Manufacturing Execution Systems (MES) Market Size, Share & Trends Analysis Report by Component (Software, Services), Deployment Mode, Enterprise Size, End-users Type, Integration Level, Production Type, Automation Level, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2026–2035

|

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Manufacturing Execution Systems (MES) Market Size, Share, and Growth

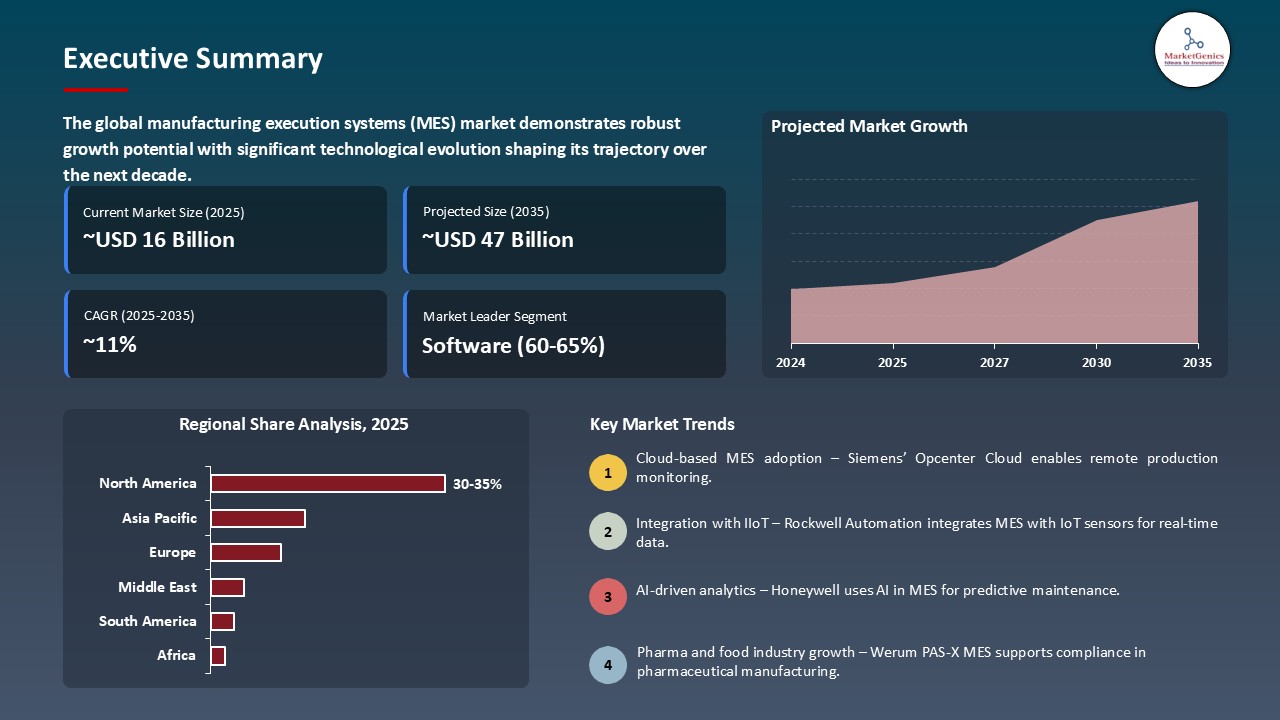

The global manufacturing execution systems (MES) market is witnessing strong growth, valued at USD 16.2 billion in 2025 and projected to reach USD 47.3 billion by 2035, expanding at a CAGR of 11.3% during the forecast period. The Asia Pacific is the fastest-growing region in the manufacturing execution systems (MES) market due to rising industrial automation, government initiatives promoting smart manufacturing, and increasing adoption of IoT- and AI-enabled MES solutions across key industries.

Tobias Lange, Senior Vice President Manufacturing Operations Management, Digital Manufacturing, Siemens Digital Industries Software, said, “The recognition of Siemens as a Manufacturing Execution System leader in the IDC MarketScape report, we believe, highlights our fast pace of innovation to provide our customers with world class integrated Manufacturing Execution Systems technology, Our continued commitment to delivering open, configurable, easily deployable and inherently scalable software is truly benefitting customers across the globe”.

The growing demand of transparency in the manufacturing processes is propelling the adoption of manufacturing execution systems. Manufacturers are using MES to observe the production processes in operation and rapidly detect bottlenecks to ensure that the downtime is minimized. MES will allow the optimization of resource use, increase productivity, and better decision-making throughout the shop floor by offering practical information on equipment performance, inventory levels, and process efficiency.

The manufacturing execution systems (MES) market is more advanced through collaborations, whereby the partners have different skills, technologies, and resources that assist in producing more sophisticated integrated solutions. AVEVA worked with Amazon Web Services (AWS) and managed to test the implementation of AVEVA Manufacturing Execution System (MES) and AVEVA System Platform on AWS EC2 platform. Through this partnership, an industrial operations platform becomes possible through the use of cloud, which makes it possible to manage data collection, process control, and execution of MES in one and scalable environment.

The recent emphasis on the sustainability and energy efficiency in the manufacturing industry has offered a great opportunity to adopt MES. MES allows the manufacturer to minimize waste, operation costs, and ensure environmental standards by tracking and optimizing energy use in production lines. High-technology MES solutions enable real-time analytics, carbon footprint, and resource-intensive workflows to contribute to the increase of the economic and ecological advantages and promote corporate sustainability efforts.

Manufacturing Execution Systems (MES) Market Dynamics and Trends

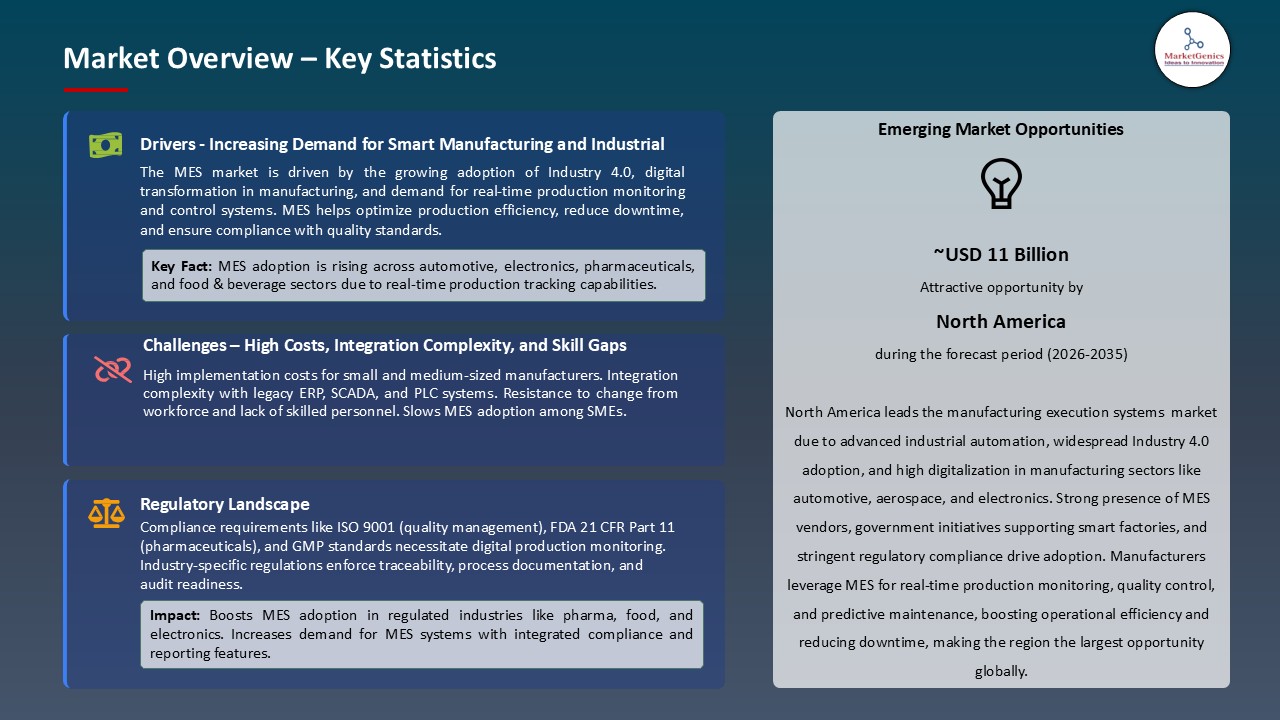

Driver: Regulatory Compliance and Industry 4.0 Transformation Imperatives

- Manufacturing execution systems assists manufacturers to comply with strict quality, safety and traceability requirements set by the industry regulation [pharmaceuticals, food and beverage and electronics] regulators. MES allows compliance with the requirements of such regulations as ISO, FDA, and GMP by automating documentation, batch tracking, and audit readiness, reducing the risk of punishment in non-compliance.

- At the same time, Industry 4.0 projects promote the digital revolution with the introduction of smart factories, real-time monitoring of the production process, the use of IoT, and data-driven decision-making. MES serves as an interface between the shop-floor process and the enterprise system and allows manufacturers to streamline production, enhance quality, and improve operational efficiency to address changing regulatory and technological demands.

- In 2025, Rockwell Automation released FactoryTalk PharmaSuite 12.00, an MES based on the next generation of applicable technology in regulated pharmaceutical and biopharmaceutical facilities. Its release has a modular architecture, cloud-ready, improved cybersecurity, and automated validation tools, which allow manufacturers to achieve scalability in production, speed deployments, stay on top of regulatory compliance, and move towards digital transformation driven by Industry 4.0 in life sciences operations.

- Manufacturing execution systems market is enhanced by regulatory compliance and Industry 4.0 that allow efficient, traceable, and digitally integrated manufacturing processes.

Restraint: Integration Complexity and Change Management Challenges

- The complexity of integrating the MES solutions with the current legacy systems, such as ERP, SCADA and PLCs, is a major limitation to the manufacturing execution systems market. A number of manufacturers have a heterogeneous environment of IT and operational technology, and it is difficult to integrate connectivity and data flow across systems.

- The requirement to customize, interoperability concerns, and the necessity to continue uninterrupted production during implementation also make implementation more challenging. Moreover, change management is a critical barrier where the workforce opposition, staff shortage, and training can create challenges in speeding up the adoption and decreasing the benefits of operation.

- Organizations usually incur high expenses and long durations to match processes, software, and workflow of employees with MES platforms. The associated change management challenges have the potential to restrain the implementation of MES, especially in small and medium-sized businesses, which limits the rapid growth of the market, even as the demand to embrace real-time monitoring and predictive maintenance, as well as transformation of Industry 4.0, is growing.

Opportunity: Cloud-Based MES and Software-as-a-Service Deployment Models

- The utilization of cloud-based MES and Software-as-a-Service (SaaS) deployment models are a remarkable opportunity to the manufacturing execution systems market. These solutions enable the manufacturers to utilize the MES capabilities without making massive initial investments on on-premise infrastructure to lower the cost of capital and IT maintenance expenses.

- Cloud MES has scalability, remote access and real-time data sharing across various production sites that enables decisions and operational efficiency to be made more quickly. The SaaS models have a flexible pricing that is based on subscription, simple upgrades, and less complexity in implementation, which makes the implementation of MES more viable to small and medium-sized enterprises.

- In 2024, Siemens presented Opcenter X software, a modular MES and Manufacturing Operations Management (MOM) solution is a cloud-based service that allows a small and middle-sized manufacturer to simplify production scheduling and enhance efficiency without excessive IT overheads. The production scheduling time cut by 93% in WKS Door Systems, which illustrates quick digital transformation and increased operational nimbleness.

- Cloud-based and SaaS MES solutions are making manufacturing operations agile, scalable, and cost-effective, leading to the adoption of many of them and increasing the pace of the digital transformation within the manufacturing execution systems market.

Key Trend: Artificial Intelligence and Machine Learning for Production Optimization

- The combination of Artificial Intelligence (AI) and Machine Learning (ML) can also be discussed as one of the major tendencies in the Manufacturing execution systems market and allow manufacturers to streamline production processes and enhance operational efficiency. AI and ML algorithms are used to examine massive real-time data on production processes to find patterns, anticipate equipment breakdowns, and prescribe corrective measures, which can be used in support of predictive and prescriptive maintenance policies.

- Dynamic scheduling, resource allocation and quality control are also made possible through the technologies and minimizing downtime and defects. MES platforms facilitate actionable insights based on AI and ML to act on, improve throughput, and bring cost efficiencies.

- In 2025, Tietoevry declared that its TIPS All-in-One MES is available as a SaaS on Microsoft Azure providing industry-specific compliance, reduced on-site IT expenses, and AI-based features including its TIPS Copilot real-time insight, autonomous task execution, and intelligent mill operation.

- AI and ML in MES are changing the manufacturing process, with the possibilities to make decisions in real-time, have predictive maintenance and optimized manufacturing, which leads to increased efficiency, quality and overall operational excellence.

Manufacturing-Execution-Systems-Market Analysis and Segmental Data

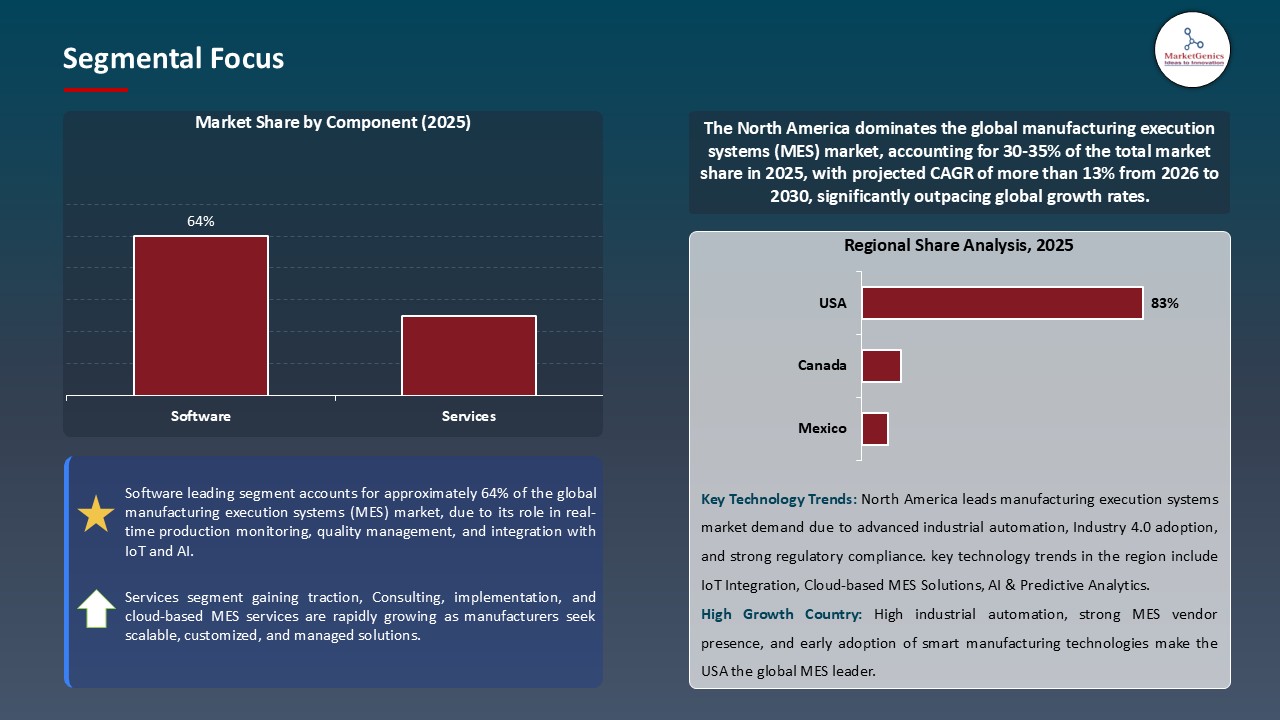

Software Dominate Global Manufacturing Execution Systems (MES) Market

- The software sector dominates the global manufacturing execution systems market having the highest percentage since it plays a significant role in controlling the production process, quality and real-time operational visibility. MES software is used to combine operations at the shop-floor level with enterprise systems, enables the production plan, resource allocation, workflow management, and regulatory compliance.

- The increased use is driven by Industry 4.0 programs, cloud implementation, IoT connectivity, and sophisticated analytics, and enables manufacturers to maximize throughput, minimize downtime, and enhance decision-making. Modular, scalable solutions to small, medium, and large enterprises are also an advantage to the software segment and a foundation of digital transformation in manufacturing as well as a primary source of market growth.

- The Manufacturing Execution System (MES) software of AVEVA provides a composable operator interface and a hybrid cloud architecture installation used in a modular manner. The software helps to see end-to-end the visibility of various plants, use industrial AI to optimize yield, quality, and productivity, and ensure sustainable operations by reducing the CO 2 footprint, facilitating smarter and data-driven manufacturing.

- The supremacy of MES software, such as modular, artificial intelligence, and cloud-enabled systems such as the platform of AVEVA, is leading to digital transformation, efficiency in operations, and sustainable, data-driven manufacturing in all industries across the world.

North America Leads Global Manufacturing Execution Systems (MES) Market Demand

- North America dominates the global manufacturing execution systems market because of the developed industrial base, the prevalence of the Industry 4.0 technologies, and priorities on the digital transformation.

- The manufacturers in the region are also adopting MES solutions to achieve real-time visibility, streamline production resources, enhance the quality control and regulatory compliance. The integration of IoT, cloud computing, and AI-powered analytics makes high demand due to the ability to predictive maintenance, optimize the allocation of resources, and make decisions based on the data. Also, the movement towards operational efficiency, sustainability, and flexibility and scalability promote the adoption of these solutions across small, medium, and large business institutions.

- The focus on operational effectiveness, sustainability, and scalable and flexible solutions dominating the region promotes the adoption of MES in small, medium-sized, and large businesses. Cloud-based MES implementation and Software-as-a-Service (SaaS) can provide manufacturers with the opportunity to save initial investment on infrastructure, collaborate across locations, and provide real-time production information remotely.

- Advanced analytics, AI, and machine learning capabilities facilitate dynamic scheduling, quality assurance, and process optimization, while integration with ERP, PLM, and supply chain systems ensures seamless end-to-end visibility.

- Combined, the factors firmly establish North America as the most prominent manufacturing execution systems market in the world.

Manufacturing-Execution-Systems-Market Ecosystem

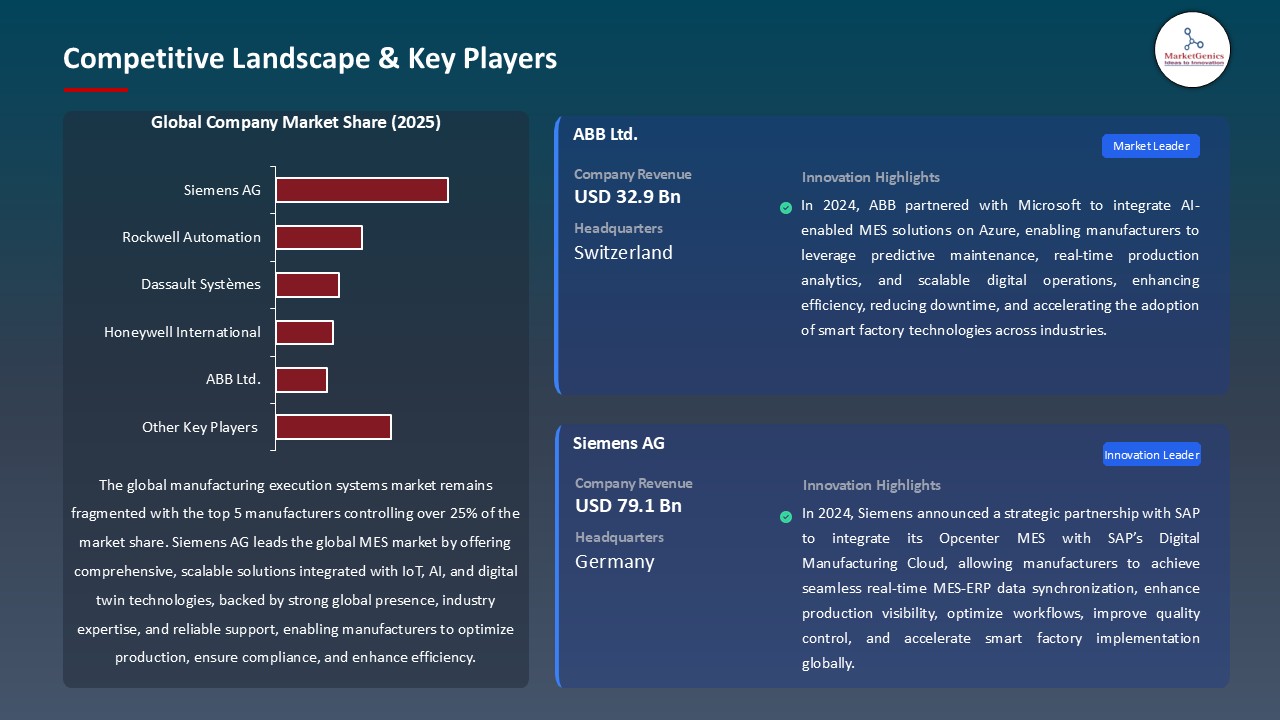

The manufacturing execution systems (MES) market in the world is a fragmented market with major players including Siemens AG, Rockwell Automation, Dassault Systèmes, Honeywell International, and ABB Ltd. controlling approximately 28% of the market share. Their main advantage is that these top vendors capitalize on the established relationship with customers, predictable and performance-scaling platform, and integration experience that is profound across the industrial operations. The other players are special software developers, local automation suppliers and system integrators which deal with niche applications or industry applications.

The MES value chain cuts across software development, the HMI and visualization tools, the communication protocol engineering, the controller manufacturing, the system integration, the commissioning, the maintenance, and the cybersecurity management. Major vendors generally build the core of MES platforms by working with hardware vendors and integration partners to offer end to end solutions.

This developed ecosystem has high barriers to entry as determined by customer dependency, system-reliability requirements, and demand in tested operating platforms, and niche players remain innovative in a certain segment.

Recent Development and Strategic Overview:

- In October 2025, PSI Polska installed PSIpenta/MES Scheduling at Espersen Poland, a major frozen food manufacturer, to optimize production scheduling, enhance operational flexibility, and better resource utilization. The system combines APS and MES capabilities and IoT-based machine connectivity, which grants real-time feedback, early bottleneck detection, and automatic scenario planning.

- In May 2025, Siemens and Cybord collaborated to embed its visual AI solution in the Opcenter MES to improve real-time quality control during Surface Mount Technology (SMT) operations. This solution allows detecting defects, traceability, and corrective actions, which can be performed instantly in Opcenter, enhancing the efficiency of the production process, minimizing scrap and rework, and providing a consistent quality of the product at the international level of electronics production operations.

Report Scope

|

Detail |

|

|

Market Size in 2025 |

USD 16.2 Bn |

|

Market Forecast Value in 2035 |

USD 47.3 Bn |

|

Growth Rate (CAGR) |

11.3% |

|

Forecast Period |

2026 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value |

|

Report Format |

Electronic (PDF) + Excel |

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Manufacturing-Execution-Systems-Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

Manufacturing Execution Systems (MES) Market, By Component |

|

|

Manufacturing Execution Systems (MES) Market, By Deployment Mode |

|

|

Manufacturing Execution Systems (MES) Market, By Enterprise Size |

|

|

Manufacturing Execution Systems (MES) Market, By End-users Type |

|

|

Manufacturing Execution Systems (MES) Market, By Integration Level |

|

|

Manufacturing Execution Systems (MES) Market, By Production Type |

|

|

Manufacturing Execution Systems (MES) Market, By Automation Level |

|

Frequently Asked Questions

The global manufacturing execution systems (MES) market was valued at USD 16.2 Bn in 2025.

The global manufacturing execution systems (MES) market industry is expected to grow at a CAGR of 11.3% from 2026 to 2035.

Key factors driving the demand for manufacturing execution systems (MES) market include Industry 4.0 adoption, real-time production monitoring, operational efficiency, predictive maintenance, quality control, and integration with IoT, AI, and cloud technologies.

In terms of component, the software segment accounted for the major share in 2025.

North America is the most attractive region for manufacturing execution systems (MES) market.

Prominent players operating in the global manufacturing execution systems (MES) market are ABB Ltd., Aegis Software, Andons Industries, AVEVA Group, Critical Manufacturing, Dassault Systèmes, Emerson Electric, Epicor Software Corporation, Forcam, General Electric (GE Digital), Honeywell International, Infor, Itac Software AG, Parsec Automation, Polytec Group, Rockwell Automation, SAP SE, Schneider Electric SE, Siemens AG, Tescom Solutions, Werum IT Solutions, Yokogawa Electric Corporation, and Other Key Players.

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Manufacturing Execution Systems (MES) Market Outlook

- 2.1.1. Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2026-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Manufacturing Execution Systems (MES) Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Automation & Process Control Industry Overview, 2025

- 3.1.1. Automation & Process Control Industry Ecosystem Analysis

- 3.1.2. Key Trends for Automation & Process Control Industry

- 3.1.3. Regional Distribution for Automation & Process Control Industry

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2025

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.1.1. Based on the component & Raw material

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.5.1. Manufacturer

- 3.6. Raw Material Analysis

- 3.1. Global Automation & Process Control Industry Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Increasing adoption of Industry 4.0 and smart manufacturing.

- 4.1.1.2. Growing demand for real-time production monitoring and operational efficiency.

- 4.1.1.3. Integration of MES with IoT, AI, and cloud technologies.

- 4.1.2. Restraints

- 4.1.2.1. High implementation and maintenance costs for small and medium enterprises.

- 4.1.2.2. Complexity in integrating MES with legacy systems and workforce skill gaps.

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Ecosystem Analysis

- 4.5. Porter’s Five Forces Analysis

- 4.6. PESTEL Analysis

- 4.7. Global Manufacturing Execution Systems (MES) Market Demand

- 4.7.1. Historical Market Size –Value (US$ Bn), 2020-2024

- 4.7.2. Current and Future Market Size –Value (US$ Bn), 2026–2035

- 4.7.2.1. Y-o-Y Growth Trends

- 4.7.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Manufacturing Execution Systems (MES) Market Analysis, By Component

- 6.1. Key Segment Analysis

- 6.2. Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, By Component, 2021-2035

- 6.2.1. Software

- 6.2.1.1. Production Management

- 6.2.1.2. Quality Management

- 6.2.1.3. Performance Analysis

- 6.2.1.4. Inventory Management

- 6.2.1.5. Maintenance Management

- 6.2.1.6. Data Collection & Acquisition

- 6.2.1.7. Scheduling & Dispatching

- 6.2.1.8. Labor Management

- 6.2.1.9. Others

- 6.2.2. Services

- 6.2.2.1. Consulting & Integration

- 6.2.2.2. Training & Education

- 6.2.2.3. Support & Maintenance

- 6.2.2.4. Managed Services

- 6.2.2.5. Others

- 6.2.1. Software

- 7. Global Manufacturing Execution Systems (MES) Market Analysis, By Deployment Mode

- 7.1. Key Segment Analysis

- 7.2. Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, By Deployment Mode, 2021-2035

- 7.2.1. On-Premises

- 7.2.1.1. Traditional Infrastructure

- 7.2.1.2. Virtualized Environment

- 7.2.2. Cloud-Based

- 7.2.2.1. Public Cloud

- 7.2.2.2. Private Cloud

- 7.2.2.3. Hybrid Cloud

- 7.2.3. Edge Deployment

- 7.2.1. On-Premises

- 8. Global Manufacturing Execution Systems (MES) Market Analysis,By Enterprise Size

- 8.1. Key Segment Analysis

- 8.2. Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, By Enterprise Size, 2021-2035

- 8.2.1. Large Enterprises

- 8.2.2. Small and Medium Enterprises (SMEs)

- 9. Global Manufacturing Execution Systems (MES) Market Analysis, By End-users Type

- 9.1. Key Segment Analysis

- 9.2. Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, By End-users Type, 2021-2035

- 9.2.1. Discrete Manufacturing

- 9.2.1.1. Automotive & Transportation

- 9.2.1.2. Assembly Line Management

- 9.2.1.3. Quality Control & Testing

- 9.2.1.4. Supply Chain Visibility

- 9.2.1.5. Just-in-Time Manufacturing

- 9.2.1.6. Traceability & Recall Management

- 9.2.1.7. Robotics Integration

- 9.2.1.8. Others

- 9.2.1.9. Aerospace & Defense

- 9.2.1.10. Complex Assembly Tracking

- 9.2.1.11. Material Traceability

- 9.2.1.12. Maintenance, Repair & Overhaul (MRO)

- 9.2.1.13. Quality Documentation

- 9.2.1.14. Others

- 9.2.1.15. Electronics & Semiconductors

- 9.2.1.16. Wafer Fabrication Management

- 9.2.1.17. Component Traceability

- 9.2.1.18. Yield Management

- 9.2.1.19. Cleanroom Monitoring

- 9.2.1.20. Equipment Interface Management

- 9.2.1.21. Others

- 9.2.1.22. Machinery & Equipment

- 9.2.1.23. Medical Devices

- 9.2.1.24. Others

- 9.2.2. Process Manufacturing

- 9.2.2.1. Food & Beverage

- 9.2.2.2. Batch Tracking & Traceability

- 9.2.2.3. Food Safety Compliance

- 9.2.2.4. Shelf-Life Management

- 9.2.2.5. Packaging Management

- 9.2.2.6. Others

- 9.2.2.7. Pharmaceuticals & Biotechnology

- 9.2.2.8. Good Manufacturing Practice (GMP) Compliance

- 9.2.2.9. Batch Genealogy

- 9.2.2.10. Laboratory Information Management

- 9.2.2.11. Serialization & Track-and-Trace

- 9.2.2.12. Others

- 9.2.2.13. Chemicals

- 9.2.2.14. Process Control & Optimization

- 9.2.2.15. Hazardous Material Management

- 9.2.2.16. Batch Formula Management

- 9.2.2.17. Safety Management

- 9.2.2.18. Others

- 9.2.2.19. Oil & Gas

- 9.2.2.20. Metals & Mining

- 9.2.2.21. Pulp & Paper

- 9.2.2.22. Others

- 9.2.1. Discrete Manufacturing

- 10. Global Manufacturing Execution Systems (MES) Market Analysis, By Integration Level

- 10.1. Key Segment Analysis

- 10.2. Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, By Integration Level, 2021-2035

- 10.2.1. Standalone MES

- 10.2.2. ERP-Integrated MES

- 10.2.3. SCADA-Integrated MES

- 10.2.4. PLM-Integrated MES

- 10.2.5. Fully Integrated Manufacturing Suite

- 11. Global Manufacturing Execution Systems (MES) Market Analysis, By Production Type

- 11.1. Key Segment Analysis

- 11.2. Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, By Production Type, 2021-2035

- 11.2.1. Batch Production

- 11.2.2. Continuous Production

- 11.2.3. Discrete Production

- 11.2.4. Job Shop Production

- 11.2.5. Mixed-Mode Production

- 12. Global Manufacturing Execution Systems (MES) Market Analysis, By Automation Level

- 12.1. Key Segment Analysis

- 12.2. Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, By Automation Level, 2021-2035

- 12.2.1. Manual Control

- 12.2.2. Semi-Automated

- 12.2.3. Fully Automated

- 12.2.4. Autonomous Manufacturing

- 13. Global Manufacturing Execution Systems (MES) Market Analysis and Forecasts, by Region

- 13.1. Key Findings

- 13.2. Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, by Region, 2021-2035

- 13.2.1. North America

- 13.2.2. Europe

- 13.2.3. Asia Pacific

- 13.2.4. Middle East

- 13.2.5. Africa

- 13.2.6. South America

- 14. North America Manufacturing Execution Systems (MES) Market Analysis

- 14.1. Key Segment Analysis

- 14.2. Regional Snapshot

- 14.3. North America Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 14.3.1. Component

- 14.3.2. Deployment Mode

- 14.3.3. Enterprise Size

- 14.3.4. End-users Type

- 14.3.5. Integration Level

- 14.3.6. Production Type

- 14.3.7. Automation Level

- 14.3.8. Country

- 14.3.8.1. USA

- 14.3.8.2. Canada

- 14.3.8.3. Mexico

- 14.4. USA Manufacturing Execution Systems (MES) Market

- 14.4.1. Country Segmental Analysis

- 14.4.2. Component

- 14.4.3. Deployment Mode

- 14.4.4. Enterprise Size

- 14.4.5. End-users Type

- 14.4.6. Integration Level

- 14.4.7. Production Type

- 14.4.8. Automation Level

- 14.5. Canada Manufacturing Execution Systems (MES) Market

- 14.5.1. Country Segmental Analysis

- 14.5.2. Component

- 14.5.3. Deployment Mode

- 14.5.4. Enterprise Size

- 14.5.5. End-users Type

- 14.5.6. Integration Level

- 14.5.7. Production Type

- 14.5.8. Automation Level

- 14.6. Mexico Manufacturing Execution Systems (MES) Market

- 14.6.1. Country Segmental Analysis

- 14.6.2. Component

- 14.6.3. Deployment Mode

- 14.6.4. Enterprise Size

- 14.6.5. End-users Type

- 14.6.6. Integration Level

- 14.6.7. Production Type

- 14.6.8. Automation Level y

- 15. Europe Manufacturing Execution Systems (MES) Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. Europe Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 15.3.1. Component

- 15.3.2. Deployment Mode

- 15.3.3. Enterprise Size

- 15.3.4. End-users Type

- 15.3.5. Integration Level

- 15.3.6. Production Type

- 15.3.7. Automation Level

- 15.3.8. Country

- 15.3.8.1. Germany

- 15.3.8.2. United Kingdom

- 15.3.8.3. France

- 15.3.8.4. Italy

- 15.3.8.5. Spain

- 15.3.8.6. Netherlands

- 15.3.8.7. Nordic Countries

- 15.3.8.8. Poland

- 15.3.8.9. Russia & CIS

- 15.3.8.10. Rest of Europe

- 15.4. Germany Manufacturing Execution Systems (MES) Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Component

- 15.4.3. Deployment Mode

- 15.4.4. Enterprise Size

- 15.4.5. End-users Type

- 15.4.6. Integration Level

- 15.4.7. Production Type

- 15.4.8. Automation Level

- 15.5. United Kingdom Manufacturing Execution Systems (MES) Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Component

- 15.5.3. Deployment Mode

- 15.5.4. Enterprise Size

- 15.5.5. End-users Type

- 15.5.6. Integration Level

- 15.5.7. Production Type

- 15.5.8. Automation Level

- 15.6. France Manufacturing Execution Systems (MES) Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Component

- 15.6.3. Deployment Mode

- 15.6.4. Enterprise Size

- 15.6.5. End-users Type

- 15.6.6. Integration Level

- 15.6.7. Production Type

- 15.6.8. Automation Level

- 15.7. Italy Manufacturing Execution Systems (MES) Market

- 15.7.1. Country Segmental Analysis

- 15.7.2. Component

- 15.7.3. Deployment Mode

- 15.7.4. Enterprise Size

- 15.7.5. End-users Type

- 15.7.6. Integration Level

- 15.7.7. Production Type

- 15.7.8. Automation Level

- 15.8. Spain Manufacturing Execution Systems (MES) Market

- 15.8.1. Country Segmental Analysis

- 15.8.2. Component

- 15.8.3. Deployment Mode

- 15.8.4. Enterprise Size

- 15.8.5. End-users Type

- 15.8.6. Integration Level

- 15.8.7. Production Type

- 15.8.8. Automation Level

- 15.9. Netherlands Manufacturing Execution Systems (MES) Market

- 15.9.1. Country Segmental Analysis

- 15.9.2. Component

- 15.9.3. Deployment Mode

- 15.9.4. Enterprise Size

- 15.9.5. End-users Type

- 15.9.6. Integration Level

- 15.9.7. Production Type

- 15.9.8. Automation Level

- 15.10. Nordic Countries Manufacturing Execution Systems (MES) Market

- 15.10.1. Country Segmental Analysis

- 15.10.2. Component

- 15.10.3. Deployment Mode

- 15.10.4. Enterprise Size

- 15.10.5. End-users Type

- 15.10.6. Integration Level

- 15.10.7. Production Type

- 15.10.8. Automation Level

- 15.11. Poland Manufacturing Execution Systems (MES) Market

- 15.11.1. Country Segmental Analysis

- 15.11.2. Component

- 15.11.3. Deployment Mode

- 15.11.4. Enterprise Size

- 15.11.5. End-users Type

- 15.11.6. Integration Level

- 15.11.7. Production Type

- 15.11.8. Automation Level

- 15.12. Russia & CIS Manufacturing Execution Systems (MES) Market

- 15.12.1. Country Segmental Analysis

- 15.12.2. Component

- 15.12.3. Deployment Mode

- 15.12.4. Enterprise Size

- 15.12.5. End-users Type

- 15.12.6. Integration Level

- 15.12.7. Production Type

- 15.12.8. Automation Level

- 15.13. Rest of Europe Manufacturing Execution Systems (MES) Market

- 15.13.1. Country Segmental Analysis

- 15.13.2. Component

- 15.13.3. Deployment Mode

- 15.13.4. Enterprise Size

- 15.13.5. End-users Type

- 15.13.6. Integration Level

- 15.13.7. Production Type

- 15.13.8. Automation Level

- 16. Asia Pacific Manufacturing Execution Systems (MES) Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Asia Pacific Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 16.3.1. Component

- 16.3.2. Deployment Mode

- 16.3.3. Enterprise Size

- 16.3.4. End-users Type

- 16.3.5. Integration Level

- 16.3.6. Production Type

- 16.3.7. Automation Level

- 16.3.8. Country

- 16.3.8.1. China

- 16.3.8.2. India

- 16.3.8.3. Japan

- 16.3.8.4. South Korea

- 16.3.8.5. Australia and New Zealand

- 16.3.8.6. Indonesia

- 16.3.8.7. Malaysia

- 16.3.8.8. Thailand

- 16.3.8.9. Vietnam

- 16.3.8.10. Rest of Asia Pacific

- 16.4. China Manufacturing Execution Systems (MES) Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Component

- 16.4.3. Deployment Mode

- 16.4.4. Enterprise Size

- 16.4.5. End-users Type

- 16.4.6. Integration Level

- 16.4.7. Production Type

- 16.4.8. Automation Level

- 16.5. India Manufacturing Execution Systems (MES) Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Component

- 16.5.3. Deployment Mode

- 16.5.4. Enterprise Size

- 16.5.5. End-users Type

- 16.5.6. Integration Level

- 16.5.7. Production Type

- 16.5.8. Automation Level

- 16.6. Japan Manufacturing Execution Systems (MES) Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Component

- 16.6.3. Deployment Mode

- 16.6.4. Enterprise Size

- 16.6.5. End-users Type

- 16.6.6. Integration Level

- 16.6.7. Production Type

- 16.6.8. Automation Level

- 16.7. South Korea Manufacturing Execution Systems (MES) Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Component

- 16.7.3. Deployment Mode

- 16.7.4. Enterprise Size

- 16.7.5. End-users Type

- 16.7.6. Integration Level

- 16.7.7. Production Type

- 16.7.8. Automation Level

- 16.8. Australia and New Zealand Manufacturing Execution Systems (MES) Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Component

- 16.8.3. Deployment Mode

- 16.8.4. Enterprise Size

- 16.8.5. End-users Type

- 16.8.6. Integration Level

- 16.8.7. Production Type

- 16.8.8. Automation Level

- 16.9. Indonesia Manufacturing Execution Systems (MES) Market

- 16.9.1. Country Segmental Analysis

- 16.9.2. Component

- 16.9.3. Deployment Mode

- 16.9.4. Enterprise Size

- 16.9.5. End-users Type

- 16.9.6. Integration Level

- 16.9.7. Production Type

- 16.9.8. Automation Level

- 16.10. Malaysia Manufacturing Execution Systems (MES) Market

- 16.10.1. Country Segmental Analysis

- 16.10.2. Component

- 16.10.3. Deployment Mode

- 16.10.4. Enterprise Size

- 16.10.5. End-users Type

- 16.10.6. Integration Level

- 16.10.7. Production Type

- 16.10.8. Automation Level

- 16.11. Thailand Manufacturing Execution Systems (MES) Market

- 16.11.1. Country Segmental Analysis

- 16.11.2. Component

- 16.11.3. Deployment Mode

- 16.11.4. Enterprise Size

- 16.11.5. End-users Type

- 16.11.6. Integration Level

- 16.11.7. Production Type

- 16.11.8. Automation Level

- 16.12. Vietnam Manufacturing Execution Systems (MES) Market

- 16.12.1. Country Segmental Analysis

- 16.12.2. Component

- 16.12.3. Deployment Mode

- 16.12.4. Enterprise Size

- 16.12.5. End-users Type

- 16.12.6. Integration Level

- 16.12.7. Production Type

- 16.12.8. Automation Level

- 16.13. Rest of Asia Pacific Manufacturing Execution Systems (MES) Market

- 16.13.1. Country Segmental Analysis

- 16.13.2. Component

- 16.13.3. Deployment Mode

- 16.13.4. Enterprise Size

- 16.13.5. End-users Type

- 16.13.6. Integration Level

- 16.13.7. Production Type

- 16.13.8. Automation Level

- 17. Middle East Manufacturing Execution Systems (MES) Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Middle East Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 17.3.1. Component

- 17.3.2. Deployment Mode

- 17.3.3. Enterprise Size

- 17.3.4. End-users Type

- 17.3.5. Integration Level

- 17.3.6. Production Type

- 17.3.7. Automation Level

- 17.3.8. Country

- 17.3.8.1. Turkey

- 17.3.8.2. UAE

- 17.3.8.3. Saudi Arabia

- 17.3.8.4. Israel

- 17.3.8.5. Rest of Middle East

- 17.4. Turkey Manufacturing Execution Systems (MES) Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Component

- 17.4.3. Deployment Mode

- 17.4.4. Enterprise Size

- 17.4.5. End-users Type

- 17.4.6. Integration Level

- 17.4.7. Production Type

- 17.4.8. Automation Level

- 17.5. UAE Manufacturing Execution Systems (MES) Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Component

- 17.5.3. Deployment Mode

- 17.5.4. Enterprise Size

- 17.5.5. End-users Type

- 17.5.6. Integration Level

- 17.5.7. Production Type

- 17.5.8. Automation Level

- 17.6. Saudi Arabia Manufacturing Execution Systems (MES) Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Component

- 17.6.3. Deployment Mode

- 17.6.4. Enterprise Size

- 17.6.5. End-users Type

- 17.6.6. Integration Level

- 17.6.7. Production Type

- 17.6.8. Automation Level

- 17.7. Israel Manufacturing Execution Systems (MES) Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Component

- 17.7.3. Deployment Mode

- 17.7.4. Enterprise Size

- 17.7.5. End-users Type

- 17.7.6. Integration Level

- 17.7.7. Production Type

- 17.7.8. Automation Level

- 17.8. Rest of Middle East Manufacturing Execution Systems (MES) Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Component

- 17.8.3. Deployment Mode

- 17.8.4. Enterprise Size

- 17.8.5. End-users Type

- 17.8.6. Integration Level

- 17.8.7. Production Type

- 17.8.8. Automation Level

- 18. Africa Manufacturing Execution Systems (MES) Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Africa Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 18.3.1. Component

- 18.3.2. Deployment Mode

- 18.3.3. Enterprise Size

- 18.3.4. End-users Type

- 18.3.5. Integration Level

- 18.3.6. Production Type

- 18.3.7. Automation Level

- 18.3.8. Country

- 18.3.8.1. South Africa

- 18.3.8.2. Egypt

- 18.3.8.3. Nigeria

- 18.3.8.4. Algeria

- 18.3.8.5. Rest of Africa

- 18.4. South Africa Manufacturing Execution Systems (MES) Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Component

- 18.4.3. Deployment Mode

- 18.4.4. Enterprise Size

- 18.4.5. End-users Type

- 18.4.6. Integration Level

- 18.4.7. Production Type

- 18.4.8. Automation Level

- 18.5. Egypt Manufacturing Execution Systems (MES) Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Component

- 18.5.3. Deployment Mode

- 18.5.4. Enterprise Size

- 18.5.5. End-users Type

- 18.5.6. Integration Level

- 18.5.7. Production Type

- 18.5.8. Automation Level

- 18.6. Nigeria Manufacturing Execution Systems (MES) Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Component

- 18.6.3. Deployment Mode

- 18.6.4. Enterprise Size

- 18.6.5. End-users Type

- 18.6.6. Integration Level

- 18.6.7. Production Type

- 18.6.8. Automation Level

- 18.7. Algeria Manufacturing Execution Systems (MES) Market

- 18.7.1. Country Segmental Analysis

- 18.7.2. Component

- 18.7.3. Deployment Mode

- 18.7.4. Enterprise Size

- 18.7.5. End-users Type

- 18.7.6. Integration Level

- 18.7.7. Production Type

- 18.7.8. Automation Level

- 18.8. Rest of Africa Manufacturing Execution Systems (MES) Market

- 18.8.1. Country Segmental Analysis

- 18.8.2. Component

- 18.8.3. Deployment Mode

- 18.8.4. Enterprise Size

- 18.8.5. End-users Type

- 18.8.6. Integration Level

- 18.8.7. Production Type

- 18.8.8. Automation Level

- 19. South America Manufacturing Execution Systems (MES) Market Analysis

- 19.1. Key Segment Analysis

- 19.2. Regional Snapshot

- 19.3. South America Manufacturing Execution Systems (MES) Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 19.3.1. Component

- 19.3.2. Component

- 19.3.3. Deployment Mode

- 19.3.4. Enterprise Size

- 19.3.5. End-users Type

- 19.3.6. Integration Level

- 19.3.7. Production Type

- 19.3.8. Automation Level

- 19.3.9. Country

- 19.3.9.1. Brazil

- 19.3.9.2. Argentina

- 19.3.9.3. Rest of South America

- 19.4. Brazil Manufacturing Execution Systems (MES) Market

- 19.4.1. Country Segmental Analysis

- 19.4.2. Component

- 19.4.3. Deployment Mode

- 19.4.4. Enterprise Size

- 19.4.5. End-users Type

- 19.4.6. Integration Level

- 19.4.7. Production Type

- 19.4.8. Automation Level

- 19.5. Argentina Manufacturing Execution Systems (MES) Market

- 19.5.1. Country Segmental Analysis

- 19.5.2. Component

- 19.5.3. Deployment Mode

- 19.5.4. Enterprise Size

- 19.5.5. End-users Type

- 19.5.6. Integration Level

- 19.5.7. Production Type

- 19.5.8. Automation Level

- 19.6. Rest of South America Manufacturing Execution Systems (MES) Market

- 19.6.1. Country Segmental Analysis

- 19.6.2. Component

- 19.6.3. Deployment Mode

- 19.6.4. Enterprise Size

- 19.6.5. End-users Type

- 19.6.6. Integration Level

- 19.6.7. Production Type

- 19.6.8. Automation Level

- 20. Key Players/ Company Profile

- 20.1. ABB Ltd.

- 20.1.1. Company Details/ Overview

- 20.1.2. Company Financials

- 20.1.3. Key Customers and Competitors

- 20.1.4. Business/ Industry Portfolio

- 20.1.5. Product Portfolio/ Specification Details

- 20.1.6. Pricing Data

- 20.1.7. Strategic Overview

- 20.1.8. Recent Developments

- 20.2. Aegis Software

- 20.3. Andons Industries

- 20.4. AVEVA Group

- 20.5. Critical Manufacturing

- 20.6. Dassault Systèmes

- 20.7. Emerson Electric

- 20.8. Epicor Software Corporation

- 20.9. Forcam

- 20.10. General Electric (GE Digital)

- 20.11. Honeywell International

- 20.12. Infor

- 20.13. Itac Software AG

- 20.14. Parsec Automation

- 20.15. Polytec Group

- 20.16. Rockwell Automation

- 20.17. SAP SE

- 20.18. Schneider Electric SE

- 20.19. Siemens AG

- 20.20. Tescom Solutions

- 20.21. Werum IT Solutions

- 20.22. Yokogawa Electric Corporation

- 20.23. Other Key Players

- 20.1. ABB Ltd.

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase and Others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players product portfolio

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources includes primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data