Pharmaceutical Packaging Equipment Market Size, Share, Growth Opportunity Analysis Report by Equipment Type (Primary Packaging Machines, Secondary Packaging Machines and Tertiary Packaging Machines), Automation Level, Packaging Format, Process Type, Durg Type, End User and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035.

|

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Pharmaceutical Packaging Equipment Market Size, Share, and Growth

With a significant compounded annual growth rate of 6.0% from 2025-2035, global pharmaceutical packaging equipment market is poised to be valued at USD 16.6 Billion in 2035. The increased demand for automation to improve operational efficiency and rise in regulatory push for serialization and anti-counterfeit measures are causing increased global drug demand. Hence the manufacturers are increasingly moving toward high-speed, fully automated systems to increase dry goods productivity and eliminate packaging errors.

"In March 2025, Groninger & Co. GmbH launched its new FlexPro 50 modular aseptic filling line designed for high-potency and small-batch pharmaceuticals, addressing the growing demand for personalized medicine packaging. The innovation allows rapid changeovers between vial, syringe, and cartridge formats in a compact, isolator-ready setup. This strategic expansion, led by Jens Groninger, Managing Director, reflects the company’s focus on flexible, scalable solutions for the biologics and sterile injectables segment. The development strengthens Groninger’s position in the high-growth aseptic and personalized pharma packaging equipment segment globally."

For instance, in 2024, Uhlmann Group brought to the market its Parenteral Tray Center 200 (PTC 200), a flexible, high-speed vial packaging solution. In a like manner, Bosch Packaging Technology also came up with new and improved blister packaging machines having integrated serialization capability with an aim to satisfy the pharmaceutical traceability standards that are changing in Europe and North America. Hence, these sorts of developments are heavily fueling the demand for the pharmaceutical packaging equipment’s that are advanced and compliant across the world.

The global pharmaceutical packaging equipment market presents vital opportunities in smart labeling and RFID technology, cold-chain logistics solutions, and systems for single-dose drug delivery. These areas correspond with the current greater concern for traceability, temperature-sensitive biologics, and patient-centric packaging formats. These ancillary innovations thus broaden both the functional abilities and the value proposition of pharmaceutical packaging equipment.

Pharmaceutical Packaging Equipment Market Dynamics and Trends

Driver: Automation & Robotics Intensification

- Several pharma packaging machine users rate automation and robotics highly to fulfill demands for packaging at high throughputs with precision and sterility. More manufacturers are employing delta robot systems and cobots and IIoT platforms to streamline their operations, minimizing manual involvement.

- Over 1,350 GMP-grade delta robots were set up on U.S. and German fill-and-finish lines by 2024, doubling the packing speed for syringes to 420 units per minute. With a certain complement of IIoT sensors and analytics based on machine learning, these robotics could further cut unplanned downtime by 17 hours per quarter, therefore very greatly enhancing OEE. Edge computing systems also give batches real-time validation to curb errors before the product goes out of packaging within ISO-5 environments.

- By promoting such automation, productivity and conformance to regulations are simultaneously assured, setting high-speed, high-precision packaging as the trend of the day.

Restraint: Complex Regulatory Compliance & Validation Costs

- A major restraint is the increase in complexity and costs associated with regulatory compliance and equipment validation. Packaging systems in pharma have to keep to stringent standards of the FDA, EMA, and WHO for sterility, tamper evidence, serialization, and cleanroom compatibility. With more documentation, software validation, and traceability come added development time and capital expenses.

- Besides, extra demand for flexibility for biologics, personalized medicines, and combination product operations impedes equipment complexity. Systems have to be reconfigurable, often with modular or multi-format capabilities, which implies further costs and lengthier qualification protocols. The more stringent these requirements will be, together with frequent product format changes, extending lead times and reducing the ROI for especially small to medium-sized vendors.

- Compliance squeeze retards speed of equipment adoption while favoring large players who can easily absorb validation overhead.

Opportunity: Sustainable & Flexible Packaging Solutions

- There is a significant opportunity for development of sustainable, flexible packaging equipment that supports using biodegradable and recyclable materials and single-dose formats. An impetus to tailor-made equipment design for eco-friendly films and monomaterials comes from environmental legislation and consumer preference.

- In the year 2024, MULTIVAC launched its combi-pack line in mono-film for better recyclability, whereas, in 2023, Marchesini launched an injection-pen packaging island with an integrated robot that cuts the use of paper and glue by 50%. Small-batch, personalized packaging lines are also in demand thanks to the growth of biologics and targeted therapies. Modular machines that can quickly switch between formats like syringes, vials, and pens could realize strong market potential.

- Green and flexible equipment offers competitive differentiation that goes toward developing packaging capabilities under sustainability mandates and dosage formats that evolve.

Key Trend: Smart Packaging & IIoT Integration

- A key trend has been the joining together of smart packaging and IIoT technologies to provide capabilities for traceability, real-time monitoring, and data-based maintenance. Industrial manufacturers incorporate serialization, RFID, and sensors into packaging lines. Further, AI vision systems identify packaging defects, unusual temperature variations, and clear-label issues. Later at PACK EXPO, companies such as Serac and Multivac exhibited weight-filling and thermoforming machines with closed-loop clean-in-place systems and smart-labels for tamper detection.

- In May 2025, Antares Vision launched advanced labeling equipment capable of supporting different print technologies, including thermal inkjet, laser, and ink transfer application, to meet serialization requirements across different industries. These smart systems are used for enhancing product compliance and integrity, and assessed for predictive maintenance applications to reduce downtime and ensure chain-of-custody accountability.

- Smart and connected packaging machines have fast become critical to fulfill serialization requirements and fulfill operational intelligence needs.

Pharmaceutical Packaging Equipment Market Analysis and Segmental Data

Based on Equipment Type, the Primary Packaging Machines Segment Retains the Largest Share

- The primary packaging machines segment ~67% share of the global pharmaceutical packaging equipment market because of the paramount importance attached toward ensuring drug integrity. These machines are an essential barrier to the environment (moisture, oxygen), biological threats (contamination), and mechanical deformities (physical agitation or mishandling of the drug) during storage or transit.

- In 2023, it accounted for the larger share of revenue in pharmaceutical packaging as the production of parenteral vials, prefillable syringes, and aseptic filling systems continued to rise, thus demanding sterility and compliance with strict regulatory standards.

- This primary status of primary packaging machines only consolidates the fact that they truly serve as the safeguard of drug safety, potency, and regulatory compliance within pharma supply chains.

North America Dominates Global Pharmaceutical Packaging Equipment Market in 2025 and Beyond

- With increasing drug approvals, high biologics production, and stringent regulatory requirements, North America has witnessed the highest demand for pharmaceutical packaging equipment. In 2023, with the FDA approving more than 50 novel drugs, packaging systems such as those for vial filling and blister packing and serialization machines have witnessed more demand. Moreover, due to the regional emphasis on precision medicine and sterile injectable formats, there stands a need for packaging technologies compliant with high-speed aseptic practices.

- To accommodate the rise in regional demand for flexible, sterile, and unit-dose pharmaceutical packaging, Nelipak Healthcare Packaging rolled out a new packaging facility in North Carolina in 2024. This expansion is in line with increasing interest by large pharmaceutical manufacturers toward automated and cleanroom-compatible equipment. In fact, this emerging trend of integrated and modular packaging systems to guarantee patient safety, quality assurance, and traceability in the supply chain prevails in the North American market.

Pharmaceutical-Packaging-Equipment-Market Ecosystem

Key players in the global pharmaceutical packaging equipment market include prominent companies such as IMA Group, Uhlmann Packaging Systems, Bosch Packaging Technology / Syntegon, Marchesini Group, Romaco Group and Other Key Players.

The pharmaceutical packaging equipment market is moderately consolidated; Tier 1 players such as Syntegon Technology, IMA Group, and Uhlmann Packaging Systems dominate the market through full automation capabilities, regulatory compliance, and servicing facilities worldwide. Tier 2 and 3 companies like Groninger and Cama Group work in specialized applications or serve clients locally. There is an average level of buyer concentration because buyers consist of pharmaceutical manufacturers and CDMOs. Supplier concentration is high due to reliance on precision engineering, sterile design standards, and integration with validated pharmaceutical production systems.

Recent Development and Strategic Overview:

- In June 2025, At the Propak Asia trade exhibition in Bangkok, Mespack launched an integrated vertical form-fill-seal and case-packer package-making system capable of making 840 stick packs a minute and compliant with the GMP, GAMP5, FDA, and 21 CFR Part 11 standards. Also, under the direction of Guillem Clofent, Mespack exhibited its Athena digital platform for production management based on data.

- In February 2024, Aptar CSP Technologies entered into a partnership with ProAmpac to develop "ProActive Intelligence Moisture Protect (MP‑1000)," a moisture-control packaging designed to help ensure potency and shelf life for sensitive pharmaceutical and healthcare products.

Report Scope

|

Detail |

|

|

Market Size in 2025 |

USD 9.2 Bn |

|

Market Forecast Value in 2035 |

USD 17.1 Bn |

|

Growth Rate (CAGR) |

5.8% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value Thousand Units for Volume |

|

Report Format |

Electronic (PDF) + Excel |

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Pharmaceutical-Packaging-Equipment-Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Equipment Type |

|

|

By Automation Level |

|

|

By Packaging Format |

|

|

By Process Type |

|

|

By Drug Type |

|

|

By End User |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Pharmaceutical Packaging Equipment Market Outlook

- 2.1.1. Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End Use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Pharmaceutical Packaging Equipment Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Industrial Machinery Overview, 2025

- 3.1.1. Industry Ecosystem Analysis

- 3.1.2. Key Trends for Industrial Machinery Industry

- 3.1.3. Regional Distribution for Industrial Machinery

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.1. Global Industrial Machinery Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Growing demand for advanced and compliant packaging due to rising biologics and sterile drug production.

- 4.1.1.2. Stricter regulatory standards (e.g., serialization, tamper-evidence) pushing upgrade of packaging machinery.

- 4.1.1.3. Shift toward patient-centric and personalized medicine driving need for flexible, small-batch packaging systems.

- 4.1.2. Restraints

- 4.1.2.1. High investment and operating costs for advanced packaging and serialization equipment.

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis/ Ecosystem Analysis

- 4.4.1. Component Suppliers

- 4.4.2. Technology Providers/ System Integrators

- 4.4.3. Pharmaceutical Packaging Equipment Manufacturers

- 4.4.4. Distributors & Dealers

- 4.4.5. End Users

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Porter’s Five Forces Analysis

- 4.7. PESTEL Analysis

- 4.8. Global Pharmaceutical Packaging Equipment Market Demand

- 4.8.1. Historical Market Size - in Value (Volume - Thousand Units & Value - US$ Billion), 2021-2024

- 4.8.2. Current and Future Market Size - in Value (Volume - Thousand Units & Value - US$ Billion), 2025–2035

- 4.8.2.1. Y-o-Y Growth Trends

- 4.8.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Pharmaceutical Packaging Equipment Market Analysis, by Equipment Type

- 6.1. Key Segment Analysis

- 6.2. Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, by Equipment Type, 2021-2035

- 6.2.1. Primary Packaging Machines

- 6.2.1.1. Filling

- 6.2.1.2. Sealing

- 6.2.1.3. Others

- 6.2.2. Secondary Packaging Machines

- 6.2.2.1. Cartoning

- 6.2.2.2. Blister Packaging

- 6.2.2.3. Others

- 6.2.3. Tertiary Packaging Machines

- 6.2.3.1. Cases

- 6.2.3.2. Pallets

- 6.2.3.3. Stretch-wrapping

- 6.2.3.4. Others

- 6.2.1. Primary Packaging Machines

- 7. Global Pharmaceutical Packaging Equipment Market Analysis, by Automation Level

- 7.1. Key Segment Analysis

- 7.2. Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, by Automation Level, 2021-2035

- 7.2.1. Manual/Operator-Dependent

- 7.2.2. PLC-Controlled

- 7.2.3. Robotic/Integrated Systems

- 8. Global Pharmaceutical Packaging Equipment Market Analysis, by Packaging Format

- 8.1. Key Segment Analysis

- 8.2. Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, by Packaging Format, 2021-2035

- 8.2.1. Blister Packs

- 8.2.2. Bottles & Vials

- 8.2.3. Ampoules & Syringes

- 8.2.4. Pouches & Sachets

- 8.2.5. Alu-Alu and LLDPE Foil Laminates

- 8.2.6. Others

- 9. Global Pharmaceutical Packaging Equipment Market Analysis, by Process Type

- 9.1. Key Segment Analysis

- 9.2. Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, by Process Type, 2021-2035

- 9.2.1. Filling & Closing

- 9.2.2. Labeling & Inspection

- 9.2.3. Cartoning & Case Packing

- 9.2.4. Sterilization & Aseptic Packaging

- 9.2.5. Others

- 10. Global Pharmaceutical Packaging Equipment Market Analysis, by Drug Type

- 10.1. Key Segment Analysis

- 10.2. Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, by Drug Type, 2021-2035

- 10.2.1. Solid Dosage (Tablets, Capsules)

- 10.2.2. Liquid Dosage (Injectables, Solutions)

- 10.2.3. Semisolid Dosage (Creams, Ointments)

- 10.2.4. Dry Powder Inhalers (DPIs)

- 10.2.5. Ophthalmic Products

- 10.2.6. Others

- 11. Global Pharmaceutical Packaging Equipment Market Analysis, by End User

- 11.1. Key Segment Analysis

- 11.2. Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, by End User, 2021-2035

- 11.2.1. Pharmaceutical Manufacturers

- 11.2.2. Contract Manufacturing Organizations (CMOs)

- 11.2.3. Biotech Companies

- 11.2.4. Research & Academic Institutions

- 11.2.5. Others

- 12. Global Pharmaceutical Packaging Equipment Market Analysis and Forecasts, by Region

- 12.1. Key Findings

- 12.2. Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, by Region, 2021-2035

- 12.2.1. North America

- 12.2.2. Europe

- 12.2.3. Asia Pacific

- 12.2.4. Middle East

- 12.2.5. Africa

- 12.2.6. South America

- 13. North America Pharmaceutical Packaging Equipment Market Analysis

- 13.1. Key Segment Analysis

- 13.2. Regional Snapshot

- 13.3. North America Pharmaceutical Packaging Equipment Market Size Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 13.3.1. Equipment Type

- 13.3.2. Automation Level

- 13.3.3. Packaging Format

- 13.3.4. Process Type

- 13.3.5. Drug Type

- 13.3.6. End User

- 13.3.7. Country

- 13.3.7.1. USA

- 13.3.7.2. Canada

- 13.3.7.3. Mexico

- 13.4. USA Pharmaceutical Packaging Equipment Market

- 13.4.1. Country Segmental Analysis

- 13.4.2. Equipment Type

- 13.4.3. Automation Level

- 13.4.4. Packaging Format

- 13.4.5. Process Type

- 13.4.6. Drug Type

- 13.4.7. End User

- 13.5. Canada Pharmaceutical Packaging Equipment Market

- 13.5.1. Country Segmental Analysis

- 13.5.2. Equipment Type

- 13.5.3. Automation Level

- 13.5.4. Packaging Format

- 13.5.5. Process Type

- 13.5.6. Drug Type

- 13.5.7. End User

- 13.6. Mexico Pharmaceutical Packaging Equipment Market

- 13.6.1. Country Segmental Analysis

- 13.6.2. Equipment Type

- 13.6.3. Automation Level

- 13.6.4. Packaging Format

- 13.6.5. Process Type

- 13.6.6. Drug Type

- 13.6.7. End User

- 14. Europe Pharmaceutical Packaging Equipment Market Analysis

- 14.1. Key Segment Analysis

- 14.2. Regional Snapshot

- 14.3. Europe Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 14.3.1. Equipment Type

- 14.3.2. Automation Level

- 14.3.3. Packaging Format

- 14.3.4. Process Type

- 14.3.5. Drug Type

- 14.3.6. End User

- 14.3.7. Country

- 14.3.7.1. Germany

- 14.3.7.2. United Kingdom

- 14.3.7.3. France

- 14.3.7.4. Italy

- 14.3.7.5. Spain

- 14.3.7.6. Netherlands

- 14.3.7.7. Nordic Countries

- 14.3.7.8. Poland

- 14.3.7.9. Russia & CIS

- 14.3.7.10. Rest of Europe

- 14.4. Germany Pharmaceutical Packaging Equipment Market

- 14.4.1. Country Segmental Analysis

- 14.4.2. Equipment Type

- 14.4.3. Automation Level

- 14.4.4. Packaging Format

- 14.4.5. Process Type

- 14.4.6. Drug Type

- 14.4.7. End User

- 14.5. United Kingdom Pharmaceutical Packaging Equipment Market

- 14.5.1. Country Segmental Analysis

- 14.5.2. Equipment Type

- 14.5.3. Automation Level

- 14.5.4. Packaging Format

- 14.5.5. Process Type

- 14.5.6. Drug Type

- 14.5.7. End User

- 14.6. France Pharmaceutical Packaging Equipment Market

- 14.6.1. Country Segmental Analysis

- 14.6.2. Equipment Type

- 14.6.3. Automation Level

- 14.6.4. Packaging Format

- 14.6.5. Process Type

- 14.6.6. Drug Type

- 14.6.7. End User

- 14.7. Italy Pharmaceutical Packaging Equipment Market

- 14.7.1. Country Segmental Analysis

- 14.7.2. Equipment Type

- 14.7.3. Automation Level

- 14.7.4. Packaging Format

- 14.7.5. Process Type

- 14.7.6. Drug Type

- 14.7.7. End User

- 14.8. Spain Pharmaceutical Packaging Equipment Market

- 14.8.1. Country Segmental Analysis

- 14.8.2. Equipment Type

- 14.8.3. Automation Level

- 14.8.4. Packaging Format

- 14.8.5. Process Type

- 14.8.6. Drug Type

- 14.8.7. End User

- 14.9. Netherlands Pharmaceutical Packaging Equipment Market

- 14.9.1. Country Segmental Analysis

- 14.9.2. Equipment Type

- 14.9.3. Automation Level

- 14.9.4. Packaging Format

- 14.9.5. Process Type

- 14.9.6. Drug Type

- 14.9.7. End User

- 14.10. Nordic Countries Pharmaceutical Packaging Equipment Market

- 14.10.1. Country Segmental Analysis

- 14.10.2. Equipment Type

- 14.10.3. Automation Level

- 14.10.4. Packaging Format

- 14.10.5. Process Type

- 14.10.6. Drug Type

- 14.10.7. End User

- 14.11. Poland Pharmaceutical Packaging Equipment Market

- 14.11.1. Country Segmental Analysis

- 14.11.2. Equipment Type

- 14.11.3. Automation Level

- 14.11.4. Packaging Format

- 14.11.5. Process Type

- 14.11.6. Drug Type

- 14.11.7. End User

- 14.12. Russia & CIS Pharmaceutical Packaging Equipment Market

- 14.12.1. Country Segmental Analysis

- 14.12.2. Equipment Type

- 14.12.3. Automation Level

- 14.12.4. Packaging Format

- 14.12.5. Process Type

- 14.12.6. Drug Type

- 14.12.7. End User

- 14.13. Rest of Europe Pharmaceutical Packaging Equipment Market

- 14.13.1. Country Segmental Analysis

- 14.13.2. Equipment Type

- 14.13.3. Automation Level

- 14.13.4. Packaging Format

- 14.13.5. Process Type

- 14.13.6. Drug Type

- 14.13.7. End User

- 15. Asia Pacific Pharmaceutical Packaging Equipment Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. East Asia Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 15.3.1. Equipment Type

- 15.3.2. Automation Level

- 15.3.3. Packaging Format

- 15.3.4. Process Type

- 15.3.5. Drug Type

- 15.3.6. End User

- 15.3.7. Country

- 15.3.7.1. China

- 15.3.7.2. India

- 15.3.7.3. Japan

- 15.3.7.4. South Korea

- 15.3.7.5. Australia and New Zealand

- 15.3.7.6. Indonesia

- 15.3.7.7. Malaysia

- 15.3.7.8. Thailand

- 15.3.7.9. Vietnam

- 15.3.7.10. Rest of Asia Pacific

- 15.4. China Pharmaceutical Packaging Equipment Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Equipment Type

- 15.4.3. Automation Level

- 15.4.4. Packaging Format

- 15.4.5. Process Type

- 15.4.6. Drug Type

- 15.4.7. End User

- 15.5. India Pharmaceutical Packaging Equipment Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Equipment Type

- 15.5.3. Automation Level

- 15.5.4. Packaging Format

- 15.5.5. Process Type

- 15.5.6. Drug Type

- 15.5.7. End User

- 15.6. Japan Pharmaceutical Packaging Equipment Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Equipment Type

- 15.6.3. Automation Level

- 15.6.4. Packaging Format

- 15.6.5. Process Type

- 15.6.6. Drug Type

- 15.6.7. End User

- 15.7. South Korea Pharmaceutical Packaging Equipment Market

- 15.7.1. Country Segmental Analysis

- 15.7.2. Equipment Type

- 15.7.3. Automation Level

- 15.7.4. Packaging Format

- 15.7.5. Process Type

- 15.7.6. Drug Type

- 15.7.7. End User

- 15.8. Australia and New Zealand Pharmaceutical Packaging Equipment Market

- 15.8.1. Country Segmental Analysis

- 15.8.2. Equipment Type

- 15.8.3. Automation Level

- 15.8.4. Packaging Format

- 15.8.5. Process Type

- 15.8.6. Drug Type

- 15.8.7. End User

- 15.9. Indonesia Pharmaceutical Packaging Equipment Market

- 15.9.1. Country Segmental Analysis

- 15.9.2. Equipment Type

- 15.9.3. Automation Level

- 15.9.4. Packaging Format

- 15.9.5. Process Type

- 15.9.6. Drug Type

- 15.9.7. End User

- 15.10. Malaysia Pharmaceutical Packaging Equipment Market

- 15.10.1. Country Segmental Analysis

- 15.10.2. Equipment Type

- 15.10.3. Automation Level

- 15.10.4. Packaging Format

- 15.10.5. Process Type

- 15.10.6. Drug Type

- 15.10.7. End User

- 15.11. Thailand Pharmaceutical Packaging Equipment Market

- 15.11.1. Country Segmental Analysis

- 15.11.2. Equipment Type

- 15.11.3. Automation Level

- 15.11.4. Packaging Format

- 15.11.5. Process Type

- 15.11.6. Drug Type

- 15.11.7. End User

- 15.12. Vietnam Pharmaceutical Packaging Equipment Market

- 15.12.1. Country Segmental Analysis

- 15.12.2. Equipment Type

- 15.12.3. Automation Level

- 15.12.4. Packaging Format

- 15.12.5. Process Type

- 15.12.6. Drug Type

- 15.12.7. End User

- 15.13. Rest of Asia Pacific Pharmaceutical Packaging Equipment Market

- 15.13.1. Country Segmental Analysis

- 15.13.2. Equipment Type

- 15.13.3. Automation Level

- 15.13.4. Packaging Format

- 15.13.5. Process Type

- 15.13.6. Drug Type

- 15.13.7. End User

- 16. Middle East Pharmaceutical Packaging Equipment Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Middle East Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 16.3.1. Equipment Type

- 16.3.2. Automation Level

- 16.3.3. Packaging Format

- 16.3.4. Process Type

- 16.3.5. Drug Type

- 16.3.6. End User

- 16.3.7. Country

- 16.3.7.1. Turkey

- 16.3.7.2. UAE

- 16.3.7.3. Saudi Arabia

- 16.3.7.4. Israel

- 16.3.7.5. Rest of Middle East

- 16.4. Turkey Pharmaceutical Packaging Equipment Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Equipment Type

- 16.4.3. Automation Level

- 16.4.4. Packaging Format

- 16.4.5. Process Type

- 16.4.6. Drug Type

- 16.4.7. End User

- 16.5. UAE Pharmaceutical Packaging Equipment Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Equipment Type

- 16.5.3. Automation Level

- 16.5.4. Packaging Format

- 16.5.5. Process Type

- 16.5.6. Drug Type

- 16.5.7. End User

- 16.6. Saudi Arabia Pharmaceutical Packaging Equipment Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Equipment Type

- 16.6.3. Automation Level

- 16.6.4. Packaging Format

- 16.6.5. Process Type

- 16.6.6. Drug Type

- 16.6.7. End User

- 16.7. Israel Pharmaceutical Packaging Equipment Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Equipment Type

- 16.7.3. Automation Level

- 16.7.4. Packaging Format

- 16.7.5. Process Type

- 16.7.6. Drug Type

- 16.7.7. End User

- 16.8. Rest of Middle East Pharmaceutical Packaging Equipment Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Equipment Type

- 16.8.3. Automation Level

- 16.8.4. Packaging Format

- 16.8.5. Process Type

- 16.8.6. Drug Type

- 16.8.7. End User

- 17. Africa Pharmaceutical Packaging Equipment Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Africa Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 17.3.1. Equipment Type

- 17.3.2. Automation Level

- 17.3.3. Packaging Format

- 17.3.4. Process Type

- 17.3.5. Drug Type

- 17.3.6. End User

- 17.3.7. Country

- 17.3.7.1. South Africa

- 17.3.7.2. Egypt

- 17.3.7.3. Nigeria

- 17.3.7.4. Algeria

- 17.3.7.5. Rest of Africa

- 17.4. South Africa Pharmaceutical Packaging Equipment Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Equipment Type

- 17.4.3. Automation Level

- 17.4.4. Packaging Format

- 17.4.5. Process Type

- 17.4.6. Drug Type

- 17.4.7. End User

- 17.5. Egypt Pharmaceutical Packaging Equipment Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Equipment Type

- 17.5.3. Automation Level

- 17.5.4. Packaging Format

- 17.5.5. Process Type

- 17.5.6. Drug Type

- 17.5.7. End User

- 17.6. Nigeria Pharmaceutical Packaging Equipment Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Equipment Type

- 17.6.3. Automation Level

- 17.6.4. Packaging Format

- 17.6.5. Process Type

- 17.6.6. Drug Type

- 17.6.7. End User

- 17.7. Algeria Pharmaceutical Packaging Equipment Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Equipment Type

- 17.7.3. Automation Level

- 17.7.4. Packaging Format

- 17.7.5. Process Type

- 17.7.6. Drug Type

- 17.7.7. End User

- 17.8. Rest of Africa Pharmaceutical Packaging Equipment Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Equipment Type

- 17.8.3. Automation Level

- 17.8.4. Packaging Format

- 17.8.5. Process Type

- 17.8.6. Drug Type

- 17.8.7. End User

- 18. South America Pharmaceutical Packaging Equipment Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Central and South Africa Pharmaceutical Packaging Equipment Market Size (Volume - Thousand Units & Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 18.3.1. Equipment Type

- 18.3.2. Automation Level

- 18.3.3. Packaging Format

- 18.3.4. Process Type

- 18.3.5. Drug Type

- 18.3.6. End User

- 18.3.7. Country

- 18.3.7.1. Brazil

- 18.3.7.2. Argentina

- 18.3.7.3. Rest of South America

- 18.4. Brazil Pharmaceutical Packaging Equipment Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Equipment Type

- 18.4.3. Automation Level

- 18.4.4. Packaging Format

- 18.4.5. Process Type

- 18.4.6. Drug Type

- 18.4.7. End User

- 18.5. Argentina Pharmaceutical Packaging Equipment Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Equipment Type

- 18.5.3. Automation Level

- 18.5.4. Packaging Format

- 18.5.5. Process Type

- 18.5.6. Drug Type

- 18.5.7. End User

- 18.6. Rest of South America Pharmaceutical Packaging Equipment Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Equipment Type

- 18.6.3. Automation Level

- 18.6.4. Packaging Format

- 18.6.5. Process Type

- 18.6.6. Drug Type

- 18.6.7. End User

- 19. Key Players/ Company Profile

- 19.1. Bausch+Strobel

- 19.1.1. Company Details/ Overview

- 19.1.2. Company Financials

- 19.1.3. Key Customers and Competitors

- 19.1.4. Business/ Industry Portfolio

- 19.1.5. Product Portfolio/ Specification Details

- 19.1.6. Pricing Data

- 19.1.7. Strategic Overview

- 19.1.8. Recent Developments

- 19.2. Bosch Packaging Technology

- 19.3. Cama Group

- 19.4. Coesia Group

- 19.5. Fedegari Group

- 19.6. Groninger & Co. GmbH

- 19.7. IMA Group

- 19.8. Jabil Inc.

- 19.9. Marchesini Group

- 19.10. OCG (Ompi, CCL, and Garçon)

- 19.11. Optima packaging group

- 19.12. ProMach

- 19.13. Recipharm

- 19.14. Romaco Group

- 19.15. SKAN AG

- 19.16. Syntegon Packaging Systems

- 19.17. Syntegon Technology (formerly Bosch Pharma)

- 19.18. Uhlmann Packaging Systems

- 19.19. Veltek Associates Inc.

- 19.20. Vetter Pharma

- 19.21. Other Key Players

- 19.1. Bausch+Strobel

Note* - This is just tentative list of players. While providing the report, we will cover a greater number of players based on their revenue and share for each geography

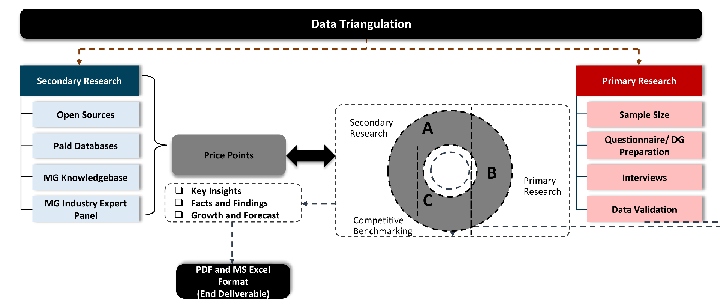

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation