EPDM Market Size, Share, Growth Opportunity Analysis Report by Product Type / Composition (Standard EPDM, High Ethylene EPDM, High Ethylene/High Mooney EPDM and Others), Diene Monomer Type, Formulation/ Grade, Packaging Format, Sales Channel, End Use Industry X Application, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

Market Structure & Evolution |

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

EPDM Market Size, Share, and Growth

The global EPDM Market is projected to grow from USD 4.4 Billion in 2025 to USD 7.9 Billion by 2035, with a strong CAGR of 6.0% during the forecast period. The market growth is fueled by growing demand from automotive, construction and renewable-energy industries. EPDM’s superior resistance to heat, ozone, and weathering makes it a preferred material for sealing, roofing membranes, and industrial insulation.

In March 2025, Freudenberg Sealing Technologies has unveiled its new 70 EPDM 335DW compound for O-rings. The new material protects health and the environment, having been designed to meet stringent drinking water application requirements. “The compound demonstrates good ageing resistance and is suitable for drinking and process water, hot water, superheated steam, and silicone oils,” said Klaus Schmieder, Segment Manager at Freudenberg Sealing Technologies.

For Instance, in 2024, Lanxess introduced a new high-performance peroxide-cured EPDM grade with enhanced thermal stability and extended service life for applications within electric vehicle components and solar energy infrastructure. This development is in line with the increasing demand for a robust material solution from energy efficient and environmentally friendly point of view.

Demand is also driven by increase in EV adoption and infrastructure investment in green building projects. Furthermore, the development of bio-based EPDM made from renewable feedstocks is further allowing manufacturers to comply with the requirements of both performance and sustainability, reshaping the way in which elastomers are being produced.

EPDM Market Dynamics and Trends

Driver: Expansion of Electric Vehicles (EVs) and Green Building Projects

- The emerging EV market is increasing the demand for EPDM in automotive sealing, gaskets, and weatherproofing. For instance, Tesla’s utilization of advanced EPDM seals in the Model Y has raised thermal insulation and reduced cabin noise, while fueling performance and sustainability aspirations. Producers have a longer-lasting material, supporting lightweighting and energy efficiency, requirements for EV performance optimization.

- EPDM roofing membranes are being specified in green building and solar energy projects due to durability, weather resistance, and sustainability. For instance, in 2025, Carlisle introduced its Sure‑Tough EPDM membrane containing post-consumer recycled content, designed to support sustainable rooftops integrated with solar panel systems.

- This enables construction companies to fulfill the green certification requirement, in conjunction with establishing a long-term low maintenance solution.

Restraint: Volatility in Ethylene and Propylene Feedstock Prices Increasing Manufacturing Costs

- There is a major constraint to EPDM producers due to fluctuations in the price of naphtha/crude oil and supply-chain disruptions in their region because of variability in the price of ethylene and propylene as feedstocks. The dynamics of feedstock costs have a direct impact on EPDM margins due to the large portion of upstream material cost being paid as monomers.

- With a spike in petrochemical feedstocks producers absorb margin pressure or transfer the cost to the buyers either of which can reduce demand in price sensitive downstream markets like the construction or consumer goods market. Further, regional imbalances (e.g. tightness in Asia or disruptions in the Gulf supply) will require either expensive spot buying or restricted output.

- This volatility makes it hard to contract long-term and capitalize on capacity expansions and makes some manufacturers postpone projects or hedge with long-term monomer contracts, which can make them less flexible.

Opportunity: Expansion into Low-carbon and Recycled EPDM for Sustainable Applications Markets

- A promising possibility is low-carbon and recycled EPDM solutions, which address the sustainability of businesses and the urgency to reduce the lifecycle emissions. Manufacturers and chemical recyclers are testing depolymerization and devulcanization pathways to recover EPDM or blend PCR (post-consumer rubber) with virgin polymer, producing lower-carbon compound solutions to use in automotive and building applications.

- Enhanced supply chains of proven supply of green EPDM grades that have a reduced embodied carbon content and enhanced end of life attributes can be achieved through strategic partnerships between polymer manufacturers, compounders and recyclers. This provides OEMs with a value in the need to show a scope-3 reduction in emissions without compromising on performance.

- Recycled and low-carbon EPDM is a high-value growth opportunity, which can meet the sustainability procurement and regulatory goals.

Key Trend: Advanced Polymerization Technologies Improving EPDM Performance and Production Efficiency Worldwide

- One of the trends is the use of sophisticated polymerization technologies and catalyst systems to allow tighter control of molecular architecture, finer molecular weight distribution and specific diene incorporation - providing EPDM grades with better processability, heat resistance and dynamic properties. Contemporary gas-phase and solution polymerization systems as well as metallocene and Ziegler -Natta catalyst improvements permit manufacturers to tailor properties to applications (e.g. high-flow extrusion grades into weatherstrips, high-molar-mass grades into tough roofing membranes).

- Such technological advancements amplify yields in the reactor, decrease cycle time and minimize unreacted monomer residuals, enhance the cost structure and environmental performance. The process of continuous control by investing in digital twins and sophisticated analytics helps in even greater improvement in throughput and consistency of quality of operations across multi-sites.

- The EPDM performance ceilings and production efficiency are increased by technological advances in polymerization and process control, which is accelerating its adoption in end-use applications that are demanding.

EPDM Market Analysis and Segmental Data

Automotive Applications Driving Strongest Demand in Global EPDM Market

- The automotive sub-segment dominates the EPDM market because of its wide application in sealing systems, weatherstrip, hose, and vibration-damping parts, which are more durable, flexible, and resistant to heat, UV, and weather. The use of EPDM is getting stronger with the automakers moving more towards lightweight, high-performance materials that will lead to increased efficiency and durability of the vehicles. An example is Continental AG that has increased its EPDM based sealing solutions to serve electric vehicles to enhance performance under stressful conditions and sustainability.

- Moreover, the quick increase of the electric and hybrid cars increases the need of EPDM due to the fact that it offers insulation and sealing that is essential in battery packs and other electric components. Manufacturers, such as Sumitomo Chemical, have increased the production of EPDM to serve automotive customers in Asia to support the growing demand of EV in China and India.

- This solidifies automotive as the quickest expanding end-use sub-section all over the world.

Asia Pacific Dominates Global EPDM Demand with Expanding Industrial Base

- Asia Pacific contributes the most to EPDM demand because of the fast industrialization, automotive production, and construction projects that are facilitated by urbanization and infrastructure development. The increase in the use of EPDM in waterproofing membranes, seals and gaskets has made the region a strategic consumer market. South Korea has exhibited an increase in regional capacity as Kumho Petrochemical increased its EPDM manufacturing plant in South Korea to satisfy the rising demand in automotive and building material sectors.

- Moreover, the growing trend of electric mobility and renewable energy initiatives in China, India and Southeast Asia impetus consumption of EPDM in battery insulation, cable coverings and sealing systems. Firms such as Mitsui chemicals have increased the EPDM offering to serve these industries and this strengthens the leadership of Asia Pacific.

- The industrial and automotive trend in Asia Pacific makes it the leader in the global EPDM market.

EPDM Market Ecosystem

The global EPDM market reflects a highly consolidated structure, with Tier 1 players such as ExxonMobil Chemical, Dow Inc., Lanxess AG, Chevron Phillips Chemical Company, and Kumho Petrochemical holding dominant capacities, while Tier 2 and Tier 3 participants, including regional firms like Jiangsu Sailboat Petrochemical and Repsol Química, enhance localized supply. The market concentration favors large-scale producers with integrated petrochemical operations, enabling cost efficiencies. From a Porter’s Five Forces perspective, buyer concentration remains moderate due to diversified end-use industries, whereas supplier concentration is relatively high, driven by dependence on major petrochemical giants.

Recent Developments and Strategic Overview

- In May 2025, Holcim’s Elevate Group announced a global rollout of RubberGard EPDM membranes optimized for solar‑ready and green roof systems. This fully compatible product has been specifically designed to support rooftop solar installations and vegetative covers, offering high durability, low weight, and long-term performance under dual loads. The upgrade targets expanding demand in sustainable infrastructure, helping clients meet green building standards while ensuring low‑maintenance reliability for renewable energy rooftops.

- In January 2025, Bellofram Elastomers expanded its product line to include new engineered foam in neoprene and EPDM. These products are in high demand for use as seals in the automotive and construction industries. They are highly resistant to environmental conditions like UV rays, ozone, and weathering, and maintain excellent elasticity even in temperatures as low as -40 degrees Celsius.

Report Scope

|

Attribute |

Detail |

|

Market Size in 2025 |

USD 4.4 Billion |

|

Market Forecast Value in 2035 |

USD 7.9 Billion |

|

Growth Rate (CAGR) |

6.0% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value Metric Tons for Volume |

|

Report Format |

Electronic (PDF) + Excel |

|

Regions and Countries Covered |

|||||

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

EPDM Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Product Type |

|

|

By Diene Monomer Type

|

|

|

By Formulation/ Grade

|

|

|

By Packaging Format |

|

|

By Sales Channel

|

|

|

By End Use Industry X Application |

|

Frequently Asked Questions

The EPDM (Ethylene Propylene Diene Monomer) Market focuses on synthetic rubber widely used in automotive weatherstrips, roofing membranes, electrical insulation, and industrial applications due to its durability and weather resistance.

The EPDM market is valued at USD 4.4 Billion in 2025.

The EPDM market is expected to grow at a CAGR of 6.0% from 2025 to 2035.

Automotive segment leads the market due to the high usage of EPDM in sealing systems, weatherstrips, and vibration control in vehicles.

Asia Pacific dominates the EPDM market with an approximate share of 58% in 2025.

Key players in the global EPDM market include prominent companies such as Chevron Phillips Chemical Company, Dow Inc., ExxonMobil Chemical, Jiangsu Sailboat Petrochemical Co., Ltd., Korea Kumho Petrochemical Co., Lanxess AG, LG Chem Ltd., Mitsui Chemicals, Inc., Repsol Química, S.A., Royal DSM N.V. (EP Elastomers segment), SABIC (Saudi Basic Industries Corporation), Shell Chemical LP, Sinopec Corporation, Sinopec SABIC Tianjin Petrochemical Co., Ltd., The Netherlands-based DSM (Thermoplastic Elastomers Division), Versalis S.p.A. (Eni), Zeon Corporation, and Other key Players

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. EPDM Market Outlook

- 2.1.1. EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. EPDM Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global EPDM Industry Overview, 2025

- 3.1.1. Packaging Industry Ecosystem Analysis

- 3.1.2. Key Trends for Packaging Industry

- 3.1.3. Regional Distribution for Packaging Industry

- 3.2. Supplier Customer Data

- 3.3. Source Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2025

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.2. Supply Chain/Distributor

- 3.5.3. End Consumer

- 3.1. Global EPDM Industry Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Rising demand for durable and weather-resistant roofing and sealing materials in construction.

- 4.1.1.2. Increasing adoption of EPDM in automotive applications for hoses, seals, and gaskets.

- 4.1.2. Restraints

- 4.1.2.1. Fluctuating crude oil prices impacting raw material costs.

- 4.1.2.2. Availability of alternative synthetic rubbers with lower production costs.

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Raw Material Supplier

- 4.4.2. EPDM Manufacturers

- 4.4.3. Dealers/ Distributors

- 4.4.4. End-users/ Customers

- 4.5. Raw Material Analysis

- 4.6. Cost Structure Analysis

- 4.6.1. Parameter’s Share for Cost Associated

- 4.6.2. COGP vs COGS

- 4.6.3. Profit Margin Analysis

- 4.7. Pricing Analysis

- 4.7.1. Regional Pricing Analysis

- 4.7.2. Segmental Pricing Trends

- 4.7.3. Factors Influencing Pricing

- 4.8. Porter’s Five Forces Analysis

- 4.9. PESTEL Analysis

- 4.10. EPDM Market Demand

- 4.10.1. Historical Market Size - in Volume (Metric Tons) and Value (US$ Billion), 2021-2024

- 4.10.2. Current and Future Market Size - in Volume (Metric Tons) and Value (US$ Billion), 2025–2035

- 4.10.2.1. Y-o-Y Growth Trends

- 4.10.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2024

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. EPDM Market Analysis, by Product Type / Composition

- 6.1. Key Segment Analysis

- 6.2. EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, by Product Type / Composition, 2021-2035

- 6.2.1. Standard EPDM

- 6.2.2. High Ethylene EPDM

- 6.2.3. High Ethylene/High Mooney EPDM

- 7. EPDM Market Analysis, by Diene Monomer Type

- 7.1. Key Segment Analysis

- 7.2. EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, by Diene Monomer Type, 2021-2035

- 7.2.1. ENB (Ethylidene Norbornene) EPDM

- 7.2.2. DCPD (Dicyclopentadiene) EPDM

- 7.2.3. VNB (Vinyl Norbornene) EPDM

- 8. EPDM Market Analysis, by Formulation/ Grade

- 8.1. Key Segment Analysis

- 8.2. EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, by Formulation/ Grade, 2021-2035

- 8.2.1. General Purpose Grades

- 8.2.2. High-Performance Grades

- 8.2.3. Polymer Blends and Compounds

- 8.2.4. Others

- 9. EPDM Market Analysis, by Packaging Format

- 9.1. Key Segment Analysis

- 9.2. EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, by Packaging Format, 2021-2035

- 9.2.1. Bulk Bags

- 9.2.2. Bales

- 9.2.3. Palletized Wrapped Bales

- 9.2.4. Loose Pellet Packaging

- 9.2.5. Others

- 10. EPDM Market Analysis, by Sales Channel

- 10.1. Key Segment Analysis

- 10.2. EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, by Sales Channel, 2021-2035

- 10.2.1. OEM (Original Equipment Manufacturer)

- 10.2.2. Aftermarket / Replacement Parts

- 10.2.3. Direct Sales

- 10.2.4. Distributor Network

- 11. EPDM Market Analysis, by End-Use Industry X Application

- 11.1. Key Segment Analysis

- 11.2. EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, by End-Use Industry X Application, 2021-2035

- 11.2.1. Automotive

- 11.2.1.1. Weather-stripping & Seals

- 11.2.1.2. Hoses (Radiator, Heater, Brake)

- 11.2.1.3. Belts & Gaskets

- 11.2.1.4. Vibration Dampening Parts

- 11.2.1.5. Others

- 11.2.2. Building & Construction

- 11.2.2.1. Roofing Membranes

- 11.2.2.2. Window and Door Seals

- 11.2.2.3. Expansion Joints

- 11.2.2.4. Waterproofing Systems

- 11.2.2.5. Others

- 11.2.3. Electrical & Electronics

- 11.2.3.1. Wire & Cable Insulation

- 11.2.3.2. Connectors and Grommets

- 11.2.3.3. Electrical Enclosures

- 11.2.3.4. Others

- 11.2.4. Industrial Manufacturing

- 11.2.4.1. Conveyor Belts

- 11.2.4.2. Sealing Systems

- 11.2.4.3. Mechanical Gaskets

- 11.2.4.4. Protective Covers

- 11.2.4.5. Others

- 11.2.5. Oil & Gas

- 11.2.5.1. Drilling Hose

- 11.2.5.2. Seals and Gaskets

- 11.2.5.3. Pipe Linings

- 11.2.5.4. Others

- 11.2.6. HVAC (Heating, Ventilation, and Air Conditioning)

- 11.2.6.1. Pipe Insulation

- 11.2.6.2. Vibration Dampers

- 11.2.6.3. Flexible Duct Connectors

- 11.2.6.4. Others

- 11.2.7. Consumer Goods

- 11.2.7.1. Appliance Gaskets

- 11.2.7.2. Sports Equipment Grips

- 11.2.7.3. Rubberized Handles

- 11.2.7.4. Others

- 11.2.8. Aerospace

- 11.2.8.1. Fuel System Seals

- 11.2.8.2. Cabin Pressure Seals

- 11.2.8.3. Vibration Isolation Pads

- 11.2.8.4. Others

- 11.2.9. Others

- 11.2.1. Automotive

- 12. EPDM Market Analysis and Forecasts, by Region

- 12.1. Key Findings

- 12.2. EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, by Region, 2021-2035

- 12.2.1. North America

- 12.2.2. Europe

- 12.2.3. Asia Pacific

- 12.2.4. Middle East

- 12.2.5. Africa

- 12.2.6. South America

- 13. North America EPDM Market Analysis

- 13.1. Key Segment Analysis

- 13.2. Regional Snapshot

- 13.3. North America EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, 2021-2035

- 13.3.1. Product Type / Composition

- 13.3.2. Diene Monomer Type

- 13.3.3. Formulation/ Grade

- 13.3.4. Packaging Format

- 13.3.5. Sales Channel

- 13.3.6. End Use Industry X Application

- 13.3.7. Country

-

- 13.3.7.1.1. USA

- 13.3.7.1.2. Canada

- 13.3.7.1.3. Mexico

-

- 13.4. USA EPDM Market

- 13.4.1. Country Segmental Analysis

- 13.4.2. Product Type / Composition

- 13.4.3. Diene Monomer Type

- 13.4.4. Formulation/ Grade

- 13.4.5. Packaging Format

- 13.4.6. Sales Channel

- 13.4.7. End Use Industry X Application

- 13.5. Canada EPDM Market

- 13.5.1. Country Segmental Analysis

- 13.5.2. Product Type / Composition

- 13.5.3. Diene Monomer Type

- 13.5.4. Formulation/ Grade

- 13.5.5. Packaging Format

- 13.5.6. Sales Channel

- 13.5.7. End Use Industry X Application

- 13.6. Mexico EPDM Market

- 13.6.1. Country Segmental Analysis

- 13.6.2. Product Type / Composition

- 13.6.3. Diene Monomer Type

- 13.6.4. Formulation/ Grade

- 13.6.5. Packaging Format

- 13.6.6. Sales Channel

- 13.6.7. End Use Industry X Application

- 14. Europe EPDM Market Analysis

- 14.1. Key Segment Analysis

- 14.2. Regional Snapshot

- 14.3. Europe EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, 2021-2035

- 14.3.1. Product Type / Composition

- 14.3.2. Diene Monomer Type

- 14.3.3. Formulation/ Grade

- 14.3.4. Packaging Format

- 14.3.5. Sales Channel

- 14.3.6. End Use Industry X Application

- 14.3.7. Country

- 14.3.7.1. Germany

- 14.3.7.2. United Kingdom

- 14.3.7.3. France

- 14.3.7.4. Italy

- 14.3.7.5. Spain

- 14.3.7.6. Netherlands

- 14.3.7.7. Nordic Countries

- 14.3.7.8. Poland

- 14.3.7.9. Russia & CIS

- 14.3.7.10. Rest of Europe

- 14.4. Germany EPDM Market

- 14.4.1. Country Segmental Analysis

- 14.4.2. Product Type / Composition

- 14.4.3. Diene Monomer Type

- 14.4.4. Formulation/ Grade

- 14.4.5. Packaging Format

- 14.4.6. Sales Channel

- 14.4.7. End Use Industry X Application

- 14.5. United Kingdom EPDM Market

- 14.5.1. Country Segmental Analysis

- 14.5.2. Product Type / Composition

- 14.5.3. Diene Monomer Type

- 14.5.4. Formulation/ Grade

- 14.5.5. Packaging Format

- 14.5.6. Sales Channel

- 14.5.7. End Use Industry X Application

- 14.6. France EPDM Market

- 14.6.1. Country Segmental Analysis

- 14.6.2. Product Type / Composition

- 14.6.3. Diene Monomer Type

- 14.6.4. Formulation/ Grade

- 14.6.5. Packaging Format

- 14.6.6. Sales Channel

- 14.6.7. End Use Industry X Application

- 14.7. Italy EPDM Market

- 14.7.1. Country Segmental Analysis

- 14.7.2. Product Type / Composition

- 14.7.3. Diene Monomer Type

- 14.7.4. Formulation/ Grade

- 14.7.5. Packaging Format

- 14.7.6. Sales Channel

- 14.7.7. End Use Industry X Application

- 14.8. Spain EPDM Market

- 14.8.1. Country Segmental Analysis

- 14.8.2. Product Type / Composition

- 14.8.3. Diene Monomer Type

- 14.8.4. Formulation/ Grade

- 14.8.5. Packaging Format

- 14.8.6. Sales Channel

- 14.8.7. End Use Industry X Application

- 14.9. Netherlands EPDM Market

- 14.9.1. Country Segmental Analysis

- 14.9.2. Product Type / Composition

- 14.9.3. Diene Monomer Type

- 14.9.4. Formulation/ Grade

- 14.9.5. Packaging Format

- 14.9.6. Sales Channel

- 14.9.7. End Use Industry X Application

- 14.10. Nordic Countries EPDM Market

- 14.10.1. Country Segmental Analysis

- 14.10.2. Product Type / Composition

- 14.10.3. Diene Monomer Type

- 14.10.4. Formulation/ Grade

- 14.10.5. Packaging Format

- 14.10.6. Sales Channel

- 14.10.7. End Use Industry X Application

- 14.11. Poland EPDM Market

- 14.11.1. Country Segmental Analysis

- 14.11.2. Product Type / Composition

- 14.11.3. Diene Monomer Type

- 14.11.4. Formulation/ Grade

- 14.11.5. Packaging Format

- 14.11.6. Sales Channel

- 14.11.7. End Use Industry X Application

- 14.12. Russia & CIS EPDM Market

- 14.12.1. Country Segmental Analysis

- 14.12.2. Product Type / Composition

- 14.12.3. Diene Monomer Type

- 14.12.4. Formulation/ Grade

- 14.12.5. Packaging Format

- 14.12.6. Sales Channel

- 14.12.7. End Use Industry X Application

- 14.13. Rest of Europe EPDM Market

- 14.13.1. Country Segmental Analysis

- 14.13.2. Product Type / Composition

- 14.13.3. Diene Monomer Type

- 14.13.4. Formulation/ Grade

- 14.13.5. Packaging Format

- 14.13.6. Sales Channel

- 14.13.7. End Use Industry X Application

- 15. Asia Pacific EPDM Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. East Asia EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), and Forecasts, 2021-2035

- 15.3.1. Product Type / Composition

- 15.3.2. Diene Monomer Type

- 15.3.3. Formulation/ Grade

- 15.3.4. Packaging Format

- 15.3.5. Sales Channel

- 15.3.6. End Use Industry X Application

- 15.3.7. Country

- 15.3.7.1. China

- 15.3.7.2. India

- 15.3.7.3. Japan

- 15.3.7.4. South Korea

- 15.3.7.5. Australia and New Zealand

- 15.3.7.6. Indonesia

- 15.3.7.7. Malaysia

- 15.3.7.8. Thailand

- 15.3.7.9. Vietnam

- 15.3.7.10. Rest of Asia Pacific

- 15.4. China EPDM Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Product Type / Composition

- 15.4.3. Diene Monomer Type

- 15.4.4. Formulation/ Grade

- 15.4.5. Packaging Format

- 15.4.6. Sales Channel

- 15.4.7. End Use Industry X Application

- 15.5. India EPDM Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Product Type / Composition

- 15.5.3. Diene Monomer Type

- 15.5.4. Formulation/ Grade

- 15.5.5. Packaging Format

- 15.5.6. Sales Channel

- 15.5.7. End Use Industry X Application

- 15.6. Japan EPDM Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Product Type / Composition

- 15.6.3. Diene Monomer Type

- 15.6.4. Formulation/ Grade

- 15.6.5. Packaging Format

- 15.6.6. Sales Channel

- 15.6.7. End Use Industry X Application

- 15.7. South Korea EPDM Market

- 15.7.1. Country Segmental Analysis

- 15.7.2. Product Type / Composition

- 15.7.3. Diene Monomer Type

- 15.7.4. Formulation/ Grade

- 15.7.5. Packaging Format

- 15.7.6. Sales Channel

- 15.7.7. End Use Industry X Application

- 15.8. Australia and New Zealand EPDM Market

- 15.8.1. Country Segmental Analysis

- 15.8.2. Product Type / Composition

- 15.8.3. Diene Monomer Type

- 15.8.4. Formulation/ Grade

- 15.8.5. Packaging Format

- 15.8.6. Sales Channel

- 15.8.7. End Use Industry X Application

- 15.9. Indonesia EPDM Market

- 15.9.1. Country Segmental Analysis

- 15.9.2. Product Type / Composition

- 15.9.3. Diene Monomer Type

- 15.9.4. Formulation/ Grade

- 15.9.5. Packaging Format

- 15.9.6. Sales Channel

- 15.9.7. End Use Industry X Application

- 15.10. Malaysia EPDM Market

- 15.10.1. Country Segmental Analysis

- 15.10.2. Product Type / Composition

- 15.10.3. Diene Monomer Type

- 15.10.4. Formulation/ Grade

- 15.10.5. Packaging Format

- 15.10.6. Sales Channel

- 15.10.7. End Use Industry X Application

- 15.11. Thailand EPDM Market

- 15.11.1. Country Segmental Analysis

- 15.11.2. Product Type / Composition

- 15.11.3. Diene Monomer Type

- 15.11.4. Formulation/ Grade

- 15.11.5. Packaging Format

- 15.11.6. Sales Channel

- 15.11.7. End Use Industry X Application

- 15.12. Vietnam EPDM Market

- 15.12.1. Country Segmental Analysis

- 15.12.2. Product Type / Composition

- 15.12.3. Diene Monomer Type

- 15.12.4. Formulation/ Grade

- 15.12.5. Packaging Format

- 15.12.6. Sales Channel

- 15.12.7. End Use Industry X Application

- 15.13. Rest of Asia Pacific EPDM Market

- 15.13.1. Country Segmental Analysis

- 15.13.2. Product Type / Composition

- 15.13.3. Diene Monomer Type

- 15.13.4. Formulation/ Grade

- 15.13.5. Packaging Format

- 15.13.6. Sales Channel

- 15.13.7. End Use Industry X Application

- 16. Middle East EPDM Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Middle East EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, 2021-2035

- 16.3.1. Product Type / Composition

- 16.3.2. Diene Monomer Type

- 16.3.3. Formulation/ Grade

- 16.3.4. Packaging Format

- 16.3.5. Sales Channel

- 16.3.6. End Use Industry X Application

- 16.3.7. Country

- 16.3.7.1. Turkey

- 16.3.7.2. UAE

- 16.3.7.3. Saudi Arabia

- 16.3.7.4. Israel

- 16.3.7.5. Rest of Middle East

- 16.4. Turkey EPDM Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Product Type / Composition

- 16.4.3. Diene Monomer Type

- 16.4.4. Formulation/ Grade

- 16.4.5. Packaging Format

- 16.4.6. Sales Channel

- 16.4.7. End Use Industry X Application

- 16.5. UAE EPDM Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Product Type / Composition

- 16.5.3. Diene Monomer Type

- 16.5.4. Formulation/ Grade

- 16.5.5. Packaging Format

- 16.5.6. Sales Channel

- 16.5.7. End Use Industry X Application

- 16.6. Saudi Arabia EPDM Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Product Type / Composition

- 16.6.3. Diene Monomer Type

- 16.6.4. Formulation/ Grade

- 16.6.5. Packaging Format

- 16.6.6. Sales Channel

- 16.6.7. End Use Industry X Application

- 16.7. Israel EPDM Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Product Type / Composition

- 16.7.3. Diene Monomer Type

- 16.7.4. Formulation/ Grade

- 16.7.5. Packaging Format

- 16.7.6. Sales Channel

- 16.7.7. End Use Industry X Application

- 16.8. Rest of Middle East EPDM Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Product Type / Composition

- 16.8.3. Diene Monomer Type

- 16.8.4. Formulation/ Grade

- 16.8.5. Packaging Format

- 16.8.6. Sales Channel

- 16.8.7. End Use Industry X Application

- 17. Africa EPDM Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Africa EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, 2021-2035

- 17.3.1. Product Type / Composition

- 17.3.2. Diene Monomer Type

- 17.3.3. Formulation/ Grade

- 17.3.4. Packaging Format

- 17.3.5. Sales Channel

- 17.3.6. End Use Industry X Application

- 17.3.7. Country

- 17.3.7.1. South Africa

- 17.3.7.2. Egypt

- 17.3.7.3. Nigeria

- 17.3.7.4. Algeria

- 17.3.7.5. Rest of Africa

- 17.4. South Africa EPDM Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Product Type / Composition

- 17.4.3. Diene Monomer Type

- 17.4.4. Formulation/ Grade

- 17.4.5. Packaging Format

- 17.4.6. Sales Channel

- 17.4.7. End Use Industry X Application

- 17.5. Egypt EPDM Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Product Type / Composition

- 17.5.3. Diene Monomer Type

- 17.5.4. Formulation/ Grade

- 17.5.5. Packaging Format

- 17.5.6. Sales Channel

- 17.5.7. End Use Industry X Application

- 17.6. Nigeria EPDM Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Product Type / Composition

- 17.6.3. Diene Monomer Type

- 17.6.4. Formulation/ Grade

- 17.6.5. Packaging Format

- 17.6.6. Sales Channel

- 17.6.7. End Use Industry X Application

- 17.7. Algeria EPDM Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Product Type / Composition

- 17.7.3. Diene Monomer Type

- 17.7.4. Formulation/ Grade

- 17.7.5. Packaging Format

- 17.7.6. Sales Channel

- 17.7.7. End Use Industry X Application

- 17.8. Rest of Africa EPDM Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Product Type / Composition

- 17.8.3. Diene Monomer Type

- 17.8.4. Formulation/ Grade

- 17.8.5. Packaging Format

- 17.8.6. Sales Channel

- 17.8.7. End Use Industry X Application

- 18. South America EPDM Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Central and South Africa EPDM Market Size in Volume (Metric Tons) and Value (US$ Billion), Analysis, and Forecasts, 2021-2035

- 18.3.1. Product Type / Composition

- 18.3.2. Diene Monomer Type

- 18.3.3. Formulation/ Grade

- 18.3.4. Packaging Format

- 18.3.5. Sales Channel

- 18.3.6. End Use Industry X Application

- 18.3.7. Country

- 18.3.7.1. Brazil

- 18.3.7.2. Argentina

- 18.3.7.3. Rest of South America

- 18.4. Brazil EPDM Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Product Type / Composition

- 18.4.3. Diene Monomer Type

- 18.4.4. Formulation/ Grade

- 18.4.5. Packaging Format

- 18.4.6. Sales Channel

- 18.4.7. End Use Industry X Application

- 18.5. Argentina EPDM Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Product Type / Composition

- 18.5.3. Diene Monomer Type

- 18.5.4. Formulation/ Grade

- 18.5.5. Packaging Format

- 18.5.6. Sales Channel

- 18.5.7. End Use Industry X Application

- 18.6. Rest of South America EPDM Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Product Type / Composition

- 18.6.3. Diene Monomer Type

- 18.6.4. Formulation/ Grade

- 18.6.5. Packaging Format

- 18.6.6. Sales Channel

- 18.6.7. End Use Industry X Application

- 19. Key Players/ Company Profile

- 19.1. Chevron Phillips Chemical Company

- 19.1.1. Company Details/ Overview

- 19.1.2. Company Financials

- 19.1.3. Key Customers and Competitors

- 19.1.4. Business/ Industry Portfolio

- 19.1.5. Product Portfolio/ Specification Details

- 19.1.6. Pricing Data

- 19.1.7. Strategic Overview

- 19.1.8. Recent Developments

- 19.2. Dow Inc.

- 19.3. ExxonMobil Chemical

- 19.4. Jiangsu Sailboat Petrochemical Co., Ltd.

- 19.5. Korea Kumho Petrochemical Co.

- 19.6. Lanxess AG

- 19.7. LG Chem Ltd.

- 19.8. Mitsui Chemicals, Inc.

- 19.9. Repsol Química, S.A.

- 19.10. Royal DSM N.V. (EP Elastomers segment)

- 19.11. SABIC (Saudi Basic Industries Corporation)

- 19.12. Shell Chemical LP

- 19.13. Sinopec Corporation

- 19.14. Sinopec SABIC Tianjin Petrochemical Co., Ltd.

- 19.15. The Netherlands-based DSM (Thermoplastic Elastomers Division)

- 19.16. Versalis S.p.A. (Eni)

- 19.17. Zeon Corporation

- 19.18. Other key Players

- 19.1. Chevron Phillips Chemical Company

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography.

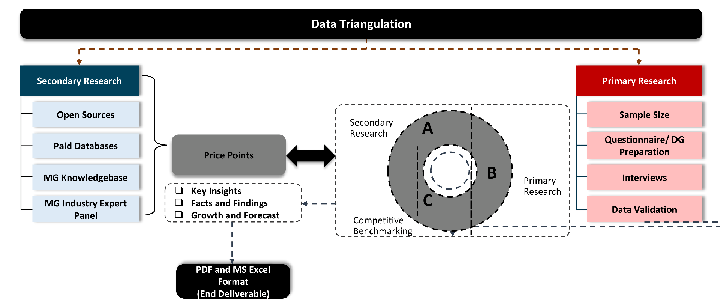

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase and Others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players product portfolio

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources includes primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data