- The global manufacturing digital twin platforms market is valued at USD 16.4 billion in 2025.

- The market is projected to grow at a CAGR of 34.1% during the forecast period of 2026 to 2035.

- The platform software (core digital twin engine) segment accounts for ~37% of the global manufacturing digital twin platforms market in 2025, driven by rising adoption of AI- and simulation-driven real-time operational optimization.

- The market for manufacturing digital twin platforms is expanding as manufacturers embrace AI and IoT-based simulations to improve operational efficiency and predictive maintenance.

- Cloud computing, IoT devices, and sophisticated analytics are enhancing precision, scalability, and immediate insight in manufacturing systems.

- The global manufacturing digital-twin-platforms-market is highly consolidated, with the top five players accounting for over 50% of the market share in 2025.

- In September 2025, Siemens introduced its Xcelerator Edge AI module, which is capable of performing real-time predictive analytics and simulations right at the edge.

- In August 2025, Dassault Systèmes has made an enhancement to its 3DEXPERIENCE Twin Cloud to offer fully interoperable, AI-enabled digital twins that integrate design, production, and supply chain data.

- Global manufacturing digital twin platforms market is likely to create the total forecasting opportunity of USD 293.2 Bn till 2035

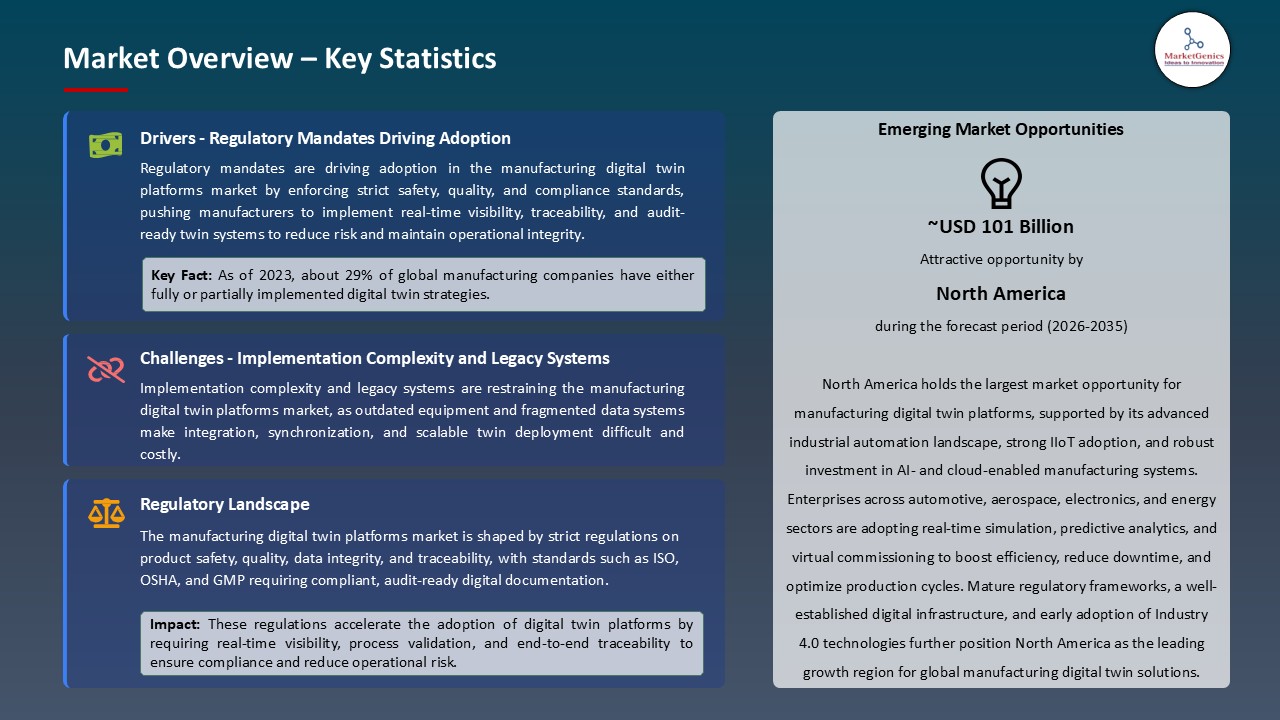

- North America is most attractive region, with the implementation of government-backed standards and innovation programs.

- The manufacturing digital twin platforms market is experiencing a rapid expansion that is largely influenced by changes in regulatory standards worldwide. For example, the EU Machinery Regulation 2024 and ISO 22400 manufacturing performance metrics are standards that require real-time monitoring, predictive maintenance, and operational traceability. As a result, manufacturers are being pushed to adopt advanced digital twin solutions.

- Requirements imposed by industry-specific regulations, such as North America's OSHA safety standards, the EU Eco-Design Directive, and environmental compliance frameworks in the Asia-Pacific region, are tightly coupling the adoption of simulation-driven risk analysis and process monitoring. To point out an example, Siemens introduced AI-powered predictive maintenance modules in its Xcelerator platform in September 2025 to demonstrate the worldwide movement to data-driven manufacturing operations that are compliance-focused.

- Likewise, the growing dependence on automated, interconnected, and AI-enabled production lines is also a major factor behind the call for digital twin solutions by which manufacturers can increase uptime, lessen their carbon footprint, and meet the safety, quality, and sustainability standards that are subject to further changes.

- While regulatory bodies encourage such moves, the complexity of integrating modern simulation and IoT frameworks with the old manufacturing execution systems (MES) and SCADA infrastructures that are common in factories, limits the widespread deployment of digital twin platforms. Moving to fully connected, real-time digital twins is costly as it requires investment in IoT sensors, edge computing, AI/ML algorithms, and cybersecurity infrastructure, notably for small- and medium-sized manufacturers.

- The challenge of balancing the need for advanced analytics and predictive capabilities with operational costs, workforce training, and interoperability issues has been recognized as a major barrier to rapid adoption worldwide. Moreover, differences in data standards between various machines and vendors cause integration bottlenecks that make it hard to have a seamless digital twin environment.

- Moreover, the lack of skilled professionals who are capable of managing, analyzing, and maintaining complex digital twin systems is a factor that hampers the implementation pace thus, the problem is most pronounced in developing regions.

- Asian, African, and Latin American economies are rapidly implementing smart manufacturing programs as the key to industrial efficiency and to keep their competitiveness in the global market. The advanced manufacturing technology initiatives in India, China’s Made in 2025 strategy and Brazil’s Industry 4.0 are among the examples of the leading countries pushing the demand for digital twin solutions that can be scaled up.

- Further, worldwide technology companies are building relationships with local manufacturers, industrial IoT companies, and governments to implement cloud-based digital twin infrastructure, real-time monitoring, and predictive maintenance solutions. As an illustration, automotive manufacturers in Southeast Asia are utilizing Dassault Systèmes’ 3DEXPERIENCE platform to enhance production planning and lower the chances of operational risks.

- Such undertakings open the door for software vendors, IoT solution providers, and AI analytics developers to offer comprehensive digital twin ecosystems that facilitate the operational visibility and efficiency of their clients and thus, contribute to their business growth.

- Modern digital twin platforms are progressively integrating IoT sensor networks, AI-driven predictive analytics, and real-time simulation to optimize manufacturing operations. Anomaly detection, predictive maintenance, and scenario planning features are thus resulting in increased uptime, quality, and safety. By the same token, the implementation of cloud computing, digital threads, and virtual commissioning is giving manufacturers the ability to simulate production processes ahead of time, thus cutting down on errors and time-to-market.

- Along with the implementation of standard frameworks for interoperability and data sharing, manufacturers make use of digital twins to revolutionize industrial operations, thus creating smart and resilient factories which are rapidly embracing the global diffusion of Industry 4.0 technologies. Besides, the embedding of augmented and virtual reality (AR/VR) devices facilitates the interaction of operators with digital twins in deeply engaging milieus, empowering them to make decisions faster and training more efficiently.

- The innovations in edge computing and 5G connectivity that are still ongoing are the main reasons why manufacturers can process large amounts of data in near-real-time, thus they are able to react to any operational changes and disruptions without any delays.

- In order to create real-time virtual replicas of their production lines, the use of platform software and digital twin engines by industries like automotive, aerospace, and electronics has surged. Consequently, these industries are enabled to carry out predictive maintenance, process optimization, and energy efficiency. A demonstrative instance is the case of the Siemens Xcelerator platform update in 2025, which shows the extent to which digital twin engines form the core of smart, connected manufacturing operations.

- The usage of AI, ML, and advanced analytics in that of IoT-enabled digital twin frameworks has had a substantial positive effect on the same in the fields of anomaly detection, production forecasting, and scenario simulation. Companies such as Dassault Systèmes and PTC have opted for edge-based analytics and cloud-connected digital twins as a means to achieve the reduction of machine downtime, the enhancement of product quality, and the improvement of operational decision-making.

- Several recent changes to regulatory and sustainability requirements like ISO 22400 performance metrics and the EU Eco-Design Directive have slowly come around to the idea that predictive simulations and digital twin monitoring are the main compliance tools. The availability of scalable digital twin software development kits and modular platform engines has opened up the way for manufacturers to quickly deploy connected and interoperable virtual factory solutions.

- North America holds the lead in the manufacturing digital twin platforms market with the implementation of government-backed standards and innovation programs. The U.S. National Institute of Standards and Technology (NIST) is conducting a "Digital Twins for Advanced Manufacturing" initiative to create open standards, testbeds, and model-validation frameworks that will facilitate the deployment of real-time twins in manufacturers in a reliable manner. Next Generation Manufacturing Canada (NGen) also reports that many SME manufacturers are already utilizing digital twins for simulation and control, and this is being supported by public/private efforts to scale adoption. Furthermore, the standard for interoperable twins such as ISO 23247 is being created with the collaboration of the U.S. and Canada to allow cross-system compatibility, thus reducing technical barriers and increasing the rate of adoption.

- Besides that, the area has a well-developed industrial ecosystem that has widely adopted the IIoT, AI, and cloud computing infrastructure, thus manufacturers are able to carry out scalable, real-time simulations across multi-site operations. The large-scale investments in smart factory initiatives, workforce training programs, and cybersecurity measures, on top of that, are making the digital twin deployments more capable and reliable, thus, North America is consolidating its leadership in this market.

- In September 2025, Siemens introduced its Xcelerator Edge AI module, which is capable of performing real-time predictive analytics and simulations right at the edge. With this platform, factories can not only track the performance of their equipment but also identify the occurrence of anomalies and even optimize their processes without the need for cloud connectivity, thus enhancing operational resilience and cutting the risk of downtime throughout multi-site operations.

- In August 2025, Dassault Systèmes has made an enhancement to its 3DEXPERIENCE Twin Cloud to offer fully interoperable, AI-enabled digital twins that integrate design, production, and supply chain data. The manufacturers are now able to simulate the entire workflows, carry-out virtual commissioning, and share the real-time insights among the facilities thus resulting in increased productivity, error reduction, and collaboration without reliance on localized systems.

- United States

- Canada

- Mexico

- Germany

- United Kingdom

- France

- Italy

- Spain

- Netherlands

- Nordic Countries

- Poland

- Russia & CIS

- China

- India

- Japan

- South Korea

- Australia and New Zealand

- Indonesia

- Malaysia

- Thailand

- Vietnam

- Turkey

- UAE

- Saudi Arabia

- Israel

- South Africa

- Egypt

- Nigeria

- Algeria

- Brazil

- Argentina

- Ansys, Inc.

- Autodesk, Inc.

- AVEVA Group

- Oracle Corporation

- Bentley Systems

- Bosch Rexroth

- Dassault Systèmes

- Siemens AG

- General Electric (GE Digital)

- Hexagon AB

- Schneider Electric

- PTC Inc.

- Hitachi Vantara

- Honeywell International Inc.

- Rockwell Automation

- IBM Corporation

- Infosys Limited

- Microsoft Corporation

- Siemens Energy

- Tata Consultancy Services (TCS)

- Other Key Players

- Platform Software (Core Digital Twin Engine)

- Modeling & Simulation Tools

- Analytics & AI/ML Modules

- Visualization & Digital Thread Interfaces

- Integration & Middleware

- Digital Twin Lifecycle Management

- Security & Governance Modules

- Others

- Cloud-Based

- On-Premises

- Hybrid

- Physics-based Simulation

- Data-driven (AI/ML) Twins

- Hybrid (Physics + Data)

- High-Fidelity 3D/CAE Integration

- Real-time Streaming & Event Processing

- Others

- R&D / Product Design

- Process Engineering

- Manufacturing Operations

- Maintenance & Reliability

- Quality Assurance

- Supply Chain & Logistics

- IT / OT Convergence Teams

- Others

- Large Enterprises

- Small & Medium Enterprises (SMEs)

- PLC / SCADA / MES Integration

- ERP Integration

- IoT Sensor & IIoT Gateways

- CAD / PLM / CAE Data Integration

- Historical Data Lakes / Data Warehouses

- External Data Feeds

- Others

- Descriptive & Diagnostic Analytics

- Predictive Analytics

- Prescriptive Optimization

- What-if / Scenario Simulation

- Digital Experimentation & A/B Testing

- Others

- Plant & Factory Layout Optimization

- Production Process Simulation & Optimization

- Predictive Maintenance & Asset Health

- Quality Control & Defect Prediction

- Energy Consumption & Efficiency Optimization

- Throughput & Capacity Planning

- Commissioning & Digital Validation

- Worker Training & AR/VR-assisted Operations

- Others

- Automotive

- Aerospace & Defense

- Heavy Machinery & Industrial Equipment

- Electronics & Semiconductor Manufacturing

- Pharmaceuticals & Bioprocessing

- Food & Beverage Manufacturing

- Chemical & Petrochemicals

- Consumer Goods

- Others

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Manufacturing Digital Twin Platforms Market Outlook

- 2.1.1. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2026-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Manufacturing Digital Twin Platforms Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Information Technology & Media Ecosystem Overview, 2025

- 3.1.1. Information Technology & Media Industry Analysis

- 3.1.2. Key Trends for Information Technology & Media Industry

- 3.1.3. Regional Distribution for Information Technology & Media Industry

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.1. Global Information Technology & Media Ecosystem Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Rising demand for real-time monitoring of manufacturing processes and predictive maintenance insights.

- 4.1.1.2. Growing adoption of AI-, ML-, and analytics-driven simulation for production optimization and quality enhancement.

- 4.1.1.3. Increasing investments in IoT-enabled smart factories, cloud-based digital twin platforms, and collaborative manufacturing ecosystems.

- 4.1.2. Restraints

- 4.1.2.1. High deployment and operational costs of digital twin infrastructure and advanced analytics tools.

- 4.1.2.2. Integration complexities with legacy manufacturing systems and heterogeneous production data sources.

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Component/ Data Suppliers

- 4.4.2. System Integrators/ Technology Providers

- 4.4.3. Manufacturing Digital Twin Platform Providers

- 4.4.4. End Users

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Pricing Analysis

- 4.6.1. Regional Pricing Analysis

- 4.6.2. Segmental Pricing Trends

- 4.6.3. Factors Influencing Pricing

- 4.7. Porter’s Five Forces Analysis

- 4.8. PESTEL Analysis

- 4.9. Global Manufacturing Digital Twin Platforms Market Demand

- 4.9.1. Historical Market Size –Value (US$ Bn), 2020-2024

- 4.9.2. Current and Future Market Size –Value (US$ Bn), 2026–2035

- 4.9.2.1. Y-o-Y Growth Trends

- 4.9.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Manufacturing Digital Twin Platforms Market Analysis, by Component

- 6.1. Key Segment Analysis

- 6.2. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, by Component, 2021-2035

- 6.2.1. Platform Software (Core Digital Twin Engine)

- 6.2.2. Modeling & Simulation Tools

- 6.2.3. Analytics & AI/ML Modules

- 6.2.4. Visualization & Digital Thread Interfaces

- 6.2.5. Integration & Middleware

- 6.2.6. Digital Twin Lifecycle Management

- 6.2.7. Security & Governance Modules

- 6.2.8. Others

- 7. Global Manufacturing Digital Twin Platforms Market Analysis, by Deployment Mode

- 7.1. Key Segment Analysis

- 7.2. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, by Deployment Mode, 2021-2035

- 7.2.1. Cloud-Based

- 7.2.2. On-Premises

- 7.2.3. Hybrid

- 8. Global Manufacturing Digital Twin Platforms Market Analysis, by Technology

- 8.1. Key Segment Analysis

- 8.2. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, by Technology, 2021-2035

- 8.2.1. Physics-based Simulation

- 8.2.2. Data-driven (AI/ML) Twins

- 8.2.3. Hybrid (Physics + Data)

- 8.2.4. High-Fidelity 3D/CAE Integration

- 8.2.5. Real-time Streaming & Event Processing

- 8.2.6. Others

- 9. Global Manufacturing Digital Twin Platforms Market Analysis, by Function

- 9.1. Key Segment Analysis

- 9.2. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, by Function, 2021-2035

- 9.2.1. R&D / Product Design

- 9.2.2. Process Engineering

- 9.2.3. Manufacturing Operations

- 9.2.4. Maintenance & Reliability

- 9.2.5. Quality Assurance

- 9.2.6. Supply Chain & Logistics

- 9.2.7. IT / OT Convergence Teams

- 9.2.8. Others

- 10. Global Manufacturing Digital Twin Platforms Market Analysis, by Enterprise Size

- 10.1. Key Segment Analysis

- 10.2. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, by Enterprise Size, 2021-2035

- 10.2.1. Large Enterprises

- 10.2.2. Small & Medium Enterprises (SMEs)

- 11. Global Manufacturing Digital Twin Platforms Market Analysis, by Integration/ Data Source

- 11.1. Key Segment Analysis

- 11.2. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, by Integration/ Data Source, 2021-2035

- 11.2.1. PLC / SCADA / MES Integration

- 11.2.2. ERP Integration

- 11.2.3. IoT Sensor & IIoT Gateways

- 11.2.4. CAD / PLM / CAE Data Integration

- 11.2.5. Historical Data Lakes / Data Warehouses

- 11.2.6. External Data Feeds

- 11.2.7. Others

- 12. Global Manufacturing Digital Twin Platforms Market Analysis, by Analytics Capability

- 12.1. Key Segment Analysis

- 12.2. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, by Analytics Capability, 2021-2035

- 12.2.1. Descriptive & Diagnostic Analytics

- 12.2.2. Predictive Analytics

- 12.2.3. Prescriptive Optimization

- 12.2.4. What-if / Scenario Simulation

- 12.2.5. Digital Experimentation & A/B Testing

- 12.2.6. Others

- 13. Global Manufacturing Digital Twin Platforms Market Analysis, by Application/ Use Case

- 13.1. Key Segment Analysis

- 13.2. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, by Application/ Use Case, 2021-2035

- 13.2.1. Plant & Factory Layout Optimization

- 13.2.2. Production Process Simulation & Optimization

- 13.2.3. Predictive Maintenance & Asset Health

- 13.2.4. Quality Control & Defect Prediction

- 13.2.5. Energy Consumption & Efficiency Optimization

- 13.2.6. Throughput & Capacity Planning

- 13.2.7. Commissioning & Digital Validation

- 13.2.8. Worker Training & AR/VR-assisted Operations

- 13.2.9. Others

- 14. Global Manufacturing Digital Twin Platforms Market Analysis, by Industry Vertical

- 14.1. Key Segment Analysis

- 14.2. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, by Industry Vertical, 2021-2035

- 14.2.1. Automotive

- 14.2.2. Aerospace & Defense

- 14.2.3. Heavy Machinery & Industrial Equipment

- 14.2.4. Electronics & Semiconductor Manufacturing

- 14.2.5. Pharmaceuticals & Bioprocessing

- 14.2.6. Food & Beverage Manufacturing

- 14.2.7. Chemical & Petrochemicals

- 14.2.8. Consumer Goods

- 14.2.9. Others

- 15. Global Manufacturing Digital Twin Platforms Market Analysis and Forecasts, by Region

- 15.1. Key Findings

- 15.2. Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, by Region, 2021-2035

- 15.2.1. North America

- 15.2.2. Europe

- 15.2.3. Asia Pacific

- 15.2.4. Middle East

- 15.2.5. Africa

- 15.2.6. South America

- 16. North America Manufacturing Digital Twin Platforms Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. North America Manufacturing Digital Twin Platforms Market Size Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 16.3.1. Component

- 16.3.2. Deployment Mode

- 16.3.3. Technology

- 16.3.4. Function

- 16.3.5. Enterprise Size

- 16.3.6. Integration/ Data Source

- 16.3.7. Analytics Capability

- 16.3.8. Application / Use Case

- 16.3.9. Industry Vertical

- 16.3.10. Country

- 16.3.10.1. USA

- 16.3.10.2. Canada

- 16.3.10.3. Mexico

- 16.4. USA Manufacturing Digital Twin Platforms Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Component

- 16.4.3. Deployment Mode

- 16.4.4. Technology

- 16.4.5. Function

- 16.4.6. Enterprise Size

- 16.4.7. Integration/ Data Source

- 16.4.8. Analytics Capability

- 16.4.9. Application / Use Case

- 16.4.10. Industry Vertical

- 16.5. Canada Manufacturing Digital Twin Platforms Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Component

- 16.5.3. Deployment Mode

- 16.5.4. Technology

- 16.5.5. Function

- 16.5.6. Enterprise Size

- 16.5.7. Integration/ Data Source

- 16.5.8. Analytics Capability

- 16.5.9. Application / Use Case

- 16.5.10. Industry Vertical

- 16.6. Mexico Manufacturing Digital Twin Platforms Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Component

- 16.6.3. Deployment Mode

- 16.6.4. Technology

- 16.6.5. Function

- 16.6.6. Enterprise Size

- 16.6.7. Integration/ Data Source

- 16.6.8. Analytics Capability

- 16.6.9. Application / Use Case

- 16.6.10. Industry Vertical

- 17. Europe Manufacturing Digital Twin Platforms Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Europe Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 17.3.1. Component

- 17.3.2. Deployment Mode

- 17.3.3. Technology

- 17.3.4. Function

- 17.3.5. Enterprise Size

- 17.3.6. Integration/ Data Source

- 17.3.7. Analytics Capability

- 17.3.8. Application / Use Case

- 17.3.9. Industry Vertical

- 17.3.10. Country

- 17.3.10.1. Germany

- 17.3.10.2. United Kingdom

- 17.3.10.3. France

- 17.3.10.4. Italy

- 17.3.10.5. Spain

- 17.3.10.6. Netherlands

- 17.3.10.7. Nordic Countries

- 17.3.10.8. Poland

- 17.3.10.9. Russia & CIS

- 17.3.10.10. Rest of Europe

- 17.4. Germany Manufacturing Digital Twin Platforms Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Component

- 17.4.3. Deployment Mode

- 17.4.4. Technology

- 17.4.5. Function

- 17.4.6. Enterprise Size

- 17.4.7. Integration/ Data Source

- 17.4.8. Analytics Capability

- 17.4.9. Application / Use Case

- 17.4.10. Industry Vertical

- 17.5. United Kingdom Manufacturing Digital Twin Platforms Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Component

- 17.5.3. Deployment Mode

- 17.5.4. Technology

- 17.5.5. Function

- 17.5.6. Enterprise Size

- 17.5.7. Integration/ Data Source

- 17.5.8. Analytics Capability

- 17.5.9. Application / Use Case

- 17.5.10. Industry Vertical

- 17.6. France Manufacturing Digital Twin Platforms Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Component

- 17.6.3. Deployment Mode

- 17.6.4. Technology

- 17.6.5. Function

- 17.6.6. Enterprise Size

- 17.6.7. Integration/ Data Source

- 17.6.8. Analytics Capability

- 17.6.9. Application / Use Case

- 17.6.10. Industry Vertical

- 17.7. Italy Manufacturing Digital Twin Platforms Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Component

- 17.7.3. Deployment Mode

- 17.7.4. Technology

- 17.7.5. Function

- 17.7.6. Enterprise Size

- 17.7.7. Integration/ Data Source

- 17.7.8. Analytics Capability

- 17.7.9. Application / Use Case

- 17.7.10. Industry Vertical

- 17.8. Spain Manufacturing Digital Twin Platforms Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Component

- 17.8.3. Deployment Mode

- 17.8.4. Technology

- 17.8.5. Function

- 17.8.6. Enterprise Size

- 17.8.7. Integration/ Data Source

- 17.8.8. Analytics Capability

- 17.8.9. Application / Use Case

- 17.8.10. Industry Vertical

- 17.9. Netherlands Manufacturing Digital Twin Platforms Market

- 17.9.1. Country Segmental Analysis

- 17.9.2. Component

- 17.9.3. Deployment Mode

- 17.9.4. Technology

- 17.9.5. Function

- 17.9.6. Enterprise Size

- 17.9.7. Integration/ Data Source

- 17.9.8. Analytics Capability

- 17.9.9. Application / Use Case

- 17.9.10. Industry Vertical

- 17.10. Nordic Countries Manufacturing Digital Twin Platforms Market

- 17.10.1. Country Segmental Analysis

- 17.10.2. Component

- 17.10.3. Deployment Mode

- 17.10.4. Technology

- 17.10.5. Function

- 17.10.6. Enterprise Size

- 17.10.7. Integration/ Data Source

- 17.10.8. Analytics Capability

- 17.10.9. Application / Use Case

- 17.10.10. Industry Vertical

- 17.11. Poland Manufacturing Digital Twin Platforms Market

- 17.11.1. Country Segmental Analysis

- 17.11.2. Component

- 17.11.3. Deployment Mode

- 17.11.4. Technology

- 17.11.5. Function

- 17.11.6. Enterprise Size

- 17.11.7. Integration/ Data Source

- 17.11.8. Analytics Capability

- 17.11.9. Application / Use Case

- 17.11.10. Industry Vertical

- 17.12. Russia & CIS Manufacturing Digital Twin Platforms Market

- 17.12.1. Country Segmental Analysis

- 17.12.2. Component

- 17.12.3. Deployment Mode

- 17.12.4. Technology

- 17.12.5. Function

- 17.12.6. Enterprise Size

- 17.12.7. Integration/ Data Source

- 17.12.8. Analytics Capability

- 17.12.9. Application / Use Case

- 17.12.10. Industry Vertical

- 17.13. Rest of Europe Manufacturing Digital Twin Platforms Market

- 17.13.1. Country Segmental Analysis

- 17.13.2. Component

- 17.13.3. Deployment Mode

- 17.13.4. Technology

- 17.13.5. Function

- 17.13.6. Enterprise Size

- 17.13.7. Integration/ Data Source

- 17.13.8. Analytics Capability

- 17.13.9. Application / Use Case

- 17.13.10. Industry Vertical

- 18. Asia Pacific Manufacturing Digital Twin Platforms Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Asia Pacific Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 18.3.1. Component

- 18.3.2. Deployment Mode

- 18.3.3. Technology

- 18.3.4. Function

- 18.3.5. Enterprise Size

- 18.3.6. Integration/ Data Source

- 18.3.7. Analytics Capability

- 18.3.8. Application / Use Case

- 18.3.9. Industry Vertical

- 18.3.10. Country

- 18.3.10.1. China

- 18.3.10.2. India

- 18.3.10.3. Japan

- 18.3.10.4. South Korea

- 18.3.10.5. Australia and New Zealand

- 18.3.10.6. Indonesia

- 18.3.10.7. Malaysia

- 18.3.10.8. Thailand

- 18.3.10.9. Vietnam

- 18.3.10.10. Rest of Asia Pacific

- 18.4. China Manufacturing Digital Twin Platforms Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Component

- 18.4.3. Deployment Mode

- 18.4.4. Technology

- 18.4.5. Function

- 18.4.6. Enterprise Size

- 18.4.7. Integration/ Data Source

- 18.4.8. Analytics Capability

- 18.4.9. Application / Use Case

- 18.4.10. Industry Vertical

- 18.5. India Manufacturing Digital Twin Platforms Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Component

- 18.5.3. Deployment Mode

- 18.5.4. Technology

- 18.5.5. Function

- 18.5.6. Enterprise Size

- 18.5.7. Integration/ Data Source

- 18.5.8. Analytics Capability

- 18.5.9. Application / Use Case

- 18.5.10. Industry Vertical

- 18.6. Japan Manufacturing Digital Twin Platforms Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Component

- 18.6.3. Deployment Mode

- 18.6.4. Technology

- 18.6.5. Function

- 18.6.6. Enterprise Size

- 18.6.7. Integration/ Data Source

- 18.6.8. Analytics Capability

- 18.6.9. Application / Use Case

- 18.6.10. Industry Vertical

- 18.7. South Korea Manufacturing Digital Twin Platforms Market

- 18.7.1. Country Segmental Analysis

- 18.7.2. Component

- 18.7.3. Deployment Mode

- 18.7.4. Technology

- 18.7.5. Function

- 18.7.6. Enterprise Size

- 18.7.7. Integration/ Data Source

- 18.7.8. Analytics Capability

- 18.7.9. Application / Use Case

- 18.7.10. Industry Vertical

- 18.8. Australia and New Zealand Manufacturing Digital Twin Platforms Market

- 18.8.1. Country Segmental Analysis

- 18.8.2. Component

- 18.8.3. Deployment Mode

- 18.8.4. Technology

- 18.8.5. Function

- 18.8.6. Enterprise Size

- 18.8.7. Integration/ Data Source

- 18.8.8. Analytics Capability

- 18.8.9. Application / Use Case

- 18.8.10. Industry Vertical

- 18.9. Indonesia Manufacturing Digital Twin Platforms Market

- 18.9.1. Country Segmental Analysis

- 18.9.2. Component

- 18.9.3. Deployment Mode

- 18.9.4. Technology

- 18.9.5. Function

- 18.9.6. Enterprise Size

- 18.9.7. Integration/ Data Source

- 18.9.8. Analytics Capability

- 18.9.9. Application / Use Case

- 18.9.10. Industry Vertical

- 18.10. Malaysia Manufacturing Digital Twin Platforms Market

- 18.10.1. Country Segmental Analysis

- 18.10.2. Component

- 18.10.3. Deployment Mode

- 18.10.4. Technology

- 18.10.5. Function

- 18.10.6. Enterprise Size

- 18.10.7. Integration/ Data Source

- 18.10.8. Analytics Capability

- 18.10.9. Application / Use Case

- 18.10.10. Industry Vertical

- 18.11. Thailand Manufacturing Digital Twin Platforms Market

- 18.11.1. Country Segmental Analysis

- 18.11.2. Component

- 18.11.3. Deployment Mode

- 18.11.4. Technology

- 18.11.5. Function

- 18.11.6. Enterprise Size

- 18.11.7. Integration/ Data Source

- 18.11.8. Analytics Capability

- 18.11.9. Application / Use Case

- 18.11.10. Industry Vertical

- 18.12. Vietnam Manufacturing Digital Twin Platforms Market

- 18.12.1. Country Segmental Analysis

- 18.12.2. Component

- 18.12.3. Deployment Mode

- 18.12.4. Technology

- 18.12.5. Function

- 18.12.6. Enterprise Size

- 18.12.7. Integration/ Data Source

- 18.12.8. Analytics Capability

- 18.12.9. Application / Use Case

- 18.12.10. Industry Vertical

- 18.13. Rest of Asia Pacific Manufacturing Digital Twin Platforms Market

- 18.13.1. Country Segmental Analysis

- 18.13.2. Component

- 18.13.3. Deployment Mode

- 18.13.4. Technology

- 18.13.5. Function

- 18.13.6. Enterprise Size

- 18.13.7. Integration/ Data Source

- 18.13.8. Analytics Capability

- 18.13.9. Application / Use Case

- 18.13.10. Industry Vertical

- 19. Middle East Manufacturing Digital Twin Platforms Market Analysis

- 19.1. Key Segment Analysis

- 19.2. Regional Snapshot

- 19.3. Middle East Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 19.3.1. Component

- 19.3.2. Deployment Mode

- 19.3.3. Technology

- 19.3.4. Function

- 19.3.5. Enterprise Size

- 19.3.6. Integration/ Data Source

- 19.3.7. Analytics Capability

- 19.3.8. Application / Use Case

- 19.3.9. Industry Vertical

- 19.3.10. Country

- 19.3.10.1. Turkey

- 19.3.10.2. UAE

- 19.3.10.3. Saudi Arabia

- 19.3.10.4. Israel

- 19.3.10.5. Rest of Middle East

- 19.4. Turkey Manufacturing Digital Twin Platforms Market

- 19.4.1. Country Segmental Analysis

- 19.4.2. Component

- 19.4.3. Deployment Mode

- 19.4.4. Technology

- 19.4.5. Function

- 19.4.6. Enterprise Size

- 19.4.7. Integration/ Data Source

- 19.4.8. Analytics Capability

- 19.4.9. Application / Use Case

- 19.4.10. Industry Vertical

- 19.5. UAE Manufacturing Digital Twin Platforms Market

- 19.5.1. Country Segmental Analysis

- 19.5.2. Component

- 19.5.3. Deployment Mode

- 19.5.4. Technology

- 19.5.5. Function

- 19.5.6. Enterprise Size

- 19.5.7. Integration/ Data Source

- 19.5.8. Analytics Capability

- 19.5.9. Application / Use Case

- 19.5.10. Industry Vertical

- 19.6. Saudi Arabia Manufacturing Digital Twin Platforms Market

- 19.6.1. Country Segmental Analysis

- 19.6.2. Component

- 19.6.3. Deployment Mode

- 19.6.4. Technology

- 19.6.5. Function

- 19.6.6. Enterprise Size

- 19.6.7. Integration/ Data Source

- 19.6.8. Analytics Capability

- 19.6.9. Application / Use Case

- 19.6.10. Industry Vertical

- 19.7. Israel Manufacturing Digital Twin Platforms Market

- 19.7.1. Country Segmental Analysis

- 19.7.2. Component

- 19.7.3. Deployment Mode

- 19.7.4. Technology

- 19.7.5. Function

- 19.7.6. Enterprise Size

- 19.7.7. Integration/ Data Source

- 19.7.8. Analytics Capability

- 19.7.9. Application / Use Case

- 19.7.10. Industry Vertical

- 19.8. Rest of Middle East Manufacturing Digital Twin Platforms Market

- 19.8.1. Country Segmental Analysis

- 19.8.2. Component

- 19.8.3. Deployment Mode

- 19.8.4. Technology

- 19.8.5. Function

- 19.8.6. Enterprise Size

- 19.8.7. Integration/ Data Source

- 19.8.8. Analytics Capability

- 19.8.9. Application / Use Case

- 19.8.10. Industry Vertical

- 20. Africa Manufacturing Digital Twin Platforms Market Analysis

- 20.1. Key Segment Analysis

- 20.2. Regional Snapshot

- 20.3. Africa Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 20.3.1. Component

- 20.3.2. Deployment Mode

- 20.3.3. Technology

- 20.3.4. Function

- 20.3.5. Enterprise Size

- 20.3.6. Integration/ Data Source

- 20.3.7. Analytics Capability

- 20.3.8. Application / Use Case

- 20.3.9. Industry Vertical

- 20.3.10. Country

- 20.3.10.1. South Africa

- 20.3.10.2. Egypt

- 20.3.10.3. Nigeria

- 20.3.10.4. Algeria

- 20.3.10.5. Rest of Africa

- 20.4. South Africa Manufacturing Digital Twin Platforms Market

- 20.4.1. Country Segmental Analysis

- 20.4.2. Component

- 20.4.3. Deployment Mode

- 20.4.4. Technology

- 20.4.5. Function

- 20.4.6. Enterprise Size

- 20.4.7. Integration/ Data Source

- 20.4.8. Analytics Capability

- 20.4.9. Application / Use Case

- 20.4.10. Industry Vertical

- 20.5. Egypt Manufacturing Digital Twin Platforms Market

- 20.5.1. Country Segmental Analysis

- 20.5.2. Component

- 20.5.3. Deployment Mode

- 20.5.4. Technology

- 20.5.5. Function

- 20.5.6. Enterprise Size

- 20.5.7. Integration/ Data Source

- 20.5.8. Analytics Capability

- 20.5.9. Application / Use Case

- 20.5.10. Industry Vertical

- 20.6. Nigeria Manufacturing Digital Twin Platforms Market

- 20.6.1. Country Segmental Analysis

- 20.6.2. Component

- 20.6.3. Deployment Mode

- 20.6.4. Technology

- 20.6.5. Function

- 20.6.6. Enterprise Size

- 20.6.7. Integration/ Data Source

- 20.6.8. Analytics Capability

- 20.6.9. Application / Use Case

- 20.6.10. Industry Vertical

- 20.7. Algeria Manufacturing Digital Twin Platforms Market

- 20.7.1. Country Segmental Analysis

- 20.7.2. Component

- 20.7.3. Deployment Mode

- 20.7.4. Technology

- 20.7.5. Function

- 20.7.6. Enterprise Size

- 20.7.7. Integration/ Data Source

- 20.7.8. Analytics Capability

- 20.7.9. Application / Use Case

- 20.7.10. Industry Vertical

- 20.8. Rest of Africa Manufacturing Digital Twin Platforms Market

- 20.8.1. Country Segmental Analysis

- 20.8.2. Component

- 20.8.3. Deployment Mode

- 20.8.4. Technology

- 20.8.5. Function

- 20.8.6. Enterprise Size

- 20.8.7. Integration/ Data Source

- 20.8.8. Analytics Capability

- 20.8.9. Application / Use Case

- 20.8.10. Industry Vertical

- 21. South America Manufacturing Digital Twin Platforms Market Analysis

- 21.1. Key Segment Analysis

- 21.2. Regional Snapshot

- 21.3. South America Manufacturing Digital Twin Platforms Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 21.3.1. Component

- 21.3.2. Deployment Mode

- 21.3.3. Technology

- 21.3.4. Function

- 21.3.5. Enterprise Size

- 21.3.6. Integration/ Data Source

- 21.3.7. Analytics Capability

- 21.3.8. Application / Use Case

- 21.3.9. Industry Vertical

- 21.3.10. Country

- 21.3.10.1. Brazil

- 21.3.10.2. Argentina

- 21.3.10.3. Rest of South America

- 21.4. Brazil Manufacturing Digital Twin Platforms Market

- 21.4.1. Country Segmental Analysis

- 21.4.2. Component

- 21.4.3. Deployment Mode

- 21.4.4. Technology

- 21.4.5. Function

- 21.4.6. Enterprise Size

- 21.4.7. Integration/ Data Source

- 21.4.8. Analytics Capability

- 21.4.9. Application / Use Case

- 21.4.10. Industry Vertical

- 21.5. Argentina Manufacturing Digital Twin Platforms Market

- 21.5.1. Country Segmental Analysis

- 21.5.2. Component

- 21.5.3. Deployment Mode

- 21.5.4. Technology

- 21.5.5. Function

- 21.5.6. Enterprise Size

- 21.5.7. Integration/ Data Source

- 21.5.8. Analytics Capability

- 21.5.9. Application / Use Case

- 21.5.10. Industry Vertical

- 21.6. Rest of South America Manufacturing Digital Twin Platforms Market

- 21.6.1. Country Segmental Analysis

- 21.6.2. Component

- 21.6.3. Deployment Mode

- 21.6.4. Technology

- 21.6.5. Function

- 21.6.6. Enterprise Size

- 21.6.7. Integration/ Data Source

- 21.6.8. Analytics Capability

- 21.6.9. Application / Use Case

- 21.6.10. Industry Vertical

- 22. Key Players/ Company Profile

- 22.1. Ansys, Inc.

- 22.1.1. Company Details/ Overview

- 22.1.2. Company Financials

- 22.1.3. Key Customers and Competitors

- 22.1.4. Business/ Industry Portfolio

- 22.1.5. Product Portfolio/ Specification Details

- 22.1.6. Pricing Data

- 22.1.7. Strategic Overview

- 22.1.8. Recent Developments

- 22.2. Autodesk, Inc.

- 22.3. AVEVA Group

- 22.4. Bentley Systems

- 22.5. Bosch Rexroth

- 22.6. Dassault Systèmes

- 22.7. General Electric (GE Digital)

- 22.8. Hexagon AB

- 22.9. Hitachi Vantara

- 22.10. Honeywell International Inc.

- 22.11. IBM Corporation

- 22.12. Infosys Limited

- 22.13. Microsoft Corporation

- 22.14. Oracle Corporation

- 22.15. PTC Inc.

- 22.16. Rockwell Automation

- 22.17. Schneider Electric

- 22.18. Siemens AG

- 22.19. Siemens Energy

- 22.20. Tata Consultancy Services (TCS)

- 22.21. Other Key Players

- 22.1. Ansys, Inc.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Manufacturing Digital Twin Platforms Market by Component, Deployment Mode, Technology, Function, Enterprise Size, Integration/ Data Source, Analytics Capability, Application/ Use Case, Industry Vertical and Geography

Insightified

Mid-to-large firms spend $20K–$40K quarterly on systematic research and typically recover multiples through improved growth and profitability

Research is no longer optional. Leading firms use it to uncover $10M+ in hidden revenue opportunities annually

Our research-consulting programs yields measurable ROI: 20–30% revenue increases from new markets, 11% profit upticks from pricing, and 20–30% cost savings from operations

Manufacturing Digital Twin Platforms Market Size, Share & Trends Analysis Report by Component (Platform Software (Core Digital Twin Engine), Modeling & Simulation Tools, Analytics & AI/ML Modules, Visualization & Digital Thread Interfaces, Integration & Middleware, Digital Twin Lifecycle Management, Security & Governance Modules and Others), Deployment Mode, Technology, Function, Enterprise Size, Integration/ Data Source, Analytics Capability, Application/ Use Case, Industry Vertical and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2026–2035

|

Market Structure & Evolution |

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Manufacturing Digital Twin Platforms Market Size, Share, and Growth

The global manufacturing digital twin platforms market is experiencing robust growth, with its estimated value of USD 16.4 billion in the year 2025 and USD 309.6 billion by the period 2035, registering a CAGR of 34.1% during the forecast period.

"Given that manufacturing processes generate extensive data sets, there are chances to identify anomalies, including cyberattacks," stated Dawn Tilbury, a professor at the University of Michigan and co-author of the research, highlighting that digital twins coupled with real-time monitoring can improve operational security and resilience in manufacturing settings.

The manufacturing digital twin platforms market is growing exponentially worldwide. Various factors impact this global market growth which includes the upgradation of the advanced and reliable digital twin solutions that not only optimize production efficiency but also help the operational resilience to adapt to any change. Siemens, for instance, unveiled its next-generation digital twin platform by end of September 2025, which included AI-driven predictive maintenance and real-time simulation capabilities, thus enabling manufacturers to both foresee equipment failures and streamline their processes simultaneously.

The active implementation of Industry 4.0 plans as well as the building of smart factories are acting as a major booster of the demand for advanced digital twin solutions. The most notable example is the upgrading of the 3DEXPERIENCE platform by Dassault Systèmes last August which was utilized by the top European automotive manufacturer for enhancing production planning and reducing machine downtime.

Moreover, manufacturing performance metrics standards like ISO 22400 are paving the way for the integration of digital twin solutions as a tool for both operational excellence and compliance. The interaction between technological innovations, regulations, and wide smart manufacturing adoption is the major contributor to market growth operating at a very high efficiency level, decreasing the operational cost, and improving the product quality.

The global manufacturing digital twin platforms market uncovers adjacent opportunities such as predictive maintenance services, virtual commissioning solutions, and real-time production monitoring, AI-driven quality analytics, and supply chain simulation platforms. By capitalizing on these neighboring sectors, manufacturers will be able to gain more operational insights, utilize resources efficiently, and have new revenue streams in industrial digital solutions.

Manufacturing Digital Twin Platforms Market Dynamics and Trends

Driver: Increasing Regulatory Mandates Driving Adoption of Advanced Digital Twin Platforms

Restraint: Implementation Complexity and Legacy Systems Integration Limiting Digital Twin Adoption

Opportunity: Expansion in Emerging Regions and Government-Backed Smart Factory Initiatives

Key Trend: Integration of AI, IoT, and Real-Time Simulation Driving Digital Twin Adoption

Manufacturing Digital Twin Platforms Market Analysis and Segmental Data

“Platform Software (Core Digital Twin Engine) Leads Global Manufacturing Digital Twin Platforms Market Amid Rising Demand for Real-Time Operational Optimization"

“North America Leads the Manufacturing Digital Twin Platforms Market"

Manufacturing-Digital-Twin-Platforms-Market Ecosystem

The manufacturing digital twin platforms market is digitally concentrated. The market leaders Siemens, Dassault Systèmes, GE Digital, PTC, Hexagon, and IBM dominate the market by using sophisticated AI-driven simulation, industrial IoT, and cloud‑native architectures technologies. These players in the market pump a lot of money into Research & Development projects to provide the state-of-the-art twin engines, thus they are ahead of their competitors who are the smaller providers.

The big companies are focusing on different niche areas. For example, Siemens Xcelerator suite with real-time AI copilots and edge analytics is integrated; the 3DEXPERIENCE platform of Dassault Systèmes is utilized to allow the product and process twins to be experienced; GE Digital is concentrating on asset‑performance management in energy-consuming industries of manufacturing; PTC's ThingWorx, which is combined with industrial IoT and augmented reality, delivers the solution; On the other hand, Hexagon provides spatially aware twins through the metrology and reality-capturing technologies, and IBM uses Watson‑powered AI for improving predictive simulations.

Public institutions and government agencies are equally important actors in the same ecosystem. Take, for instance, the NIST move in January 2024 to initiate an exploratory study as part of its "Digital Twins for Advanced Manufacturing" program aiming at creating measurement science, trustworthiness frameworks, and interoperability standards for digital twin ecosystems. The central strategy of product diversification is motivated by the providers' willingness to expand the portfolios so as to offer integrated solutions that can boost productivity, sustainability, and operational efficiency.

Recent Development and Strategic Overview:

Report Scope

|

Attribute |

Detail |

|

Market Size in 2025 |

USD 16.4 Bn |

|

Market Forecast Value in 2035 |

USD 309.6 Bn |

|

Growth Rate (CAGR) |

34.1% |

|

Forecast Period |

2026 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

USD Bn for Value |

|

Report Format |

Electronic (PDF) + Excel |

|

Regions and Countries Covered |

|||||

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

|

Manufacturing-Digital-Twin-Platforms-Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

Manufacturing Digital Twin Platforms Market, By Component |

|

|

Manufacturing Digital Twin Platforms Market, By Deployment Mode |

|

|

Manufacturing Digital Twin Platforms Market, By Technology |

|

|

Manufacturing Digital Twin Platforms Market, By Function |

|

|

Manufacturing Digital Twin Platforms Market, By Enterprise Size |

|

|

Manufacturing Digital Twin Platforms Market, By Integration/ Data Source |

|

|

Manufacturing Digital Twin Platforms Market, By Analytics Capability |

|

|

Manufacturing Digital Twin Platforms Market, By Application/ Use Case |

|

|

Manufacturing Digital Twin Platforms Market, By Industry Vertical |

|

Frequently Asked Questions

Table of Contents

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

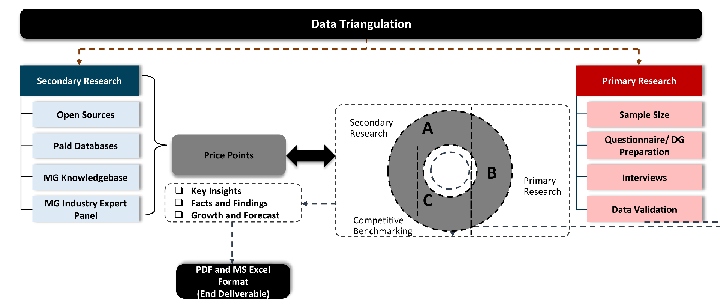

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

Forecasting Models / Techniques

Multiple Regression Analysis

Time Series Analysis – Seasonal Patterns

Time Series Analysis – Trend Analysis

Expert Opinion – Expert Interviews

Multi-Scenario Development

Time Series Analysis – Moving Averages

Econometric Models

Expert Opinion – Delphi Method

Monte Carlo Simulation

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation