.8.1. Country Segmental Analysis

- 21.8.2. Technology Type

- 21.8.3. Product Type

- 21.8.4. Scanning Mode

- 21.8.5. Energy Level

- 21.8.6. Throughput Capacity

- 21.8.7. Container Size Compatibility

- 21.8.8. Detection Capability

- 21.8.9. Integration Level

- 21.8.10. Deployment Model

- 21.8.11. Automation Level

- 21.8.12. Image Processing Capability

- 21.8.13. End-users

- 21.9. Indonesia Cargo Container X-ray Inspection Systems Market

- 21.9.1. Country Segmental Analysis

- 21.9.2. Technology Type

- 21.9.3. Product Type

- 21.9.4. Scanning Mode

- 21.9.5. Energy Level

- 21.9.6. Throughput Capacity

- 21.9.7. Container Size Compatibility

- 21.9.8. Detection Capability

- 21.9.9. Integration Level

- 21.9.10. Deployment Model

- 21.9.11. Automation Level

- 21.9.12. Image Processing Capability

- 21.9.13. End-users

- 21.10. Malaysia Cargo Container X-ray Inspection Systems Market

- 21.10.1. Country Segmental Analysis

- 21.10.2. Technology Type

- 21.10.3. Product Type

- 21.10.4. Scanning Mode

- 21.10.5. Energy Level

- 21.10.6. Throughput Capacity

- 21.10.7. Container Size Compatibility

- 21.10.8. Detection Capability

- 21.10.9. Integration Level

- 21.10.10. Deployment Model

- 21.10.11. Automation Level

- 21.10.12. Image Processing Capability

- 21.10.13. End-users

- 21.11. Thailand Cargo Container X-ray Inspection Systems Market

- 21.11.1. Country Segmental Analysis

- 21.11.2. Technology Type

- 21.11.3. Product Type

- 21.11.4. Scanning Mode

- 21.11.5. Energy Level

- 21.11.6. Throughput Capacity

- 21.11.7. Container Size Compatibility

- 21.11.8. Detection Capability

- 21.11.9. Integration Level

- 21.11.10. Deployment Model

- 21.11.11. Automation Level

- 21.11.12. Image Processing Capability

- 21.11.13. End-users

- 21.12. Vietnam Cargo Container X-ray Inspection Systems Market

- 21.12.1. Country Segmental Analysis

- 21.12.2. Technology Type

- 21.12.3. Product Type

- 21.12.4. Scanning Mode

- 21.12.5. Energy Level

- 21.12.6. Throughput Capacity

- 21.12.7. Container Size Compatibility

- 21.12.8. Detection Capability

- 21.12.9. Integration Level

- 21.12.10. Deployment Model

- 21.12.11. Automation Level

- 21.12.12. Image Processing Capability

- 21.12.13. End-users

- 21.13. Rest of Asia Pacific Cargo Container X-ray Inspection Systems Market

- 21.13.1. Country Segmental Analysis

- 21.13.2. Technology Type

- 21.13.3. Product Type

- 21.13.4. Scanning Mode

- 21.13.5. Energy Level

- 21.13.6. Throughput Capacity

- 21.13.7. Container Size Compatibility

- 21.13.8. Detection Capability

- 21.13.9. Integration Level

- 21.13.10. Deployment Model

- 21.13.11. Automation Level

- 21.13.12. Image Processing Capability

- 21.13.13. End-users

- 22. Middle East Cargo Container X-ray Inspection Systems Market Analysis

- 22.1. Key Segment Analysis

- 22.2. Regional Snapshot

- 22.3. Middle East Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 22.3.1. Technology Type

- 22.3.2. Product Type

- 22.3.3. Scanning Mode

- 22.3.4. Energy Level

- 22.3.5. Throughput Capacity

- 22.3.6. Container Size Compatibility

- 22.3.7. Detection Capability

- 22.3.8. Integration Level

- 22.3.9. Deployment Model

- 22.3.10. Automation Level

- 22.3.11. Image Processing Capability

- 22.3.12. End-users

- 22.3.13. Country

- 22.3.13.1. Turkey

- 22.3.13.2. UAE

- 22.3.13.3. Saudi Arabia

- 22.3.13.4. Israel

- 22.3.13.5. Rest of Middle East

- 22.4. Turkey Cargo Container X-ray Inspection Systems Market

- 22.4.1. Country Segmental Analysis

- 22.4.2. Technology Type

- 22.4.3. Product Type

- 22.4.4. Scanning Mode

- 22.4.5. Energy Level

- 22.4.6. Throughput Capacity

- 22.4.7. Container Size Compatibility

- 22.4.8. Detection Capability

- 22.4.9. Integration Level

- 22.4.10. Deployment Model

- 22.4.11. Automation Level

- 22.4.12. Image Processing Capability

- 22.4.13. End-users

- 22.5. UAE Cargo Container X-ray Inspection Systems Market

- 22.5.1. Country Segmental Analysis

- 22.5.2. Technology Type

- 22.5.3. Product Type

- 22.5.4. Scanning Mode

- 22.5.5. Energy Level

- 22.5.6. Throughput Capacity

- 22.5.7. Container Size Compatibility

- 22.5.8. Detection Capability

- 22.5.9. Integration Level

- 22.5.10. Deployment Model

- 22.5.11. Automation Level

- 22.5.12. Image Processing Capability

- 22.5.13. End-users

- 22.6. Saudi Arabia Cargo Container X-ray Inspection Systems Market

- 22.6.1. Country Segmental Analysis

- 22.6.2. Technology Type

- 22.6.3. Product Type

- 22.6.4. Scanning Mode

- 22.6.5. Energy Level

- 22.6.6. Throughput Capacity

- 22.6.7. Container Size Compatibility

- 22.6.8. Detection Capability

- 22.6.9. Integration Level

- 22.6.10. Deployment Model

- 22.6.11. Automation Level

- 22.6.12. Image Processing Capability

- 22.6.13. End-users

- 22.7. Israel Cargo Container X-ray Inspection Systems Market

- 22.7.1. Country Segmental Analysis

- 22.7.2. Technology Type

- 22.7.3. Product Type

- 22.7.4. Scanning Mode

- 22.7.5. Energy Level

- 22.7.6. Throughput Capacity

- 22.7.7. Container Size Compatibility

- 22.7.8. Detection Capability

- 22.7.9. Integration Level

- 22.7.10. Deployment Model

- 22.7.11. Automation Level

- 22.7.12. Image Processing Capability

- 22.7.13. End-users

- 22.8. Rest of Middle East Cargo Container X-ray Inspection Systems Market

- 22.8.1. Country Segmental Analysis

- 22.8.2. Technology Type

- 22.8.3. Product Type

- 22.8.4. Scanning Mode

- 22.8.5. Energy Level

- 22.8.6. Throughput Capacity

- 22.8.7. Container Size Compatibility

- 22.8.8. Detection Capability

- 22.8.9. Integration Level

- 22.8.10. Deployment Model

- 22.8.11. Automation Level

- 22.8.12. Image Processing Capability

- 22.8.13. End-users

- 23. Africa Cargo Container X-ray Inspection Systems Market Analysis

- 23.1. Key Segment Analysis

- 23.2. Regional Snapshot

- 23.3. Africa Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 23.3.1. Technology Type

- 23.3.2. Product Type

- 23.3.3. Scanning Mode

- 23.3.4. Energy Level

- 23.3.5. Throughput Capacity

- 23.3.6. Container Size Compatibility

- 23.3.7. Detection Capability

- 23.3.8. Integration Level

- 23.3.9. Deployment Model

- 23.3.10. Automation Level

- 23.3.11. Image Processing Capability

- 23.3.12. End-users

- 23.3.13. Country

- 23.3.13.1. South Africa

- 23.3.13.2. Egypt

- 23.3.13.3. Nigeria

- 23.3.13.4. Algeria

- 23.3.13.5. Rest of Africa

- 23.4. South Africa Cargo Container X-ray Inspection Systems Market

- 23.4.1. Country Segmental Analysis

- 23.4.2. Technology Type

- 23.4.3. Product Type

- 23.4.4. Scanning Mode

- 23.4.5. Energy Level

- 23.4.6. Throughput Capacity

- 23.4.7. Container Size Compatibility

- 23.4.8. Detection Capability

- 23.4.9. Integration Level

- 23.4.10. Deployment Model

- 23.4.11. Automation Level

- 23.4.12. Image Processing Capability

- 23.4.13. End-users

- 23.5. Egypt Cargo Container X-ray Inspection Systems Market

- 23.5.1. Country Segmental Analysis

- 23.5.2. Technology Type

- 23.5.3. Product Type

- 23.5.4. Scanning Mode

- 23.5.5. Energy Level

- 23.5.6. Throughput Capacity

- 23.5.7. Container Size Compatibility

- 23.5.8. Detection Capability

- 23.5.9. Integration Level

- 23.5.10. Deployment Model

- 23.5.11. Automation Level

- 23.5.12. Image Processing Capability

- 23.5.13. End-users

- 23.6. Nigeria Cargo Container X-ray Inspection Systems Market

- 23.6.1. Country Segmental Analysis

- 23.6.2. Technology Type

- 23.6.3. Product Type

- 23.6.4. Scanning Mode

- 23.6.5. Energy Level

- 23.6.6. Throughput Capacity

- 23.6.7. Container Size Compatibility

- 23.6.8. Detection Capability

- 23.6.9. Integration Level

- 23.6.10. Deployment Model

- 23.6.11. Automation Level

- 23.6.12. Image Processing Capability

- 23.6.13. End-users

- 23.7. Algeria Cargo Container X-ray Inspection Systems Market

- 23.7.1. Country Segmental Analysis

- 23.7.2. Technology Type

- 23.7.3. Product Type

- 23.7.4. Scanning Mode

- 23.7.5. Energy Level

- 23.7.6. Throughput Capacity

- 23.7.7. Container Size Compatibility

- 23.7.8. Detection Capability

- 23.7.9. Integration Level

- 23.7.10. Deployment Model

- 23.7.11. Automation Level

- 23.7.12. Image Processing Capability

- 23.7.13. End-users

- 23.8. Rest of Africa Cargo Container X-ray Inspection Systems Market

- 23.8.1. Country Segmental Analysis

- 23.8.2. Technology Type

- 23.8.3. Product Type

- 23.8.4. Scanning Mode

- 23.8.5. Energy Level

- 23.8.6. Throughput Capacity

- 23.8.7. Container Size Compatibility

- 23.8.8. Detection Capability

- 23.8.9. Integration Level

- 23.8.10. Deployment Model

- 23.8.11. Automation Level

- 23.8.12. Image Processing Capability

- 23.8.13. End-users

- 24. South America Cargo Container X-ray Inspection Systems Market Analysis

- 24.1. Key Segment Analysis

- 24.2. Regional Snapshot

- 24.3. Central and South Africa Cargo Container X-ray Inspection Systems Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 24.3.1. Technology Type

- 24.3.2. Product Type

- 24.3.3. Scanning Mode

- 24.3.4. Energy Level

- 24.3.5. Throughput Capacity

- 24.3.6. Container Size Compatibility

- 24.3.7. Detection Capability

- 24.3.8. Integration Level

- 24.3.9. Deployment Model

- 24.3.10. Automation Level

- 24.3.11. Image Processing Capability

- 24.3.12. End-users

- 24.3.13. Country

- 24.3.13.1. Brazil

- 24.3.13.2. Argentina

- 24.3.13.3. Rest of South America

- 24.4. Brazil Cargo Container X-ray Inspection Systems Market

- 24.4.1. Country Segmental Analysis

- 24.4.2. Technology Type

- 24.4.3. Product Type

- 24.4.4. Scanning Mode

- 24.4.5. Energy Level

- 24.4.6. Throughput Capacity

- 24.4.7. Container Size Compatibility

- 24.4.8. Detection Capability

- 24.4.9. Integration Level

- 24.4.10. Deployment Model

- 24.4.11. Automation Level

- 24.4.12. Image Processing Capability

- 24.4.13. End-users

- 24.5. Argentina Cargo Container X-ray Inspection Systems Market

- 24.5.1. Country Segmental Analysis

- 24.5.2. Technology Type

- 24.5.3. Product Type

- 24.5.4. Scanning Mode

- 24.5.5. Energy Level

- 24.5.6. Throughput Capacity

- 24.5.7. Container Size Compatibility

- 24.5.8. Detection Capability

- 24.5.9. Integration Level

- 24.5.10. Deployment Model

- 24.5.11. Automation Level

- 24.5.12. Image Processing Capability

- 24.5.13. End-users

- 24.6. Rest of South America Cargo Container X-ray Inspection Systems Market

- 24.6.1. Country Segmental Analysis

- 24.6.2. Technology Type

- 24.6.3. Product Type

- 24.6.4. Scanning Mode

- 24.6.5. Energy Level

- 24.6.6. Throughput Capacity

- 24.6.7. Container Size Compatibility

- 24.6.8. Detection Capability

- 24.6.9. Integration Level

- 24.6.10. Deployment Model

- 24.6.11. Automation Level

- 24.6.12. Image Processing Capability

- 24.6.13. End-users

- 25. Key Players/ Company Profile

- 25.1. LINEV Systems

- 25.1.1. Company Details/ Overview

- 25.1.2. Company Financials

- 25.1.3. Key Customers and Competitors

- 25.1.4. Business/ Industry Portfolio

- 25.1.5. Product Portfolio/ Specification Details

- 25.1.6. Pricing Data

- 25.1.7. Strategic Overview

- 25.1.8. Recent Developments

- 25.2. Astrophysics Inc.

- 25.3. Autoclear LLC

- 25.4. Aventura Technologies, Inc.

- 25.5. Gilardoni S.p.A.

- 25.6. Leidos, Inc.

- 25.7. Nuctech Company Limited

- 25.8. Rapiscan Systems

- 25.9. Safran SA

- 25.10. Scanna MSC Ltd.

- 25.11. Scantech Group

- 25.12. Smiths Detection Group Ltd.

- 25.13. Todd Research Ltd.

- 25.14. Vidisco Ltd.

- 25.15. Varex Imaging Corporation

- 25.16. VMI Security Systems

- 25.17. Other Key Players

- 25.1. LINEV Systems

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

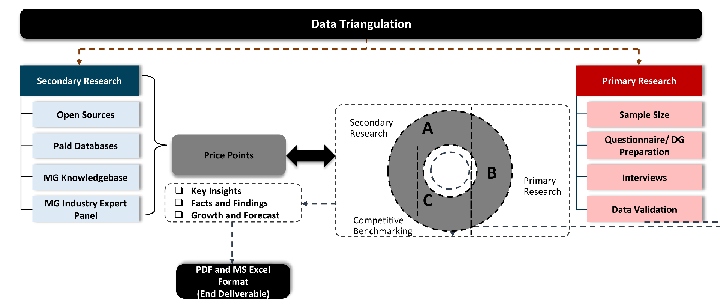

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation