Industrial Floor Coating Market Size, Share, Growth Opportunity Analysis Report by Product Type (Epoxy, Polyurethane, Polyaspartic, Acrylic, Methyl Methacrylate (MMA), Alkyd, Others (Novolac resins, Polyester-based, etc.)), Component Type, Coating Type, Technology, Floor Type, Surface Finishing Characteristics, Application Method, Installation Type, End-users, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025–2035

|

Market Structure & Evolution |

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Industrial Floor Coating Market Size, Share, and Growth

The global industrial floor coatings market is experiencing robust growth, with its estimated value of USD 6.7 billion in the year 2025 and USD 10.7 billion by the period 2035, registering a CAGR of 4.8%. Asia Pacific leads the market with market share of 54% with USD 3.6 billion revenue.

In 2025, the industrial floor coating industry experienced significant growth spurts driven by the expansion of advanced manufacturing facilities worldwide and a growing demand for clean, chemical-free surfaces. In Germany, a prominent vehicle manufacturer partnered with a specialist coatings company to introduce a fresh generation of water-based epoxy flooring solutions throughout its manufacturing facilities.

The industrial floor coating sector is receiving widespread interest in a range of sectors, including manufacturing, warehousing, automotive, and commercial infrastructure, because market leaders are the companies that have invested in state-of-the-art coating technology and large-scale applications to offer durable, chemical-resistant, high-performance flooring solutions with consistent quality and updated longevity. In early 2024, Sherwin-Williams and PPG Industries announced substantial capital investments in new automated spraying systems and ‘green’ coating compositions for Efficiency in the field, while lowering the impact on the environment.

Simultaneously, there is a growing demand for coatings that provide enhanced durability, fast curing, and encapsulation from strong chemicals in vertical sectors that demand strict operational methods. These developments are primarily driven by the need for floors that must be able to accommodate multiple shifts with heavy machinery, designed to withstand excessive abrasions, and withstand the frequent maintenance of cleaning, especially in pharmaceutical, food processing and logistics related industries.

Further, leading manufacturers like BASF, RPM International, and AkzoNobel are developing sustainable, low-VOC coatings and continuing investments in the production technologies to meet compliance and fulfill customer requirements.

Additionally, steps taken towards green building practices and stricter safety regulations have also extended the market potential for industrial floor coatings. The ongoing trend for sustainable material utilization and energy-efficient application methods in all industries will continue to influence the developments of this market in the future.

Industrial Floor Coating Market Dynamics and Trends

Drivers: Industrial Expansion & Safety Regulations Fuel Demand for High-Performance Floor Coatings

- The increased growth of manufacturing, logistics, food processing, and pharmaceutical industries is critical to the industrial floor coating market, as these industries demand durable, chemical-resistant, and easy-to-maintain flooring systems. Increased health, safety, and hygiene regulations are leading to more demand for coatings that provide anti-slip surfaces, antimicrobial properties, and thermal resistance are all contributing to the growth of floor coating systems as suitable flooring upgrade.

- Additionally, the need for quick turnaround times for production cycles and limiting downtime means innovation in rapid-curing and solvent-free coatings are occurring that lead to obvious efficiencies and environmental adherence. As industrial facilities continue to modernize, the demand for long-term and sustainable floor coating solutions will continue to increase and drive the overall market for industrial floor coatings.

Restraints: High Application Costs & Surface Preparation Challenges Limit Floor Coating Adoption

- While industrial floor coatings provide measurable functional advantages, there are many factors which prevent their adoption due to their high installation costs and complicated surface preparation protocols. The two biggest hurdles are that most coating systems often need extensive substrate preparation, including cleaning, mitigating moisture levels, as well as cure time before the surface can be used, all of which can bring production to a standstill and reasons to put off upgrading the existing surface.

- Also, specialized trades and equipment necessary for the proper application add to operational overhead, and floor coatings have increased costs for large operations and regulated environments. This can impact regions where sensitive budget environments face little in technical infrastructure which can take projects off advertising points or have buyers revert to traditional types of flooring.

- Additionally, cost fluctuations in raw materials, like epoxy and polyurethane, have also created market uncertainty for many manufacturers and end users is limiting any formal or general adoption of some types of advanced coatings, even though the performance benefits in the long-run are apparent.

Opportunity: Innovations in Eco-Friendly Coatings & Rapid-Cure Systems Expand Industrial Flooring Potential

- The industrial floor coating landscape is being primed for significant growth opportunities via eco-friendly, low-VOC, and water-based formulations to meet environmental regulations and green building standards globally. Many industries are moving toward sustainability and worker safety with solutions that provide non-toxic application, no-odor spaces, and the ability to cure more quickly.

- Moreover, the innovations of UV-cured and polyaspartic coatings provide quick turnaround time with minimal downtime for 24/7 manufacturing and logistics centers. In addition, the increase of automated application and robotic application techniques is decreasing labor cost and achieving better consistency once again. And where there is increasing attention on smart and energy-efficient facilities, there is increasing opportunity for coatings that include reflective, antimicrobial, or static dissipative properties, leading to new areas for application primarily within the pharmaceutical, cleanroom, and electronic manufacturing spaces.

Key Trend: Growing Adoption of Sustainable & High-Performance Coatings Aligns with Green Manufacturing Goals

- An important trend impacting the industrial floor coating market is the increasing demand for environmentally-sustainable and performance-based products. Manufacturers have been shifting to low-VOC, solvent-free and water-based coatings, which, in addition to being compliant, offered a safer workplace and better indoor air quality.

- Simultaneously, industry is demanding coatings that provided different performance benefits including abrasion resistance, protection with antimicrobial protection and completion with faster curing time, especially in areas with a lot of traffic and hygiene concerns. As green manufacturing and LEED facilities are developed, floor coatings were becoming a key part of the whole green industrial operation push. Concurrently shifting toward both sustainability and performance resulting in again influencing innovation in products, and preferences in buyers.

Industrial Floor Coating Market Analysis and Segmental Data

Based on Product Type, Epoxy holds the largest share

- Epoxy accounts for the largest segment of the industrial floor coating market, due to its durability, high chemical resistance, cost-effectiveness, and suitability for multiple industrial uses. Epoxy coatings provide a heavy duty, durable surfaces, resistant to damage from heavy machinery and foot traffic, and harsh cleaning chemicals essential to industries like manufacturing, pharmaceuticals and warehouse facilities.

- Beneficial qualities of epoxy coatings include adherence to concrete, full depth customizable finishes, high resistance to oils, greases, and solvents, which is attractive to facilities managers. Easy to apply and maintain, offering long service life and minimizing downtime, is critical in high traffic industrial facilities. Overall, these properties make epoxy the desired material chosen for new industrial flooring installations and for the rehabilitation of existing industrial flooring systems.

Asia Pacific Dominates Global Industrial Floor Coating Market in 2025 and beyond

- The Asia Pacific region leads the industrial floor coating market primarily because of the rapid industrialization, development of infrastructures, and development of manufacturing sectors. The emerging countries of China, India, and the Southeast Asian countries are developing factories, warehouses, pharmaceutical and food processing plants that rely on durable, protective floor coats.

- The demand for more advanced coating systems, such as epoxy and polyurethane, rely heavily on an abundance of inexpensive labor, high levels of construction activity, and awareness of safety and hygiene.

- Furthermore, governments in the region are promoting the industrial concept of modernization and environmental regulation that encourages the usage of low-VOC coating products. In all, there are many factors contributing to the Asia Pacific countries' lead in the global industrial floor coating market.

Industrial Floor Coating Market Ecosystem

The industrial floor coating market is highly consolidated to tier 1 player such as Sherwin-Williams, Akzo Nobel, BASF, and PPG Industries, who leverage substantial production portfolios and presence globally. Tier 2 and tier 3 players such as Ardex Group, Carboline, and Flowcrete Group are generally niche players in their offerings, services, and regional or local expertise. The buyer concentration is moderate - and they prefer customized, durable solutions. The supplier concentration is low with raw materials from many different sources providing competitive prices and a stable or sustainable supply source

Recent Development and Strategic Overview:

- In April 2025, PPG Industries, a recognized name in surface coatings, has launched PPG EnviroShield Ultra, a next-generation low-VOC epoxy floor covering made specifically for pharmaceutical and food processing facilities. This specialty coating provides chemical resistance, anti-microbials, and dry time, which functions to limit operational downtime and helps maintain sanitary compliance. This offering is representative of PPG’s movement toward eco-friendly, and compliant solutions on industrial surfaces for highly controlled environments.

- In February 2025, AkzoNobel has launched Interfloor RapidCure 200, a polyaspartic based floor coating solution specifically designed for purpose-built logistics bases and fast-paced manufacturing sites. RapidCure 200 offers superior abrasion resistance, UV stability and allows full cure in hours, even at lower temperatures. The products show AkzoNobel's commitment to provide a solution for growing demands of time-saving and high durability flooring solutions that manage the need for continuous industrial service with minimal disruption.

Report Scope

|

Attribute |

Detail |

|

Market Size in 2025 |

USD 6.7 Bn |

|

Market Forecast Value in 2035 |

USD 10.7 Bn |

|

Growth Rate (CAGR) |

4.8% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

USD Bn for Value |

|

Report Format |

Electronic (PDF) + Excel |

|

Regions and Countries Covered |

|||||

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Industrial Floor Coating Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Product Type |

|

|

By Component Type |

|

|

By Coating Type |

|

|

By Technology |

|

|

By Floor Type |

|

|

By Surface Finishing Characteristics |

|

|

By Application Method |

|

|

By Installation Type |

|

|

By End-users |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Industrial Floor Coating Market Outlook

- 2.1.1. Industrial Floor Coating Market Size (Value - USD Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Industrial Floor Coating Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Industrial Floor Coating Industry Overview, 2025

- 3.1.1. Chemicals & Materials Industry Ecosystem Analysis

- 3.1.2. Key Trends for Chemicals & Materials Industry

- 3.1.3. Regional Distribution for Chemicals & Materials Industry

- 3.2. Supplier Customer Data

- 3.3. Source Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2025

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.6. Raw Material Analysis

- 3.1. Industrial Floor Coating Industry Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Industrial Expansion & Safety Regulations Fuel Demand for High-Performance Floor Coatings

- 4.1.2. Restraints

- 4.1.2.1. High Application Costs & Surface Preparation Challenges Limit Floor Coating Adoption

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Raw Material Sourcing

- 4.4.2. Processing

- 4.4.3. Wholesalers/ E-commerce Platform

- 4.4.4. End-use/ Customers

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Pricing Analysis

- 4.6.1. Regional Pricing Analysis

- 4.6.2. Segmental Pricing Trends

- 4.6.3. Factors Influencing Pricing

- 4.7. Porter’s Five Forces Analysis

- 4.8. PESTEL Analysis

- 4.9. Industrial Floor Coating Market Demand

- 4.9.1. Historical Market Size – (Value - USD Bn), 2021-2024

- 4.9.2. Current and Future Market Size – (Value - USD Bn), 2025–2035

- 4.9.2.1. Y-o-Y Growth Trends

- 4.9.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2024

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Industrial Floor Coating Market Analysis, by Product Type

- 6.1. Key Segment Analysis

- 6.2. Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, by Product Type, 2021-2035

- 6.2.1. Epoxy

- 6.2.2. Polyurethane

- 6.2.3. Polyaspartic

- 6.2.4. Acrylic

- 6.2.5. Methyl Methacrylate (MMA)

- 6.2.6. Alkyd

- 6.2.7. Others (Novolac resins, Polyester-based, etc.)

- 7. Industrial Floor Coating Market Analysis, by Component Type

- 7.1. Key Segment Analysis

- 7.2. Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, by Component Type, 2021-2035

- 7.2.1. Single Component

- 7.2.2. Two Component

- 7.2.3. Three Component

- 7.2.4. Multi-component Systems

- 8. Industrial Floor Coating Market Analysis, by Coating Type

- 8.1. Key Segment Analysis

- 8.2. Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, by Coating Type, 2021-2035

- 8.2.1. Primer Coatings

- 8.2.2. Topcoats

- 8.2.3. Underlayment

- 8.2.4. Sealers

- 8.2.5. Anti-slip Coatings

- 8.2.6. Electrostatic Dissipative (ESD) Coatings

- 8.2.7. Decorative Coatings

- 8.2.8. Others

- 9. Industrial Floor Coating Market Analysis, by Technology

- 9.1. Key Segment Analysis

- 9.2. Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, by Technology, 2021-2035

- 9.2.1. Solvent-borne Coatings

- 9.2.2. Water-borne Coatings

- 9.2.3. UV-Cured Coatings

- 9.2.4. Powder Coatings

- 9.2.5. High Solid Coatings

- 9.2.6. Thermoset and Thermoplastic Coatings

- 9.2.7. Others

- 10. Industrial Floor Coating Market Analysis, by Floor Type

- 10.1. Key Segment Analysis

- 10.2. Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, by Floor Type, 2021-2035

- 10.2.1. Concrete

- 10.2.2. Steel

- 10.2.3. Asphalt

- 10.2.4. Wood

- 10.2.5. Tiles & Stones

- 10.2.6. Hybrid Substrates

- 11. Industrial Floor Coating Market Analysis, by Surface Finishing Characteristics

- 11.1. Key Segment Analysis

- 11.2. Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, by Surface Finishing Characteristics, 2021-2035

- 11.2.1. Glossy Finish

- 11.2.2. Matte Finish

- 11.2.3. Anti-slip Textured Finish

- 11.2.4. Smooth Finish

- 11.2.5. Reflective/Anti-glare Finish

- 11.2.6. Others

- 12. Industrial Floor Coating Market Analysis, by Application Method

- 12.1. Key Segment Analysis

- 12.2. Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, by Application Method, 2021-2035

- 12.2.1. Roller Coating

- 12.2.2. Trowel Application

- 12.2.3. Spray Coating

- 12.2.4. Self-leveling Pour Application

- 13. Industrial Floor Coating Market Analysis, by Installation Type

- 13.1. Key Segment Analysis

- 13.2. Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, by Installation Type, 2021-2035

- 13.2.1. New Construction

- 13.2.2. Maintenance & Retrofit

- 13.2.3. Fast-Curing Emergency Installation

- 13.2.4. Self-Leveling Application

- 13.2.5. Manual Application

- 14. Industrial Floor Coating Market Analysis, by End-users

- 14.1. Key Segment Analysis

- 14.2. Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, by End- users, 2021-2035

- 14.2.1. Manufacturing Facilities

- 14.2.1.1. Heavy Machinery Assembly

- 14.2.1.2. Electronics Production

- 14.2.1.3. Textile Processing Plants

- 14.2.1.4. Tooling & Metal Fabrication

- 14.2.1.5. Automotive OEM Facilities

- 14.2.1.6. Others

- 14.2.2. Food & Beverage Processing

- 14.2.2.1. Dairy & Meat Processing Plants

- 14.2.2.2. Commercial Kitchens

- 14.2.2.3. Beverage Bottling Units

- 14.2.2.4. Cold Storage Warehouses

- 14.2.2.5. Breweries and Distilleries

- 14.2.2.6. Others

- 14.2.3. Pharmaceuticals & Healthcare

- 14.2.3.1. Cleanrooms

- 14.2.3.2. Sterile Packaging Units

- 14.2.3.3. Laboratory Floors

- 14.2.3.4. R&D Centers

- 14.2.3.5. Others

- 14.2.4. Chemical & Petrochemical

- 14.2.4.1. Chemical Processing Plants

- 14.2.4.2. Refineries

- 14.2.4.3. Storage Tank Yards

- 14.2.4.4. Hazardous Waste Zones

- 14.2.4.5. Corrosive Fluid Handling Areas

- 14.2.4.6. Others

- 14.2.5. Warehouses & Logistics Centers

- 14.2.5.1. High-traffic loading zones

- 14.2.5.2. Pallet Movement Areas

- 14.2.5.3. Automated Storage and Retrieval Systems (AS/RS)

- 14.2.5.4. Forklift Operation Zones

- 14.2.5.5. Others

- 14.2.6. Aerospace & Defense

- 14.2.6.1. Aircraft Hangars

- 14.2.6.2. Engine Testing Bays

- 14.2.6.3. Weapon Manufacturing Zones

- 14.2.6.4. Assembly Floors for Aerospace Components

- 14.2.6.5. Others

- 14.2.7. Electronics & Semiconductor

- 14.2.7.1. Anti-static (ESD) Zones

- 14.2.7.2. Precision Equipment Zones

- 14.2.7.3. Dust-Control Areas

- 14.2.7.4. Wafer Packaging Units

- 14.2.7.5. Others

- 14.2.8. Power Generation & Utilities

- 14.2.8.1. Thermal Power Plants

- 14.2.8.2. Hydroelectric Maintenance Bays

- 14.2.8.3. Nuclear Power Clean Areas

- 14.2.8.4. Energy Storage Areas

- 14.2.8.5. Others

- 14.2.9. Others

- 14.2.1. Manufacturing Facilities

- 15. Industrial Floor Coating Market Analysis and Forecasts, by Region

- 15.1. Key Findings

- 15.2. Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, by Region, 2021-2035

- 15.2.1. North America

- 15.2.2. Europe

- 15.2.3. Asia Pacific

- 15.2.4. Middle East

- 15.2.5. Africa

- 15.2.6. South America

- 16. North America Industrial Floor Coating Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. North America Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 16.3.1. Product Type

- 16.3.2. Component Type

- 16.3.3. Coating Type

- 16.3.4. Technology

- 16.3.5. Floor Type

- 16.3.6. Surface Finishing Characteristics

- 16.3.7. Application Method

- 16.3.8. Installation Type

- 16.3.9. End-users

- 16.3.10. Country

- 16.3.10.1. USA

- 16.3.10.2. Canada

- 16.3.10.3. Mexico

- 16.4. USA Industrial Floor Coating Market

- 16.4.1. Product Type

- 16.4.2. Component Type

- 16.4.3. Coating Type

- 16.4.4. Technology

- 16.4.5. Floor Type

- 16.4.6. Surface Finishing Characteristics

- 16.4.7. Application Method

- 16.4.8. Installation Type

- 16.4.9. End-users

- 16.5. Canada Industrial Floor Coating Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Product Type

- 16.5.3. Component Type

- 16.5.4. Coating Type

- 16.5.5. Technology

- 16.5.6. Floor Type

- 16.5.7. Surface Finishing Characteristics

- 16.5.8. Application Method

- 16.5.9. Installation Type

- 16.5.10. End-users

- 16.6. Mexico Industrial Floor Coating Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Product Type

- 16.6.3. Component Type

- 16.6.4. Coating Type

- 16.6.5. Technology

- 16.6.6. Floor Type

- 16.6.7. Surface Finishing Characteristics

- 16.6.8. Application Method

- 16.6.9. Installation Type

- 16.6.10. End-users

- 17. Europe Industrial Floor Coating Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. Europe Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 17.3.1. Product Type

- 17.3.2. Component Type

- 17.3.3. Coating Type

- 17.3.4. Technology

- 17.3.5. Floor Type

- 17.3.6. Surface Finishing Characteristics

- 17.3.7. Application Method

- 17.3.8. Installation Type

- 17.3.9. End-users

- 17.3.10. Country

- 17.3.10.1. Germany

- 17.3.10.2. United Kingdom

- 17.3.10.3. France

- 17.3.10.4. Italy

- 17.3.10.5. Spain

- 17.3.10.6. Netherlands

- 17.3.10.7. Nordic Countries

- 17.3.10.8. Poland

- 17.3.10.9. Russia & CIS

- 17.3.10.10. Rest of Europe

- 17.4. Germany Industrial Floor Coating Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Product Type

- 17.4.3. Component Type

- 17.4.4. Coating Type

- 17.4.5. Technology

- 17.4.6. Floor Type

- 17.4.7. Surface Finishing Characteristics

- 17.4.8. Application Method

- 17.4.9. Installation Type

- 17.4.10. End-users

- 17.5. United Kingdom Industrial Floor Coating Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Product Type

- 17.5.3. Component Type

- 17.5.4. Coating Type

- 17.5.5. Technology

- 17.5.6. Floor Type

- 17.5.7. Surface Finishing Characteristics

- 17.5.8. Application Method

- 17.5.9. Installation Type

- 17.5.10. End-users

- 17.6. France Industrial Floor Coating Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Product Type

- 17.6.3. Component Type

- 17.6.4. Coating Type

- 17.6.5. Technology

- 17.6.6. Floor Type

- 17.6.7. Surface Finishing Characteristics

- 17.6.8. Application Method

- 17.6.9. Installation Type

- 17.6.10. End-users

- 17.7. Italy Industrial Floor Coating Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Product Type

- 17.7.3. Component Type

- 17.7.4. Coating Type

- 17.7.5. Technology

- 17.7.6. Floor Type

- 17.7.7. Surface Finishing Characteristics

- 17.7.8. Application Method

- 17.7.9. Installation Type

- 17.7.10. End-users

- 17.8. Spain Industrial Floor Coating Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Product Type

- 17.8.3. Component Type

- 17.8.4. Coating Type

- 17.8.5. Technology

- 17.8.6. Floor Type

- 17.8.7. Surface Finishing Characteristics

- 17.8.8. Application Method

- 17.8.9. Installation Type

- 17.8.10. End-users

- 17.9. Netherlands Industrial Floor Coating Market

- 17.9.1. Country Segmental Analysis

- 17.9.2. Product Type

- 17.9.3. Component Type

- 17.9.4. Coating Type

- 17.9.5. Technology

- 17.9.6. Floor Type

- 17.9.7. Surface Finishing Characteristics

- 17.9.8. Application Method

- 17.9.9. Installation Type

- 17.9.10. End-users

- 17.10. Nordic Countries Industrial Floor Coating Market

- 17.10.1. Country Segmental Analysis

- 17.10.2. Product Type

- 17.10.3. Component Type

- 17.10.4. Coating Type

- 17.10.5. Technology

- 17.10.6. Floor Type

- 17.10.7. Surface Finishing Characteristics

- 17.10.8. Application Method

- 17.10.9. Installation Type

- 17.10.10. End-users

- 17.11. Poland Industrial Floor Coating Market

- 17.11.1. Country Segmental Analysis

- 17.11.2. Product Type

- 17.11.3. Component Type

- 17.11.4. Coating Type

- 17.11.5. Technology

- 17.11.6. Floor Type

- 17.11.7. Surface Finishing Characteristics

- 17.11.8. Application Method

- 17.11.9. Installation Type

- 17.11.10. End-users

- 17.12. Russia & CIS Industrial Floor Coating Market

- 17.12.1. Country Segmental Analysis

- 17.12.2. Product Type

- 17.12.3. Component Type

- 17.12.4. Coating Type

- 17.12.5. Technology

- 17.12.6. Floor Type

- 17.12.7. Surface Finishing Characteristics

- 17.12.8. Application Method

- 17.12.9. Installation Type

- 17.12.10. End-users

- 17.13. Rest of Europe Industrial Floor Coating Market

- 17.13.1. Country Segmental Analysis

- 17.13.2. Product Type

- 17.13.3. Component Type

- 17.13.4. Coating Type

- 17.13.5. Technology

- 17.13.6. Floor Type

- 17.13.7. Surface Finishing Characteristics

- 17.13.8. Application Method

- 17.13.9. Installation Type

- 17.13.10. End-users

- 18. Asia Pacific Industrial Floor Coating Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. East Asia Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 18.3.1. Product Type

- 18.3.2. Component Type

- 18.3.3. Coating Type

- 18.3.4. Technology

- 18.3.5. Floor Type

- 18.3.6. Surface Finishing Characteristics

- 18.3.7. Application Method

- 18.3.8. Installation Type

- 18.3.9. End-users

- 18.3.10. Country

- 18.3.10.1. China

- 18.3.10.2. India

- 18.3.10.3. Japan

- 18.3.10.4. South Korea

- 18.3.10.5. Australia and New Zealand

- 18.3.10.6. Indonesia

- 18.3.10.7. Malaysia

- 18.3.10.8. Thailand

- 18.3.10.9. Vietnam

- 18.3.10.10. Rest of Asia-Pacific

- 18.4. China Industrial Floor Coating Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Product Type

- 18.4.3. Component Type

- 18.4.4. Coating Type

- 18.4.5. Technology

- 18.4.6. Floor Type

- 18.4.7. Surface Finishing Characteristics

- 18.4.8. Application Method

- 18.4.9. Installation Type

- 18.4.10. End-users

- 18.5. India Industrial Floor Coating Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Product Type

- 18.5.3. Component Type

- 18.5.4. Coating Type

- 18.5.5. Technology

- 18.5.6. Floor Type

- 18.5.7. Surface Finishing Characteristics

- 18.5.8. Application Method

- 18.5.9. Installation Type

- 18.5.10. End-users

- 18.6. Japan Industrial Floor Coating Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Product Type

- 18.6.3. Component Type

- 18.6.4. Coating Type

- 18.6.5. Technology

- 18.6.6. Floor Type

- 18.6.7. Surface Finishing Characteristics

- 18.6.8. Application Method

- 18.6.9. Installation Type

- 18.6.10. End-users

- 18.7. South Korea Industrial Floor Coating Market

- 18.7.1. Country Segmental Analysis

- 18.7.2. Product Type

- 18.7.3. Component Type

- 18.7.4. Coating Type

- 18.7.5. Technology

- 18.7.6. Floor Type

- 18.7.7. Surface Finishing Characteristics

- 18.7.8. Application Method

- 18.7.9. Installation Type

- 18.7.10. End-users

- 18.8. Australia and New Zealand Industrial Floor Coating Market

- 18.8.1. Country Segmental Analysis

- 18.8.2. Product Type

- 18.8.3. Component Type

- 18.8.4. Coating Type

- 18.8.5. Technology

- 18.8.6. Floor Type

- 18.8.7. Surface Finishing Characteristics

- 18.8.8. Application Method

- 18.8.9. Installation Type

- 18.8.10. End-users

- 18.9. Indonesia Industrial Floor Coating Market

- 18.9.1. Country Segmental Analysis

- 18.9.2. Product Type

- 18.9.3. Component Type

- 18.9.4. Coating Type

- 18.9.5. Technology

- 18.9.6. Floor Type

- 18.9.7. Surface Finishing Characteristics

- 18.9.8. Application Method

- 18.9.9. Installation Type

- 18.9.10. End-users

- 18.10. Malaysia Industrial Floor Coating Market

- 18.10.1. Country Segmental Analysis

- 18.10.2. Product Type

- 18.10.3. Component Type

- 18.10.4. Coating Type

- 18.10.5. Technology

- 18.10.6. Floor Type

- 18.10.7. Surface Finishing Characteristics

- 18.10.8. Application Method

- 18.10.9. Installation Type

- 18.10.10. End-users

- 18.11. Thailand Industrial Floor Coating Market

- 18.11.1. Country Segmental Analysis

- 18.11.2. Product Type

- 18.11.3. Component Type

- 18.11.4. Coating Type

- 18.11.5. Technology

- 18.11.6. Floor Type

- 18.11.7. Surface Finishing Characteristics

- 18.11.8. Application Method

- 18.11.9. Installation Type

- 18.11.10. End-users

- 18.12. Vietnam Industrial Floor Coating Market

- 18.12.1. Country Segmental Analysis

- 18.12.2. Product Type

- 18.12.3. Component Type

- 18.12.4. Coating Type

- 18.12.5. Technology

- 18.12.6. Floor Type

- 18.12.7. Surface Finishing Characteristics

- 18.12.8. Application Method

- 18.12.9. Installation Type

- 18.12.10. End-users

- 18.13. Rest of Asia Pacific Industrial Floor Coating Market

- 18.13.1. Country Segmental Analysis

- 18.13.2. Product Type

- 18.13.3. Component Type

- 18.13.4. Coating Type

- 18.13.5. Technology

- 18.13.6. Floor Type

- 18.13.7. Surface Finishing Characteristics

- 18.13.8. Application Method

- 18.13.9. Installation Type

- 18.13.10. End-users

- 19. Middle East Industrial Floor Coating Market Analysis

- 19.1. Key Segment Analysis

- 19.2. Regional Snapshot

- 19.3. Middle East Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 19.3.1. Product Type

- 19.3.2. Component Type

- 19.3.3. Coating Type

- 19.3.4. Technology

- 19.3.5. Floor Type

- 19.3.6. Surface Finishing Characteristics

- 19.3.7. Application Method

- 19.3.8. Installation Type

- 19.3.9. End-users

- 19.3.10. Country

- 19.3.10.1. Turkey

- 19.3.10.2. UAE

- 19.3.10.3. Saudi Arabia

- 19.3.10.4. Israel

- 19.3.10.5. Rest of Middle East

- 19.4. Turkey Industrial Floor Coating Market

- 19.4.1. Country Segmental Analysis

- 19.4.2. Product Type

- 19.4.3. Component Type

- 19.4.4. Coating Type

- 19.4.5. Technology

- 19.4.6. Floor Type

- 19.4.7. Surface Finishing Characteristics

- 19.4.8. Application Method

- 19.4.9. Installation Type

- 19.4.10. End-users

- 19.5. UAE Industrial Floor Coating Market

- 19.5.1. Country Segmental Analysis

- 19.5.2. Product Type

- 19.5.3. Component Type

- 19.5.4. Coating Type

- 19.5.5. Technology

- 19.5.6. Floor Type

- 19.5.7. Surface Finishing Characteristics

- 19.5.8. Application Method

- 19.5.9. Installation Type

- 19.5.10. End-users

- 19.6. Saudi Arabia Industrial Floor Coating Market

- 19.6.1. Country Segmental Analysis

- 19.6.2. Product Type

- 19.6.3. Component Type

- 19.6.4. Coating Type

- 19.6.5. Technology

- 19.6.6. Floor Type

- 19.6.7. Surface Finishing Characteristics

- 19.6.8. Application Method

- 19.6.9. Installation Type

- 19.6.10. End-users

- 19.7. Israel Industrial Floor Coating Market

- 19.7.1. Country Segmental Analysis

- 19.7.2. Product Type

- 19.7.3. Component Type

- 19.7.4. Coating Type

- 19.7.5. Technology

- 19.7.6. Floor Type

- 19.7.7. Surface Finishing Characteristics

- 19.7.8. Application Method

- 19.7.9. Installation Type

- 19.7.10. End-users

- 19.8. Rest of Middle East Industrial Floor Coating Market

- 19.8.1. Country Segmental Analysis

- 19.8.2. Product Type

- 19.8.3. Component Type

- 19.8.4. Coating Type

- 19.8.5. Technology

- 19.8.6. Floor Type

- 19.8.7. Surface Finishing Characteristics

- 19.8.8. Application Method

- 19.8.9. Installation Type

- 19.8.10. End-users

- 20. Africa Industrial Floor Coating Market Analysis

- 20.1. Key Segment Analysis

- 20.2. Regional Snapshot

- 20.3. Africa Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 20.3.1. Product Type

- 20.3.2. Component Type

- 20.3.3. Coating Type

- 20.3.4. Technology

- 20.3.5. Floor Type

- 20.3.6. Surface Finishing Characteristics

- 20.3.7. Application Method

- 20.3.8. Installation Type

- 20.3.9. End-users

- 20.3.10. Country

- 20.3.10.1. South Africa

- 20.3.10.2. Egypt

- 20.3.10.3. Nigeria

- 20.3.10.4. Algeria

- 20.3.10.5. Rest of Africa

- 20.4. South Africa Industrial Floor Coating Market

- 20.4.1. Country Segmental Analysis

- 20.4.2. Product Type

- 20.4.3. Component Type

- 20.4.4. Coating Type

- 20.4.5. Technology

- 20.4.6. Floor Type

- 20.4.7. Surface Finishing Characteristics

- 20.4.8. Application Method

- 20.4.9. Installation Type

- 20.4.10. End-users

- 20.5. Egypt Industrial Floor Coating Market

- 20.5.1. Country Segmental Analysis

- 20.5.2. Product Type

- 20.5.3. Component Type

- 20.5.4. Coating Type

- 20.5.5. Technology

- 20.5.6. Floor Type

- 20.5.7. Surface Finishing Characteristics

- 20.5.8. Application Method

- 20.5.9. Installation Type

- 20.5.10. End-users

- 20.6. Nigeria Industrial Floor Coating Market

- 20.6.1. Country Segmental Analysis

- 20.6.2. Product Type

- 20.6.3. Component Type

- 20.6.4. Coating Type

- 20.6.5. Technology

- 20.6.6. Floor Type

- 20.6.7. Surface Finishing Characteristics

- 20.6.8. Application Method

- 20.6.9. Installation Type

- 20.6.10. End-users

- 20.7. Algeria Industrial Floor Coating Market

- 20.7.1. Country Segmental Analysis

- 20.7.2. Product Type

- 20.7.3. Component Type

- 20.7.4. Coating Type

- 20.7.5. Technology

- 20.7.6. Floor Type

- 20.7.7. Surface Finishing Characteristics

- 20.7.8. Application Method

- 20.7.9. Installation Type

- 20.7.10. End-users

- 20.8. Rest of Africa Industrial Floor Coating Market

- 20.8.1. Country Segmental Analysis

- 20.8.2. Product Type

- 20.8.3. Component Type

- 20.8.4. Coating Type

- 20.8.5. Technology

- 20.8.6. Floor Type

- 20.8.7. Surface Finishing Characteristics

- 20.8.8. Application Method

- 20.8.9. Installation Type

- 20.8.10. End-users

- 21. South America Industrial Floor Coating Market Analysis

- 21.1. Key Segment Analysis

- 21.2. Regional Snapshot

- 21.3. Central and South Africa Industrial Floor Coating Market Size (Value - USD Bn), Analysis, and Forecasts, 2021-2035

- 21.3.1. Product Type

- 21.3.2. Component Type

- 21.3.3. Coating Type

- 21.3.4. Technology

- 21.3.5. Floor Type

- 21.3.6. Surface Finishing Characteristics

- 21.3.7. Application Method

- 21.3.8. Installation Type

- 21.3.9. End-users

- 21.3.10. Country

- 21.3.10.1. Brazil

- 21.3.10.2. Argentina

- 21.3.10.3. Rest of South America

- 21.4. Brazil Industrial Floor Coating Market

- 21.4.1. Country Segmental Analysis

- 21.4.2. Product Type

- 21.4.3. Component Type

- 21.4.4. Coating Type

- 21.4.5. Technology

- 21.4.6. Floor Type

- 21.4.7. Surface Finishing Characteristics

- 21.4.8. Application Method

- 21.4.9. Installation Type

- 21.4.10. End-users

- 21.5. Argentina Industrial Floor Coating Market

- 21.5.1. Country Segmental Analysis

- 21.5.2. Product Type

- 21.5.3. Component Type

- 21.5.4. Coating Type

- 21.5.5. Technology

- 21.5.6. Floor Type

- 21.5.7. Surface Finishing Characteristics

- 21.5.8. Application Method

- 21.5.9. Installation Type

- 21.5.10. End-users

- 21.6. Rest of South America Industrial Floor Coating Market

- 21.6.1. Country Segmental Analysis

- 21.6.2. Product Type

- 21.6.3. Component Type

- 21.6.4. Coating Type

- 21.6.5. Technology

- 21.6.6. Floor Type

- 21.6.7. Surface Finishing Characteristics

- 21.6.8. Application Method

- 21.6.9. Installation Type

- 21.6.10. End-users

- 22. Key Players/ Company Profile

- 22.1. 3M

- 22.1.1. Company Details/ Overview

- 22.1.2. Company Financials

- 22.1.3. Key Customers and Competitors

- 22.1.4. Business/ Industry Portfolio

- 22.1.5. Product Portfolio/ Specification Details

- 22.1.6. Pricing Data

- 22.1.7. Strategic Overview

- 22.1.8. Recent Developments

- 22.2. Akzo Nobel

- 22.3. Ardex Group

- 22.4. Asian Paints PPG

- 22.5. Axalta Coating Systems

- 22.6. BASF

- 22.7. Berger Paints

- 22.8. Carboline

- 22.9. DAW SE

- 22.10. Flowcrete Group

- 22.11. Fosroc

- 22.12. Hempel A/S

- 22.13. Jotun

- 22.14. Kansai Paint

- 22.15. Nippon Paint

- 22.16. PPG Industries

- 22.17. RPM International

- 22.18. Sherwin-Williams

- 22.19. Sika AG

- 22.20. Sto SE & Co.

- 22.21. Teknos Group

- 22.22. Tikkurila

- 22.23. Other Key Players

- 22.1. 3M

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

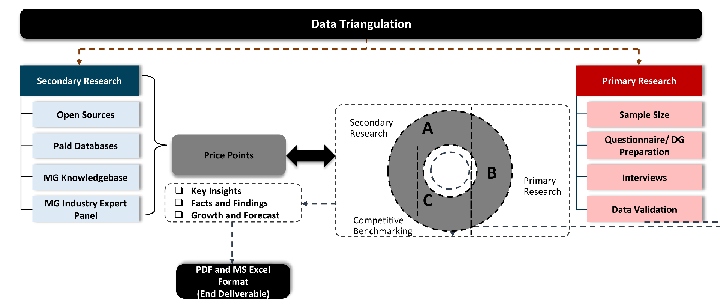

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation