CF & CFRP Market Size, Share, Growth Opportunity Analysis Report by Raw Material Type (Polyacrylonitrile (PAN)-based, Pitch-based, Rayon-based, Others), Resin Type, Form Type, Manufacturing Process, Modulus Grade, End-users, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

Market Structure & Evolution |

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

CF & CFRP Market Size, Share, and Growth

The global CF & CFRP market is experiencing robust growth, with its estimated value of USD 20.6 Billion in the year 2025 and USD 47.5 Billion by the period 2035, registering a CAGR of 8.7%. Europe leads the market with market share of 44% with USD 9.1 billion revenue.

Associated with a top tier aerospace consortium, engineers obtained a patent on a next generation thermoplastic CFRP composite patent, “Rapid-Cure Carbon Fiber Composite for Aerospace and Automotive Structures”. The material is designed to cure in less than two minutes and can be cured without an autoclave.

Increasingly, Carbon Fiber (CF) and Carbon Fiber Reinforced Polymer (CFRP) materials are essential material systems in the aerospace, automotive, construction, and energy industries due to their superior strength, weight characteristics, and durability. The markets for CF and CFRP are advancing based on results of better manufacturing techniques such as automated fiber placement (AFP) and resin transfer molding (RTM) that offer greater manufacturing efficiency and performance characteristics for the material itself.

An illustrative case can be observed in January of 2024, which was when Toray Industries introduced next-generation CFRP solutions featuring industry-leading resistance to damage from high-thermal exposure, and quality control systems utilizing AI integration for aerospace and automotive applications.

The last few years have seen significant push for next generation materials due to rapid industrialization, a shift towards lightweight and sustainable materials is making CF and CFRP into a strategic material system for manufacturers. The speed at which manufacturers are employing robotics and digital simulation into their composite fabrication in order to improve accuracy - while eliminating waste - is changing possibilities in-process and for future production.

Given that manufacturing grows, aerospace and automotive are still core sectors for growth, as manufacturers such as Hexcel, SGL Carbon, and Mitsubishi Chemical focus their attention on scalable and cost-effective production and recycling technologies.

CF & CFRP Market Dynamics and Trends

Drivers: Light-weighting the Future, CFRP at the Crossroads of Strength, Efficiency, and Sustainability

- Carbon fiber and CFRP (carbon fiber reinforced polymer) materials are becoming increasingly important to industries that require high strength, low weight, and enhanced energy efficiency. The demand for energy efficiency specifically reduced fuel consumption and emissions through lightweight materials has led to rapid adoption, particularly in aerospace and automotive markets.

- Electric vehicle (EV) manufacturers are commencing to use CFRPs as a way to improve battery range by reducing the structure's weight without compromising safety and durability. Wind turbine manufacturers are using CFRPs in the blades for stiffness and fatigue performance to capture maximum energy and reliability. New technologies are being introduced such as thermoplastic CFRP and recyclable resins to cure manufacturing bottlenecks in producing CFRP and will enable shorter waits and less cost in the entire process.

- Currently sustainability is becoming a market driver, the concept of designing scalable recycling processes for the future, like pyrolysis and chemical breakdown processes, is also being investigated. CFRP, once considered an expensive low demand niche product, is fast becoming a "must have" product with a playbook for needed performance, efficiency, and meeting the triple bottom line with a sustainable focus

Restraints: High Production Costs, Energy Intensity, and Recycling Challenges Hinder CFRP Mass Adoption

- The carbon fiber and CFRP (Carbon Fiber Reinforced Polymer) industry is growing, though a number of key restraints will ultimately hold growth back and ultimately keep the industry from reaching full commercial maturity. The restraints of the industry can be explained from several angles. The primary and most apparent restraint is the cost of production.

-

Carbon fibers are made from precursors that are costly, including polyacrylonitrile (PAN), and the carbonization process is also energy intense. All of these factors ultimately serve as significant economic barriers to companies with price sensitive structures, which is why CFRPs are largely restricted to high-value use sectors such as aerospace and high performance automotive.

- Another significant challenge facing the industry, while many companies express the need for sustainability and carbon footprints, the industry has not yet adopted any truly scalable recycling processes. Given a rise in demand for sustainable material applications, organic carbon fiber composite materials can be tricky to recycle. CFRPs are composites which really mean they are being held together by a method other than melting and reforming a single material.

Opportunity: Surging Demand for Lightweight, High-Performance Materials across Mobility, Energy, and Infrastructure Sectors

- The carbon fiber and CFRP market is primed to benefit from the global transition toward lighter, stronger, and more sustainable material. Demand from EVs, aerospace, and wind energy are creating additional growth opportunities, especially in energy efficiency and emissions reduction; key drivers for these sectors.

- Simultaneously, innovations in recyclable CFRP composites and low-cost carbon fiber CA precursors are not only lowering the barriers of entry and accelerating demand; infrastructures, sporting goods, and consumer electronics are now expanding the use of CFRPs; opening up opportunities for market penetration well beyond aerospace and defense applications.

Key Trend: Rising Use of Recyclable Composites and Thermoplastic CFRPs Drives Sustainable Innovation across Mobility and Energy Sectors

- The CFRP market has rapidly shifted towards recyclability and adaptable design. Thus, in order to respond to this development, manufacturers are concentrating on thermoplastic CFRP's and recyclable resin systems that lessen manufacturing ability and allow for easier reprocessing at end-of-life biomass a bonus in automotive, aerospace, and wind.

- Furthermore, with the pressure continuing for markets to offer light-weight and energy-efficient strategies for designing products, demand for the CFRP market continues. Demand is also being met with the shift towards automation, and digital fabrication systems that continue to decrease manufacturing costs and sustainably provide mass production.

CF & CFRP Market Analysis and Segmental Data

Based on End-users, Aerospace & Defense holds the largest share

- Carbon fiber (CF) and carbon fiber reinforced plastics (CFRP) are being utilized by the aerospace and defense industries more than any other industry because of the many important advantages these materials deliver to meet the industry's needs.

- Furthermore, according to the U.S. Department of Energy, carbon fiber is selected for its low density (low weight) and because it allows for light weight vehicles and aircraft (in terms of weight-to-strength ratio), which permits reduced fuel consumption and better performance - critical considerations for both commercial and military aircraft.

- NASA and other federal groups point out those carbon fiber composites enhance structural efficiency. Carbon fiber products also lessen maintenance costs because of their improved corrosion resistance. Scientific ownership also reinforces the fact that CFRPs are extensively utilized in modern aircraft structures (facade, wing, interior components, etc.) specifically used because of the significant weight reductions and improved durability.

Europe Dominates Global CF & CFRP Market in 2025 and beyond

- There are several causes for Europe's leadership in the carbon fiber (CF) and carbon fiber reinforced polymer (CFRP) industry. High demand for advanced composite materials results from the presence of major aerospace and automotive original manufacturers, including Airbus and BMW, who employ CFRP to produce lighter and more fuel-efficient cars and aircraft.

- In parallel, European politicians are equally keen to advance CF and CFRP through support and incubating innovation and sustainability initiatives. Regional policies like the EU Emissions Trading System and the EU Circular Economy Action Plan all gesture towards the need for industry to utilize advanced lightweight materials that would help reduce carbon emissions.

- Moreover, the investment into research and development and upwards of a billion euros in various EU segment funding programs to develop CF and CFRP manufacturing and recycling further solidifies Europe’s commercial and technical leadership in the world.

CF & CFRP Market Ecosystem

The global CF & CFRP market shows high consolidation. Tier 1 firms such as Toray Industries, Teijin, Mitsubishi Chemical, Hexcel, and SGL Carbon, will produce the majority of CF and CFRP output, and utilize vertical integration and R&D leverage. Tier 2 and Tier 3 firms (e.g., Cytec, DowAksa, Formosa, Solvay, Gurit, and so on) exist within unstructured segements or as regional players. Buyer concentration is high, especially amongst aerospace and automotive OEMs who have significant leverage. Supplier concentration is moderate to high since the products come from a small number of vertically integrated carbon-fiber producers.

Recent Development and Strategic Overview:

- In July 2025, Teijin Limited established a state-of-the-art carbon fiber manufacturing facility in Japan's Tokuyama plant to meet the increasing demand for lightweight and sturdy materials. With 25% reduced energy usage and an advanced low-emission stabilization technique, the new line dramatically lowers CO₂ emissions. Specializing in CFRP applications for automotive and aerospace industries, the plant creates next-generation fiber with enhanced durability and recyclability.

- In June 2025, Mitsubishi Chemical Group launched an advanced CFRP manufacturing facility in Nagoya meant to boost sustainable composite materials for industrial automation, mobility, and wind energy applications. Integrating recycling systems for offcuts and end-of-life components, the plant boasts a high-throughput, energy-optimized method that reduces manufacturing emissions by 30%. Mitsubishi's new factory increases the availability of green CFRP solutions by concentrating on lightweight construction and circular economy techniques.

Report Scope

|

Attribute |

Detail |

|

Market Size in 2025 |

USD 20.6 Bn |

|

Market Forecast Value in 2035 |

USD 47.5 Bn |

|

Growth Rate (CAGR) |

8.7% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

USD Bn for Value Kilo Tons for Volume |

|

Report Format |

Electronic (PDF) + Excel |

|

Regions and Countries Covered |

|||||

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

CF & CFRP Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Raw Material Type |

|

|

By Resin Type |

|

|

By Form Type |

|

|

By Manufacturing Process |

|

|

By Modulus Grade |

|

|

By End-users |

|

Frequently Asked Questions

The global CF & CFRP market was valued at USD 20.6 Bn in 2025.

The global CF & CFRP market industry is expected to grow at a CAGR of 8.7% from 2025 to 2035.

Demand for CF and CFRP is driven by their lightweight strength, aiding fuel efficiency. Growth in aerospace, automotive, and wind energy boosts usage.

Aerospace & Defense, with nearly 40% of the total CF & CFRP market, contributed the largest share of the business in 2025.

Europe is anticipated to be the most for CF & CFRP market vendors.

Key players operating in the CF & CFRP market include A&P Technology, Bally Ribbon Mills, Cytec Industries, DowAksa, Formosa Plastics Corporation, Gurit Holding AG, Hexcel Corporation, Hyosung Advanced Materials, Mitsubishi Chemical Group, Nippon Graphite Fiber Corporation, Park Aerospace Corp., SGL Carbon, Solvay S.A., TCR Composites Inc., Teijin Limited, Toho Tenax Co. Ltd., Toray Industries Inc., Zoltek Corporation, and other key players, along with several other key players.

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global CF & CFRP Market Outlook

- 2.1.1. Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global CF & CFRP Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. CF & CFRP Industry Overview, 2024

- 3.1.1. Chemicals & Materials Industry Ecosystem Analysis

- 3.1.2. Key Trends for Chemicals & Materials Industry

- 3.1.3. Regional Distribution for Chemicals & Materials Industry

- 3.2. Supplier Customer Data

- 3.3. Source Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2024

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.6. Raw Material Analysis

- 3.1. CF & CFRP Industry Overview, 2024

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Light-weighting the Future, CFRP at the Crossroads of Strength, Efficiency, and Sustainability

- 4.1.2. Restraints

- 4.1.2.1. High Production Costs, Energy Intensity, and Recycling Challenges Hinder CFRP Mass Adoption

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Raw Material Sourcing

- 4.4.2. Processing

- 4.4.3. Wholesalers/ E-commerce Platform

- 4.4.4. End-use/ Customers

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Pricing Analysis

- 4.6.1. Regional Pricing Analysis

- 4.6.2. Segmental Pricing Trends

- 4.6.3. Factors Influencing Pricing

- 4.7. Porter’s Five Forces Analysis

- 4.8. PESTEL Analysis

- 4.9. Global CF & CFRP Market Demand

- 4.9.1. Historical Market Size - (Volume - Kilo Tons and Value - USD Bn), 2021-2024

- 4.9.2. Current and Future Market Size - (Volume - Kilo Tons and Value - USD Bn), 2025–2035

- 4.9.2.1. Y-o-Y Growth Trends

- 4.9.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2024

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global CF & CFRP Market Analysis, by Raw Material Type

- 6.1. Key Segment Analysis

- 6.2. Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, by Raw Material Type, 2021-2035

- 6.2.1. Polyacrylonitrile (PAN)-based

- 6.2.2. Pitch-based

- 6.2.3. Rayon-based

- 6.2.4. Others

- 7. Global CF & CFRP Market Analysis, by Resin Type

- 7.1. Key Segment Analysis

- 7.2. Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, by Resin Type, 2021-2035

- 7.2.1. Epoxy Resin

- 7.2.2. Polyester Resin

- 7.2.3. Vinyl Ester Resin

- 7.2.4. Polyether Ether Ketone (PEEK)

- 7.2.5. Polyamide

- 7.2.6. Phenolic Resin

- 7.2.7. Others

- 8. Global CF & CFRP Market Analysis, by Form Type

- 8.1. Key Segment Analysis

- 8.2. Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, by Form Type, 2021-2035

- 8.2.1. Continuous Carbon Fiber

- 8.2.2. Chopped Carbon Fiber

- 8.2.3. Woven Fabric

- 8.2.4. Prepreg

- 8.2.5. Tow

- 8.2.6. Mat

- 8.2.7. Others

- 9. Global CF & CFRP Market Analysis, by Manufacturing Process

- 9.1. Key Segment Analysis

- 9.2. Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, by Manufacturing Process, 2021-2035

- 9.2.1. Lay-up Process

- 9.2.2. Filament Winding

- 9.2.3. Resin Transfer Molding (RTM)

- 9.2.4. Pultrusion

- 9.2.5. Compression Molding

- 9.2.6. Injection Molding

- 9.2.7. Autoclave Processing

- 9.2.8. Others

- 10. Global CF & CFRP Market Analysis, by Modulus Grade

- 10.1. Key Segment Analysis

- 10.2. Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, by Modulus Grade, 2021-2035

- 10.2.1. Standard

- 10.2.2. Intermediate

- 10.2.3. High

- 10.2.4. Ultra-high

- 11. Global CF & CFRP Market Analysis, by End-users

- 11.1. Key Segment Analysis

- 11.2. Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, by End-users, 2021-2035

- 11.2.1. Aerospace & Defense

- 11.2.1.1. Aircraft Wings & Fuselage

- 11.2.1.2. Engine Components

- 11.2.1.3. Military Drones

- 11.2.1.4. Satellite Structures

- 11.2.1.5. Others

- 11.2.2. Automotive & Transportation

- 11.2.2.1. Body Panels

- 11.2.2.2. Chassis Components

- 11.2.2.3. Crash Management Systems

- 11.2.2.4. Interior Trims

- 11.2.2.5. Others

- 11.2.3. Wind Energy

- 11.2.3.1. Wind Turbine Blades

- 11.2.3.2. Nacelle Covers

- 11.2.3.3. Spar Caps

- 11.2.3.4. Others

- 11.2.4. Industrial & Manufacturing

- 11.2.4.1. Pressure Vessels

- 11.2.4.2. Robot Arms

- 11.2.4.3. Rollers & Shafts

- 11.2.4.4. Drive Shafts

- 11.2.4.5. Others

- 11.2.5. Marine

- 11.2.5.1. Boat Hulls

- 11.2.5.2. Yacht Masts

- 11.2.5.3. Propeller Blades

- 11.2.5.4. Others

- 11.2.6. Sports & Leisure

- 11.2.6.1. Bicycle Frames

- 11.2.6.2. Tennis Rackets

- 11.2.6.3. Golf Clubs

- 11.2.6.4. Skis and Snowboards

- 11.2.6.5. Others

- 11.2.7. Construction & Infrastructure

- 11.2.7.1. Bridge Cables

- 11.2.7.2. Reinforcement Strips

- 11.2.7.3. Seismic Retrofitting Panels

- 11.2.7.4. Others

- 11.2.8. Medical

- 11.2.8.1. Imaging Equipment

- 11.2.8.2. Prosthetics

- 11.2.8.3. Surgical Tools

- 11.2.8.4. Others

- 11.2.9. Electronics

- 11.2.9.1. EMI/RFI Shielding Enclosures

- 11.2.9.2. Mobile Device Casings

- 11.2.9.3. Printed Circuit Boards (PCBs)

- 11.2.9.4. Others

- 11.2.10. Other End-users

- 11.2.1. Aerospace & Defense

- 12. Global CF & CFRP Market Analysis and Forecasts, by Region

- 12.1. Key Findings

- 12.2. Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, by Region, 2021-2035

- 12.2.1. North America

- 12.2.2. Europe

- 12.2.3. Asia Pacific

- 12.2.4. Middle East

- 12.2.5. Africa

- 12.2.6. South America

- 13. North America Global CF & CFRP Market Analysis

- 13.1. Key Segment Analysis

- 13.2. Regional Snapshot

- 13.3. North America Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 13.3.1. Raw Material Type

- 13.3.2. Resin Type

- 13.3.3. Form Type

- 13.3.4. Manufacturing Process

- 13.3.5. Modulus Grade

- 13.3.6. End-users

- 13.3.7. Country

- 13.3.7.1. USA

- 13.3.7.2. Canada

- 13.3.7.3. Mexico

- 13.4. USA Global CF & CFRP Market

- 13.4.1. Country Segmental Analysis

- 13.4.2. Raw Material Type

- 13.4.3. Resin Type

- 13.4.4. Form Type

- 13.4.5. Manufacturing Process

- 13.4.6. Modulus Grade

- 13.4.7. End-users

- 13.5. Canada Global CF & CFRP Market

- 13.5.1. Country Segmental Analysis

- 13.5.2. Raw Material Type

- 13.5.3. Resin Type

- 13.5.4. Form Type

- 13.5.5. Manufacturing Process

- 13.5.6. Modulus Grade

- 13.5.7. End-users

- 13.6. Mexico Global CF & CFRP Market

- 13.6.1. Country Segmental Analysis

- 13.6.2. Raw Material Type

- 13.6.3. Resin Type

- 13.6.4. Form Type

- 13.6.5. Manufacturing Process

- 13.6.6. Modulus Grade

- 13.6.7. End-users

- 14. Europe Global CF & CFRP Market Analysis

- 14.1. Key Segment Analysis

- 14.2. Regional Snapshot

- 14.3. Europe Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 14.3.1. Raw Material Type

- 14.3.2. Resin Type

- 14.3.3. Form Type

- 14.3.4. Manufacturing Process

- 14.3.5. Modulus Grade

- 14.3.6. End-users

- 14.3.7. Country

- 14.3.7.1. Germany

- 14.3.7.2. United Kingdom

- 14.3.7.3. France

- 14.3.7.4. Italy

- 14.3.7.5. Spain

- 14.3.7.6. Netherlands

- 14.3.7.7. Nordic Countries

- 14.3.7.8. Poland

- 14.3.7.9. Russia & CIS

- 14.3.7.10. Rest of Europe

- 14.4. Germany Global CF & CFRP Market

- 14.4.1. Country Segmental Analysis

- 14.4.2. Raw Material Type

- 14.4.3. Resin Type

- 14.4.4. Form Type

- 14.4.5. Manufacturing Process

- 14.4.6. Modulus Grade

- 14.4.7. End-users

- 14.5. United Kingdom Global CF & CFRP Market

- 14.5.1. Country Segmental Analysis

- 14.5.2. Raw Material Type

- 14.5.3. Resin Type

- 14.5.4. Form Type

- 14.5.5. Manufacturing Process

- 14.5.6. Modulus Grade

- 14.5.7. End-users

- 14.6. France Global CF & CFRP Market

- 14.6.1. Country Segmental Analysis

- 14.6.2. Raw Material Type

- 14.6.3. Resin Type

- 14.6.4. Form Type

- 14.6.5. Manufacturing Process

- 14.6.6. Modulus Grade

- 14.6.7. End-users

- 14.7. Italy Global CF & CFRP Market

- 14.7.1. Country Segmental Analysis

- 14.7.2. Raw Material Type

- 14.7.3. Resin Type

- 14.7.4. Form Type

- 14.7.5. Manufacturing Process

- 14.7.6. Modulus Grade

- 14.7.7. End-users

- 14.8. Spain Global CF & CFRP Market

- 14.8.1. Country Segmental Analysis

- 14.8.2. Raw Material Type

- 14.8.3. Resin Type

- 14.8.4. Form Type

- 14.8.5. Manufacturing Process

- 14.8.6. Modulus Grade

- 14.8.7. End-users

- 14.9. Netherlands Global CF & CFRP Market

- 14.9.1. Country Segmental Analysis

- 14.9.2. Raw Material Type

- 14.9.3. Resin Type

- 14.9.4. Form Type

- 14.9.5. Manufacturing Process

- 14.9.6. Modulus Grade

- 14.9.7. End-users

- 14.10. Nordic Countries Global CF & CFRP Market

- 14.10.1. Country Segmental Analysis

- 14.10.2. Raw Material Type

- 14.10.3. Resin Type

- 14.10.4. Form Type

- 14.10.5. Manufacturing Process

- 14.10.6. Modulus Grade

- 14.10.7. End-users

- 14.11. Poland Global CF & CFRP Market

- 14.11.1. Country Segmental Analysis

- 14.11.2. Raw Material Type

- 14.11.3. Resin Type

- 14.11.4. Form Type

- 14.11.5. Manufacturing Process

- 14.11.6. Modulus Grade

- 14.11.7. End-users

- 14.12. Russia & CIS Global CF & CFRP Market

- 14.12.1. Country Segmental Analysis

- 14.12.2. Raw Material Type

- 14.12.3. Resin Type

- 14.12.4. Form Type

- 14.12.5. Manufacturing Process

- 14.12.6. Modulus Grade

- 14.12.7. End-users

- 14.13. Rest of Europe Global CF & CFRP Market

- 14.13.1. Country Segmental Analysis

- 14.13.2. Raw Material Type

- 14.13.3. Resin Type

- 14.13.4. Form Type

- 14.13.5. Manufacturing Process

- 14.13.6. Modulus Grade

- 14.13.7. End-users

- 15. Asia Pacific Global CF & CFRP Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. East Asia Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 15.3.1. Raw Material Type

- 15.3.2. Resin Type

- 15.3.3. Form Type

- 15.3.4. Manufacturing Process

- 15.3.5. Modulus Grade

- 15.3.6. End-users

- 15.3.7. Country

- 15.3.7.1. China

- 15.3.7.2. India

- 15.3.7.3. Japan

- 15.3.7.4. South Korea

- 15.3.7.5. Australia and New Zealand

- 15.3.7.6. Indonesia

- 15.3.7.7. Malaysia

- 15.3.7.8. Thailand

- 15.3.7.9. Vietnam

- 15.3.7.10. Rest of Asia-Pacific

- 15.4. China Global CF & CFRP Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Raw Material Type

- 15.4.3. Resin Type

- 15.4.4. Form Type

- 15.4.5. Manufacturing Process

- 15.4.6. Modulus Grade

- 15.4.7. End-users

- 15.5. India Global CF & CFRP Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Raw Material Type

- 15.5.3. Resin Type

- 15.5.4. Form Type

- 15.5.5. Manufacturing Process

- 15.5.6. Modulus Grade

- 15.5.7. End-users

- 15.6. Japan Global CF & CFRP Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Raw Material Type

- 15.6.3. Resin Type

- 15.6.4. Form Type

- 15.6.5. Manufacturing Process

- 15.6.6. Modulus Grade

- 15.6.7. End-users

- 15.7. South Korea Global CF & CFRP Market

- 15.7.1. Country Segmental Analysis

- 15.7.2. Raw Material Type

- 15.7.3. Resin Type

- 15.7.4. Form Type

- 15.7.5. Manufacturing Process

- 15.7.6. Modulus Grade

- 15.7.7. End-users

- 15.8. Australia and New Zealand Global CF & CFRP Market

- 15.8.1. Country Segmental Analysis

- 15.8.2. Raw Material Type

- 15.8.3. Resin Type

- 15.8.4. Form Type

- 15.8.5. Manufacturing Process

- 15.8.6. Modulus Grade

- 15.8.7. End-users

- 15.9. Indonesia Global CF & CFRP Market

- 15.9.1. Country Segmental Analysis

- 15.9.2. Raw Material Type

- 15.9.3. Resin Type

- 15.9.4. Form Type

- 15.9.5. Manufacturing Process

- 15.9.6. Modulus Grade

- 15.9.7. End-users

- 15.10. Malaysia Global CF & CFRP Market

- 15.10.1. Country Segmental Analysis

- 15.10.2. Raw Material Type

- 15.10.3. Resin Type

- 15.10.4. Form Type

- 15.10.5. Manufacturing Process

- 15.10.6. Modulus Grade

- 15.10.7. End-users

- 15.11. Thailand Global CF & CFRP Market

- 15.11.1. Country Segmental Analysis

- 15.11.2. Raw Material Type

- 15.11.3. Resin Type

- 15.11.4. Form Type

- 15.11.5. Manufacturing Process

- 15.11.6. Modulus Grade

- 15.11.7. End-users

- 15.12. Vietnam Global CF & CFRP Market

- 15.12.1. Country Segmental Analysis

- 15.12.2. Raw Material Type

- 15.12.3. Resin Type

- 15.12.4. Form Type

- 15.12.5. Manufacturing Process

- 15.12.6. Modulus Grade

- 15.12.7. End-users

- 15.13. Rest of Asia Pacific Global CF & CFRP Market

- 15.13.1. Country Segmental Analysis

- 15.13.2. Raw Material Type

- 15.13.3. Resin Type

- 15.13.4. Form Type

- 15.13.5. Manufacturing Process

- 15.13.6. Modulus Grade

- 15.13.7. End-users

- 16. Middle East Global CF & CFRP Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Middle East Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 16.3.1. Raw Material Type

- 16.3.2. Resin Type

- 16.3.3. Form Type

- 16.3.4. Manufacturing Process

- 16.3.5. Modulus Grade

- 16.3.6. End-users

- 16.3.7. Country

- 16.3.7.1. Turkey

- 16.3.7.2. UAE

- 16.3.7.3. Saudi Arabia

- 16.3.7.4. Israel

- 16.3.7.5. Rest of Middle East

- 16.4. Turkey Global CF & CFRP Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Raw Material Type

- 16.4.3. Resin Type

- 16.4.4. Form Type

- 16.4.5. Manufacturing Process

- 16.4.6. Modulus Grade

- 16.4.7. End-users

- 16.5. UAE Global CF & CFRP Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Raw Material Type

- 16.5.3. Resin Type

- 16.5.4. Form Type

- 16.5.5. Manufacturing Process

- 16.5.6. Modulus Grade

- 16.5.7. End-users

- 16.6. Saudi Arabia Global CF & CFRP Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Raw Material Type

- 16.6.3. Resin Type

- 16.6.4. Form Type

- 16.6.5. Manufacturing Process

- 16.6.6. Modulus Grade

- 16.6.7. End-users

- 16.7. Israel Global CF & CFRP Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Raw Material Type

- 16.7.3. Resin Type

- 16.7.4. Form Type

- 16.7.5. Manufacturing Process

- 16.7.6. Modulus Grade

- 16.7.7. End-users

- 16.8. Rest of Middle East Global CF & CFRP Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Raw Material Type

- 16.8.3. Resin Type

- 16.8.4. Form Type

- 16.8.5. Manufacturing Process

- 16.8.6. Modulus Grade

- 16.8.7. End-users

- 17. Africa Global CF & CFRP Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Africa Global CF & CFRP Market Size (Volume - Kilo Tons and Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 17.3.1. Raw Material Type

- 17.3.2. Resin Type

- 17.3.3. Form Type

- 17.3.4. Manufacturing Process

- 17.3.5. Modulus Grade

- 17.3.6. End-users

- 17.3.7. Country

- 17.3.7.1. South Africa

- 17.3.7.2. Egypt

- 17.3.7.3. Nigeria

- 17.3.7.4. Algeria

- 17.3.7.5. Rest of Africa

- 17.4. South Africa Global CF & CFRP Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Raw Material Type

- 17.4.3. Resin Type

- 17.4.4. Form Type

- 17.4.5. Manufacturing Process

- 17.4.6. Modulus Grade

- 17.4.7. End-users

- 17.5. Egypt Global CF & CFRP Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Raw Material Type

- 17.5.3. Resin Type

- 17.5.4. Form Type

- 17.5.5. Manufacturing Process

- 17.5.6. Modulus Grade

- 17.5.7. End-users

- 17.6. Nigeria Global CF & CFRP Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Raw Material Type

- 17.6.3. Resin Type

- 17.6.4. Form Type

- 17.6.5. Manufacturing Process

- 17.6.6. Modulus Grade

- 17.6.7. End-users

- 17.7. Algeria Global CF & CFRP Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Raw Material Type

- 17.7.3. Resin Type

- 17.7.4. Form Type

- 17.7.5. Manufacturing Process

- 17.7.6. Modulus Grade

- 17.7.7. End-users

- 17.8. Rest of Africa Global CF & CFRP Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Raw Material Type

- 17.8.3. Resin Type

- 17.8.4. Form Type

- 17.8.5. Manufacturing Process

- 17.8.6. Modulus Grade

- 17.8.7. End-users

- 18. South America Global CF & CFRP Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Central and South Africa Global CF & CFRP Market Size ( Value - US$ Billion), Analysis, and Forecasts, 2021-2035

- 18.3.1. Raw Material Type

- 18.3.2. Resin Type

- 18.3.3. Form Type

- 18.3.4. Manufacturing Process

- 18.3.5. Modulus Grade

- 18.3.6. End-users

- 18.3.7. Country

- 18.3.7.1. Brazil

- 18.3.7.2. Argentina

- 18.3.7.3. Rest of South America

- 18.4. Brazil Global CF & CFRP Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Raw Material Type

- 18.4.3. Resin Type

- 18.4.4. Form Type

- 18.4.5. Manufacturing Process

- 18.4.6. Modulus Grade

- 18.4.7. End-users

- 18.5. Argentina Global CF & CFRP Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Raw Material Type

- 18.5.3. Resin Type

- 18.5.4. Form Type

- 18.5.5. Manufacturing Process

- 18.5.6. Modulus Grade

- 18.5.7. End-users

- 18.6. Rest of South America Global CF & CFRP Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Raw Material Type

- 18.6.3. Resin Type

- 18.6.4. Form Type

- 18.6.5. Manufacturing Process

- 18.6.6. Modulus Grade

- 18.6.7. End-users

- 19. Key Players/ Company Profile

- 19.1. A&P Technology

- 19.1.1. Company Details/ Overview

- 19.1.2. Company Financials

- 19.1.3. Key Customers and Competitors

- 19.1.4. Business/ Industry Portfolio

- 19.1.5. Product Portfolio/ Specification Details

- 19.1.6. Pricing Data

- 19.1.7. Strategic Overview

- 19.1.8. Recent Developments

- 19.2. Bally Ribbon Mills

- 19.3. Cytec Industries

- 19.4. DowAksa

- 19.5. Formosa Plastics Corporation

- 19.6. Gurit Holding AG

- 19.7. Hexcel Corporation

- 19.8. Hyosung Advanced Materials

- 19.9. Mitsubishi Chemical Group

- 19.10. Nippon Graphite Fiber Corporation

- 19.11. Park Aerospace Corp.

- 19.12. SGL Carbon

- 19.13. Solvay S.A.

- 19.14. TCR Composites Inc.

- 19.15. Teijin Limited

- 19.16. Toho Tenax Co. Ltd.

- 19.17. Toray Industries Inc.

- 19.18. Zoltek Corporation

- 19.19. Other Key Players

- 19.1. A&P Technology

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

petitive Landscape & Key Players

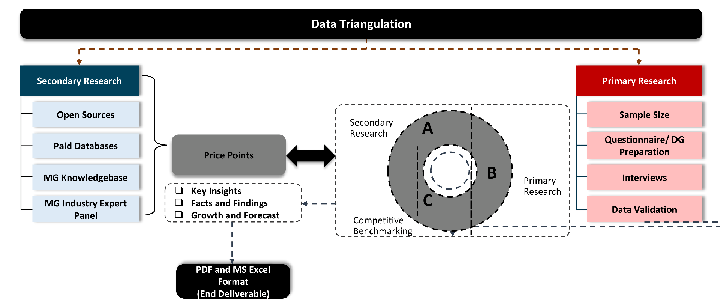

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase and Others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players product portfolio

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources includes primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data