Mineralization Technology Market Size, Share & Trends Analysis Report by Technology Type (Biological Mineralization, Chemical Mineralization, Physical Mineralization, Hybrid Technologies), Process Method, Target Minerals, Application Scale, Equipment Type, Raw Material Source, End Product Type, Automation Level, End-Use Industry, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Mineralization Technology Market Size, Share, and Growth

The global mineralization technology market is experiencing robust growth, with its estimated value of USD 1.3 billion in the year 2025 and ~USD 3 billion by the period 2035, registering a CAGR of 9.2%, during the forecast period. The global mineralization technology market is growing because of developments in technology, supportive government policies, new commercial opportunities, and demand from across industries such as construction, steel, and mining.

Brent Constantz, Blue Planet's Founder, CEO and Chief Scientist, noted,

"We are pleased to have the technical and commercial support of Marathon Petroleum at this critical phase of the scale up and commercialization of our low and negative embodied carbon building materials."

The global mineralization technology market is driven by rising global demand for carbon removal technologies, particularly in hard-to-abate sectors such as cement, steel, and mining. For instance, in June 2025, Dutch construction firm Hakkers and startup Paebbl have launched carbon-storing harbour infrastructure in Rotterdam, this innovation able to minimise carbon footprint at industrial scale.

In addition, the continuous innovations can be expected to be the driving force in mineralization technology market. For instance, Vancouver-based carbon mineralization company Arca is also hitting the cleantech scene with the help of the B.C. Centre for Innovation and Clean Energy (CICE), and the technologies like the Air-to-Rock carbon mineralization technology of Arca are making a splash in the carbon dioxide removal (CDR) space by turning waste products of mining into an effective means of atmospheric CO 2 capture. Such a development highlights the critical role of innovative solutions on the path of industrial progress with the objective of global decarbonization.

CO₂ Mineralization Additives, Synthetic Aggregates for Construction, Direct Air Capture (DAC) Technologies, Green Hydrogen Production, and Enhanced Weathering Techniques are creating additional opportunities for the mineralization technology market.

The scope of application of mineralization technology is these sectors is also growing as more sophisticated technologies are considered in terms of efficiency, scalability, cost-effectiveness, and integration with existing industrial processes to accelerate carbon capture and promote sustainable development. For instance, in February 2025, Sirona Technologies and Cella proud to introduced Project Jacaranda, pioneer pilot located in Kenya’s iconic Great Rift Valley at Lake Elementaita. By integrating solar energy, Direct Air Capture (DAC), and enhanced carbon mineralization, this project captures CO₂ from the air and permanently stores it underground. This launch not only marks the fastest DAC pilot deployment in the world but also positions Kenya as a leader in next-generation carbon removal technology.

Mineralization Technology Market Dynamics and Trends

Driver: Net-Zero Emissions Targets Fueling Market Expansion

- Net-zero emissions goals are rapidly boosting the mineralization technology market by growing demand for carbon capture and utilization (CCU), pushing industries and governments to invest in effective CO₂ removal solutions. For instance, the government of the United Kingdom has contracted two commercial projects to store and capture carbon dioxide emissions and the United Kingdom has set the goal of net-zero emissions by 2050 and has recognized carbon capture and storage (CCS) as a key technology to reduce the emissions of the energy-intensive industrial sectors.

- The growing demand to achieve net-zero emissions, especially in hard-to-abate sectors such as steel, mining, and cement where long-term carbon removal solutions are essential, is a significant global driver of the mineralization technology market. For instance, in January 2024, Mitsubishi Heavy Industries (MHI) Group has installed a compact pilot CO₂ capture system “CO₂MPACT” at a cement plant for Heidelberg Materials in Edmonton, Alberta, Canada. The project is anticipated to become the first comprehensive CCUS solution for the industry in the world.

Restraint: Lack of Standardized Measurement, Reporting, and Verification (MRV) Frameworks

- The credibility, comparability, and scalability of mineralization technologies is hampered by the absence of standardized measurement, reporting systems, and verification systems. The MRV systems are critical in the determination and verification of the quantity of CO2 that is permanently stored in the process of mineralization and in their absence, carbon removal claims are unacceptable and highly suspect.

- The lack of standard MRV systems is also recognized to lead to a lack of investor confidence, inability to access carbon markets and climate finance, delayed regulatory authorizations and ultimately impediment adoption of and commercial expansion of mineralization technologies.

- The absence of standardized measurement, reporting, and verification (MRV) systems may be viewed as a limitation to the development of the mineralization technology market.

Opportunity: Growing Demand for Carbon Removal Solutions

- The increasing requirements in carbon removal technologies are motivated by rising climate goal, the policy requirements, and corporate sustainability obligations this is an excellent opportunity to expand the market of mineralization technologies. This expansion is evident in most sectors including technology, agriculture and energy. For instance, in June 2024, 3Degrees, a global provider of sustainability solutions, introduced its new Carbon Removal Suite. The unique products are designed in such a way that it becomes easier and affordable companies to participate in the carbon dioxide removal (CDR) business.

- The mineralization technology market growing by rising investment, strategic partenership, and innovation in carbon removal solutions. For instance, in September 2025, NorthX Climate Tech, a BC-based innovation catalyst backing the builders of Canadian climate hard tech, announced $1.6 million in investments in three innovative companies developing energy storage solutions. Richmond’s Foreseeson Technology, Vancouver-based FUTURi Power, and Alberta-based Aqua-Cell Energy, which is piloting its technology at a microgrid in Victoria. This funding aims to accelerate the commercialization and scaling of Canadian energy storage solutions, following NorthX’s Call for Energy Storage Innovation in partnership with BC Hydro, to enhance clean and reliable power options in British Columbia.

Key Trend: Integration with Air Capture

- Integration with air capture has recently emerged as a key trend in the market for mineralization technologies. Mineralization will be more than a supplemental remedy it is a major contributor to climate targets by enhancing the validity, permanence, and extent of carbon removal. For instance, in March 2025, California-based Company Clarity Tech has launched Project Juniper, a first-of-its-kind integrated DAC and ex-situ mineralization plant in North America.

- The combination of air capture and mineralization is stimulating the development of the global market of technology of mineralization because of it offers a secure and durable solution to the removal of carbon from the atmosphere by capturing it (via DAC) and then locking it into rock or mineral forms. For an example, in November 2024, ADNOC and the Omani climate tech company 44.01 are advancing their carbon mineralization program after a successful test. By the goal of utilizing 44.01's technology to sequester CO2 in Fujairah's rock formations, ADNOC and 44.01, in collaboration with Masdar and Fujairah Natural Resources Corporation, launched the project in 2023.

Mineralization Technology Market Analysis and Segmental Data

Construction Materials Dominate Global Mineralization Technology Market

- The construction materials segment continues to lead the global mineralization technology market, driven by the increasing need for carbon capture, utilization, and storage (CCUS) solutions in the building sector. In November, 2025, Heidelberg Materials North America has reported a new Front End Engineering Design (FEED) contract as part of its ongoing work to choose carbon capture technology and a contractor to the CO2 separation solution to its Carbon Capture, Utilization, and Storage (CCUS) Project in Edmonton, Alberta.

- Furthermore, mineralization of construction materials such as cement and concrete greatly minimize carbon footprints, improves strength and durability, rendering these materials, commercially viable and scalable in the mineralization market especially at large volumes such as infrastructures and urban development. An example is CarbonCure technologies, which injects captured CO2 into fresh concrete, which mineralizes to calcium carbonate, and permanently stores the CO2.

- The high enhances strength and durability of integration technologies in construction materials continued lead the market and ensure the growth of the mineralization technology market in building and constructional material.

North America Leads Global Mineralization Technology Market Demand

- The mineralization technology market is dominated North America because of ongoing advancement in research and development, strong investment in sustainable construction industry, and environmental regulations. For instance, in April 2024, a first-of-its-kind industrial CO2 mineralization facility for the production of green cement, the company's Redding ReCarb facility emits 70% less CO2 than regular cement. ReCarb technology from Fortera reduces the carbon footprint of cement and concrete in an affordable and easily accessible manner by integrating with existing infrastructure.

- Additionally, the strong government policies and incentives driven the mineralization technology market. An example, the U.S. Inflation Reduction Act (IRA) provides significant tax credits to capture carbon on a large scale across industrial and power generation sources, which renders the large-scale adoption of mineralization technologies economical. The strong incentive system which IRA has is driving investments, pilot projects and rollouts of commercial rollouts throughout North America which is enhancing the regions leadership in the field of carbon mineralization innovation.

Mineralization Technology Market Ecosystem

The global mineralization technology market is moderately consolidated, with high concentration among key players such as CarbonCure Technologies, Carbfix, Climeworks AG, Carbon Engineering Ltd., and Blue Planet Ltd., who dominate large-scale commercialization and cross-border collaborations. Key players are scaling innovative solutions through regional partnerships and pilot programs. For instance, in January 2024, Blue Planet Systems Corporation announced completion of new funding and a strategic partnership with Marathon Petroleum Corporation to advance the commercialization of mineralization technology.

Recent Development and Strategic Overview:

- In August 2025, Graymont and Fortera announced they have signed a strategic partnership agreement providing the framework to produce Fortera’s ReAct™ low-carbon cement by leveraging Graymont’s existing lime production operations and its innovations in sustainable building materials. The partnership will combine Graymont's experience with calcium-based products and its extensive global industrial network with Fortera's carbon mineralization technology.

- In January 2025, Mitsubishi UBE Cement Corporation (MUCC) has invested USD $5 million into Australian cleantech MCi Carbon (MCi). This is MCi's fourth significant investment from a key Japanese partner, opening the door to increased cooperation with ITOCHU Corporation and quicker commercialization in the Japanese cement sector.

Report Scope

|

Detail |

|

|

Market Size in 2025 |

USD 1.3 Bn |

|

Market Forecast Value in 2035 |

~USD 3 Bn |

|

Growth Rate (CAGR) |

9.2% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value |

|

Report Format |

Electronic (PDF) + Excel |

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Mineralization Technology Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

Mineralization Technology, By Technology Type |

|

|

Mineralization Technology, By Process Method

|

|

|

Mineralization Technology, By Target Minerals

|

|

|

Mineralization Technology, By Application Scale

|

|

|

Mineralization Technology, By Equipment Type

|

|

|

Mineralization Technology, By Raw Material Source

|

|

|

Mineralization Technology, By End Product Type

|

|

|

Mineralization Technology, By Automation Level

|

|

|

Mineralization Technology, By End-Use Industry

|

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Mineralization Technology Market Outlook

- 2.1.1. Mineralization Technology Market Size (Value - US$ Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Mineralization Technology Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Mineralization Technology Industry Overview, 2025

- 3.1.1. Chemical & MaterialsIndustry Ecosystem Analysis

- 3.1.2. Key Trends for Chemical & Materials Industry

- 3.1.3. Regional Distribution for Chemical & Materials Industry

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2025

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.1.1. Based on the component & Raw material

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.5.1. Manufacturer

- 3.6. Raw Material Analysis

- 3.1. Global Mineralization Technology Industry Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Increasing focus on carbon capture, utilization, and storage (CCUS) to meet climate goals

- 4.1.1.2. Supportive government policies and funding for carbon reduction technologies

- 4.1.1.3. Growing industrial demand for sustainable waste management and CO₂ utilization

- 4.1.2. Restraints

- 4.1.2.1. High operational and capital costs of mineralization processes

- 4.1.2.2. Technical challenges in scaling and optimizing mineralization for different feed stocks

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Raw Material Suppliers

- 4.4.2. Mineralization Technology Manufacturers

- 4.4.3. Distributors/ Suppliers

- 4.4.4. End-users/ Customers

- 4.5. Porter’s Five Forces Analysis

- 4.6. PESTEL Analysis

- 4.7. Global Mineralization Technology Market Demand

- 4.7.1. Historical Market Size - in Value (US$ Bn), 2020-2024

- 4.7.2. Current and Future Market Size - in Value (US$ Bn), 2025–2035

- 4.7.2.1. Y-o-Y Growth Trends

- 4.7.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Mineralization Technology Market Analysis, by Technology Type

- 6.1. Key Segment Analysis

- 6.2. Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, by Technology Type, 2021-2035

- 6.2.1. Biological Mineralization

- 6.2.1.1. Biomineralization processes

- 6.2.1.2. Microbial-induced mineralization

- 6.2.1.3. Enzymatic mineralization

- 6.2.1.4. Others

- 6.2.2. Chemical Mineralization

- 6.2.2.1. Chemical precipitation

- 6.2.2.2. Ion exchange processes

- 6.2.2.3. Crystallization techniques

- 6.2.2.4. Others

- 6.2.3. Physical Mineralization

- 6.2.3.1. Mechanical processing

- 6.2.3.2. Thermal treatment

- 6.2.3.3. Pressure-induced mineralization

- 6.2.3.4. Others

- 6.2.4. Hybrid Technologies

- 6.2.4.1. Bio-chemical processes

- 6.2.4.2. Physico-chemical methods

- 6.2.4.3. Others

- 6.2.1. Biological Mineralization

- 7. Global Mineralization Technology Market Analysis, by Process Method

- 7.1. Key Segment Analysis

- 7.2. Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, by Process Method, 2021-2035

- 7.2.1. In-Situ Mineralization

- 7.2.2. Ex-Situ Mineralization

- 7.2.3. Continuous Processing

- 7.2.4. Batch Processing

- 8. Global Mineralization Technology Market Analysis and Forecasts, by Target Minerals

- 8.1. Key Findings

- 8.2. Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, by Target Minerals, 2021-2035

- 8.2.1. Carbonate Minerals

- 8.2.1.1. Calcium carbonate

- 8.2.1.2. Magnesium carbonate

- 8.2.1.3. Iron carbonate

- 8.2.2. Sulfate Minerals

- 8.2.2.1. Gypsum formation

- 8.2.2.2. Barite precipitation

- 8.2.3. Phosphate Minerals

- 8.2.3.1. Hydroxyapatite

- 8.2.3.2. Calcium phosphate

- 8.2.4. Silicate Minerals

- 8.2.4.1. Zeolite formation

- 8.2.4.2. Clay mineralization

- 8.2.5. Oxide Minerals

- 8.2.5.1. Iron oxides

- 8.2.5.2. Aluminum oxides

- 8.2.6. Sulfide Minerals

- 8.2.7. Others

- 8.2.1. Carbonate Minerals

- 9. Global Mineralization Technology Market Analysis and Forecasts, by Application Scale

- 9.1. Key Findings

- 9.2. Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, by Application Scale, 2021-2035

- 9.2.1. Laboratory Scale

- 9.2.2. Pilot Scale

- 9.2.3. Commercial Scale

- 9.2.4. Mega-Scale

- 10. Global Mineralization Technology Market Analysis and Forecasts, by Equipment Type

- 10.1. Key Findings

- 10.2. Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, by Equipment Type, 2021-2035

- 10.2.1. Reactors and Vessels

- 10.2.1.1. Bioreactors

- 10.2.1.2. Chemical reactors

- 10.2.1.3. Pressure vessels

- 10.2.1.4. Others

- 10.2.2. Separation Equipment

- 10.2.2.1. Filtration systems

- 10.2.2.2. Centrifuges

- 10.2.2.3. Settling tanks

- 10.2.2.4. Others

- 10.2.3. Monitoring and Control Systems

- 10.2.3.1. Process sensors

- 10.2.3.2. Automated control systems

- 10.2.3.3. Data acquisition systems

- 10.2.3.4. Others

- 10.2.4. Auxiliary Equipment

- 10.2.4.1. Pumping systems

- 10.2.4.2. Heating/cooling systems

- 10.2.4.3. Material handling equipment

- 10.2.4.4. Others

- 10.2.1. Reactors and Vessels

- 11. Global Mineralization Technology Market Analysis and Forecasts, by Raw Material Source

- 11.1. Key Findings

- 11.2. Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, by Raw Material Source, 2021-2035

- 11.2.1. Industrial Waste Streams

- 11.2.1.1. Manufacturing byproducts

- 11.2.1.2. Process effluents

- 11.2.1.3. Solid waste materials

- 11.2.2. Natural Resources

- 11.2.2.1. Mineral ores

- 11.2.2.2. Brine solutions

- 11.2.2.3. Geological formations

- 11.2.3. Synthetic Sources

- 11.2.3.1. Laboratory-prepared solutions

- 11.2.3.2. Engineered substrates

- 11.2.4. Recycled Materials

- 11.2.4.1. Secondary mineral sources

- 11.2.4.2. Reclaimed materials

- 11.2.1. Industrial Waste Streams

- 12. Global Mineralization Technology Market Analysis and Forecasts, by End Product Type

- 12.1. Key Findings

- 12.2. Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, by End Product Type, 2021-2035

- 12.2.1. Construction Materials

- 12.2.1.1. Cement additives

- 12.2.1.2. Aggregate materials

- 12.2.1.3. Building blocks

- 12.2.2. Industrial Chemicals

- 12.2.2.1. Specialty chemicals

- 12.2.2.2. Catalysts

- 12.2.2.3. Pigments and fillers

- 12.2.3. Environmental Products

- 12.2.3.1. Sorbent materials

- 12.2.3.2. Filtration media

- 12.2.3.3. Remediation agents

- 12.2.4. Advanced Materials

- 12.2.4.1. Nanostructured materials

- 12.2.4.2. Functional coatings

- 12.2.4.3. Smart materials

- 12.2.1. Construction Materials

- 13. Global Mineralization Technology Market Analysis and Forecasts, by Automation Level

- 13.1. Key Findings

- 13.2. Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, by Automation Level, 2021-2035

- 13.2.1. Manual Operations

- 13.2.2. Semi-Automated Systems

- 13.2.3. Fully Automated Systems

- 13.2.4. AI-Enabled Systems

- 14. Global Mineralization Technology Market Analysis and Forecasts, by End-Use Industry

- 14.1. Key Findings

- 14.2. Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, by End-Use Industry, 2021-2035

- 14.2.1. Mining & Mineral Processing

- 14.2.1.1. Ore Processing

- 14.2.1.2. Waste Valorization

- 14.2.1.3. Resource Recovery

- 14.2.1.4. Environmental Compliance

- 14.2.1.5. Others

- 14.2.2. Construction & Building Materials

- 14.2.2.1. Cement Production

- 14.2.2.2. Aggregate Manufacturing

- 14.2.2.3. Concrete Enhancement

- 14.2.2.4. Green Building Materials

- 14.2.2.5. Others

- 14.2.3. Environmental Services

- 14.2.3.1. Carbon Capture & Storage

- 14.2.3.2. Soil Remediation

- 14.2.3.3. Air Pollution Control

- 14.2.3.4. Others

- 14.2.4. Chemical & Petrochemical

- 14.2.4.1. Catalyst Production

- 14.2.4.2. Specialty Chemicals

- 14.2.4.3. Process Enhancement

- 14.2.4.4. Waste Management

- 14.2.4.5. Others

- 14.2.5. Steel & Metallurgy

- 14.2.5.1. Slag Utilization

- 14.2.5.2. Process Optimization

- 14.2.5.3. Byproduct Recovery

- 14.2.5.4. Others

- 14.2.6. Power Generation

- 14.2.6.1. Coal Power Plants

- 14.2.6.2. Renewable Energy

- 14.2.6.3. Nuclear Industry

- 14.2.6.4. Geothermal

- 14.2.6.5. Others

- 14.2.7. Oil & Gas

- 14.2.7.1. Enhanced Oil Recovery

- 14.2.7.2. Produced Water Treatment

- 14.2.7.3. Pipeline Protection

- 14.2.7.4. Decommissioning

- 14.2.7.5. Others

- 14.2.8. Water Treatment & Management

- 14.2.8.1. Desalination

- 14.2.8.2. Municipal Water

- 14.2.8.3. Industrial Process

- 14.2.8.4. Groundwater Remediation

- 14.2.8.5. Others

- 14.2.9. Agriculture & Food Processing

- 14.2.9.1. Soil Amendment

- 14.2.9.2. Fertilizer Production

- 14.2.9.3. Food Preservation

- 14.2.9.4. Waste Management

- 14.2.9.5. Others

- 14.2.10. Pharmaceuticals & Healthcare

- 14.2.11. Automotive & Transportation

- 14.2.12. Electronics & Semiconductors

- 14.2.13. Others

- 14.2.1. Mining & Mineral Processing

- 15. Global Mineralization Technology Market Analysis and Forecasts, by Region

- 15.1. Key Findings

- 15.2. Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, by Region, 2021-2035

- 15.2.1. North America

- 15.2.2. Europe

- 15.2.3. Asia Pacific

- 15.2.4. Middle East

- 15.2.5. Africa

- 15.2.6. South America

- 16. North America Mineralization Technology Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. North America Mineralization Technology Market Size Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 16.3.1. Technology Type

- 16.3.2. Process Method

- 16.3.3. Target Minerals

- 16.3.4. Application Scale

- 16.3.5. Equipment Type

- 16.3.6. Raw Material Source

- 16.3.7. End Product Type

- 16.3.8. Automation Level

- 16.3.9. End-Use Industry

- 16.3.10. Country

- 16.3.10.1. USA

- 16.3.10.2. Canada

- 16.3.10.3. Mexico

- 16.4. USA Mineralization Technology Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Technology Type

- 16.4.3. Process Method

- 16.4.4. Target Minerals

- 16.4.5. Application Scale

- 16.4.6. Equipment Type

- 16.4.7. Raw Material Source

- 16.4.8. End Product Type

- 16.4.9. Automation Level

- 16.4.10. End-Use Industry

- 16.5. Canada Mineralization Technology Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Technology Type

- 16.5.3. Process Method

- 16.5.4. Target Minerals

- 16.5.5. Application Scale

- 16.5.6. Equipment Type

- 16.5.7. Raw Material Source

- 16.5.8. End Product Type

- 16.5.9. Automation Level

- 16.5.10. End-Use Industry

- 16.6. Mexico Mineralization Technology Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Technology Type

- 16.6.3. Process Method

- 16.6.4. Target Minerals

- 16.6.5. Application Scale

- 16.6.6. Equipment Type

- 16.6.7. Raw Material Source

- 16.6.8. End Product Type

- 16.6.9. Automation Level

- 16.6.10. End-Use Industry

- 17. Europe Mineralization Technology Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Europe Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 17.3.1. Technology Type

- 17.3.2. Process Method

- 17.3.3. Target Minerals

- 17.3.4. Application Scale

- 17.3.5. Equipment Type

- 17.3.6. Raw Material Source

- 17.3.7. End Product Type

- 17.3.8. Automation Level

- 17.3.9. End-Use Industry

- 17.3.10. Country

- 17.3.10.1. Germany

- 17.3.10.2. United Kingdom

- 17.3.10.3. France

- 17.3.10.4. Italy

- 17.3.10.5. Spain

- 17.3.10.6. Netherlands

- 17.3.10.7. Nordic Countries

- 17.3.10.8. Poland

- 17.3.10.9. Russia & CIS

- 17.3.10.10. Rest of Europe

- 17.4. Germany Mineralization Technology Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Technology Type

- 17.4.3. Process Method

- 17.4.4. Target Minerals

- 17.4.5. Application Scale

- 17.4.6. Equipment Type

- 17.4.7. Raw Material Source

- 17.4.8. End Product Type

- 17.4.9. Automation Level

- 17.4.10. End-Use Industry

- 17.5. United Kingdom Mineralization Technology Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Technology Type

- 17.5.3. Process Method

- 17.5.4. Target Minerals

- 17.5.5. Application Scale

- 17.5.6. Equipment Type

- 17.5.7. Raw Material Source

- 17.5.8. End Product Type

- 17.5.9. Automation Level

- 17.5.10. End-Use Industry

- 17.6. France Mineralization Technology Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Technology Type

- 17.6.3. Process Method

- 17.6.4. Target Minerals

- 17.6.5. Application Scale

- 17.6.6. Equipment Type

- 17.6.7. Raw Material Source

- 17.6.8. End Product Type

- 17.6.9. Automation Level

- 17.6.10. End-Use Industry

- 17.7. Italy Mineralization Technology Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Technology Type

- 17.7.3. Process Method

- 17.7.4. Target Minerals

- 17.7.5. Application Scale

- 17.7.6. Equipment Type

- 17.7.7. Raw Material Source

- 17.7.8. End Product Type

- 17.7.9. Automation Level

- 17.7.10. End-Use Industry

- 17.8. Spain Mineralization Technology Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Technology Type

- 17.8.3. Process Method

- 17.8.4. Target Minerals

- 17.8.5. Application Scale

- 17.8.6. Equipment Type

- 17.8.7. Raw Material Source

- 17.8.8. End Product Type

- 17.8.9. Automation Level

- 17.8.10. End-Use Industry

- 17.9. Netherlands Mineralization Technology Market

- 17.9.1. Country Segmental Analysis

- 17.9.2. Technology Type

- 17.9.3. Process Method

- 17.9.4. Target Minerals

- 17.9.5. Application Scale

- 17.9.6. Equipment Type

- 17.9.7. Raw Material Source

- 17.9.8. End Product Type

- 17.9.9. Automation Level

- 17.9.10. End-Use Industry

- 17.10. Nordic Countries Mineralization Technology Market

- 17.10.1. Country Segmental Analysis

- 17.10.2. Technology Type

- 17.10.3. Process Method

- 17.10.4. Target Minerals

- 17.10.5. Application Scale

- 17.10.6. Equipment Type

- 17.10.7. Raw Material Source

- 17.10.8. End Product Type

- 17.10.9. Automation Level

- 17.10.10. End-Use Industry

- 17.11. Poland Mineralization Technology Market

- 17.11.1. Country Segmental Analysis

- 17.11.2. Technology Type

- 17.11.3. Process Method

- 17.11.4. Target Minerals

- 17.11.5. Application Scale

- 17.11.6. Equipment Type

- 17.11.7. Raw Material Source

- 17.11.8. End Product Type

- 17.11.9. Automation Level

- 17.11.10. End-Use Industry

- 17.12. Russia & CIS Mineralization Technology Market

- 17.12.1. Country Segmental Analysis

- 17.12.2. Technology Type

- 17.12.3. Process Method

- 17.12.4. Target Minerals

- 17.12.5. Application Scale

- 17.12.6. Equipment Type

- 17.12.7. Raw Material Source

- 17.12.8. End Product Type

- 17.12.9. Automation Level

- 17.12.10. End-Use Industry

- 17.13. Rest of Europe Mineralization Technology Market

- 17.13.1. Country Segmental Analysis

- 17.13.2. Technology Type

- 17.13.3. Process Method

- 17.13.4. Target Minerals

- 17.13.5. Application Scale

- 17.13.6. Equipment Type

- 17.13.7. Raw Material Source

- 17.13.8. End Product Type

- 17.13.9. Automation Level

- 17.13.10. End-Use Industry

- 18. Asia Pacific Mineralization Technology Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. East Asia Mineralization Technology Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 18.3.1. Technology Type

- 18.3.2. Process Method

- 18.3.3. Target Minerals

- 18.3.4. Application Scale

- 18.3.5. Equipment Type

- 18.3.6. Raw Material Source

- 18.3.7. End Product Type

- 18.3.8. Automation Level

- 18.3.9. End-Use Industry

- 18.3.10. Country

- 18.3.10.1. China

- 18.3.10.2. India

- 18.3.10.3. Japan

- 18.3.10.4. South Korea

- 18.3.10.5. Australia and New Zealand

- 18.3.10.6. Indonesia

- 18.3.10.7. Malaysia

- 18.3.10.8. Thailand

- 18.3.10.9. Vietnam

- 18.3.10.10. Rest of Asia Pacific

- 18.4. China Mineralization Technology Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Technology Type

- 18.4.3. Process Method

- 18.4.4. Target Minerals

- 18.4.5. Application Scale

- 18.4.6. Equipment Type

- 18.4.7. Raw Material Source

- 18.4.8. End Product Type

- 18.4.9. Automation Level

- 18.4.10. End-Use Industry

- 18.5. India Mineralization Technology Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Technology Type

- 18.5.3. Process Method

- 18.5.4. Target Minerals

- 18.5.5. Application Scale

- 18.5.6. Equipment Type

- 18.5.7. Raw Material Source

- 18.5.8. End Product Type

- 18.5.9. Automation Level

- 18.5.10. End-Use Industry

- 18.6. Japan Mineralization Technology Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Technology Type

- 18.6.3. Process Method

- 18.6.4. Target Minerals

- 18.6.5. Application Scale

- 18.6.6. Equipment Type

- 18.6.7. Raw Material Source

- 18.6.8. End Product Type

- 18.6.9. Automation Level

- 18.6.10. End-Use Industry

- 18.7. South Korea Mineralization Technology Market

- 18.7.1. Country Segmental Analysis

- 18.7.2. Technology Type

- 18.7.3. Process Method

- 18.7.4. Target Minerals

- 18.7.5. Application Scale

- 18.7.6. Equipment Type

- 18.7.7. Raw Material Source

- 18.7.8. End Product Type

- 18.7.9. Automation Level

- 18.7.10. End-Use Industry

- 18.8. Australia and New Zealand Mineralization Technology Market

- 18.8.1. Country Segmental Analysis

- 18.8.2. Technology Type

- 18.8.3. Process Method

- 18.8.4. Target Minerals

- 18.8.5. Application Scale

- 18.8.6. Equipment Type

- 18.8.7. Raw Material Source

- 18.8.8. End Product Type

- 18.8.9. Automation Level

- 18.8.10. End-Use Industry

- 18.9. Indonesia Mineralization Technology Market

- 18.9.1. Country Segmental Analysis

- 18.9.2. Technology Type

- 18.9.3. Process Method

- 18.9.4. Target Minerals

- 18.9.5. Application Scale

- 18.9.6. Equipment Type

- 18.9.7. Raw Material Source

- 18.9.8. End Product Type

- 18.9.9. Automation Level

- 18.9.10. End-Use Industry

- 18.10. Malaysia Mineralization Technology Market

- 18.10.1. Country Segmental Analysis

- 18.10.2. Technology Type

- 18.10.3. Process Method

- 18.10.4. Target Minerals

- 18.10.5. Application Scale

- 18.10.6. Equipment Type

- 18.10.7. Raw Material Source

- 18.10.8. End Product Type

- 18.10.9. Automation Level

- 18.10.10. End-Use Industry

- 18.11. Thailand Mineralization Technology Market

- 18.11.1. Country Segmental Analysis

- 18.11.2. Technology Type

- 18.11.3. Process Method

- 18.11.4. Target Minerals

- 18.11.5. Application Scale

- 18.11.6. Equipment Type

- 18.11.7. Raw Material Source

- 18.11.8. End Product Type

- 18.11.9. Automation Level

- 18.11.10. End-Use Industry

- 18.12. Vietnam Mineralization Technology Market

- 18.12.1. Country Segmental Analysis

- 18.12.2. Technology Type

- 18.12.3. Process Method

- 18.12.4. Target Minerals

- 18.12.5. Application Scale

- 18.12.6. Equipment Type

- 18.12.7. Raw Material Source

- 18.12.8. End Product Type

- 18.12.9. Automation Level

- 18.12.10. End-Use Industry

- 18.13. Rest of Asia Pacific Mineralization Technology Market

- 18.13.1. Country Segmental Analysis

- 18.13.2. Technology Type

- 18.13.3. Process Method

- 18.13.4. Target Minerals

- 18.13.5. Application Scale

- 18.13.6. Equipment Type

- 18.13.7. Raw Material Source

- 18.13.8. End Product Type

- 18.13.9. Automation Level

- 18.13.10. End-Use Industry

- 19. Middle East Mineralization Technology Market Analysis

- 19.1. Key Segment Analysis

- 19.2. Regional Snapshot

- 19.3. Middle East Mineralization Technology Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 19.3.1. Technology Type

- 19.3.2. Process Method

- 19.3.3. Target Minerals

- 19.3.4. Application Scale

- 19.3.5. Equipment Type

- 19.3.6. Raw Material Source

- 19.3.7. End Product Type

- 19.3.8. Automation Level

- 19.3.9. End-Use Industry

- 19.3.10. Country

- 19.3.10.1. Turkey

- 19.3.10.2. UAE

- 19.3.10.3. Saudi Arabia

- 19.3.10.4. Israel

- 19.3.10.5. Rest of Middle East

- 19.4. Turkey Mineralization Technology Market

- 19.4.1. Country Segmental Analysis

- 19.4.2. Technology Type

- 19.4.3. Process Method

- 19.4.4. Target Minerals

- 19.4.5. Application Scale

- 19.4.6. Equipment Type

- 19.4.7. Raw Material Source

- 19.4.8. End Product Type

- 19.4.9. Automation Level

- 19.4.10. End-Use Industry

- 19.5. UAE Mineralization Technology Market

- 19.5.1. Country Segmental Analysis

- 19.5.2. Technology Type

- 19.5.3. Process Method

- 19.5.4. Target Minerals

- 19.5.5. Application Scale

- 19.5.6. Equipment Type

- 19.5.7. Raw Material Source

- 19.5.8. End Product Type

- 19.5.9. Automation Level

- 19.5.10. End-Use Industry

- 19.6. Saudi Arabia Mineralization Technology Market

- 19.6.1. Country Segmental Analysis

- 19.6.2. Technology Type

- 19.6.3. Process Method

- 19.6.4. Target Minerals

- 19.6.5. Application Scale

- 19.6.6. Equipment Type

- 19.6.7. Raw Material Source

- 19.6.8. End Product Type

- 19.6.9. Automation Level

- 19.6.10. End-Use Industry

- 19.7. Israel Mineralization Technology Market

- 19.7.1. Country Segmental Analysis

- 19.7.2. Technology Type

- 19.7.3. Process Method

- 19.7.4. Target Minerals

- 19.7.5. Application Scale

- 19.7.6. Equipment Type

- 19.7.7. Raw Material Source

- 19.7.8. End Product Type

- 19.7.9. Automation Level

- 19.7.10. End-Use Industry

- 19.8. Rest of Middle East Mineralization Technology Market

- 19.8.1. Country Segmental Analysis

- 19.8.2. Technology Type

- 19.8.3. Process Method

- 19.8.4. Target Minerals

- 19.8.5. Application Scale

- 19.8.6. Equipment Type

- 19.8.7. Raw Material Source

- 19.8.8. End Product Type

- 19.8.9. Automation Level

- 19.8.10. End-Use Industry

- 20. Africa Mineralization Technology Market Analysis

- 20.1. Key Segment Analysis

- 20.2. Regional Snapshot

- 20.3. Africa Mineralization Technology Market Size (Volume - THOUSAND UNITS and Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 20.3.1. Technology Type

- 20.3.2. Process Method

- 20.3.3. Target Minerals

- 20.3.4. Application Scale

- 20.3.5. Equipment Type

- 20.3.6. Raw Material Source

- 20.3.7. End Product Type

- 20.3.8. Automation Level

- 20.3.9. End-Use Industry

- 20.3.10. Country

- 20.3.10.1. South Africa

- 20.3.10.2. Egypt

- 20.3.10.3. Nigeria

- 20.3.10.4. Algeria

- 20.3.10.5. Rest of Africa

- 20.4. South Africa Mineralization Technology Market

- 20.4.1. Country Segmental Analysis

- 20.4.2. Technology Type

- 20.4.3. Process Method

- 20.4.4. Target Minerals

- 20.4.5. Application Scale

- 20.4.6. Equipment Type

- 20.4.7. Raw Material Source

- 20.4.8. End Product Type

- 20.4.9. Automation Level

- 20.4.10. End-Use Industry

- 20.5. Egypt Mineralization Technology Market

- 20.5.1. Country Segmental Analysis

- 20.5.2. Technology Type

- 20.5.3. Process Method

- 20.5.4. Target Minerals

- 20.5.5. Application Scale

- 20.5.6. Equipment Type

- 20.5.7. Raw Material Source

- 20.5.8. End Product Type

- 20.5.9. Automation Level

- 20.5.10. End-Use Industry

- 20.6. Nigeria Mineralization Technology Market

- 20.6.1. Country Segmental Analysis

- 20.6.2. Technology Type

- 20.6.3. Process Method

- 20.6.4. Target Minerals

- 20.6.5. Application Scale

- 20.6.6. Equipment Type

- 20.6.7. Raw Material Source

- 20.6.8. End Product Type

- 20.6.9. Automation Level

- 20.6.10. End-Use Industry

- 20.7. Algeria Mineralization Technology Market

- 20.7.1. Country Segmental Analysis

- 20.7.2. Technology Type

- 20.7.3. Process Method

- 20.7.4. Target Minerals

- 20.7.5. Application Scale

- 20.7.6. Equipment Type

- 20.7.7. Raw Material Source

- 20.7.8. End Product Type

- 20.7.9. Automation Level

- 20.7.10. End-Use Industry

- 20.8. Rest of Africa Mineralization Technology Market

- 20.8.1. Country Segmental Analysis

- 20.8.2. Technology Type

- 20.8.3. Process Method

- 20.8.4. Target Minerals

- 20.8.5. Application Scale

- 20.8.6. Equipment Type

- 20.8.7. Raw Material Source

- 20.8.8. End Product Type

- 20.8.9. Automation Level

- 20.8.10. End-Use Industry

- 21. South America Mineralization Technology Market Analysis

- 21.1. Key Segment Analysis

- 21.2. Regional Snapshot

- 21.3. Central and South Africa Mineralization Technology Market Size (Volume - Thousand Units and Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 21.3.1. Technology Type

- 21.3.2. Process Method

- 21.3.3. Target Minerals

- 21.3.4. Application Scale

- 21.3.5. Equipment Type

- 21.3.6. Raw Material Source

- 21.3.7. End Product Type

- 21.3.8. Automation Level

- 21.3.9. End-Use Industry

- 21.3.10. Country

- 21.3.10.1. Brazil

- 21.3.10.2. Argentina

- 21.3.10.3. Rest of South America

- 21.4. Brazil Mineralization Technology Market

- 21.4.1. Country Segmental Analysis

- 21.4.2. Technology Type

- 21.4.3. Process Method

- 21.4.4. Target Minerals

- 21.4.5. Application Scale

- 21.4.6. Equipment Type

- 21.4.7. Raw Material Source

- 21.4.8. End Product Type

- 21.4.9. Automation Level

- 21.4.10. End-Use Industry

- 21.5. Argentina Mineralization Technology Market

- 21.5.1. Country Segmental Analysis

- 21.5.2. Technology Type

- 21.5.3. Process Method

- 21.5.4. Target Minerals

- 21.5.5. Application Scale

- 21.5.6. Equipment Type

- 21.5.7. Raw Material Source

- 21.5.8. End Product Type

- 21.5.9. Automation Level

- 21.5.10. End-Use Industry

- 21.6. Rest of South America Mineralization Technology Market

- 21.6.1. Country Segmental Analysis

- 21.6.2. Technology Type

- 21.6.3. Process Method

- 21.6.4. Target Minerals

- 21.6.5. Application Scale

- 21.6.6. Equipment Type

- 21.6.7. Raw Material Source

- 21.6.8. End Product Type

- 21.6.9. Automation Level

- 21.6.10. End-Use Industry

- 22. Key Players/ Company Profile

- 22.1. BASF SE

- 22.1.1. Company Details/ Overview

- 22.1.2. Company Financials

- 22.1.3. Key Customers and Competitors

- 22.1.4. Business/ Industry Portfolio

- 22.1.5. Product Portfolio/ Specification Details

- 22.1.6. Pricing Data

- 22.1.7. Strategic Overview

- 22.1.8. Recent Developments

- 22.2. Alfa Laval AB

- 22.3. Blue Planet Ltd.

- 22.4. Calera Corporation

- 22.5. Carbfix

- 22.6. Carbon Engineering Ltd.

- 22.7. Carbon Upcycling Technologies

- 22.8. CarbonCure Technologies Inc.

- 22.9. Climeworks AG

- 22.10. FLSmidth & Co. A/S

- 22.11. General Electric Company

- 22.12. Green Minerals

- 22.13. MCi Carbon

- 22.14. Metso Outotec Corporation

- 22.15. Mineral Carbonation International

- 22.16. Siemens AG

- 22.17. Solideon Technologies

- 22.18. Solidia Technologies

- 22.19. ThyssenKrupp AG

- 22.20. Veolia Environment S.A.

- 22.21. Other Key Players

- 22.1. BASF SE

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

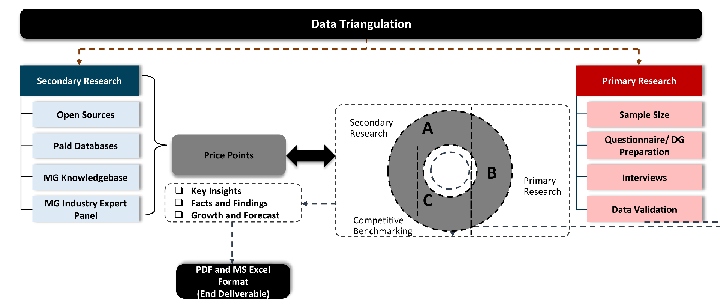

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation