Composite Tooling Market anticipated surpassing USD 1 Billion by 2035.

An extensive study of propelling opportunities in, “Composite Tooling Market Size, Share & Trends Analysis Report by Substation Type (Air-Insulated Substation (AIS), Gas-Insulated Substation (GIS), Hybrid / Compact Substation, Modular / Containerized Substation, Others), by Voltage Level (Low Voltage (<1 kV), Medium Voltage (1 kV–36 kV), High Voltage (36 kV–220 kV), Extra High Voltage (>220 kV)), Product / Equipment, Insulation / Cooling Technology, Installation Location, Service Type, Ownership / Delivery Model, End-User / Application and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035” A comprehensive report of growing market landscapes in the Composite Tooling sector uncovering key growth drivers including niche market leadership, technology-enabled distribution, and increasing consumer needs supporting Composite Tooling market potential to scale globally.

Composite Tooling Market Forecast 2035:

According to recent analysis, the global composite tooling market is expected to grow from USD 0.6 Billion in 2025 to USD 1.1 Billion by 2035, registering a robust CAGR of 6.3% during the forecast period. This growth is spurred by light weight, high strength composite tooling solutions with a thermal stability, especially in aerospace, automotive, and wind energy.

While composite components increase in complexity and manufacturers are being pressured to manufacture faster and more accurately, companies are adopting advanced automated and hybrid tooling technologies. In 2024, Hexcel and Toray took their modular composite tooling platforms to the next level to support next-generation aircraft and EV components, establishing a new standard for accuracy and durability. With the rising demand for lightweight structures and sustainable manufacturing, the composite tooling market is expected to grow steadily and innovatively as it heads toward 2035.

“Key Driver, Restraint, and Growth Opportunity Defining the Composite Tooling Market”

The composite tooling industry is expected to continue to grow rapidly, with interest in composites from the aerospace and automotive sectors and high-performance industrial applications where low mass, structural integrity and thermal stability are crucial. Today, advanced composite tooling has incorporated elements such as additive manufacturing, modular tooling, and automation to deliver a better product to users, while increasing accuracy, decreasing total cycle times and allowing for more complex component designs. In 2024, Hexcel and Toray ramped up production capabilities for modular and a more automated composite tooling offering to support next-generation aircraft and electric vehicle components, and this established a metric for quality and efficiency consistent with those products.

Risks remain in the composite space, including rising raw material costs, complicated manufacturing processes, and specialized labor requirements that deter individual and smaller organizational participation, which also leads to increased dependence by OEMs on their tier 1 supplier.

Simultaneously, there is a public will from government agencies to increase clean energy and aerospace hardware manufacturing in North America, as well as some degree of responsible reshoring of manufacturing back into North America. This is generating new opportunities, creating ecosystem development for their third-party suppliers, and fuelling adoption of advanced composite tooling throughout the world.

"Impact of Global Tariff Policies on the Composite Tooling Market Growth and Strategy"

In the composite tooling market, global tariffs on raw materials like carbon fiber, epoxy resins, and automated tooling equipment can change the economics of supply chains and ultimately the cost of final products. If tariffs between global regions such as North America, Europe, and Asia Pacific are implemented, manufacturers may be encouraged to establish localized production or form collaborative partnerships so they are not reliant on imports from across a border.

Moreover, companies such as Hexcel and Toray may evaluate sourcing strategies and/or invest in domestic production capacity, or assess logistics ways to remain competitive and reduce costs. Tariffs can create cost pressure that leads to increased R&D investments in either alternative materials or modular approaches to tooling technology and can potentially lessen costs to stay viable and keep the market growing.

Regional Analysis of Composite Tooling Market

- The composite tooling market is primarily located in North America with support from aerospace, defense, and automotive, and advanced manufacturing technology sectors. The U.S. and Canada are investing heavily in the development of lightweight, high-precision tooling for applications in aircraft, EVs, and wind energy components.

- Further, Europe follows closely with growth in aerospace and renewable energy applications. Asia Pacific regions are seeing significant uptake due to industrialization and growth in EV production in China, Japan, and India. Latin America and the Middle East & Africa remain in a position of emerging markets with limited yet growing opportunities.

Key players in the global composite tooling market include prominent companies such as AdamWorks, LLC, Airtech Advanced Materials Group, Cytec Solvay Group, Formaplex, Gurit Holding AG, Hexcel Corporation, Huntsman Corporation, Mitsubishi Chemical Corporation, Owens Corning, PRF Composite Materials, Rampf Group, Inc., Royal TenCate N.V., Sika AG, Solvay S.A., Startasys, Teijin Limited, Toray Industries, Inc., Trelleborg AB, Weber Manufacturing Technologies Inc., and other key players, along with several other key players contributing to market growth through innovation, strategic partnerships, and global expansion.

The composite tooling market has been segmented as follows:

Composite Tooling Market Analysis, by Fiber Type

- Carbon Fiber

- Standard modulus carbon fiber

- Intermediate modulus carbon fiber

- High modulus carbon fiber

- Ultra-high modulus carbon fiber

- Others

- Glass Fiber

- E-glass fiber

- S-glass fiber

- D-glass fiber

- AR-glass fiber

- Others

- Aramid Fiber

- Kevlar-based tooling

- Nomex-based tooling

- Para-aramid fibers

- Meta-aramid fibers

- Others

- Natural Fibers

- Flax fiber

- Hemp fiber

- Jute fiber

- Basalt fiber

- Others

- Hybrid Fiber Systems

- Carbon-glass hybrid

- Carbon-aramid hybrid

- Multi-fiber combinations

- Others

Composite Tooling Market Analysis, by Form

- Fabric

- Prepreg

Composite Tooling Market Analysis, by Resin Type

- Epoxy

- Phenolic Resins

- Bismaleimide (BMI)

- Polyester Resins

- Polyurethane Resins

- Others

Composite Tooling Market Analysis, by Manufacturing Process

- Hand Layup

- Vacuum Infusion

- Filament Winding

- Resin Transfer Molding (RTM)

- Autoclave Processing

- Compression Molding

- Pultrusion Process

- Filament Winding

- Others

Composite Tooling Market Analysis, by End-use Industry

- Aerospace & Defense

- Commercial Aviation

- Fuselage section tooling

- Engine nacelle tooling

- Landing gear door tooling

- Others

- Military Aviation

- Fighter aircraft tooling

- Helicopter rotor blade tooling

- UAV/Drone component tooling

- Others

- Space Applications

- Satellite structure tooling

- Rocket component tooling

- Space station module tooling

- Others

- Others

- Automotive

- Body & Exterior

- Body panel tooling

- Bumper and spoiler tooling

- Hood and trunk lid tooling

- Door and fender tooling

- Others

- Performance & Racing

- Racing car body tooling

- Aftermarket parts tooling

- High-performance component tooling

- Others

- Electric Vehicles

- Battery enclosure tooling

- Lightweight structural tooling

- EV-specific component tooling

- Others

- Others

- Construction & Infrastructure

- Architectural panel tooling

- Bridge component tooling

- Building facade tooling

- Infrastructure element tooling

- Decorative element tooling

- Others

- Industrial Equipment

- Pressure vessel tooling

- Pipe and tank tooling

- Conveyor component tooling

- Industrial housing tooling

- Equipment enclosure tooling

- Others

- Transportation

- Train car body tooling

- Interior panel tooling

- Structural component tooling

- Subway car tooling

- Others

- Electronics & Telecommunications

- Medical & Healthcare

- Marine & Shipbuilding

- Wind Energy

- Sports & Recreation

- Others

Composite Tooling Market Analysis, by Tooling Type

- Prototype Tooling

- Production Tooling

Composite Tooling Market Analysis, by Tool Configuration

- Single-Use Tools

- Reusable Tools

- Modular Tool Systems

- Reconfigurable Tools

- Multi-Part Tool Systems

Composite Tooling Market Analysis, by Region

- North America

- Europe

- Asia Pacific

- Middle East

- Africa

- South America

About Us

MarketGenics is a global market research and management consulting company empowering decision makers from startups, Fortune 500 companies, non-profit organizations, universities and government institutions. Our main goal is to assist and partner organizations to make lasting strategic improvements and realize growth targets. Our industry research reports are designed to provide granular quantitative information, combined with key industry insights, aimed at assisting sustainable organizational development.

We serve clients on every aspect of strategy, including product development, application modeling, exploring new markets and tapping into niche growth opportunities.

Contact US

USA Address:

800 N King Street Suite 304 #4208 Wilmington, DE 19801 United States.

+1(302)303-2617

India Address:

3rd floor, Indeco Equinox, Baner Road, Baner, Pune, Maharashtra 411045 India.

+91-8788594158

sales@marketdigits.co

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Industrial Substation Market Outlook

- 2.1.1. Global Industrial Substation Market Size (Value - USD Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Industrial Substation Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Industrial Substation Industry Overview, 2025

- 3.1.1. Energy & Power Ecosystem Analysis

- 3.1.2. Key Trends for Energy & Power Industry

- 3.1.3. Regional Distribution for Energy & Power Industry

- 3.2. Supplier Customer Data

- 3.3. Source Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2025

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.6. Raw Material Analysis

- 3.1. Global Industrial Substation Industry Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Industrial Expansion and Grid Digitalization Fueling Advanced Substation Deployments

- 4.1.2. Restraints

- 4.1.2.1. High Installation Costs and Land Constraints Limit Industrial Substation Expansion

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Resource Supply

- 4.4.2. Power Generation

- 4.4.3. Transmission & Distribution

- 4.4.4. Storage & Retail

- 4.4.5. End-Use & Sustainability

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Pricing Analysis

- 4.6.1. Regional Pricing Analysis

- 4.6.2. Segmental Pricing Trends

- 4.6.3. Factors Influencing Pricing

- 4.7. Porter’s Five Forces Analysis

- 4.8. PESTEL Analysis

- 4.9. Global Industrial Substation Market Demand

- 4.9.1. Historical Market Size - (Value - USD Bn), 2021-2024

- 4.9.2. Current and Future Market Size - (Value - USD Bn), 2025–2035

- 4.9.2.1. Y-o-Y Growth Trends

- 4.9.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Industrial Substation Market Analysis, by Fiber Type

- 6.1. Key Segment Analysis

- 6.2. Global Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, by Fiber Type, 2021-2035

- 6.2.1. Carbon Fiber

- 6.2.1.1. Standard modulus carbon fiber

- 6.2.1.2. Intermediate modulus carbon fiber

- 6.2.1.3. High modulus carbon fiber

- 6.2.1.4. Ultra-high modulus carbon fiber

- 6.2.1.5. Others

- 6.2.2. Glass Fiber

- 6.2.2.1. E-glass fiber

- 6.2.2.2. S-glass fiber

- 6.2.2.3. D-glass fiber

- 6.2.2.4. AR-glass fiber

- 6.2.2.5. Others

- 6.2.3. Aramid Fiber

- 6.2.3.1. Kevlar-based tooling

- 6.2.3.2. Nomex-based tooling

- 6.2.3.3. Para-aramid fibers

- 6.2.3.4. Meta-aramid fibers

- 6.2.3.5. Others

- 6.2.4. Natural Fibers

- 6.2.4.1. Flax fiber

- 6.2.4.2. Hemp fiber

- 6.2.4.3. Jute fiber

- 6.2.4.4. Basalt fiber

- 6.2.4.5. Others

- 6.2.5. Hybrid Fiber Systems

- 6.2.5.1. Carbon-glass hybrid

- 6.2.5.2. Carbon-aramid hybrid

- 6.2.5.3. Multi-fiber combinations

- 6.2.5.4. Others

- 6.2.1. Carbon Fiber

- 7. Global Industrial Substation Market Analysis, by Form

- 7.1. Key Segment Analysis

- 7.2. Global Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, by Form, 2021-2035

- 7.2.1. Fabric

- 7.2.2. Prepreg

- 8. Global Industrial Substation Market Analysis, by Resin Type

- 8.1. Key Segment Analysis

- 8.2. Global Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, Resin Type, 2021-2035

- 8.2.1. Epoxy

- 8.2.2. Phenolic Resins

- 8.2.3. Bismaleimide (BMI)

- 8.2.4. Polyester Resins

- 8.2.5. Polyurethane Resins

- 8.2.6. Others

- 9. Global Industrial Substation Market Analysis, by Manufacturing Process

- 9.1. Key Segment Analysis

- 9.2. Global Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, by Manufacturing Process, 2021-2035

- 9.2.1. Hand Layup

- 9.2.2. Vacuum Infusion

- 9.2.3. Filament Winding

- 9.2.4. Resin Transfer Molding (RTM)

- 9.2.5. Autoclave Processing

- 9.2.6. Compression Molding

- 9.2.7. Pultrusion Process

- 9.2.8. Filament Winding

- 9.2.9. Others

- 10. Global Industrial Substation Market Analysis, by End-use Industry

- 10.1. Key Segment Analysis

- 10.2. Global Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, by End-use Industry, 2021-2035

- 10.2.1. Indoor Substations

- 10.2.2. Outdoor Substations

- 10.2.3. Rooftop/ On-site Industrial Substations

- 10.2.4. Others

- 11. Global Industrial Substation Market Analysis, by Service Type

- 11.1. Key Segment Analysis

- 11.2. Global Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, by Service Type, 2021-2035

- 11.2.1. Aerospace & Defense

- 11.2.1.1. Commercial Aviation

- 11.2.1.1.1. Fuselage section tooling

- 11.2.1.1.2. Engine nacelle tooling

- 11.2.1.1.3. Landing gear door tooling

- 11.2.1.1.4. Others

- 11.2.1.2. Military Aviation

- 11.2.1.2.1. Fighter aircraft tooling

- 11.2.1.2.2. Helicopter rotor blade tooling

- 11.2.1.2.3. UAV/Drone component tooling

- 11.2.1.2.4. Others

- 11.2.1.3. Space Applications

- 11.2.1.3.1. Satellite structure tooling

- 11.2.1.3.2. Rocket component tooling

- 11.2.1.3.3. Space station module tooling

- 11.2.1.3.4. Others

- 11.2.1.4. Others

- 11.2.1.1. Commercial Aviation

- 11.2.2. Automotive

- 11.2.2.1. Body & Exterior

- 11.2.2.1.1. Body panel tooling

- 11.2.2.1.2. Bumper and spoiler tooling

- 11.2.2.1.3. Hood and trunk lid tooling

- 11.2.2.1.4. Door and fender tooling

- 11.2.2.1.5. Others

- 11.2.2.2. Performance & Racing

- 11.2.2.2.1. Racing car body tooling

- 11.2.2.2.2. Aftermarket parts tooling

- 11.2.2.2.3. High-performance component tooling

- 11.2.2.2.4. Others

- 11.2.2.3. Electric Vehicles

- 11.2.2.3.1. Battery enclosure tooling

- 11.2.2.3.2. Lightweight structural tooling

- 11.2.2.3.3. EV-specific component tooling

- 11.2.2.3.4. Others

- 11.2.2.4. Others

- 11.2.2.1. Body & Exterior

- 11.2.3. Construction & Infrastructure

- 11.2.3.1. Architectural panel tooling

- 11.2.3.2. Bridge component tooling

- 11.2.3.3. Building facade tooling

- 11.2.3.4. Infrastructure element tooling

- 11.2.3.5. Decorative element tooling

- 11.2.3.6. Others

- 11.2.4. Industrial Equipment

- 11.2.4.1. Pressure vessel tooling

- 11.2.4.2. Pipe and tank tooling

- 11.2.4.3. Conveyor component tooling

- 11.2.4.4. Industrial housing tooling

- 11.2.4.5. Equipment enclosure tooling

- 11.2.4.6. Others

- 11.2.5. Transportation

- 11.2.5.1. Train car body tooling

- 11.2.5.2. Interior panel tooling

- 11.2.5.3. Structural component tooling

- 11.2.5.4. Subway car tooling

- 11.2.5.5. Others

- 11.2.6. Electronics & Telecommunications

- 11.2.7. Medical & Healthcare

- 11.2.8. Marine & Shipbuilding

- 11.2.9. Wind Energy

- 11.2.10. Sports & Recreation

- 11.2.11. Others

- 11.2.1. Aerospace & Defense

- 12. Global Industrial Substation Market Analysis, by Tooling Type

- 12.1. Key Segment Analysis

- 12.2. Global Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, by Tooling Type, 2021-2035

- 12.2.1. Prototype Tooling

- 12.2.2. Production Tooling

- 13. Global Industrial Substation Market Analysis, by Tool Configuration

- 13.1. Key Segment Analysis

- 13.2. Global Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, by Tool Configuration, 2021-2035

- 13.2.1. Single-Use Tools

- 13.2.2. Reusable Tools

- 13.2.3. Modular Tool Systems

- 13.2.4. Reconfigurable Tools

- 13.2.5. Multi-Part Tool Systems

- 14. Global Industrial Substation Market Analysis and Forecasts, by Region

- 14.1. Key Findings

- 14.2. Global Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, by Region, 2021-2035

- 14.2.1. North America

- 14.2.2. Europe

- 14.2.3. Asia Pacific

- 14.2.4. Middle East

- 14.2.5. Africa

- 14.2.6. South America

- 15. North America Industrial Substation Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. North America Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 15.3.1. Fiber Type

- 15.3.2. Form

- 15.3.3. Resin Type

- 15.3.4. Manufacturing Process

- 15.3.5. End-use Industry

- 15.3.6. Tooling Type

- 15.3.7. Tool Configuration

- 15.3.8. Country

- 15.3.8.1. USA

- 15.3.8.2. Canada

- 15.3.8.3. Mexico

- 15.4. USA Industrial Substation Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Fiber Type

- 15.4.3. Form

- 15.4.4. Resin Type

- 15.4.5. Manufacturing Process

- 15.4.6. End-use Industry

- 15.4.7. Tooling Type

- 15.4.8. Tool Configuration

- 15.5. Canada Industrial Substation Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Fiber Type

- 15.5.3. Form

- 15.5.4. Resin Type

- 15.5.5. Manufacturing Process

- 15.5.6. End-use Industry

- 15.5.7. Tooling Type

- 15.5.8. Tool Configuration

- 15.6. Mexico Industrial Substation Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Fiber Type

- 15.6.3. Form

- 15.6.4. Resin Type

- 15.6.5. Manufacturing Process

- 15.6.6. End-use Industry

- 15.6.7. Tooling Type

- 15.6.8. Tool Configuration

- 16. Europe Industrial Substation Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Europe Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 16.3.1. Fiber Type

- 16.3.2. Form

- 16.3.3. Resin Type

- 16.3.4. Manufacturing Process

- 16.3.5. End-use Industry

- 16.3.6. Tooling Type

- 16.3.7. Tool Configuration

- 16.3.8. Country

- 16.3.8.1. Germany

- 16.3.8.2. United Kingdom

- 16.3.8.3. France

- 16.3.8.4. Italy

- 16.3.8.5. Spain

- 16.3.8.6. Netherlands

- 16.3.8.7. Nordic Countries

- 16.3.8.8. Poland

- 16.3.8.9. Russia & CIS

- 16.3.8.10. Rest of Europe

- 16.4. Germany Industrial Substation Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Fiber Type

- 16.4.3. Form

- 16.4.4. Resin Type

- 16.4.5. Manufacturing Process

- 16.4.6. End-use Industry

- 16.4.7. Tooling Type

- 16.4.8. Tool Configuration

- 16.5. United Kingdom Industrial Substation Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Fiber Type

- 16.5.3. Form

- 16.5.4. Resin Type

- 16.5.5. Manufacturing Process

- 16.5.6. End-use Industry

- 16.5.7. Tooling Type

- 16.5.8. Tool Configuration

- 16.6. France Industrial Substation Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Fiber Type

- 16.6.3. Form

- 16.6.4. Resin Type

- 16.6.5. Manufacturing Process

- 16.6.6. End-use Industry

- 16.6.7. Tooling Type

- 16.6.8. Tool Configuration

- 16.7. Italy Industrial Substation Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Fiber Type

- 16.7.3. Form

- 16.7.4. Resin Type

- 16.7.5. Manufacturing Process

- 16.7.6. End-use Industry

- 16.7.7. Tooling Type

- 16.7.8. Tool Configuration

- 16.8. Spain Industrial Substation Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Fiber Type

- 16.8.3. Form

- 16.8.4. Resin Type

- 16.8.5. Manufacturing Process

- 16.8.6. End-use Industry

- 16.8.7. Tooling Type

- 16.8.8. Tool Configuration

- 16.9. Netherlands Industrial Substation Market

- 16.9.1. Country Segmental Analysis

- 16.9.2. Fiber Type

- 16.9.3. Form

- 16.9.4. Resin Type

- 16.9.5. Manufacturing Process

- 16.9.6. End-use Industry

- 16.9.7. Tooling Type

- 16.9.8. Tool Configuration

- 16.10. Nordic Countries Industrial Substation Market

- 16.10.1. Country Segmental Analysis

- 16.10.2. Fiber Type

- 16.10.3. Form

- 16.10.4. Resin Type

- 16.10.5. Manufacturing Process

- 16.10.6. End-use Industry

- 16.10.7. Tooling Type

- 16.10.8. Tool Configuration

- 16.11. Poland Industrial Substation Market

- 16.11.1. Country Segmental Analysis

- 16.11.2. Fiber Type

- 16.11.3. Form

- 16.11.4. Resin Type

- 16.11.5. Manufacturing Process

- 16.11.6. End-use Industry

- 16.11.7. Tooling Type

- 16.11.8. Tool Configuration

- 16.12. Russia & CIS Industrial Substation Market

- 16.12.1. Country Segmental Analysis

- 16.12.2. Fiber Type

- 16.12.3. Form

- 16.12.4. Resin Type

- 16.12.5. Manufacturing Process

- 16.12.6. End-use Industry

- 16.12.7. Tooling Type

- 16.12.8. Tool Configuration

- 16.13. Rest of Europe Industrial Substation Market

- 16.13.1. Country Segmental Analysis

- 16.13.2. Fiber Type

- 16.13.3. Form

- 16.13.4. Resin Type

- 16.13.5. Manufacturing Process

- 16.13.6. End-use Industry

- 16.13.7. Tooling Type

- 16.13.8. Tool Configuration

- 17. Asia Pacific Industrial Substation Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. East Asia Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 17.3.1. Fiber Type

- 17.3.2. Form

- 17.3.3. Resin Type

- 17.3.4. Manufacturing Process

- 17.3.5. End-use Industry

- 17.3.6. Tooling Type

- 17.3.7. Tool Configuration

- 17.3.8. Country

- 17.3.8.1. China

- 17.3.8.2. India

- 17.3.8.3. Japan

- 17.3.8.4. South Korea

- 17.3.8.5. Australia and New Zealand

- 17.3.8.6. Indonesia

- 17.3.8.7. Malaysia

- 17.3.8.8. Thailand

- 17.3.8.9. Vietnam

- 17.3.8.10. Rest of Asia-Pacific

- 17.4. China Industrial Substation Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Fiber Type

- 17.4.3. Form

- 17.4.4. Resin Type

- 17.4.5. Manufacturing Process

- 17.4.6. End-use Industry

- 17.4.7. Tooling Type

- 17.4.8. Tool Configuration

- 17.5. India Industrial Substation Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Fiber Type

- 17.5.3. Form

- 17.5.4. Resin Type

- 17.5.5. Manufacturing Process

- 17.5.6. End-use Industry

- 17.5.7. Tooling Type

- 17.5.8. Tool Configuration

- 17.6. Japan Industrial Substation Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Fiber Type

- 17.6.3. Form

- 17.6.4. Resin Type

- 17.6.5. Manufacturing Process

- 17.6.6. End-use Industry

- 17.6.7. Tooling Type

- 17.6.8. Tool Configuration

- 17.7. South Korea Industrial Substation Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Fiber Type

- 17.7.3. Form

- 17.7.4. Resin Type

- 17.7.5. Manufacturing Process

- 17.7.6. End-use Industry

- 17.7.7. Tooling Type

- 17.7.8. Tool Configuration

- 17.8. Australia and New Zealand Industrial Substation Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Fiber Type

- 17.8.3. Form

- 17.8.4. Resin Type

- 17.8.5. Manufacturing Process

- 17.8.6. End-use Industry

- 17.8.7. Tooling Type

- 17.8.8. Tool Configuration

- 17.9. Indonesia Industrial Substation Market

- 17.9.1. Country Segmental Analysis

- 17.9.2. Fiber Type

- 17.9.3. Form

- 17.9.4. Resin Type

- 17.9.5. Manufacturing Process

- 17.9.6. End-use Industry

- 17.9.7. Tooling Type

- 17.9.8. Tool Configuration

- 17.10. Malaysia Industrial Substation Market

- 17.10.1. Country Segmental Analysis

- 17.10.2. Fiber Type

- 17.10.3. Form

- 17.10.4. Resin Type

- 17.10.5. Manufacturing Process

- 17.10.6. End-use Industry

- 17.10.7. Tooling Type

- 17.10.8. Tool Configuration

- 17.11. Thailand Industrial Substation Market

- 17.11.1. Country Segmental Analysis

- 17.11.2. Fiber Type

- 17.11.3. Form

- 17.11.4. Resin Type

- 17.11.5. Manufacturing Process

- 17.11.6. End-use Industry

- 17.11.7. Tooling Type

- 17.11.8. Tool Configuration

- 17.12. Vietnam Industrial Substation Market

- 17.12.1. Country Segmental Analysis

- 17.12.2. Fiber Type

- 17.12.3. Form

- 17.12.4. Resin Type

- 17.12.5. Manufacturing Process

- 17.12.6. End-use Industry

- 17.12.7. Tooling Type

- 17.12.8. Tool Configuration

- 17.13. Rest of Asia Pacific Industrial Substation Market

- 17.13.1. Country Segmental Analysis

- 17.13.2. Fiber Type

- 17.13.3. Form

- 17.13.4. Resin Type

- 17.13.5. Manufacturing Process

- 17.13.6. End-use Industry

- 17.13.7. Tooling Type

- 17.13.8. Tool Configuration

- 18. Middle East Industrial Substation Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Middle East Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 18.3.1. Fiber Type

- 18.3.2. Form

- 18.3.3. Resin Type

- 18.3.4. Manufacturing Process

- 18.3.5. End-use Industry

- 18.3.6. Tooling Type

- 18.3.7. Tool Configuration

- 18.3.8. Country

- 18.3.8.1. Turkey

- 18.3.8.2. UAE

- 18.3.8.3. Saudi Arabia

- 18.3.8.4. Israel

- 18.3.8.5. Rest of Middle East

- 18.4. Turkey Industrial Substation Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Fiber Type

- 18.4.3. Form

- 18.4.4. Resin Type

- 18.4.5. Manufacturing Process

- 18.4.6. End-use Industry

- 18.4.7. Tooling Type

- 18.4.8. Tool Configuration

- 18.5. UAE Industrial Substation Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Fiber Type

- 18.5.3. Form

- 18.5.4. Resin Type

- 18.5.5. Manufacturing Process

- 18.5.6. End-use Industry

- 18.5.7. Tooling Type

- 18.5.8. Tool Configuration

- 18.6. Saudi Arabia Industrial Substation Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Fiber Type

- 18.6.3. Form

- 18.6.4. Resin Type

- 18.6.5. Manufacturing Process

- 18.6.6. End-use Industry

- 18.6.7. Tooling Type

- 18.6.8. Tool Configuration

- 18.7. Israel Industrial Substation Market

- 18.7.1. Country Segmental Analysis

- 18.7.2. Fiber Type

- 18.7.3. Form

- 18.7.4. Resin Type

- 18.7.5. Manufacturing Process

- 18.7.6. End-use Industry

- 18.7.7. Tooling Type

- 18.7.8. Tool Configuration

- 18.8. Rest of Middle East Industrial Substation Market

- 18.8.1. Country Segmental Analysis

- 18.8.2. Fiber Type

- 18.8.3. Form

- 18.8.4. Resin Type

- 18.8.5. Manufacturing Process

- 18.8.6. End-use Industry

- 18.8.7. Tooling Type

- 18.8.8. Tool Configuration

- 19. Africa Industrial Substation Market Analysis

- 19.1. Key Segment Analysis

- 19.2. Regional Snapshot

- 19.3. Africa Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 19.3.1. Fiber Type

- 19.3.2. Form

- 19.3.3. Resin Type

- 19.3.4. Manufacturing Process

- 19.3.5. End-use Industry

- 19.3.6. Tooling Type

- 19.3.7. Tool Configuration

- 19.3.8. Country

- 19.3.8.1. South Africa

- 19.3.8.2. Egypt

- 19.3.8.3. Nigeria

- 19.3.8.4. Algeria

- 19.3.8.5. Rest of Africa

- 19.4. South Africa Industrial Substation Market

- 19.4.1. Country Segmental Analysis

- 19.4.2. Fiber Type

- 19.4.3. Form

- 19.4.4. Resin Type

- 19.4.5. Manufacturing Process

- 19.4.6. End-use Industry

- 19.4.7. Tooling Type

- 19.4.8. Tool Configuration

- 19.5. Egypt Industrial Substation Market

- 19.5.1. Country Segmental Analysis

- 19.5.2. Fiber Type

- 19.5.3. Form

- 19.5.4. Resin Type

- 19.5.5. Manufacturing Process

- 19.5.6. End-use Industry

- 19.5.7. Tooling Type

- 19.5.8. Tool Configuration

- 19.6. Nigeria Industrial Substation Market

- 19.6.1. Country Segmental Analysis

- 19.6.2. Fiber Type

- 19.6.3. Form

- 19.6.4. Resin Type

- 19.6.5. Manufacturing Process

- 19.6.6. End-use Industry

- 19.6.7. Tooling Type

- 19.6.8. Tool Configuration

- 19.7. Algeria Industrial Substation Market

- 19.7.1. Country Segmental Analysis

- 19.7.2. Fiber Type

- 19.7.3. Form

- 19.7.4. Resin Type

- 19.7.5. Manufacturing Process

- 19.7.6. End-use Industry

- 19.7.7. Tooling Type

- 19.7.8. Tool Configuration

- 19.8. Rest of Africa Industrial Substation Market

- 19.8.1. Country Segmental Analysis

- 19.8.2. Fiber Type

- 19.8.3. Form

- 19.8.4. Resin Type

- 19.8.5. Manufacturing Process

- 19.8.6. End-use Industry

- 19.8.7. Tooling Type

- 19.8.8. Tool Configuration

- 20. South America Industrial Substation Market Analysis

- 20.1. Key Segment Analysis

- 20.2. Regional Snapshot

- 20.3. Central and South Africa Industrial Substation Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 20.3.1. Fiber Type

- 20.3.2. Form

- 20.3.3. Resin Type

- 20.3.4. Manufacturing Process

- 20.3.5. End-use Industry

- 20.3.6. Tooling Type

- 20.3.7. Tool Configuration

- 20.3.8. Country

- 20.3.8.1. Brazil

- 20.3.8.2. Argentina

- 20.3.8.3. Rest of South America

- 20.4. Brazil Industrial Substation Market

- 20.4.1. Country Segmental Analysis

- 20.4.2. Fiber Type

- 20.4.3. Form

- 20.4.4. Resin Type

- 20.4.5. Manufacturing Process

- 20.4.6. End-use Industry

- 20.4.7. Tooling Type

- 20.4.8. Tool Configuration

- 20.5. Argentina Industrial Substation Market

- 20.5.1. Country Segmental Analysis

- 20.5.2. Fiber Type

- 20.5.3. Form

- 20.5.4. Resin Type

- 20.5.5. Manufacturing Process

- 20.5.6. End-use Industry

- 20.5.7. Tooling Type

- 20.5.8. Tool Configuration

- 20.6. Rest of South America Industrial Substation Market

- 20.6.1. Country Segmental Analysis

- 20.6.2. Fiber Type

- 20.6.3. Form

- 20.6.4. Resin Type

- 20.6.5. Manufacturing Process

- 20.6.6. End-use Industry

- 20.6.7. Tooling Type

- 20.6.8. Tool Configuration

- 21. Key Players/ Company Profile

- 21.1. AdamWorks, LLC

- 21.1.1. Company Details/ Overview

- 21.1.2. Company Financials

- 21.1.3. Key Customers and Competitors

- 21.1.4. Business/ Industry Portfolio

- 21.1.5. Product Portfolio/ Specification Details

- 21.1.6. Pricing Data

- 21.1.7. Strategic Overview

- 21.1.8. Recent Developments

- 21.2. Airtech Advanced Materials Group

- 21.3. Cytec Solvay Group

- 21.4. Formaplex

- 21.5. Gurit Holding AG

- 21.6. Hexcel Corporation

- 21.7. Huntsman Corporation

- 21.8. Mitsubishi Chemical Corporation

- 21.9. Owens Corning

- 21.10. PRF Composite Materials

- 21.11. Rampf Group, Inc.

- 21.12. Royal TenCate N.V.

- 21.13. Sika AG

- 21.14. Solvay S.A.

- 21.15. Startasys

- 21.16. Teijin Limited

- 21.17. Toray Industries, Inc.

- 21.18. Trelleborg AB

- 21.19. Weber Manufacturing Technologies Inc.

- 21.20. Others Key Players

- 21.1. AdamWorks, LLC

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

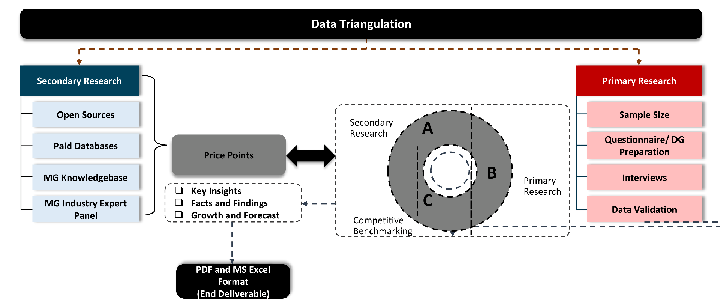

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase and Others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players product portfolio

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources includes primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data