Conformal Coatings Market Size, Share, Growth Opportunity Analysis Report by Type of Coating (Acrylic, Silicone, Epoxy, Polyurethane, Parylene, Fluoropolymer, Alkyd, Hybrid Coatings), Formulation, Method of Application, Substrate Compatibility, Thickness, Cure Mechanism, End-use Industry, Distribution Channel and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

Market Structure & Evolution |

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Conformal Coatings Market Size, Share, and Growth

The global conformal coatings market is experiencing robust growth, with its estimated value of USD 1.6 billion in the year 2025 and USD 2.7 billion by the period 2035, registering a CAGR of 5.4%. Asia Pacific leads the market with market share of 67.2% with USD 1.1 billion revenue.

In 2025, the conformal coatings market was thriving as aerospace and electric vehicle (EV) electronics demand increased. One of notable achievements was in Germany with one of the aerospace electronics suppliers adopting a new nano-ceramic conformal coating for printed circuit boards (PCBs) that are utilized in aircraft and drones.

The conformal coatings market is growing steadily in electronics, automotive, aerospace, medical, and defense sectors as more manufacturers shift to using coatings to protect sensitive electric components from moisture, dust, chemicals, and temperature changes to ensure long-term reliability in challenging environments.

Advanced coatings based on acrylics, silicones, polyurethanes, and parylene represent the current growth area in the market due to dielectric strength and resistance to environmental degradation. Dow recently launched a new silicone-based conformal coating line for automotive and consumer electronics with improved thermal management and low VOC-level compliance.

Many companies in the sector are turning to selective conformal coating technologies, UV-curable systems, and robotic applications to make more compact designs with higher performance. For example, AI-enabled monitoring systems are being employed to find defects and monitor coating quality.

The automotive and aerospace sectors are continuing to be major growth areas. Electric vehicle manufacturers such as BYD and Tesla are using conformal coatings to protect onboard electronics and battery systems, while aerospace players like Airbus and Boeing are using high-performance coatings to protect avionics and flight control systems from extreme conditions.

New applications in 5G, medical devices, and defense electronics are adding to the demand. Medical manufacturers are using biocompatible coatings to produce wearables and implantable, while defense contractors are looking for durable coatings for mission-critical systems.

The companies that are arguably leading the industry, H.B. Fuller, Henkel, Electrolube, and Chase Corporation, are developing eco-friendly formulations, as well as more advanced application technologies, while aligning their R&D programs with the emerging industry trends related to sustainability, automation, and electronics protection.

Conformal Coatings Market Dynamics and Trends

Drivers: Rise in Electronics & Harsh Environment Use Fuels Conformal Coatings Demand

- The use of conformal coatings is growing, due to the increasing use of electronics in the automotive, aerospace, consumer electronics & renewable energy industries. From automotive to renewable energy, protecting electronic circuits from moisture, dust and chemical damage is critical in some of the harshest environments. With electric vehicle (EV) applications, smart devices, and industrial automation strategies emerging globally.

- Additionally, manufacturers have a demand for reliable alternatives in coating solutions to extend the functional lifetime and reliability of circuit board performance. The miniaturization and increased performance requirements of electronics fabrication is driving the development of new coatings from silicone, acrylics, and parylene. Other drivers in the conformal coating market include automation in all aspects of the coating process and the need for compliance with stringent industry safety and technical standards.

Restraints: Complex Application and High Material Costs Limit Wider Use of Conformal Coatings

- Conformal coatings are critical to protecting sensitive electronics, but applying them can be tricky and expensive in practice. Some coatings like parylene use fancy and expensive retrofitted vacuum based vapor deposition systems while also reflecting highly controlled environments. Parylene is not very accessible, but even silicone and urethane may require skilled technicians, testing, and quality assurance to achieve a uniform (bubble-free) coating, especially with high-density and miniaturized circuit boards.

- Moreover, the cost of the coating material can be high too, particularly with high-performance coatings requiring superior chemical or thermal resistance. For smaller electronics producers or users in closely monitored cost markets, this can be an issue.

- Environmental regulation can substantially complicate matters. There are many solvent-based coatings that emit volatile organic compounds (VOCs), and many environmental agencies in North America, Europe, and parts of Asia are beginning to restrict their use. With water-based products, the need may arise for process changes or re-certifications that can impose either additional product adoption time or costs.

- All of these varyingly related challenges contribute to the slow adoption of conformal coatings, especially in electronics markets more sensitive to price or operating in lower margin situations.

Opportunity: Miniaturized Electronics and Emerging Applications Open New Growth Paths

- The conformal coatings market is discovering new areas of growth as electronic device size diminishes and devices grow more complex with increased functionality. Modern electronic devices such as smartphones, wearables, advanced sensors, etc., require coatings that are exceedingly thin, exact, and layer precisely on internal circuits without added bulk.

- Moreover, the growth of wearables, automotive electronics, aerospace electronics, industrial automation, and medical devices with extreme reliability requirements in extreme environments is just the tip of the iceberg. The rise in coatings that are UV-resistant, chemical-resistant, and humidity-resistant creates avenues for the development of more credible and long-lasting coatings. Also, new water-based and sustainable coatings that meet sustainability goals are an example of new growth opportunities.

- Furthermore, the move towards robotic and automated systems of integration for efficiency gains creates opportunities for automated coating application, particularly on high-volume production lines.

Key Trend: Growing Demand for Miniaturized & High-Density Electronics Boosts Need for Advanced Conformal Coatings

- With electronic apparatuses shrinking, getting more powerful and housing more parts, the demand for high-performance conformal coatings is rapidly increasing. In consumer electronics, automotive (especially EVs), medical devices, and aerospace there is a desire for smaller components, but the end product must still be able to withstand the challenges of heat, moisture, dust, and vibration.

- Further, conventional conformal coatings may no longer offer the required protection, and the demand is witnessed to grow for advanced materials like parylene, and nano-coatings that can provide even thicknesses, ultra-thin coatings, and better overall protection than traditional coatings.

- In addition, investments in selective conformal coating technologies driven by trends in smart factories or Industry 4.0 innovation concepts that require coatings were applied with great precision and efficiency. As the market adapts, there is a clear focus on innovation that reflects the changing market towards long-lasting electronics that can withstand changing environments.

Conformal Coatings Market Analysis and Segmental Data

Based on Type of Coating, Acrylic holds the largest share

- Acrylic has the largest share of the global conformal coatings market, as a consequence of its balance of performance, ease of application, and price. Acrylic coatings are adequate protection against moisture, dust, and some chemicals while offering good electrical insulation.

- Because of their drying time, re-workability, and compatibility with a variety of application forms, acrylic is a good choice for new consumer electronics, automotive applications, and industrial applications that require a conformal coating.

- In 2024, H.B. Fuller and Electrolube are examples of companies increasing their acrylic product lines to meet a host of environmental and regulatory guidelines. These combined benefits on performance and economics justify the relatively wider use of acrylic coatings across these important industries.

Asia Pacific Dominates Global Conformal Coatings Market in 2025 and beyond

- Asia Pacific region is dominating the overall Conformal Coatings Market across the globe due to favorable industrial policies, a mature electronics manufacturing base, and growth potential in devices for consumer electronics, automotive, and industrial purposes. These factors have strengthened the important role of the region, not only due to their domestic support, but also the amount of investment from other key manufacturers in China, Japan, South Korea, and Taiwan.

- Further, China's domestic capabilities for electronics and materials are being prompted by government industrial policy called Made in China 2025 who recently directed its sizeable planned investment in conformal coatings to applications for electric vehicles (EVs), IoT, and smart devices in 2024.

- In particular, the reliability of coatings from Japan's manufacturers such as Shin-Etsu and Mitsubishi Electric provide opportunities for growth supported by a national R&D strategy. South Korea's Samsung SDI and LG Chem, with the government's ambition via Digital New Deal, are positioning themselves to enhance electric technology through material innovations relevant to conformal coatings.

Conformal Coatings Market Ecosystem

The market for conformal coatings is highly fragmented and has a medium level of consolidation, including Tier 1 players such as Henkel, Dow, H.B. Fuller, Shin-Etsu Chemical, Tier 2 players such as EP/MG, Chase Corporation, Dymax), and Tier 3 players such as MG Chemicals, Novagard Solutions, CSL Silicones. The concentration of buyers is moderate; so there is some degree of negotiating power as there are a greater number of suppliers as opposed to buyers. The concentration of suppliers is low; therefore, suppliers have limited power over the availability of raw materials.

Recent Development and Strategic Overview:

- In March 2025, H.B. Fuller processes a spray able adhesive called Millennium PG-1 EF ECO₂, very different than traditional adhesives; Millennium PG-1 EF ECO₂ has a unique spray able adhesive with a canister-based propellant system to avoid conventional chemical blowing agents to advance the application methods of the adhesive. The technology hinges on roof and flat top applications but illustrates the company’s advancements in safe and applicable and environmentally aware application systems. It is the next phase of the company's directions maturing into its broad formats of conformal coatings and electronics protection technologies.

- In April 2024, Chase Corp had published findings on the various challenges of coating ultra-dense and sharp-edged PCB assemblies with coatings that created coverage with uniformity and reliability. The company continues to innovate with high-performance conformal coatings that are designed to meet the demands of aerospace, automotive, and medical electronics.

Report Scope

|

Attribute |

Detail |

|

Market Size in 2025 |

USD 1.6 Bn |

|

Market Forecast Value in 2035 |

USD 2.7 Bn |

|

Growth Rate (CAGR) |

5.4% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2020 – 2024 |

|

Market Size Units |

USD Billion for Value

|

|

Report Format |

Electronic (PDF) + Excel |

|

Regions and Countries Covered |

|||||

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

Henkel AG & Co. KGaA |

|

|

Co., Ltd.

|

Conformal coatings Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Type of Coating |

|

|

By Formulation |

|

|

By Method of Application |

|

|

By Substrate Compatibility |

|

|

By Thickness |

|

|

By Cure Mechanism |

|

|

By End-use Industry |

|

|

By Distribution Channel |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Conformal Coatings Market Outlook

- 2.1.1. Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Conformal Coatings Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Conformal Coatings Industry Overview, 2024

- 3.1.1. Chemicals & Materials Industry Ecosystem Analysis

- 3.1.2. Key Trends for Chemicals & Materials Industry

- 3.1.3. Regional Distribution for Chemicals & Materials Industry

- 3.2. Supplier Customer Data

- 3.3. Source Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2024

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.6. Raw Material Analysis

- 3.1. Conformal Coatings Industry Overview, 2024

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Rise in Electronics & Harsh Environment Use Fuels Conformal Coatings Demand

- 4.1.2. Restraints

- 4.1.2.1. Complex Application and High Material Costs Limit Wider Use of Conformal Coatings

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Ingredients Sourcing

- 4.4.2. Processing

- 4.4.3. Wholesalers/ E-commerce Platform

- 4.4.4. End-use/ Customers

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Pricing Analysis

- 4.6.1. Regional Pricing Analysis

- 4.6.2. Segmental Pricing Trends

- 4.6.3. Factors Influencing Pricing

- 4.7. Porter’s Five Forces Analysis

- 4.8. PESTEL Analysis

- 4.9. Global Conformal Coatings Market Demand

- 4.9.1. Historical Market Size - Volume - Million Units and Value - USD Bn), 2021-2024

- 4.9.2. Current and Future Market Size - Volume - Million Units and Value - USD Bn), 2025–2035

- 4.9.2.1. Y-o-Y Growth Trends

- 4.9.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2024

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Conformal Coatings Market Analysis, by Type of Coating

- 6.1. Key Segment Analysis

- 6.2. Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, by Type of Coating, 2021-2035

- 6.2.1. Acrylic

- 6.2.2. Silicone

- 6.2.3. Epoxy

- 6.2.4. Polyurethane

- 6.2.5. Parylene

- 6.2.6. Fluoropolymer

- 6.2.7. Alkyd

- 6.2.8. Hybrid Coatings

- 7. Global Conformal Coatings Market Analysis, by Formulation

- 7.1. Key Segment Analysis

- 7.2. Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, by Formulation, 2021-2035

- 7.2.1. Solvent-based

- 7.2.2. Water-based

- 7.2.3. UV-Cured

- 7.2.4. Solvent-less

- 7.2.5. Hybrid Formulations

- 8. Global Conformal Coatings Market Analysis, by Method of Application

- 8.1. Key Segment Analysis

- 8.2. Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, by Method of Application, 2021-2035

- 8.2.1. Brushing

- 8.2.2. Dipping

- 8.2.3. Spraying

- 8.2.4. Selective Coating

- 8.2.5. Vapor Deposition

- 8.2.6. Others

- 9. Global Conformal Coatings Market Analysis, by Substrate Compatibility

- 9.1. Key Segment Analysis

- 9.2. Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, by Substrate Compatibility, 2021-2035

- 9.2.1. Printed Circuit Boards (PCBs)

- 9.2.2. Ceramic Substrates

- 9.2.3. Plastic Components

- 9.2.4. Metal Housings

- 9.2.5. Flexible Electronics

- 9.2.6. Others

- 10. Global Conformal Coatings Market Analysis, by Thickness

- 10.1. Key Segment Analysis

- 10.2. Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, by Thickness, 2021-2035

- 10.2.1. Ultra-thin (<5 µm)

- 10.2.2. Standard (5–50 µm)

- 10.2.3. Thick (>50 µm)

- 11. Global Conformal Coatings Market Analysis, by Cure Mechanism

- 11.1. Key Segment Analysis

- 11.2. Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, by Cure Mechanism, 2021-2035

- 11.2.1. Heat Cured

- 11.2.2. Moisture Cured

- 11.2.3. UV Cured

- 11.2.4. Dual Cured

- 11.2.5. Room Temperature Cure

- 12. Global Conformal Coatings Market Analysis, by End Use Industry

- 12.1. Key Segment Analysis

- 12.2. Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, by End Use Industry, 2021-2035

- 12.2.1. Consumer Electronics

- 12.2.1.1. Smartphones

- 12.2.1.2. Laptops

- 12.2.1.3. Wearables

- 12.2.1.4. Smart Home Devices

- 12.2.1.5. Others

- 12.2.2. Automotive

- 12.2.2.1. Engine Control Units (ECUs)

- 12.2.2.2. Infotainment Systems

- 12.2.2.3. ADAS Modules

- 12.2.2.4. Battery Management Systems (BMS)

- 12.2.2.5. EV Inverters

- 12.2.2.6. Others

- 12.2.3. Aerospace & Defense

- 12.2.3.1. Avionics

- 12.2.3.2. Communication Systems

- 12.2.3.3. Radar Modules

- 12.2.3.4. Flight Control Systems

- 12.2.3.5. Others

- 12.2.4. Industrial

- 12.2.4.1. Industrial Automation Systems

- 12.2.4.2. Motor Drives

- 12.2.4.3. Robotics

- 12.2.4.4. PLCs

- 12.2.4.5. Others

- 12.2.5. Medical Devices

- 12.2.5.1. Implantable Devices

- 12.2.5.2. Diagnostic Equipment

- 12.2.5.3. Monitoring Sensors

- 12.2.5.4. Others

- 12.2.6. Telecommunications

- 12.2.6.1. Base Stations

- 12.2.6.2. Network Switches

- 12.2.6.3. Fiber Optic Modules

- 12.2.6.4. Others

- 12.2.7. Others (Renewable Energy, etc.)

- 12.2.7.1. Perfumes

- 12.2.7.2. Lotions

- 12.2.7.3. Hair Sprays

- 12.2.8. Others (Industrial Solvents, Cleaning Agents, etc.)

- 12.2.1. Consumer Electronics

- 13. Global Conformal Coatings Market Analysis, by Distribution Channel

- 13.1. Key Segment Analysis

- 13.2. Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, by Distribution Channel, 2021-2035

- 13.2.1. Direct Sales

- 13.2.2. Distributors

- 13.2.3. Online Platforms

- 13.2.4. Specialty Chemical Retailers

- 14. Global Conformal Coatings Market Analysis and Forecasts, by Region

- 14.1. Key Findings

- 14.2. Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, by Region, 2021-2035

- 14.2.1. North America

- 14.2.2. Europe

- 14.2.3. Asia Pacific

- 14.2.4. Middle East

- 14.2.5. Africa

- 14.2.6. South America

- 15. North America Global Conformal Coatings Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. North America Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 15.3.1. Type of Coating

- 15.3.2. Formulation

- 15.3.3. Method of Application

- 15.3.4. Substrate Compatibility

- 15.3.5. Thickness

- 15.3.6. Cure Mechanism

- 15.3.7. End-use Industry

- 15.3.8. Distribution Channel

- 15.3.9. Country

- 15.3.9.1. USA

- 15.3.9.2. Canada

- 15.3.9.3. Mexico

- 15.4. USA Global Conformal Coatings Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Type of Coating

- 15.4.3. Formulation

- 15.4.4. Method of Application

- 15.4.5. Substrate Compatibility

- 15.4.6. Thickness

- 15.4.7. Cure Mechanism

- 15.4.8. End-use Industry

- 15.4.9. Distribution Channel

- 15.5. Canada Global Conformal Coatings Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Type of Coating

- 15.5.3. Formulation

- 15.5.4. Method of Application

- 15.5.5. Substrate Compatibility

- 15.5.6. Thickness

- 15.5.7. Cure Mechanism

- 15.5.8. End-use Industry

- 15.5.9. Distribution Channel

- 15.6. Mexico Global Conformal Coatings Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Type of Coating

- 15.6.3. Formulation

- 15.6.4. Method of Application

- 15.6.5. Substrate Compatibility

- 15.6.6. Thickness

- 15.6.7. Cure Mechanism

- 15.6.8. End-use Industry

- 15.6.9. Distribution Channel

- 16. Europe Global Conformal Coatings Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Europe Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 16.3.1. Type of Coating

- 16.3.2. Formulation

- 16.3.3. Method of Application

- 16.3.4. Substrate Compatibility

- 16.3.5. Thickness

- 16.3.6. Cure Mechanism

- 16.3.7. End-use Industry

- 16.3.8. Distribution Channel

- 16.3.9. Country

- 16.3.9.1. Germany

- 16.3.9.2. United Kingdom

- 16.3.9.3. France

- 16.3.9.4. Italy

- 16.3.9.5. Spain

- 16.3.9.6. Netherlands

- 16.3.9.7. Nordic Countries

- 16.3.9.8. Poland

- 16.3.9.9. Russia & CIS

- 16.3.9.10. Rest of Europe

- 16.4. Germany Global Conformal Coatings Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Type of Coating

- 16.4.3. Formulation

- 16.4.4. Method of Application

- 16.4.5. Substrate Compatibility

- 16.4.6. Thickness

- 16.4.7. Cure Mechanism

- 16.4.8. End-use Industry

- 16.4.9. Distribution Channel

- 16.5. United Kingdom Global Conformal Coatings Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Type of Coating

- 16.5.3. Formulation

- 16.5.4. Method of Application

- 16.5.5. Substrate Compatibility

- 16.5.6. Thickness

- 16.5.7. Cure Mechanism

- 16.5.8. End-use Industry

- 16.5.9. Distribution Channel

- 16.6. France Global Conformal Coatings Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Type of Coating

- 16.6.3. Formulation

- 16.6.4. Method of Application

- 16.6.5. Substrate Compatibility

- 16.6.6. Thickness

- 16.6.7. Cure Mechanism

- 16.6.8. End-use Industry

- 16.6.9. Distribution Channel

- 16.7. Italy Global Conformal Coatings Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Type of Coating

- 16.7.3. Formulation

- 16.7.4. Method of Application

- 16.7.5. Substrate Compatibility

- 16.7.6. Thickness

- 16.7.7. Cure Mechanism

- 16.7.8. End-use Industry

- 16.7.9. Distribution Channel

- 16.8. Spain Global Conformal Coatings Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Type of Coating

- 16.8.3. Formulation

- 16.8.4. Method of Application

- 16.8.5. Substrate Compatibility

- 16.8.6. Thickness

- 16.8.7. Cure Mechanism

- 16.8.8. End-use Industry

- 16.8.9. Distribution Channel

- 16.9. Netherlands Global Conformal Coatings Market

- 16.9.1. Country Segmental Analysis

- 16.9.2. Type of Coating

- 16.9.3. Formulation

- 16.9.4. Method of Application

- 16.9.5. Substrate Compatibility

- 16.9.6. Thickness

- 16.9.7. Cure Mechanism

- 16.9.8. End-use Industry

- 16.9.9. Distribution Channel

- 16.10. Nordic Countries Global Conformal Coatings Market

- 16.10.1. Country Segmental Analysis

- 16.10.2. Type of Coating

- 16.10.3. Formulation

- 16.10.4. Method of Application

- 16.10.5. Substrate Compatibility

- 16.10.6. Thickness

- 16.10.7. Cure Mechanism

- 16.10.8. End-use Industry

- 16.10.9. Distribution Channel

- 16.11. Poland Global Conformal Coatings Market

- 16.11.1. Country Segmental Analysis

- 16.11.2. Type of Coating

- 16.11.3. Formulation

- 16.11.4. Method of Application

- 16.11.5. Substrate Compatibility

- 16.11.6. Thickness

- 16.11.7. Cure Mechanism

- 16.11.8. End-use Industry

- 16.11.9. Distribution Channel

- 16.12. Russia & CIS Global Conformal Coatings Market

- 16.12.1. Country Segmental Analysis

- 16.12.2. Type of Coating

- 16.12.3. Formulation

- 16.12.4. Method of Application

- 16.12.5. Substrate Compatibility

- 16.12.6. Thickness

- 16.12.7. Cure Mechanism

- 16.12.8. End-use Industry

- 16.12.9. Distribution Channel

- 16.13. Rest of Europe Global Conformal Coatings Market

- 16.13.1. Country Segmental Analysis

- 16.13.2. Type of Coating

- 16.13.3. Formulation

- 16.13.4. Method of Application

- 16.13.5. Substrate Compatibility

- 16.13.6. Thickness

- 16.13.7. Cure Mechanism

- 16.13.8. End-use Industry

- 16.13.9. Distribution Channel

- 17. Asia Pacific Global Conformal Coatings Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. East Asia Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 17.3.1. Type of Coating

- 17.3.2. Formulation

- 17.3.3. Method of Application

- 17.3.4. Substrate Compatibility

- 17.3.5. Thickness

- 17.3.6. Cure Mechanism

- 17.3.7. End-use Industry

- 17.3.8. Distribution Channel

- 17.3.9. Country

- 17.3.9.1. China

- 17.3.9.2. India

- 17.3.9.3. Japan

- 17.3.9.4. South Korea

- 17.3.9.5. Australia and New Zealand

- 17.3.9.6. Indonesia

- 17.3.9.7. Malaysia

- 17.3.9.8. Thailand

- 17.3.9.9. Vietnam

- 17.3.9.10. Rest of Asia-Pacific

- 17.4. China Global Conformal Coatings Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Type of Coating

- 17.4.3. Formulation

- 17.4.4. Method of Application

- 17.4.5. Substrate Compatibility

- 17.4.6. Thickness

- 17.4.7. Cure Mechanism

- 17.4.8. End-use Industry

- 17.4.9. Distribution Channel

- 17.5. India Global Conformal Coatings Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Type of Coating

- 17.5.3. Formulation

- 17.5.4. Method of Application

- 17.5.5. Substrate Compatibility

- 17.5.6. Thickness

- 17.5.7. Cure Mechanism

- 17.5.8. End-use Industry

- 17.5.9. Distribution Channel

- 17.6. Japan Global Conformal Coatings Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Type of Coating

- 17.6.3. Formulation

- 17.6.4. Method of Application

- 17.6.5. Substrate Compatibility

- 17.6.6. Thickness

- 17.6.7. Cure Mechanism

- 17.6.8. End-use Industry

- 17.6.9. Distribution Channel

- 17.7. South Korea Global Conformal Coatings Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Type of Coating

- 17.7.3. Formulation

- 17.7.4. Method of Application

- 17.7.5. Substrate Compatibility

- 17.7.6. Thickness

- 17.7.7. Cure Mechanism

- 17.7.8. End-use Industry

- 17.7.9. Distribution Channel

- 17.8. Australia and New Zealand Global Conformal Coatings Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Type of Coating

- 17.8.3. Formulation

- 17.8.4. Method of Application

- 17.8.5. Substrate Compatibility

- 17.8.6. Thickness

- 17.8.7. Cure Mechanism

- 17.8.8. End-use Industry

- 17.8.9. Distribution Channel

- 17.9. Indonesia Global Conformal Coatings Market

- 17.9.1. Country Segmental Analysis

- 17.9.2. Type of Coating

- 17.9.3. Formulation

- 17.9.4. Method of Application

- 17.9.5. Substrate Compatibility

- 17.9.6. Thickness

- 17.9.7. Cure Mechanism

- 17.9.8. End-use Industry

- 17.9.9. Distribution Channel

- 17.10. Malaysia Global Conformal Coatings Market

- 17.10.1. Country Segmental Analysis

- 17.10.2. Type of Coating

- 17.10.3. Formulation

- 17.10.4. Method of Application

- 17.10.5. Substrate Compatibility

- 17.10.6. Thickness

- 17.10.7. Cure Mechanism

- 17.10.8. End-use Industry

- 17.10.9. Distribution Channel

- 17.11. Thailand Global Conformal Coatings Market

- 17.11.1. Country Segmental Analysis

- 17.11.2. Type of Coating

- 17.11.3. Formulation

- 17.11.4. Method of Application

- 17.11.5. Substrate Compatibility

- 17.11.6. Thickness

- 17.11.7. Cure Mechanism

- 17.11.8. End-use Industry

- 17.11.9. Distribution Channel

- 17.12. Vietnam Global Conformal Coatings Market

- 17.12.1. Country Segmental Analysis

- 17.12.2. Type of Coating

- 17.12.3. Formulation

- 17.12.4. Method of Application

- 17.12.5. Substrate Compatibility

- 17.12.6. Thickness

- 17.12.7. Cure Mechanism

- 17.12.8. End-use Industry

- 17.12.9. Distribution Channel

- 17.13. Rest of Asia Pacific Global Conformal Coatings Market

- 17.13.1. Country Segmental Analysis

- 17.13.2. Type of Coating

- 17.13.3. Formulation

- 17.13.4. Method of Application

- 17.13.5. Substrate Compatibility

- 17.13.6. Thickness

- 17.13.7. Cure Mechanism

- 17.13.8. End-use Industry

- 17.13.9. Distribution Channel

- 18. Middle East Global Conformal Coatings Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Middle East Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 18.3.1. Type of Coating

- 18.3.2. Formulation

- 18.3.3. Method of Application

- 18.3.4. Substrate Compatibility

- 18.3.5. Thickness

- 18.3.6. Cure Mechanism

- 18.3.7. End-use Industry

- 18.3.8. Distribution Channel

- 18.3.9. Country

- 18.3.9.1. Turkey

- 18.3.9.2. UAE

- 18.3.9.3. Saudi Arabia

- 18.3.9.4. Israel

- 18.3.9.5. Rest of Middle East

- 18.4. Turkey Global Conformal Coatings Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Type of Coating

- 18.4.3. Formulation

- 18.4.4. Method of Application

- 18.4.5. Substrate Compatibility

- 18.4.6. Thickness

- 18.4.7. Cure Mechanism

- 18.4.8. End-use Industry

- 18.4.9. Distribution Channel

- 18.5. UAE Global Conformal Coatings Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Type of Coating

- 18.5.3. Formulation

- 18.5.4. Method of Application

- 18.5.5. Substrate Compatibility

- 18.5.6. Thickness

- 18.5.7. Cure Mechanism

- 18.5.8. End-use Industry

- 18.5.9. Distribution Channel

- 18.6. Saudi Arabia Global Conformal Coatings Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Type of Coating

- 18.6.3. Formulation

- 18.6.4. Method of Application

- 18.6.5. Substrate Compatibility

- 18.6.6. Thickness

- 18.6.7. Cure Mechanism

- 18.6.8. End-use Industry

- 18.6.9. Distribution Channel

- 18.7. Israel Global Conformal Coatings Market

- 18.7.1. Country Segmental Analysis

- 18.7.2. Type of Coating

- 18.7.3. Formulation

- 18.7.4. Method of Application

- 18.7.5. Substrate Compatibility

- 18.7.6. Thickness

- 18.7.7. Cure Mechanism

- 18.7.8. End-use Industry

- 18.7.9. Distribution Channel

- 18.8. Rest of Middle East Global Conformal Coatings Market

- 18.8.1. Country Segmental Analysis

- 18.8.2. Type of Coating

- 18.8.3. Formulation

- 18.8.4. Method of Application

- 18.8.5. Substrate Compatibility

- 18.8.6. Thickness

- 18.8.7. Cure Mechanism

- 18.8.8. End-use Industry

- 18.8.9. Distribution Channel

- 19. Africa Global Conformal Coatings Market Analysis

- 19.1. Key Segment Analysis

- 19.2. Regional Snapshot

- 19.3. Africa Global Conformal Coatings Market Size (Volume - Million Units and Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 19.3.1. Type of Coating

- 19.3.2. Formulation

- 19.3.3. Method of Application

- 19.3.4. Substrate Compatibility

- 19.3.5. Thickness

- 19.3.6. Cure Mechanism

- 19.3.7. End-use Industry

- 19.3.8. Distribution Channel

- 19.3.9. Country

- 19.3.9.1. South Africa

- 19.3.9.2. Egypt

- 19.3.9.3. Nigeria

- 19.3.9.4. Algeria

- 19.3.9.5. Rest of Africa

- 19.4. South Africa Global Conformal Coatings Market

- 19.4.1. Country Segmental Analysis

- 19.4.2. Type of Coating

- 19.4.3. Formulation

- 19.4.4. Method of Application

- 19.4.5. Substrate Compatibility

- 19.4.6. Thickness

- 19.4.7. Cure Mechanism

- 19.4.8. End-use Industry

- 19.4.9. Distribution Channel

- 19.5. Egypt Global Conformal Coatings Market

- 19.5.1. Country Segmental Analysis

- 19.5.2. Type of Coating

- 19.5.3. Formulation

- 19.5.4. Method of Application

- 19.5.5. Substrate Compatibility

- 19.5.6. Thickness

- 19.5.7. Cure Mechanism

- 19.5.8. End-use Industry

- 19.5.9. Distribution Channel

- 19.6. Nigeria Global Conformal Coatings Market

- 19.6.1. Country Segmental Analysis

- 19.6.2. Type of Coating

- 19.6.3. Formulation

- 19.6.4. Method of Application

- 19.6.5. Substrate Compatibility

- 19.6.6. Thickness

- 19.6.7. Cure Mechanism

- 19.6.8. End-use Industry

- 19.6.9. Distribution Channel

- 19.7. Algeria Global Conformal Coatings Market

- 19.7.1. Country Segmental Analysis

- 19.7.2. Type of Coating

- 19.7.3. Formulation

- 19.7.4. Method of Application

- 19.7.5. Substrate Compatibility

- 19.7.6. Thickness

- 19.7.7. Cure Mechanism

- 19.7.8. End-use Industry

- 19.7.9. Distribution Channel

- 19.8. Rest of Africa Global Conformal Coatings Market

- 19.8.1. Country Segmental Analysis

- 19.8.2. Type of Coating

- 19.8.3. Formulation

- 19.8.4. Method of Application

- 19.8.5. Substrate Compatibility

- 19.8.6. Thickness

- 19.8.7. Cure Mechanism

- 19.8.8. End-use Industry

- 19.8.9. Distribution Channel

- 20. South America Global Conformal Coatings Market Analysis

- 20.1. Key Segment Analysis

- 20.2. Regional Snapshot

- 20.3. Central and South Africa Global Conformal Coatings Market Size ( Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 20.3.1. Type of Coating

- 20.3.2. Formulation

- 20.3.3. Method of Application

- 20.3.4. Substrate Compatibility

- 20.3.5. Thickness

- 20.3.6. Cure Mechanism

- 20.3.7. End-use Industry

- 20.3.8. Distribution Channel

- 20.3.9. Country

- 20.3.9.1. Brazil

- 20.3.9.2. Argentina

- 20.3.9.3. Rest of South America

- 20.4. Brazil Global Conformal Coatings Market

- 20.4.1. Country Segmental Analysis

- 20.4.2. Type of Coating

- 20.4.3. Formulation

- 20.4.4. Method of Application

- 20.4.5. Substrate Compatibility

- 20.4.6. Thickness

- 20.4.7. Cure Mechanism

- 20.4.8. End-use Industry

- 20.4.9. Distribution Channel

- 20.5. Argentina Global Conformal Coatings Market

- 20.5.1. Country Segmental Analysis

- 20.5.2. Type of Coating

- 20.5.3. Formulation

- 20.5.4. Method of Application

- 20.5.5. Substrate Compatibility

- 20.5.6. Thickness

- 20.5.7. Cure Mechanism

- 20.5.8. End-use Industry

- 20.5.9. Distribution Channel

- 20.6. Rest of South America Global Conformal Coatings Market

- 20.6.1. Country Segmental Analysis

- 20.6.2. Type of Coating

- 20.6.3. Formulation

- 20.6.4. Method of Application

- 20.6.5. Substrate Compatibility

- 20.6.6. Thickness

- 20.6.7. Cure Mechanism

- 20.6.8. End-use Industry

- 20.6.9. Distribution Channel

- 21. Key Players/ Company Profile

- 21.1. Altana AG

- 21.1.1. Company Details/ Overview

- 21.1.2. Company Financials

- 21.1.3. Key Customers and Competitors

- 21.1.4. Business/ Industry Portfolio

- 21.1.5. Product Portfolio/ Specification Details

- 21.1.6. Pricing Data

- 21.1.7. Strategic Overview

- 21.1.8. Recent Developments

- 21.2. Chase Corporation

- 21.3. Chemence Inc.

- 21.4. CSL Silicones Inc.

- 21.5. Dow

- 21.6. Dymax Corporation

- 21.7. Electrolube

- 21.8. Europlasma NV

- 21.9. H.B. Fuller Company

- 21.10. Henkel AG & Co. KGaA

- 21.11. Kisco Ltd.

- 21.12. Master Bond Inc.

- 21.13. MG Chemicals

- 21.14. Nordson Corporation

- 21.15. Novagard Solutions

- 21.16. Parker Hannifin Corporation

- 21.17. Shin-Etsu Chemical Co., Ltd.

- 21.18. Specialty Coating Systems Inc.

- 21.19. Other Key Players

- 21.1. Altana AG

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

Research Design

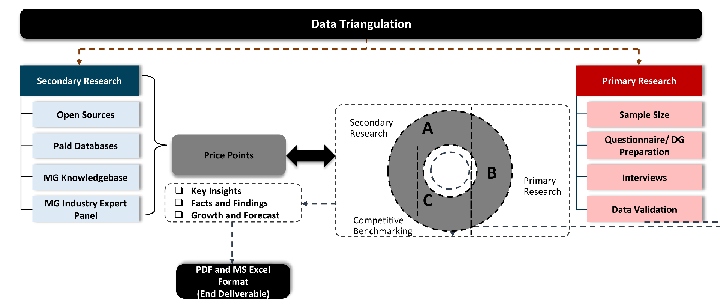

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation