Carbon Fiber Composites Market Size, Share, Growth Opportunity Analysis Report by Matrix Type (Polymer Matrix Composites, Metal Matrix Composites), Ceramic Matrix Composites, Carbon Matrix Composites, Hybrid Matrix Composites, Others), Fiber Type, Fiber Modulus, Manufacturing Process, Fiber Raw Material, Application, End Use Industry, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Carbon Fiber Composites Market Size, Share, and Growth

The global market for carbon fiber composites is witnessed to grow at a compound annual growth rate (CAGR) of 7.1% from USD 17.8 billion in 2025 to USD 35.3 billion by 2035. The carbon fiber composites market has been growing items because manufacturers across varied industries, including automotive and aerospace, are looking for alternative materials that are light, strong, durable, and emphasizes long-term energy efficiency and reductions in fuel consumption while providing comparable safety and performance to metal products.

In 2025, the carbon fiber composites industry continued to make new strides with new developments focused on performance and sustainability. Hexcel introduced Hy‑Bor, a high-modulus hybrid prepreg that uses carbon and boron fibers and can be used in aerospace structural applications. Teijin introduced Tenax IMS65 E23 36K, an intermediate modulus fiber with industrial-grade tensile strength and stiffness for pressure vessels.

Moreover, carbon fiber composites are indeed present in high-performance electric vehicles, lightweight components in aircraft, wind turbines, and in sporting goods - the carbon fiber composites superior strength-to-weight properties means companies can realize energy efficiency and fuel consumption improvements, while prolonging product life. For industries such as aerospace and automotive it means more rapid, rapid designs with an ever-smaller environmental footprint.

The key market opportunities of the global carbon fiber composites market are lightweight electric vehicles components, aerospace structural parts, and the wind turbine blades of renewable energy. The sectors are becoming more of high-strength and low-weight materials to enhance efficiency and performance. Impact: The increase in adoption in these industries will likely drive the growth of the carbon fiber composites market to a major level.

Carbon Fiber Composites Dynamics and Trends

Drivers: High Strength-to-Weight Ratio, Sustainability Demands, and Aerospace & EV Adoption

- Carbon fiber composites are gradually gaining popularity owing to the fact that it possesses something very desirable which is; it is very strong yet very light. This renders them highly useful to such industries as aerospace and electric vehicles (EVs) in which reduced weight can save a significant amount of fuel or extend the battery range. The use of lighter planes and vehicles consumes less energy resulting in better emission and performance.

- The world is rapidly moving toward cleaner energy and greener transportation, and carbon fiber composites helping companies build more efficient products without sacrificing strength or safety. Even EV makers, renowned for building lightweight vehicles with carbon fiber-bodied parts to extend operating ranges, are excited about carbon fiber composites.

- This increased demand and potential carbon fiber composites market is emerging from sectors such as wind energy, which utilizes large yet lightweight blades that are persons of the turbine, the sports industry, where both strength and precision are vital and medical applications, which also requires strength and precision as well. Moreover, carbon fiber composites always had a reputation of high cost and difficulty to recycle. Currently, companies are beginning to develop more sustainable production methodologies that are at least not extremely expensive.

Restraints: High Material Costs, Complex Manufacturing, and Limited Recyclability Slowing Carbon Fiber Composite Adoption

- The carbon fiber composites have incredible strength-to-weight ratios, their extremely high production costs will inhibit their ongoing growth in the market. Carbon fiber composites are notoriously expensive to produce, in part due to their raw materials that are designated as hazardous waste; but more importantly because their production methods are energy intensive, and increased energy intensity raises costs.

- Cost-sensitive markets, such as consumer goods or infrastructure, may think twice about carbon fiber composites compared to more traditionally sourced materials, albeit the materials and process may be more environmentally considerate.

- Moreover, the carbon fiber composites manufacturing and engineering process includes too many different processes that require skilled people and precision manufacturing equipment. Carbon fiber composites recycling is also undeveloped and expensive, but are environmental hazards at time of disposal, limiting circularity and environmental effects over the long term. All these issues together are significant hurdles to mass-market commodification.

Opportunity: Shift Toward Lightweight, High-Strength Materials in Mobility and Infrastructure Fuels Next Wave of Innovation

- The market of carbon fiber composites is growing at a high rate due to the shift towards lightweight and strong materials in the industries. Composites made of carbon fiber are applied as an alternative to heavy metals in automobiles, aircraft, wind turbines and building components. As the weight is reduced and yet high strength maintained, safety approved, fuel consumption and emissions are reduced.

- The growing sustainability, many industries are embracing design philosophy based on carbon fiber composites in electric vehicles and the next generation of aircraft. Other transportation modalities also include carbon fiber composites in upgrades for trains, drones, and various industrial machines for performance and reduced energy consumption. In infrastructure, carbon fiber composites are being reviewed for bridges, boats, buildings, and reinforcement projects due to their strength and corrosion resistance.

- The carbon fiber composites market will benefit from continued improvements in cost-effective manufacturing methods, increased recyclability, and hybridization of carbon fiber composites with a wide-range of sustainable materials. More so, Governments are using investments towards cleaner transportation, and infrastructure with energy-efficient buildings. In taking sustainability seriously and utilizing carbon fiber composites to lighter, stronger, and more sustainable products, there are substantial growth opportunities for stakeholders in the carbon composites industry.

Key Trend: Increasing Demand for Lightweight, Durable Components Driving Expansion across Transport and Construction Sectors

- The carbon fiber composites market is steadily increasing as many sectors want lightweight, strong materials that can enhance function and performance. Carbon fiber composites are now being used in electric vehicles, airplanes, athletic goods, wind turbines, and even buildings because they are substantially lighter weight than metals with the same strength.

- One major trend is their increasing use in electric and hybrid vehicles as a weight reduction, which also has a positive impact on battery life and driving range of the vehicles. In aeronautics, carbon composites are replacing metal parts for the reduction of fuel consumption and emissions. In construction, carbon composites are being used to reinforce bridge and building structures, particularly in seismic/earthquake prone areas and corrosion zones.

- Therefore, with increasing fabrication/production technologies there is rise in effectiveness, applications and processes that use high-performance materials are becoming less expensive and easier. There is increasing interest in recycling waste from carbon fiber production, and creating more sustainable composites as well. As industries gravitate more toward sustainable practices and seek performance, carbon fiber composites are becoming a solutions-centric material in addressing modern designs and engineering challenges.

Carbon Fiber Composite Market Analysis and Segmental Data

Based on Application, Aerospace and Defense hold the largest share in global market

- The defense and aerospace segment holds a major share ~42% in the global carbon fiber composites market, owing to the characteristics of these sectors where very strong materials but light ones are needed. The carbon fiber composites reduce weight on aircrafts and military equipment without affecting the safety and performance and enhance fuel efficiency and range. Therefore, they have wide-ranging applications in aerospace in aircraft construction, wings, and interiors and in defense in drones, armored tanks, and body armor.

- Moreover, carbon fiber is the key material to use in these harsh applications due to its high strength, heat resistance as well as endurance to the rough conditions. In addition, the demand in this industry is also being fueled by rising global air travel and defense expenditure on global air travel and defense.

Asia Pacific Dominates Global Carbon Fiber Composites Market in 2025 and beyond

- The carbon fiber composites market globally anticipated to continue to be dominated by the Asia Pacific region, since Asia Pacific offers incredible support in its growing related key sectors which significantly contribute to the increased use of carbon fiber composite materials. Manufacturers of long carbon fiber and related products from Asia, mainly China, Japan and South Korea, dominate the industry based on their technologies, qualified workforce, capable economy and market size, efficient in manufacturing a range of products based on customer needs.

- Moreover, the aerospace, automotive and wind energy sectors in Asia are also utilizing carbon fiber composite materials to decrease the weight of products to make them more fuel efficient. In addition to the growing usage of carbon fiber reinforced composites in associated industries, investments in infrastructure and defense with advanced composite / high performance materials are having an increasing impact on manufacturers today.

- Overall, producing carbon fiber composites has a lower cost of production, a larger qualified workforce and potential new market opportunities in an increasing global market, thus Asia Pacific is likely to continue to lead this product sector for years to come.

Carbon Fiber Composites Market Ecosystem

The carbon fiber composites market in the globe is moderately consolidated and the Tier 1 players of Toray Industries, Teijin Limited, Mitsubishi Chemical Holdings, Hexcel Corporation and Solvay S.A, have the medium-to-high concentration with the possession of extensive market shares by advanced technologies and global coverage. The Tier 2 and Tier 3 players such as the RTP Company and National Composites have minimal influence. According to Porters 5 forces, there is moderate to high concentration among suppliers because of the specialization in sourcing the raw materials, and the concentration among buyers is moderate because of the diversification of demand to aerospace, auto, and energy products.

Recent Development and Strategic Overview:

- In June 2025, SGL Carbon SE unveiled its new SigraLite XT-Series, a next-generation carbon fiber composite solution for electric mobility and urban air mobility (UAM) platforms. The XT-Series offers ultra-lightweight and high-strength properties with a newly developed thermal management layer perfect for battery enclosures, drone frames, and lightweight aircraft components. The composites use SGL’s smart resin system that has embedded sensors to allow live monitoring of structural health.

- In March 2025, Teijin Limited. has launched its Tenax Next series which is their second big step in carbon fiber composites. These new fibers are also based on circular feedstock, so that the CO2 emissions are reduced by some 35 percent, yet they are still highly strong. These sustainable composites comprise high-performance and reduced carbon footprint aimed at aerospace structures, pressure vessels and high-performance transport.

Report Scope

|

Detail |

|

|

Market Size in 2025 |

USD 17.8 Bn |

|

Market Forecast Value in 2035 |

USD 35.3 Bn |

|

Growth Rate (CAGR) |

7.1% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value |

|

Report Format |

Electronic (PDF) + Excel |

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Carbon Fiber Composites Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Matrix Type |

|

|

By Fiber Type |

|

|

By Fiber Modulus |

|

|

By Manufacturing Process |

|

|

By Fiber Raw Material |

|

|

By Application |

|

|

By End Use Industry |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Carbon Fiber Composites Market Outlook

- 2.1.1. Carbon Fiber Composites Market Size (Value - US$ Billion), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Carbon Fiber Composites Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Carbon Fiber Composites Industry Overview, 2024

- 3.1.1. Chemicals & Materials Industry Ecosystem Analysis

- 3.1.2. Key Trends for Chemicals & Materials Industry

- 3.1.3. Regional Distribution for Chemicals & Materials Industry

- 3.2. Supplier Customer Data

- 3.3. Source Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2024

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.6. Raw Material Analysis

- 3.1. Carbon Fiber Composites Industry Overview, 2024

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. High Strength-to-Weight Ratio, Sustainability Demands, and Aerospace & EV Adoption Fueling Growth in Carbon Fiber Composites Market

- 4.1.2. Restraints

- 4.1.2.1. High Material Costs, Complex Manufacturing, and Limited Recyclability Slowing Carbon Fiber Composite Adoption

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Raw Composites Sourcing

- 4.4.2. Manufacturing and Processing

- 4.4.3. Wholesalers/ E-commerce Platform

- 4.4.4. End-use/ Customers

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Pricing Analysis

- 4.6.1. Regional Pricing Analysis

- 4.6.2. Segmental Pricing Trends

- 4.6.3. Factors Influencing Pricing

- 4.7. Porter’s Five Forces Analysis

- 4.8. PESTEL Analysis

- 4.9. Carbon Fiber Composites Market Demand

- 4.9.1. Historical Market Size - Value (US$ Billion), 2021-2024

- 4.9.2. Current and Future Market Size - Value (US$ Billion), 2025–2035

- 4.9.2.1. Y-o-Y Growth Trends

- 4.9.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2024

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Carbon Fiber Composites Market Analysis, by Matrix Type

- 6.1. Key Segment Analysis

- 6.2. Global Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, by Matrix Type, 2021-2035

- 6.2.1. Polymer Matrix Composites (PMC)

- 6.2.2. Metal Matrix Composites (MMC)

- 6.2.3. Ceramic Matrix Composites (CMC)

- 6.2.4. Carbon Matrix Composites

- 6.2.5. Hybrid Matrix Composites

- 6.2.6. Others

- 7. Global Carbon Fiber Composites Market Analysis, by Fiber Type

- 7.1. Key Segment Analysis

- 7.2. Global Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, by Fiber Type, 2021-2035

- 7.2.1. Virgin Carbon Fiber

- 7.2.2. Recycled Carbon

- 8. Global Carbon Fiber Composites Market Analysis, by Fiber Modulus

- 8.1. Key Segment Analysis

- 8.2. Global Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, by Fiber Modulus, 2021-2035

- 8.2.1. Standard Modulus

- 8.2.2. Intermediate Modulus

- 8.2.3. High Modulus

- 8.2.4. Ultra High Modulus

- 9. Global Carbon Fiber Composites Market Analysis, by Manufacturing Process

- 9.1. Key Segment Analysis

- 9.2. Global Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, by Manufacturing Process, 2021-2035

- 9.2.1. Prepreg Layup Process

- 9.2.2. Pultrusion and Winding

- 9.2.3. Wet Lamination and Infusion Process

- 9.2.4. Press and Injection Processes

- 9.2.5. Other Processes

- 10. Global Carbon Fiber Composites Market Analysis, by Fiber Raw Material

- 10.1. Key Segment Analysis

- 10.2. Global Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, by Fiber Raw Material, 2021-2035

- 10.2.1. Polyacrylonitrile (PAN)

- 10.2.2. Pitch

- 10.2.3. Recycled Materials

- 11. Global Carbon Fiber Composites Market Analysis, by Application

- 11.1. Key Segment Analysis

- 11.2. Global Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, by Application, 2021-2035

- 11.2.1. Aerospace and Defense

- 11.2.2. Automotive

- 11.2.3. Wind Turbines

- 11.2.4. Sports and Leisure

- 11.2.5. Civil Engineering

- 11.2.6. Marine Applications

- 11.2.7. Medical Devices

- 11.2.8. Consumer Electronics

- 11.2.9. Others

- 12. Global Carbon Fiber Composites Market Analysis, by End Use Industry

- 12.1. Key Segment Analysis

- 12.2. Global Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, by End Use Industry, 2021-2035

- 12.2.1. Aerospace

- 12.2.2. Automotive

- 12.2.3. Wind Energy

- 12.2.4. Sports and Leisure

- 12.2.5. Construction and Infrastructure

- 12.2.6. Marine

- 12.2.7. Medical Devices

- 12.2.8. Electronics

- 12.2.9. Others

- 13. Global Carbon Fiber Composites Market Analysis and Forecasts, by Region

- 13.1. Key Findings

- 13.2. Global Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, by Region, 2021-2035

- 13.2.1. North America

- 13.2.2. Europe

- 13.2.3. Asia Pacific

- 13.2.4. Middle East

- 13.2.5. Africa

- 13.2.6. South America

- 14. North America Carbon Fiber Composites Market Analysis

- 14.1. Key Segment Analysis

- 14.2. Regional Snapshot

- 14.3. North America Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 14.3.1. Matrix Type

- 14.3.2. Fiber Type

- 14.3.3. Fiber Modulus

- 14.3.4. Manufacturing Process

- 14.3.5. Fiber Raw Material

- 14.3.6. Application

- 14.3.7. End Use Industry

- 14.3.8. Country

- 14.3.8.1. USA

- 14.3.8.2. Canada

- 14.3.8.3. Mexico

- 14.4. USA Carbon Fiber Composites Market

- 14.4.1. Country Segmental Analysis

- 14.4.2. Matrix Type

- 14.4.3. Fiber Type

- 14.4.4. Fiber Modulus

- 14.4.5. Manufacturing Process

- 14.4.6. Fiber Raw Material

- 14.4.7. Application

- 14.4.8. End Use Industry

- 14.5. Canada Carbon Fiber Composites Market

- 14.5.1. Country Segmental Analysis

- 14.5.2. Matrix Type

- 14.5.3. Fiber Type

- 14.5.4. Fiber Modulus

- 14.5.5. Manufacturing Process

- 14.5.6. Fiber Raw Material

- 14.5.7. Application

- 14.5.8. End Use Industry

- 14.6. Mexico Carbon Fiber Composites Market

- 14.6.1. Country Segmental Analysis

- 14.6.2. Matrix Type

- 14.6.3. Fiber Type

- 14.6.4. Fiber Modulus

- 14.6.5. Manufacturing Process

- 14.6.6. Fiber Raw Material

- 14.6.7. Application

- 14.6.8. End Use Industry

- 15. Europe Carbon Fiber Composites Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. Europe Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 15.3.1. Matrix Type

- 15.3.2. Fiber Type

- 15.3.3. Fiber Modulus

- 15.3.4. Manufacturing Process

- 15.3.5. Fiber Raw Material

- 15.3.6. Application

- 15.3.7. End Use Industry

- 15.3.8. Country

- 15.3.8.1. Germany

- 15.3.8.2. United Kingdom

- 15.3.8.3. France

- 15.3.8.4. Italy

- 15.3.8.5. Spain

- 15.3.8.6. Netherlands

- 15.3.8.7. Nordic Countries

- 15.3.8.8. Poland

- 15.3.8.9. Russia & CIS

- 15.3.8.10. Rest of Europe

- 15.4. Germany Carbon Fiber Composites Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Matrix Type

- 15.4.3. Fiber Type

- 15.4.4. Fiber Modulus

- 15.4.5. Manufacturing Process

- 15.4.6. Fiber Raw Material

- 15.4.7. Application

- 15.4.8. End Use Industry

- 15.5. United Kingdom Carbon Fiber Composites Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Matrix Type

- 15.5.3. Fiber Type

- 15.5.4. Fiber Modulus

- 15.5.5. Manufacturing Process

- 15.5.6. Fiber Raw Material

- 15.5.7. Application

- 15.5.8. End Use Industry

- 15.6. France Carbon Fiber Composites Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Matrix Type

- 15.6.3. Fiber Type

- 15.6.4. Fiber Modulus

- 15.6.5. Manufacturing Process

- 15.6.6. Fiber Raw Material

- 15.6.7. Application

- 15.6.8. End Use Industry

- 15.7. Italy Carbon Fiber Composites Market

- 15.7.1. Country Segmental Analysis

- 15.7.2. Matrix Type

- 15.7.3. Fiber Type

- 15.7.4. Fiber Modulus

- 15.7.5. Manufacturing Process

- 15.7.6. Fiber Raw Material

- 15.7.7. Application

- 15.7.8. End Use Industry

- 15.8. Spain Carbon Fiber Composites Market

- 15.8.1. Country Segmental Analysis

- 15.8.2. Matrix Type

- 15.8.3. Fiber Type

- 15.8.4. Fiber Modulus

- 15.8.5. Manufacturing Process

- 15.8.6. Fiber Raw Material

- 15.8.7. Application

- 15.8.8. End Use Industry

- 15.9. Netherlands Carbon Fiber Composites Market

- 15.9.1. Country Segmental Analysis

- 15.9.2. Matrix Type

- 15.9.3. Fiber Type

- 15.9.4. Fiber Modulus

- 15.9.5. Manufacturing Process

- 15.9.6. Fiber Raw Material

- 15.9.7. Application

- 15.9.8. End Use Industry

- 15.10. Nordic Countries Carbon Fiber Composites Market

- 15.10.1. Country Segmental Analysis

- 15.10.2. Matrix Type

- 15.10.3. Fiber Type

- 15.10.4. Fiber Modulus

- 15.10.5. Manufacturing Process

- 15.10.6. Fiber Raw Material

- 15.10.7. Application

- 15.10.8. End Use Industry

- 15.11. Poland Carbon Fiber Composites Market

- 15.11.1. Country Segmental Analysis

- 15.11.2. Matrix Type

- 15.11.3. Fiber Type

- 15.11.4. Fiber Modulus

- 15.11.5. Manufacturing Process

- 15.11.6. Fiber Raw Material

- 15.11.7. Application

- 15.11.8. End Use Industry

- 15.12. Russia & CIS Carbon Fiber Composites Market

- 15.12.1. Country Segmental Analysis

- 15.12.2. Matrix Type

- 15.12.3. Fiber Type

- 15.12.4. Fiber Modulus

- 15.12.5. Manufacturing Process

- 15.12.6. Fiber Raw Material

- 15.12.7. Application

- 15.12.8. End Use Industry

- 15.13. Rest of Europe Carbon Fiber Composites Market

- 15.13.1. Country Segmental Analysis

- 15.13.2. Matrix Type

- 15.13.3. Fiber Type

- 15.13.4. Fiber Modulus

- 15.13.5. Manufacturing Process

- 15.13.6. Fiber Raw Material

- 15.13.7. Application

- 15.13.8. End Use Industry

- 16. Asia Pacific Carbon Fiber Composites Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. East Asia Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 16.3.1. Matrix Type

- 16.3.2. Fiber Type

- 16.3.3. Fiber Modulus

- 16.3.4. Manufacturing Process

- 16.3.5. Fiber Raw Material

- 16.3.6. Application

- 16.3.7. End Use Industry

- 16.3.8. Country

- 16.3.8.1. China

- 16.3.8.2. India

- 16.3.8.3. Japan

- 16.3.8.4. South Korea

- 16.3.8.5. Australia and New Zealand

- 16.3.8.6. Indonesia

- 16.3.8.7. Malaysia

- 16.3.8.8. Thailand

- 16.3.8.9. Vietnam

- 16.3.8.10. Rest of Asia-Pacific

- 16.4. China Carbon Fiber Composites Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Matrix Type

- 16.4.3. Fiber Type

- 16.4.4. Fiber Modulus

- 16.4.5. Manufacturing Process

- 16.4.6. Fiber Raw Material

- 16.4.7. Application

- 16.4.8. End Use Industry

- 16.5. India Carbon Fiber Composites Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Matrix Type

- 16.5.3. Fiber Type

- 16.5.4. Fiber Modulus

- 16.5.5. Manufacturing Process

- 16.5.6. Fiber Raw Material

- 16.5.7. Application

- 16.5.8. End Use Industry

- 16.6. Japan Carbon Fiber Composites Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Matrix Type

- 16.6.3. Fiber Type

- 16.6.4. Fiber Modulus

- 16.6.5. Manufacturing Process

- 16.6.6. Fiber Raw Material

- 16.6.7. Application

- 16.6.8. End Use Industry

- 16.7. South Korea Carbon Fiber Composites Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Matrix Type

- 16.7.3. Fiber Type

- 16.7.4. Fiber Modulus

- 16.7.5. Manufacturing Process

- 16.7.6. Fiber Raw Material

- 16.7.7. Application

- 16.7.8. End Use Industry

- 16.8. Australia and New Zealand Carbon Fiber Composites Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Matrix Type

- 16.8.3. Fiber Type

- 16.8.4. Fiber Modulus

- 16.8.5. Manufacturing Process

- 16.8.6. Fiber Raw Material

- 16.8.7. Application

- 16.8.8. End Use Industry

- 16.9. Indonesia Carbon Fiber Composites Market

- 16.9.1. Country Segmental Analysis

- 16.9.2. Matrix Type

- 16.9.3. Fiber Type

- 16.9.4. Fiber Modulus

- 16.9.5. Manufacturing Process

- 16.9.6. Fiber Raw Material

- 16.9.7. Application

- 16.9.8. End Use Industry

- 16.10. Malaysia Carbon Fiber Composites Market

- 16.10.1. Country Segmental Analysis

- 16.10.2. Matrix Type

- 16.10.3. Fiber Type

- 16.10.4. Fiber Modulus

- 16.10.5. Manufacturing Process

- 16.10.6. Fiber Raw Material

- 16.10.7. Application

- 16.10.8. End Use Industry

- 16.11. Thailand Carbon Fiber Composites Market

- 16.11.1. Country Segmental Analysis

- 16.11.2. Matrix Type

- 16.11.3. Fiber Type

- 16.11.4. Fiber Modulus

- 16.11.5. Manufacturing Process

- 16.11.6. Fiber Raw Material

- 16.11.7. Application

- 16.11.8. End Use Industry

- 16.12. Vietnam Carbon Fiber Composites Market

- 16.12.1. Country Segmental Analysis

- 16.12.2. Matrix Type

- 16.12.3. Fiber Type

- 16.12.4. Fiber Modulus

- 16.12.5. Manufacturing Process

- 16.12.6. Fiber Raw Material

- 16.12.7. Application

- 16.12.8. End Use Industry

- 16.13. Rest of Asia Pacific Carbon Fiber Composites Market

- 16.13.1. Country Segmental Analysis

- 16.13.2. Matrix Type

- 16.13.3. Fiber Type

- 16.13.4. Fiber Modulus

- 16.13.5. Manufacturing Process

- 16.13.6. Fiber Raw Material

- 16.13.7. Application

- 16.13.8. End Use Industry

- 17. Middle East Carbon Fiber Composites Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Middle East Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 17.3.1. Matrix Type

- 17.3.2. Fiber Type

- 17.3.3. Fiber Modulus

- 17.3.4. Manufacturing Process

- 17.3.5. Fiber Raw Material

- 17.3.6. Application

- 17.3.7. End Use Industry

- 17.3.8. Country

- 17.3.8.1. Turkey

- 17.3.8.2. UAE

- 17.3.8.3. Saudi Arabia

- 17.3.8.4. Israel

- 17.3.8.5. Rest of Middle East

- 17.4. Turkey Carbon Fiber Composites Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Matrix Type

- 17.4.3. Fiber Type

- 17.4.4. Fiber Modulus

- 17.4.5. Manufacturing Process

- 17.4.6. Fiber Raw Material

- 17.4.7. Application

- 17.4.8. End Use Industry

- 17.5. UAE Carbon Fiber Composites Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Matrix Type

- 17.5.3. Fiber Type

- 17.5.4. Fiber Modulus

- 17.5.5. Manufacturing Process

- 17.5.6. Fiber Raw Material

- 17.5.7. Application

- 17.5.8. End Use Industry

- 17.6. Saudi Arabia Carbon Fiber Composites Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Matrix Type

- 17.6.3. Fiber Type

- 17.6.4. Fiber Modulus

- 17.6.5. Manufacturing Process

- 17.6.6. Fiber Raw Material

- 17.6.7. Application

- 17.6.8. End Use Industry

- 17.7. Israel Carbon Fiber Composites Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Matrix Type

- 17.7.3. Fiber Type

- 17.7.4. Fiber Modulus

- 17.7.5. Manufacturing Process

- 17.7.6. Fiber Raw Material

- 17.7.7. Application

- 17.7.8. End Use Industry

- 17.8. Rest of Middle East Carbon Fiber Composites Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Matrix Type

- 17.8.3. Fiber Type

- 17.8.4. Fiber Modulus

- 17.8.5. Manufacturing Process

- 17.8.6. Fiber Raw Material

- 17.8.7. Application

- 17.8.8. End Use Industry

- 18. Africa Carbon Fiber Composites Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Africa Carbon Fiber Composites Market Size (Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 18.3.1. Matrix Type

- 18.3.2. Fiber Type

- 18.3.3. Fiber Modulus

- 18.3.4. Manufacturing Process

- 18.3.5. Fiber Raw Material

- 18.3.6. Application

- 18.3.7. End Use Industry

- 18.3.8. Country

- 18.3.8.1. South Africa

- 18.3.8.2. Egypt

- 18.3.8.3. Nigeria

- 18.3.8.4. Algeria

- 18.3.8.5. Rest of Africa

- 18.4. South Africa Carbon Fiber Composites Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Matrix Type

- 18.4.3. Fiber Type

- 18.4.4. Fiber Modulus

- 18.4.5. Manufacturing Process

- 18.4.6. Fiber Raw Material

- 18.4.7. Application

- 18.4.8. End Use Industry

- 18.5. Egypt Carbon Fiber Composites Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Matrix Type

- 18.5.3. Fiber Type

- 18.5.4. Fiber Modulus

- 18.5.5. Manufacturing Process

- 18.5.6. Fiber Raw Material

- 18.5.7. Application

- 18.5.8. End Use Industry

- 18.6. Nigeria Carbon Fiber Composites Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Matrix Type

- 18.6.3. Fiber Type

- 18.6.4. Fiber Modulus

- 18.6.5. Manufacturing Process

- 18.6.6. Fiber Raw Material

- 18.6.7. Application

- 18.6.8. End Use Industry

- 18.7. Algeria Carbon Fiber Composites Market

- 18.7.1. Country Segmental Analysis

- 18.7.2. Matrix Type

- 18.7.3. Fiber Type

- 18.7.4. Fiber Modulus

- 18.7.5. Manufacturing Process

- 18.7.6. Fiber Raw Material

- 18.7.7. Application

- 18.7.8. End Use Industry

- 18.8. Rest of Africa Carbon Fiber Composites Market

- 18.8.1. Country Segmental Analysis

- 18.8.2. Matrix Type

- 18.8.3. Fiber Type

- 18.8.4. Fiber Modulus

- 18.8.5. Manufacturing Process

- 18.8.6. Fiber Raw Material

- 18.8.7. Application

- 18.8.8. End Use Industry

- 19. South America Carbon Fiber Composites Market Analysis

- 19.1. Key Segment Analysis

- 19.2. Regional Snapshot

- 19.3. Central and South Africa Carbon Fiber Composites Market Size ( Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 19.3.1. Matrix Type

- 19.3.2. Fiber Type

- 19.3.3. Fiber Modulus

- 19.3.4. Manufacturing Process

- 19.3.5. Fiber Raw Material

- 19.3.6. Application

- 19.3.7. End Use Industry

- 19.3.8. Country

- 19.3.8.1. Brazil

- 19.3.8.2. Argentina

- 19.3.8.3. Rest of South America

- 19.4. Brazil Carbon Fiber Composites Market

- 19.4.1. Country Segmental Analysis

- 19.4.2. Matrix Type

- 19.4.3. Fiber Type

- 19.4.4. Fiber Modulus

- 19.4.5. Manufacturing Process

- 19.4.6. Fiber Raw Material

- 19.4.7. Application

- 19.4.8. End Use Industry

- 19.5. Argentina Carbon Fiber Composites Market

- 19.5.1. Country Segmental Analysis

- 19.5.2. Matrix Type

- 19.5.3. Fiber Type

- 19.5.4. Fiber Modulus

- 19.5.5. Manufacturing Process

- 19.5.6. Fiber Raw Material

- 19.5.7. Application

- 19.5.8. End Use Industry

- 19.6. Rest of South America Carbon Fiber Composites Market

- 19.6.1. Country Segmental Analysis

- 19.6.2. Matrix Type

- 19.6.3. Fiber Type

- 19.6.4. Fiber Modulus

- 19.6.5. Manufacturing Process

- 19.6.6. Fiber Raw Material

- 19.6.7. Application

- 19.6.8. End Use Industry

- 20. Key Players/ Company Profile

- 20.1. BASF SE

- 20.1.1. Company Details/ Overview

- 20.1.2. Company Financials

- 20.1.3. Key Customers and Competitors

- 20.1.4. Business/ Industry Portfolio

- 20.1.5. Product Portfolio/ Specification Details

- 20.1.6. Pricing Data

- 20.1.7. Strategic Overview

- 20.1.8. Recent Developments

- 20.2. Carbon Composites GmbH

- 20.3. Cytec Solvay Group

- 20.4. DowAksa

- 20.5. Far Eastern New Century Corporation

- 20.6. Formosa Plastics Corporation

- 20.7. Gurit Holding AG

- 20.8. Hexcel Corporation

- 20.9. Hexion Inc.

- 20.10. Huntsman Corporation

- 20.11. Mitsubishi Chemical Holdings Corporation

- 20.12. National Composites

- 20.13. Owens Corning

- 20.14. PPG Industries

- 20.15. RTP Company

- 20.16. SGL Carbon SE

- 20.17. Solvay S.A.

- 20.18. Teijin Limited

- 20.19. Toray Industries, Inc.

- 20.20. Zhongtai International Holdings Ltd.

- 20.21. Other key Players

- 20.1. BASF SE

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

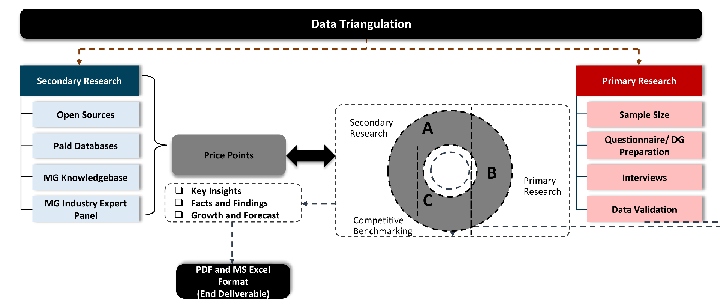

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation