Protective Coatings Market Size, Share & Trends Analysis Report by Resin Type (Epoxy Coatings, Polyurethane Coatings, Acrylic Coatings, Alkyd Coatings, Fluoropolymer Coatings, Silicone Coatings, Vinyl Ester Coatings, Polyaspartic Coatings, Others), Technology, Substrate Type, Functionality, Product Type, Application Method, End-users, Distribution Channel, and Geography (North America, Europe, Asia Pacific, Middle East, Africa, and South America) – Global Industry Data, Trends, and Forecasts, 2025 – 2035

|

Market Structure & Evolution |

|

|

Segmental Data Insights |

|

|

Demand Trends |

|

|

Competitive Landscape |

|

|

Strategic Development |

|

|

Future Outlook & Opportunities |

|

Protective Coatings Market Size, Share, and Growth

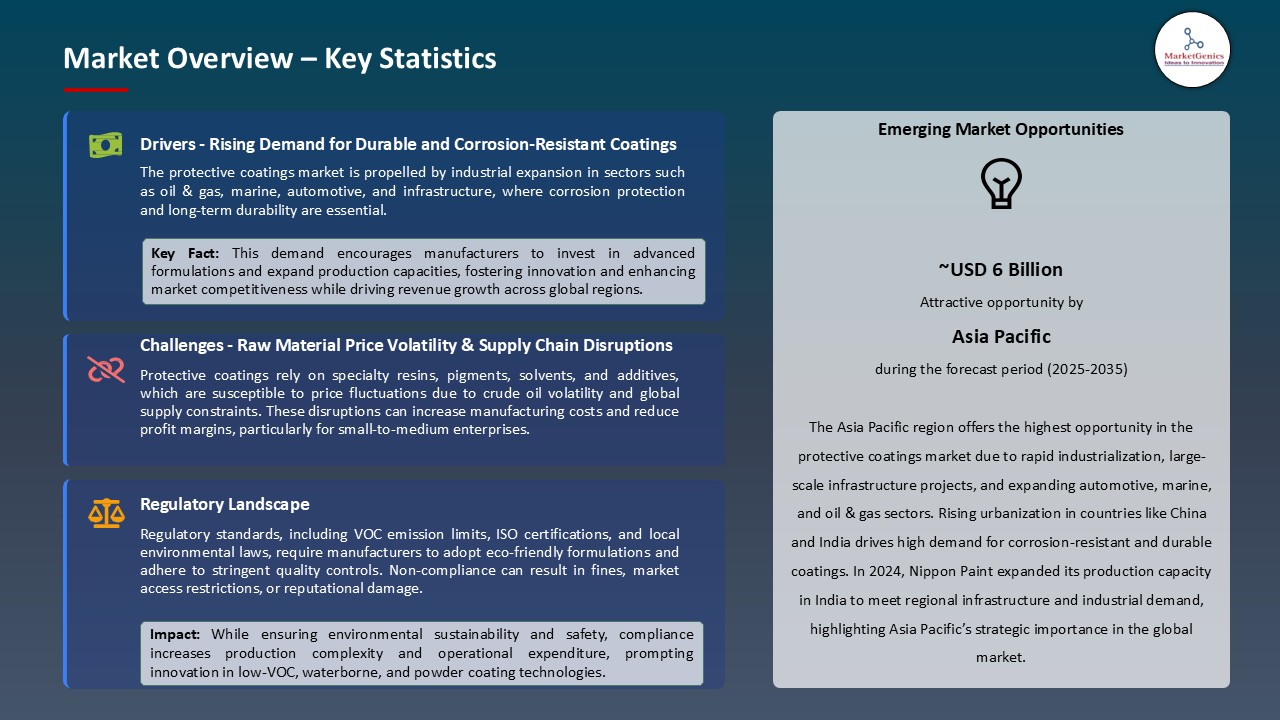

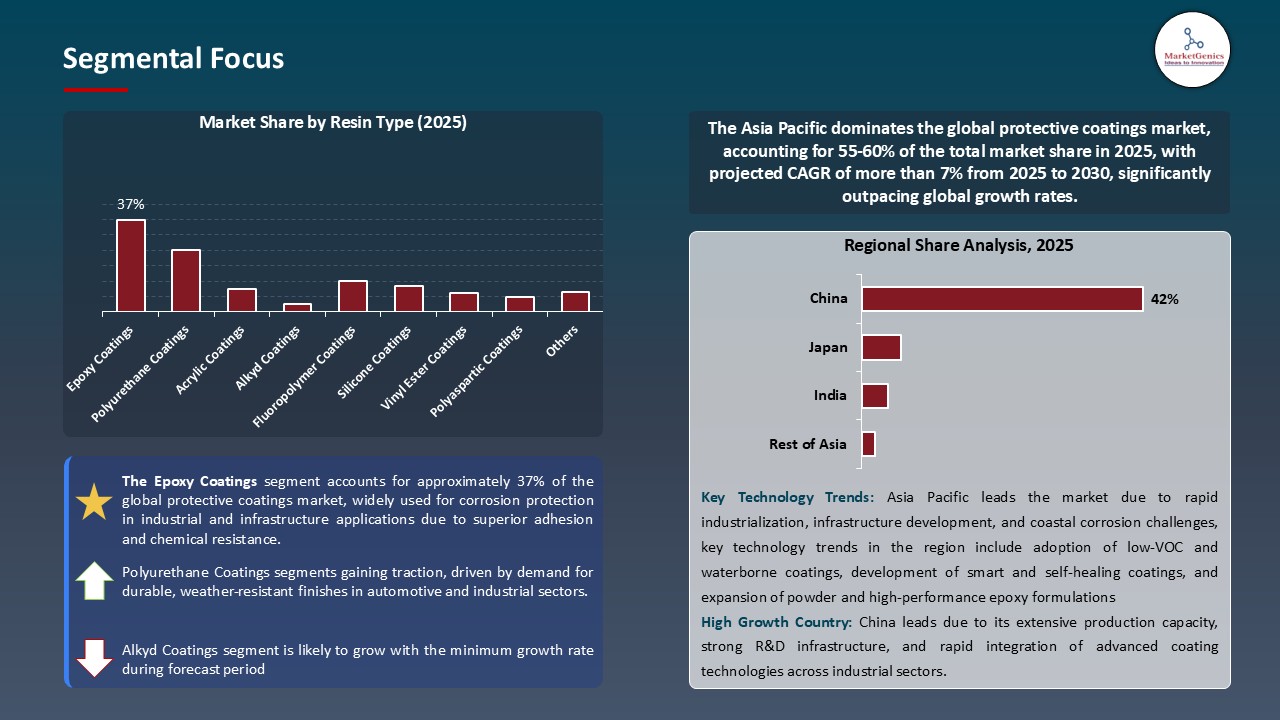

The global protective coatings market is experiencing robust growth, with its estimated value of USD 13.6 billion in the year 2025 and USD 23.9 billion by the period 2035, registering a CAGR of 5.8%. Asia Pacific leads the market with market share of 56.3% with USD 7.7 billion revenue.

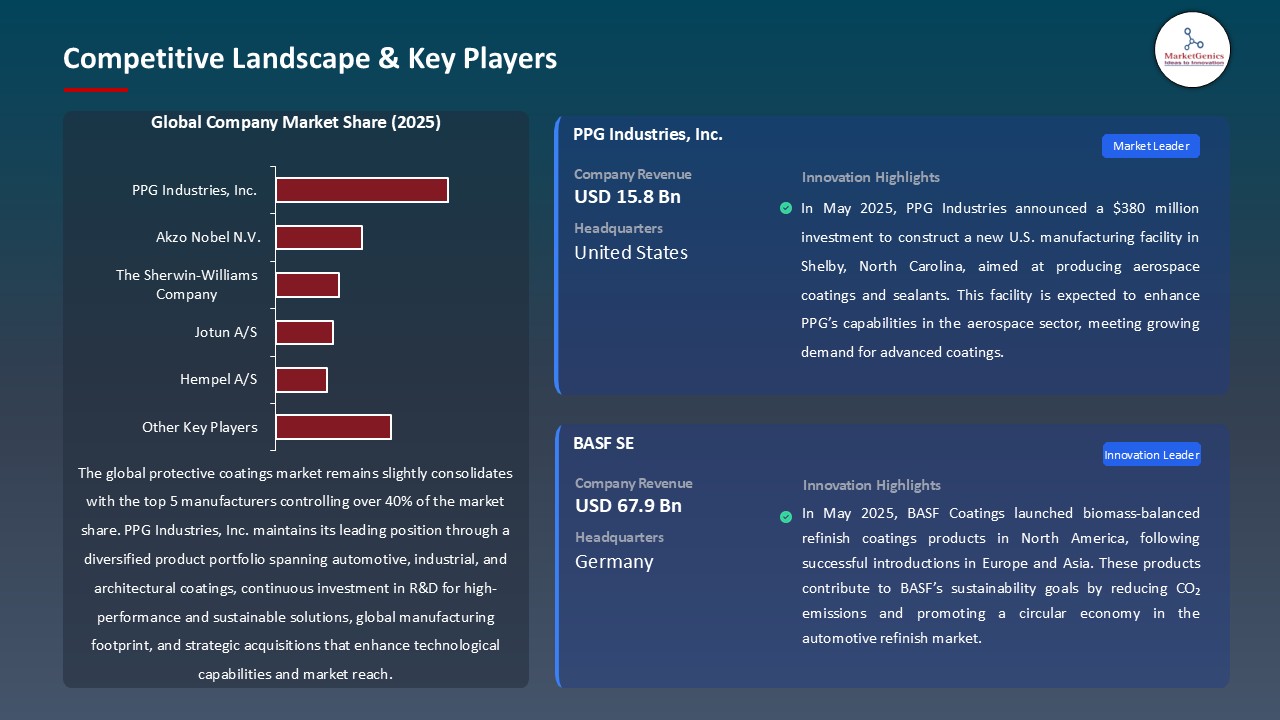

In May 2024, PPG Industries announced a $300 million investment to enhance its manufacturing capabilities in North America, including constructing a new 250,000-square-foot facility in Loudon County, Tennessee. This facility aims to produce more than 11 million gallons of paint and coatings annually by 2026, strategically located near major automakers to optimize supply chain efficiency.

The global protective coatings market is being fueled by the rapid urbanization process, a growing industrial infrastructure, and increased application requirements of durability and resistance to corrosion in oil and gas, automotive, marine and building sectors. The manufacturers are targeting intense development of high-performance epoxy and polyurethane paints to pass-on it advanced achievements in the field. In May 2024, AkzoNobel announced the launch of its new coatings system- Interpon Redox coating system that will be applied on the steel infrastructure project and aims to offer better corrosion protection in the global infrastructure market.

Furthermore, renewed investment in solar and wind power is driving the need of longer lasting protective coatings, and aerospace and defense industries remain assets demanding superior, lightweight high strength coatings. A move towards environmentally friendly, low-VOC products is also transforming their offerings, hence aligning with the global sustainability agenda.

The adjacent markets of the global protective coatings industry offer huge potential in marine protective coatings, automotive refinishes, industrial flooring, pipeline protective coatings and renewable energy infrastructure coatings. These applications require high strength, anti-corrosion, and sustainable-based coatings, which enlighten coatings companies to expand portfolio and exploit high growth industries.

The market will increase in size by steady rates as the fields of innovation and sustainability merge with the expansion requirements of the infrastructural global infrastructure.

Protective Coatings Market Dynamics and Trends

Driver: Increasing demand for protective coatings in renewable energy infrastructure and offshore wind projects

- Rising renewable energy plants especially off-shore wind-farm installation has increased the use of sophisticated protective coatings that can resist severe marine conditions. Such coatings are imperative in protecting steel foundations, towers, and blades against corrosion, erosion, and weathering to increase the functionality lifespan of the renewable energy assets.

- The increasing demand on a sustainable and long-term energy project strengthens the need of long-term coating technology. Governments and energy corporations are spending on offshore wind tremendously and as a result, continuous purchase of protective coatings of high performance is notable. An example would be, in June 2024, AkzoNobel teamed up with Ørsted to deliver protective coatings with high durability to the offshore wind farms located in North Sea.

- The incorporation of protective coatings into renewable energy projects is one of the factors that contribute immensely to market expansion because the energy transition domains experience frequency in demand.

Restraint: Rising raw material price volatility affecting protective coating production and supply chain stability

- The protective coatings market experiences significant cost pressures in terms of fluctuating prices of raw materials especially more significantly epoxy resins, solvents and titanium dioxide. This extreme volatility interferes with the stability of the supply chain, raises the cost of production, and strains margins on manufacturers. Reliance on petrochemical sources of feedstocks also increases risks of exposure to global risks in the oil markets.

- Smaller manufacturers, especially, find it very difficult to cope with such volatility, and this results in variance in competitive excellence among the manufacturers. The lack of pricing consistency undermines the bargaining power of suppliers in large scale projects against downstream clients. In February 2024, PPG Industries has announced the titanium dioxide prices had a substantial effect on the coatings department, forcing the corporation to impose price fluctuations on some protective coatings products.

- The fluctuations of raw materials have aggravated growth and profitability thus posing cost management challenges to protective coating manufacturers across the world.

Opportunity: Growing adoption of eco-friendly and low-VOC protective coatings in industrial applications

- The emerging trend in sustainability across the globe has opened up a powerful chance to the growth and use of environmentally friendly protective coatings mainly water borne and powder coats. These coats minimize volatile organic compound (VOC) emissions and are still durable and perform in the industrial setting. Rapid rises in the number of environmentally sensitive regulations across the world market are reinforcing the need to move toward greener alternatives, and customer attention when it comes to purchasing sustainable goods contributes to the growth of the market. Producers who develop new things in this segmentation will be able to secure competitive advantage in demand cycles to come.

- In May 2024, Sherwin-Williams introduced a new (or rather a new name) of its waterborne protective coating disposed of the industrial equipment and machinery in order to meet the sustainability standards internationally. Not only did the launch increase the product range of the company but it also made it a leader in the field of sustainable coating innovations.

- The move to environment-friendly coatings presents a high-potential direction to manufacturers, which meets sustainability and regulatory trends.

Key Trend: Rising integration of smart and self-healing protective coatings with nanotechnology applications

- Protective coatings industry is increasingly adopting smart coatings enabled with self-healing properties and nanotechnology to enhance performance, a direction closely aligned with advances seen in the conformal coatings for high-reliability industrial and electronic protection. Such coatings also have the automatic ability to self-heal minor damages including micro-cracks or scratches forming, thus decreasing the demand of maintenance and prolonging the lifespan of industrial assets. The aerospace, automotive industries, and oil & gas are some of the examples that are opting such systems to critical applications where the cost of downtimes is exorbitant. The trend is a manifestation of a convergence of high technology in materials science, and functional innovation, a redefining of the protective coating’s marketplace.

- In April 2024, Hempel launched a next-generation protective coating that includes nanostructured additives to provide self-healing properties within oil & gas pipelines to minimize corrosion-related failures. Such innovation symbolizes the increment in convergence to smart coating systems that embrace functionality and the safeguarding of assets over the long-term.

- The ability to integrate smart, self-healing coatings marks a game-changing phenomenon, where performance can be improved and customer expectations in the sphere of protective coating are transformed.

Protective Coatings Market Analysis and Segmental Data

Epoxy Coatings: The Backbone of Protective Coatings Market Growth

- The epoxy coatings segment leads the resin type segment because its properties make it indispensable in oil and gas, marine and infrastructure industries due to its incredible chemical resistance, adhesiveness and toughness. Their capabilities of shielding steel and concrete against corrosion under highly challenging environments also makes them their preferred options of ensuring long term asset protection, particularly in heavy-duty applications overlapping with industrial floor coating requirements. The fast growth of industries in developing countries also promotes their application in heavy-duty uses.

- In March 2024, Jotun launched their new higher-level epoxy coating line in offshore energy structures and provided facilities that had better resistance towards the saline condition and mechanical stress. These types of product innovations reinforce the supremacy of the epoxy coating in various industries that need the sturdy corrosion resistance.

Asia Pacific: The Core Growth Hub for Protective Coatings

- The Asia Pacific region leads the global protective coatings market because the region is experiencing high rate of infrastructure development, booming industrial ventures, and a growing marine and automotive sector. Increasing expenditure in developments of urbanization, transportation, and severe weather conditions of coastal areas simultaneously are impelling large-scale adaptation of high-performance protective coatings over a variety of applications.

- Nippon Paint in February 2024 increased capacity in its protective coatings production in India to meet increasing demand of the construction and the industrial industries and this is held as evidence of the strength of Indian regional consumption. This trend is enhanced due to the growing government sponsored infrastructure projects.

- The most promising marketplace of protective coatings is Asia Pacific because of its active industrial base and the development of the infrastructure.

Protective Coatings Market Ecosystem

The global protective coatings market is slightly consolidated, with Tier 1 companies such as Akzo Nobel N.V., PPG Industries, Sherwin-Williams, BASF SE, and Nippon Paint commanding significant market share through global reach and R&D capabilities. Tier 2 firms like Jotun, Kansai Paint, Hempel, and Asian Paints strengthen regional dominance, while Tier 3 players including Shalimar Paints and Yung Chi Paint focus on niche markets and local presence. From Porter’s perspective, buyer concentration is moderate due to diversified end-user industries, whereas supplier concentration is relatively high given dependency on specialty chemical raw materials, strengthening supplier bargaining power.

Recent Development and Strategic Overview:

- In July 2025, Nippon Paint expanded into India’s automotive paint-protection film segment with the n-SHIELD product line and a targeted commercial rollout, signifying a strategic push into vehicle aftercare and premium protection services. This adjacency enables Nippon Paint to capture higher-margin vehicle protection revenues while leveraging its strong aftermarket distribution and service networks.

- In May 2025, BASF Coatings launched biomass-balanced refinish products for the automotive refinish market, expanding its sustainability roadmap by offering solutions that reduce CO₂ footprint while maintaining OEM performance. The initiative targets fleet and repair operations seeking measurable lifecycle emissions reductions, and reinforces BASF’s strategy to scale low-carbon product portfolios across regions.

Report Scope

|

Attribute |

Detail |

|

Market Size in 2025 |

USD 13.6 Bn |

|

Market Forecast Value in 2035 |

USD 23.9 Bn |

|

Growth Rate (CAGR) |

5.8% |

|

Forecast Period |

2025 – 2035 |

|

Historical Data Available for |

2021 – 2024 |

|

Market Size Units |

US$ Billion for Value |

|

Report Format |

Electronic (PDF) + Excel |

|

Regions and Countries Covered |

|||||

|

North America |

Europe |

Asia Pacific |

Middle East |

Africa |

South America |

|

|

|

|

|

|

|

Companies Covered |

|||||

|

|

|

|

|

|

Protective Coatings Market Segmentation and Highlights

|

Segment |

Sub-segment |

|

By Resin Type |

|

|

By Technology |

|

|

By Substrate Type |

|

|

By Functionality |

|

|

By Product Type |

|

|

By Application Method |

|

|

By End-users |

|

|

By Distribution Channel |

|

Frequently Asked Questions

Table of Contents

- 1. Research Methodology and Assumptions

- 1.1. Definitions

- 1.2. Research Design and Approach

- 1.3. Data Collection Methods

- 1.4. Base Estimates and Calculations

- 1.5. Forecasting Models

- 1.5.1. Key Forecast Factors & Impact Analysis

- 1.6. Secondary Research

- 1.6.1. Open Sources

- 1.6.2. Paid Databases

- 1.6.3. Associations

- 1.7. Primary Research

- 1.7.1. Primary Sources

- 1.7.2. Primary Interviews with Stakeholders across Ecosystem

- 2. Executive Summary

- 2.1. Global Protective Coatings Market Outlook

- 2.1.1. Protective Coatings Market Size (Value - US$ Bn), and Forecasts, 2021-2035

- 2.1.2. Compounded Annual Growth Rate Analysis

- 2.1.3. Growth Opportunity Analysis

- 2.1.4. Segmental Share Analysis

- 2.1.5. Geographical Share Analysis

- 2.2. Market Analysis and Facts

- 2.3. Supply-Demand Analysis

- 2.4. Competitive Benchmarking

- 2.5. Go-to- Market Strategy

- 2.5.1. Customer/ End-use Industry Assessment

- 2.5.2. Growth Opportunity Data, 2025-2035

- 2.5.2.1. Regional Data

- 2.5.2.2. Country Data

- 2.5.2.3. Segmental Data

- 2.5.3. Identification of Potential Market Spaces

- 2.5.4. GAP Analysis

- 2.5.5. Potential Attractive Price Points

- 2.5.6. Prevailing Market Risks & Challenges

- 2.5.7. Preferred Sales & Marketing Strategies

- 2.5.8. Key Recommendations and Analysis

- 2.5.9. A Way Forward

- 2.1. Global Protective Coatings Market Outlook

- 3. Industry Data and Premium Insights

- 3.1. Global Chemicals & Materials Industry Overview, 2025

- 3.1.1. Industry Ecosystem Analysis

- 3.1.2. Key Trends for Chemicals & Materials Industry

- 3.1.3. Regional Distribution for Chemicals & Materials Industry

- 3.2. Supplier Customer Data

- 3.3. Technology Roadmap and Developments

- 3.4. Trade Analysis

- 3.4.1. Import & Export Analysis, 2025

- 3.4.2. Top Importing Countries

- 3.4.3. Top Exporting Countries

- 3.5. Trump Tariff Impact Analysis

- 3.5.1. Manufacturer

- 3.5.1.1. Based on the component & Raw material

- 3.5.2. Supply Chain

- 3.5.3. End Consumer

- 3.5.1. Manufacturer

- 3.6. Raw Material Analysis

- 3.1. Global Chemicals & Materials Industry Overview, 2025

- 4. Market Overview

- 4.1. Market Dynamics

- 4.1.1. Drivers

- 4.1.1.1. Increasing industrialization and urban infrastructure development requiring corrosion-resistant coatings

- 4.1.1.2. Growing demand for durable, high-performance coatings in oil & gas, marine, and automotive sectors

- 4.1.2. Restraints

- 4.1.2.1. Volatility in raw material prices affecting production costs

- 4.1.2.2. Stringent environmental and regulatory compliance requirements increasing operational complexity

- 4.1.1. Drivers

- 4.2. Key Trend Analysis

- 4.3. Regulatory Framework

- 4.3.1. Key Regulations, Norms, and Subsidies, by Key Countries

- 4.3.2. Tariffs and Standards

- 4.3.3. Impact Analysis of Regulations on the Market

- 4.4. Value Chain Analysis

- 4.4.1. Raw Material Suppliers

- 4.4.2. Protective Coating Manufacturers

- 4.4.3. Distributors/ Suppliers

- 4.4.4. End-users/ Customers

- 4.5. Cost Structure Analysis

- 4.5.1. Parameter’s Share for Cost Associated

- 4.5.2. COGP vs COGS

- 4.5.3. Profit Margin Analysis

- 4.6. Pricing Analysis

- 4.6.1. Regional Pricing Analysis

- 4.6.2. Segmental Pricing Trends

- 4.6.3. Factors Influencing Pricing

- 4.7. Porter’s Five Forces Analysis

- 4.8. PESTEL Analysis

- 4.9. Global Protective Coatings Market Demand

- 4.9.1. Historical Market Size - in Value (US$ Bn), 2020-2024

- 4.9.2. Current and Future Market Size - in Value (US$ Bn), 2025–2035

- 4.9.2.1. Y-o-Y Growth Trends

- 4.9.2.2. Absolute $ Opportunity Assessment

- 4.1. Market Dynamics

- 5. Competition Landscape

- 5.1. Competition structure

- 5.1.1. Fragmented v/s consolidated

- 5.2. Company Share Analysis, 2025

- 5.2.1. Global Company Market Share

- 5.2.2. By Region

- 5.2.2.1. North America

- 5.2.2.2. Europe

- 5.2.2.3. Asia Pacific

- 5.2.2.4. Middle East

- 5.2.2.5. Africa

- 5.2.2.6. South America

- 5.3. Product Comparison Matrix

- 5.3.1. Specifications

- 5.3.2. Market Positioning

- 5.3.3. Pricing

- 5.1. Competition structure

- 6. Global Protective Coatings Market Analysis, by Resin Type

- 6.1. Key Segment Analysis

- 6.2. Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, by Resin Type, 2021-2035

- 6.2.1. Epoxy Coatings

- 6.2.2. Polyurethane Coatings

- 6.2.3. Acrylic Coatings

- 6.2.4. Alkyd Coatings

- 6.2.5. Fluoropolymer Coatings

- 6.2.6. Silicone Coatings

- 6.2.7. Vinyl Ester Coatings

- 6.2.8. Polyaspartic Coatings

- 6.2.9. Others

- 7. Global Protective Coatings Market Analysis, by Technology

- 7.1. Key Segment Analysis

- 7.2. Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, by Technology, 2021-2035

- 7.2.1. Solvent-borne Coatings

- 7.2.2. Water-borne Coatings

- 7.2.3. Powder Coatings

- 7.2.4. UV-Curable Coatings

- 7.2.5. High Solids Coatings

- 7.2.6. Others

- 8. Global Protective Coatings Market Analysis, by Substrate Type

- 8.1. Key Segment Analysis

- 8.2. Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, by Substrate Type, 2021-2035

- 8.2.1. Metal

- 8.2.2. Concrete

- 8.2.3. Wood

- 8.2.4. Plastic

- 8.2.5. Fiberglass

- 8.2.6. Composite Materials

- 8.2.7. Others

- 9. Global Protective Coatings Market Analysis, by Functionality

- 9.1. Key Segment Analysis

- 9.2. Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, by Functionality, 2021-2035

- 9.2.1. Corrosion Resistance

- 9.2.2. Abrasion Resistance

- 9.2.3. Chemical Resistance

- 9.2.4. UV Protection

- 9.2.5. Fire Resistance

- 9.2.6. Anti-fouling

- 9.2.7. Waterproofing / Moisture Barrier

- 9.2.8. Thermal Resistance

- 9.2.9. Others

- 10. Global Protective Coatings Market Analysis, by Product Type

- 10.1. Key Segment Analysis

- 10.2. Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, by Product Type, 2021-2035

- 10.2.1. Primer Coatings

- 10.2.2. Intermediate Coatings

- 10.2.3. Topcoat Coatings

- 10.2.4. Tank Linings

- 10.2.5. Floor Coatings

- 10.2.6. Roof Coatings

- 10.2.7. Pipe Coatings

- 10.2.8. Heat-Resistant Coatings

- 10.2.9. Others

- 11. Global Protective Coatings Market Analysis, by Application Method

- 11.1. Key Segment Analysis

- 11.2. Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, by Application Method, 2021-2035

- 11.2.1. Spray Coating

- 11.2.2. Brush Coating

- 11.2.3. Roller Coating

- 11.2.4. Dip Coating

- 11.2.5. Electrostatic Coating

- 11.2.6. Others

- 12. Global Protective Coatings Market Analysis, by End-users

- 12.1. Key Segment Analysis

- 12.2. Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, by End-users, 2021-2035

- 12.2.1. Oil & Gas Industry

- 12.2.1.1. Offshore Platforms & Rigs

- 12.2.1.2. Refineries & Petrochemical Plants

- 12.2.1.3. Pipelines & Storage Tanks

- 12.2.1.4. Drilling Equipment

- 12.2.1.5. Others

- 12.2.2. Marine Industry

- 12.2.2.1. Ship Hulls & Superstructures

- 12.2.2.2. Offshore Vessels

- 12.2.2.3. Port Infrastructure

- 12.2.2.4. Underwater Equipment

- 12.2.2.5. Others

- 12.2.3. Infrastructure & Construction

- 12.2.3.1. Bridges & Highways

- 12.2.3.2. Buildings & Facilities

- 12.2.3.3. Water Treatment Plants

- 12.2.3.4. Tunnels & Underground Structures

- 12.2.3.5. Others

- 12.2.4. Power Generation

- 12.2.4.1. Thermal Power Plants

- 12.2.4.2. Nuclear Facilities

- 12.2.4.3. Renewable Energy (Wind, Solar)

- 12.2.4.4. Hydroelectric Dams

- 12.2.4.5. Others

- 12.2.5. Chemical Processing

- 12.2.5.1. Chemical Plants

- 12.2.5.2. Pharmaceutical Manufacturing

- 12.2.5.3. Food & Beverage Processing

- 12.2.5.4. Pulp & Paper Mills

- 12.2.5.5. Others

- 12.2.6. Automotive & Transportation

- 12.2.6.1. Automotive Components

- 12.2.6.2. Rail Infrastructure

- 12.2.6.3. Aerospace Components

- 12.2.6.4. Heavy Equipment

- 12.2.6.5. Others

- 12.2.7. Industrial Manufacturing

- 12.2.7.1. Steel Mills

- 12.2.7.2. Mining Equipment

- 12.2.7.3. General Manufacturing

- 12.2.7.4. Storage & Handling Equipment

- 12.2.7.5. Others

- 12.2.8. Water & Wastewater

- 12.2.8.1. Water Treatment Facilities

- 12.2.8.2. Sewage Treatment Plants

- 12.2.8.3. Desalination Plants

- 12.2.8.4. Water Distribution Systems

- 12.2.8.5. Others

- 12.2.9. Other End-Users

- 12.2.1. Oil & Gas Industry

- 13. Global Protective Coatings Market Analysis, by Distribution Channel

- 13.1. Key Segment Analysis

- 13.2. Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, by Distribution Channel, 2021-2035

- 13.2.1. Direct Sales

- 13.2.2. Distributors/Dealers

- 13.2.3. Online Platforms

- 14. Global Protective Coatings Market Analysis and Forecasts, by Region

- 14.1. Key Findings

- 14.2. Protective Coatings Market Size (Volume - Million Units and Value - US$ Mn), Analysis, and Forecasts, by Region, 2021-2035

- 14.2.1. North America

- 14.2.2. Europe

- 14.2.3. Asia Pacific

- 14.2.4. Middle East

- 14.2.5. Africa

- 14.2.6. South America

- 15. North America Protective Coatings Market Analysis

- 15.1. Key Segment Analysis

- 15.2. Regional Snapshot

- 15.3. North America Protective Coatings Market Size Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 15.3.1. Resin Type

- 15.3.2. Technology

- 15.3.3. Substrate Type

- 15.3.4. Functionality

- 15.3.5. Product Type

- 15.3.6. Application Method

- 15.3.7. End-users

- 15.3.8. Distribution Channel

- 15.3.9. Country

- 15.3.9.1. USA

- 15.3.9.2. Canada

- 15.3.9.3. Mexico

- 15.4. USA Protective Coatings Market

- 15.4.1. Country Segmental Analysis

- 15.4.2. Resin Type

- 15.4.3. Technology

- 15.4.4. Substrate Type

- 15.4.5. Functionality

- 15.4.6. Product Type

- 15.4.7. Application Method

- 15.4.8. End-users

- 15.4.9. Distribution Channel

- 15.5. Canada Protective Coatings Market

- 15.5.1. Country Segmental Analysis

- 15.5.2. Resin Type

- 15.5.3. Technology

- 15.5.4. Substrate Type

- 15.5.5. Functionality

- 15.5.6. Product Type

- 15.5.7. Application Method

- 15.5.8. End-users

- 15.5.9. Distribution Channel

- 15.6. Mexico Protective Coatings Market

- 15.6.1. Country Segmental Analysis

- 15.6.2. Resin Type

- 15.6.3. Technology

- 15.6.4. Substrate Type

- 15.6.5. Functionality

- 15.6.6. Product Type

- 15.6.7. Application Method

- 15.6.8. End-users

- 15.6.9. Distribution Channel

- 16. Europe Protective Coatings Market Analysis

- 16.1. Key Segment Analysis

- 16.2. Regional Snapshot

- 16.3. Europe Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 16.3.1. Resin Type

- 16.3.2. Technology

- 16.3.3. Substrate Type

- 16.3.4. Functionality

- 16.3.5. Product Type

- 16.3.6. Application Method

- 16.3.7. End-users

- 16.3.8. Distribution Channel

- 16.3.9. Country

- 16.3.9.1. Germany

- 16.3.9.2. United Kingdom

- 16.3.9.3. France

- 16.3.9.4. Italy

- 16.3.9.5. Spain

- 16.3.9.6. Netherlands

- 16.3.9.7. Nordic Countries

- 16.3.9.8. Poland

- 16.3.9.9. Russia & CIS

- 16.3.9.10. Rest of Europe

- 16.4. Germany Protective Coatings Market

- 16.4.1. Country Segmental Analysis

- 16.4.2. Resin Type

- 16.4.3. Technology

- 16.4.4. Substrate Type

- 16.4.5. Functionality

- 16.4.6. Product Type

- 16.4.7. Application Method

- 16.4.8. End-users

- 16.4.9. Distribution Channel

- 16.5. United Kingdom Protective Coatings Market

- 16.5.1. Country Segmental Analysis

- 16.5.2. Resin Type

- 16.5.3. Technology

- 16.5.4. Substrate Type

- 16.5.5. Functionality

- 16.5.6. Product Type

- 16.5.7. Application Method

- 16.5.8. End-users

- 16.5.9. Distribution Channel

- 16.6. France Protective Coatings Market

- 16.6.1. Country Segmental Analysis

- 16.6.2. Resin Type

- 16.6.3. Technology

- 16.6.4. Substrate Type

- 16.6.5. Functionality

- 16.6.6. Product Type

- 16.6.7. Application Method

- 16.6.8. End-users

- 16.6.9. Distribution Channel

- 16.7. Italy Protective Coatings Market

- 16.7.1. Country Segmental Analysis

- 16.7.2. Resin Type

- 16.7.3. Technology

- 16.7.4. Substrate Type

- 16.7.5. Functionality

- 16.7.6. Product Type

- 16.7.7. Application Method

- 16.7.8. End-users

- 16.7.9. Distribution Channel

- 16.8. Spain Protective Coatings Market

- 16.8.1. Country Segmental Analysis

- 16.8.2. Resin Type

- 16.8.3. Technology

- 16.8.4. Substrate Type

- 16.8.5. Functionality

- 16.8.6. Product Type

- 16.8.7. Application Method

- 16.8.8. End-users

- 16.8.9. Distribution Channel

- 16.9. Netherlands Protective Coatings Market

- 16.9.1. Country Segmental Analysis

- 16.9.2. Resin Type

- 16.9.3. Technology

- 16.9.4. Substrate Type

- 16.9.5. Functionality

- 16.9.6. Product Type

- 16.9.7. Application Method

- 16.9.8. End-users

- 16.9.9. Distribution Channel

- 16.10. Nordic Countries Protective Coatings Market

- 16.10.1. Country Segmental Analysis

- 16.10.2. Resin Type

- 16.10.3. Technology

- 16.10.4. Substrate Type

- 16.10.5. Functionality

- 16.10.6. Product Type

- 16.10.7. Application Method

- 16.10.8. End-users

- 16.10.9. Distribution Channel

- 16.11. Poland Protective Coatings Market

- 16.11.1. Country Segmental Analysis

- 16.11.2. Resin Type

- 16.11.3. Technology

- 16.11.4. Substrate Type

- 16.11.5. Functionality

- 16.11.6. Product Type

- 16.11.7. Application Method

- 16.11.8. End-users

- 16.11.9. Distribution Channel

- 16.12. Russia & CIS Protective Coatings Market

- 16.12.1. Country Segmental Analysis

- 16.12.2. Resin Type

- 16.12.3. Technology

- 16.12.4. Substrate Type

- 16.12.5. Functionality

- 16.12.6. Product Type

- 16.12.7. Application Method

- 16.12.8. End-users

- 16.12.9. Distribution Channel

- 16.13. Rest of Europe Protective Coatings Market

- 16.13.1. Country Segmental Analysis

- 16.13.2. Resin Type

- 16.13.3. Technology

- 16.13.4. Substrate Type

- 16.13.5. Functionality

- 16.13.6. Product Type

- 16.13.7. Application Method

- 16.13.8. End-users

- 16.13.9. Distribution Channel

- 17. Asia Pacific Protective Coatings Market Analysis

- 17.1. Key Segment Analysis

- 17.2. Regional Snapshot

- 17.3. East Asia Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 17.3.1. Resin Type

- 17.3.2. Technology

- 17.3.3. Substrate Type

- 17.3.4. Functionality

- 17.3.5. Product Type

- 17.3.6. Application Method

- 17.3.7. End-users

- 17.3.8. Distribution Channel

- 17.3.9. Country

- 17.3.9.1. China

- 17.3.9.2. India

- 17.3.9.3. Japan

- 17.3.9.4. South Korea

- 17.3.9.5. Australia and New Zealand

- 17.3.9.6. Indonesia

- 17.3.9.7. Malaysia

- 17.3.9.8. Thailand

- 17.3.9.9. Vietnam

- 17.3.9.10. Rest of Asia Pacific

- 17.4. China Protective Coatings Market

- 17.4.1. Country Segmental Analysis

- 17.4.2. Resin Type

- 17.4.3. Technology

- 17.4.4. Substrate Type

- 17.4.5. Functionality

- 17.4.6. Product Type

- 17.4.7. Application Method

- 17.4.8. End-users

- 17.4.9. Distribution Channel

- 17.5. India Protective Coatings Market

- 17.5.1. Country Segmental Analysis

- 17.5.2. Resin Type

- 17.5.3. Technology

- 17.5.4. Substrate Type

- 17.5.5. Functionality

- 17.5.6. Product Type

- 17.5.7. Application Method

- 17.5.8. End-users

- 17.5.9. Distribution Channel

- 17.6. Japan Protective Coatings Market

- 17.6.1. Country Segmental Analysis

- 17.6.2. Resin Type

- 17.6.3. Technology

- 17.6.4. Substrate Type

- 17.6.5. Functionality

- 17.6.6. Product Type

- 17.6.7. Application Method

- 17.6.8. End-users

- 17.6.9. Distribution Channel

- 17.7. South Korea Protective Coatings Market

- 17.7.1. Country Segmental Analysis

- 17.7.2. Resin Type

- 17.7.3. Technology

- 17.7.4. Substrate Type

- 17.7.5. Functionality

- 17.7.6. Product Type

- 17.7.7. Application Method

- 17.7.8. End-users

- 17.7.9. Distribution Channel

- 17.8. Australia and New Zealand Protective Coatings Market

- 17.8.1. Country Segmental Analysis

- 17.8.2. Resin Type

- 17.8.3. Technology

- 17.8.4. Substrate Type

- 17.8.5. Functionality

- 17.8.6. Product Type

- 17.8.7. Application Method

- 17.8.8. End-users

- 17.8.9. Distribution Channel

- 17.9. Indonesia Protective Coatings Market

- 17.9.1. Country Segmental Analysis

- 17.9.2. Resin Type

- 17.9.3. Technology

- 17.9.4. Substrate Type

- 17.9.5. Functionality

- 17.9.6. Product Type

- 17.9.7. Application Method

- 17.9.8. End-users

- 17.9.9. Distribution Channel

- 17.10. Malaysia Protective Coatings Market

- 17.10.1. Country Segmental Analysis

- 17.10.2. Resin Type

- 17.10.3. Technology

- 17.10.4. Substrate Type

- 17.10.5. Functionality

- 17.10.6. Product Type

- 17.10.7. Application Method

- 17.10.8. End-users

- 17.10.9. Distribution Channel

- 17.11. Thailand Protective Coatings Market

- 17.11.1. Country Segmental Analysis

- 17.11.2. Resin Type

- 17.11.3. Technology

- 17.11.4. Substrate Type

- 17.11.5. Functionality

- 17.11.6. Product Type

- 17.11.7. Application Method

- 17.11.8. End-users

- 17.11.9. Distribution Channel

- 17.12. Vietnam Protective Coatings Market

- 17.12.1. Country Segmental Analysis

- 17.12.2. Resin Type

- 17.12.3. Technology

- 17.12.4. Substrate Type

- 17.12.5. Functionality

- 17.12.6. Product Type

- 17.12.7. Application Method

- 17.12.8. End-users

- 17.12.9. Distribution Channel

- 17.13. Rest of Asia Pacific Protective Coatings Market

- 17.13.1. Country Segmental Analysis

- 17.13.2. Resin Type

- 17.13.3. Technology

- 17.13.4. Substrate Type

- 17.13.5. Functionality

- 17.13.6. Product Type

- 17.13.7. Application Method

- 17.13.8. End-users

- 17.13.9. Distribution Channel

- 18. Middle East Protective Coatings Market Analysis

- 18.1. Key Segment Analysis

- 18.2. Regional Snapshot

- 18.3. Middle East Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 18.3.1. Resin Type

- 18.3.2. Technology

- 18.3.3. Substrate Type

- 18.3.4. Functionality

- 18.3.5. Product Type

- 18.3.6. Application Method

- 18.3.7. End-users

- 18.3.8. Distribution Channel

- 18.3.9. Country

- 18.3.9.1. Turkey

- 18.3.9.2. UAE

- 18.3.9.3. Saudi Arabia

- 18.3.9.4. Israel

- 18.3.9.5. Rest of Middle East

- 18.4. Turkey Protective Coatings Market

- 18.4.1. Country Segmental Analysis

- 18.4.2. Resin Type

- 18.4.3. Technology

- 18.4.4. Substrate Type

- 18.4.5. Functionality

- 18.4.6. Product Type

- 18.4.7. Application Method

- 18.4.8. End-users

- 18.4.9. Distribution Channel

- 18.5. UAE Protective Coatings Market

- 18.5.1. Country Segmental Analysis

- 18.5.2. Resin Type

- 18.5.3. Technology

- 18.5.4. Substrate Type

- 18.5.5. Functionality

- 18.5.6. Product Type

- 18.5.7. Application Method

- 18.5.8. End-users

- 18.5.9. Distribution Channel

- 18.6. Saudi Arabia Protective Coatings Market

- 18.6.1. Country Segmental Analysis

- 18.6.2. Resin Type

- 18.6.3. Technology

- 18.6.4. Substrate Type

- 18.6.5. Functionality

- 18.6.6. Product Type

- 18.6.7. Application Method

- 18.6.8. End-users

- 18.6.9. Distribution Channel

- 18.7. Israel Protective Coatings Market

- 18.7.1. Country Segmental Analysis

- 18.7.2. Resin Type

- 18.7.3. Technology

- 18.7.4. Substrate Type

- 18.7.5. Functionality

- 18.7.6. Product Type

- 18.7.7. Application Method

- 18.7.8. End-users

- 18.7.9. Distribution Channel

- 18.8. Rest of Middle East Protective Coatings Market

- 18.8.1. Country Segmental Analysis

- 18.8.2. Resin Type

- 18.8.3. Technology

- 18.8.4. Substrate Type

- 18.8.5. Functionality

- 18.8.6. Product Type

- 18.8.7. Application Method

- 18.8.8. End-users

- 18.8.9. Distribution Channel

- 19. Africa Protective Coatings Market Analysis

- 19.1. Key Segment Analysis

- 19.2. Regional Snapshot

- 19.3. Africa Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 19.3.1. Resin Type

- 19.3.2. Technology

- 19.3.3. Substrate Type

- 19.3.4. Functionality

- 19.3.5. Product Type

- 19.3.6. Application Method

- 19.3.7. End-users

- 19.3.8. Distribution Channel

- 19.3.9. Country

- 19.3.9.1. South Africa

- 19.3.9.2. Egypt

- 19.3.9.3. Nigeria

- 19.3.9.4. Algeria

- 19.3.9.5. Rest of Africa

- 19.4. South Africa Protective Coatings Market

- 19.4.1. Country Segmental Analysis

- 19.4.2. Resin Type

- 19.4.3. Technology

- 19.4.4. Substrate Type

- 19.4.5. Functionality

- 19.4.6. Product Type

- 19.4.7. Application Method

- 19.4.8. End-users

- 19.4.9. Distribution Channel

- 19.5. Egypt Protective Coatings Market

- 19.5.1. Country Segmental Analysis

- 19.5.2. Resin Type

- 19.5.3. Technology

- 19.5.4. Substrate Type

- 19.5.5. Functionality

- 19.5.6. Product Type

- 19.5.7. Application Method

- 19.5.8. End-users

- 19.5.9. Distribution Channel

- 19.6. Nigeria Protective Coatings Market

- 19.6.1. Country Segmental Analysis

- 19.6.2. Resin Type

- 19.6.3. Technology

- 19.6.4. Substrate Type

- 19.6.5. Functionality

- 19.6.6. Product Type

- 19.6.7. Application Method

- 19.6.8. End-users

- 19.6.9. Distribution Channel

- 19.7. Algeria Protective Coatings Market

- 19.7.1. Country Segmental Analysis

- 19.7.2. Resin Type

- 19.7.3. Technology

- 19.7.4. Substrate Type

- 19.7.5. Functionality

- 19.7.6. Product Type

- 19.7.7. Application Method

- 19.7.8. End-users

- 19.7.9. Distribution Channel

- 19.8. Rest of Africa Protective Coatings Market

- 19.8.1. Country Segmental Analysis

- 19.8.2. Resin Type

- 19.8.3. Technology

- 19.8.4. Substrate Type

- 19.8.5. Functionality

- 19.8.6. Product Type

- 19.8.7. Application Method

- 19.8.8. End-users

- 19.8.9. Distribution Channel

- 20. South America Protective Coatings Market Analysis

- 20.1. Key Segment Analysis

- 20.2. Regional Snapshot

- 20.3. Central and South Africa Protective Coatings Market Size (Value - US$ Bn), Analysis, and Forecasts, 2021-2035

- 20.3.1. Resin Type

- 20.3.2. Technology

- 20.3.3. Substrate Type

- 20.3.4. Functionality

- 20.3.5. Product Type

- 20.3.6. Application Method

- 20.3.7. End-users

- 20.3.8. Distribution Channel

- 20.3.9. Country

- 20.3.9.1. Brazil

- 20.3.9.2. Argentina

- 20.3.9.3. Rest of South America

- 20.4. Brazil Protective Coatings Market

- 20.4.1. Country Segmental Analysis

- 20.4.2. Resin Type

- 20.4.3. Technology

- 20.4.4. Substrate Type

- 20.4.5. Functionality

- 20.4.6. Product Type

- 20.4.7. Application Method

- 20.4.8. End-users

- 20.4.9. Distribution Channel

- 20.5. Argentina Protective Coatings Market

- 20.5.1. Country Segmental Analysis

- 20.5.2. Resin Type

- 20.5.3. Technology

- 20.5.4. Substrate Type

- 20.5.5. Functionality

- 20.5.6. Product Type

- 20.5.7. Application Method

- 20.5.8. End-users

- 20.5.9. Distribution Channel

- 20.6. Rest of South America Protective Coatings Market

- 20.6.1. Country Segmental Analysis

- 20.6.2. Resin Type

- 20.6.3. Technology

- 20.6.4. Substrate Type

- 20.6.5. Functionality

- 20.6.6. Product Type

- 20.6.7. Application Method

- 20.6.8. End-users

- 20.6.9. Distribution Channel

- 21. Key Players/ Company Profile

- 21.1. Akzo Nobel N.V.

- 21.1.1. Company Details/ Overview

- 21.1.2. Company Financials

- 21.1.3. Key Customers and Competitors

- 21.1.4. Business/ Industry Portfolio

- 21.1.5. Product Portfolio/ Specification Details

- 21.1.6. Pricing Data

- 21.1.7. Strategic Overview

- 21.1.8. Recent Developments

- 21.2. Asian Paints Ltd.

- 21.3. Axalta Coating Systems Ltd.

- 21.4. BASF SE

- 21.5. Beckers Group

- 21.6. Berger Paints India Limited

- 21.7. Carboline Company (RPM International)

- 21.8. DAW SE

- 21.9. Hempel A/S

- 21.10. Jotun A/S

- 21.11. Kansai Paint Co., Ltd.

- 21.12. Nippon Paint Holdings Co., Ltd.

- 21.13. PPG Industries, Inc.

- 21.14. RPM International Inc.

- 21.15. Sika AG

- 21.16. The Sherwin-Williams Company

- 21.17. Tikkurila Oyj

- 21.18. Tnemec Company, Inc.

- 21.19. Valspar Corporation

- 21.20. Weilburger Coatings GmbH

- 21.21. Wörwag Coatings GmbH & Co. KG

- 21.22. Wacker Chemie AG

- 21.23. Shalimar Paints Ltd.

- 21.24. Yung Chi Paint & Varnish Mfg. Co. Ltd.

- 21.25. Other Key Players

- 21.1. Akzo Nobel N.V.

Note* - This is just tentative list of players. While providing the report, we will cover more number of players based on their revenue and share for each geography

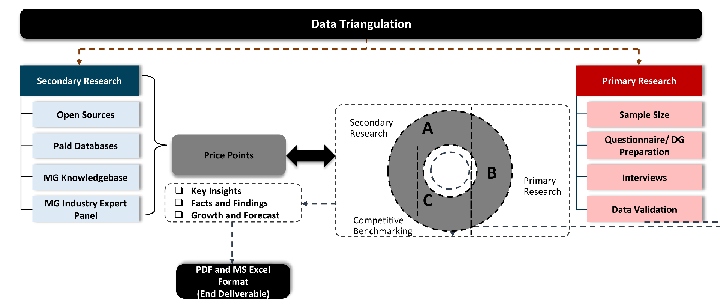

Research Design

Our research design integrates both demand-side and supply-side analysis through a balanced combination of primary and secondary research methodologies. By utilizing both bottom-up and top-down approaches alongside rigorous data triangulation methods, we deliver robust market intelligence that supports strategic decision-making.

MarketGenics' comprehensive research design framework ensures the delivery of accurate, reliable, and actionable market intelligence. Through the integration of multiple research approaches, rigorous validation processes, and expert analysis, we provide our clients with the insights needed to make informed strategic decisions and capitalize on market opportunities.

MarketGenics leverages a dedicated industry panel of experts and a comprehensive suite of paid databases to effectively collect, consolidate, and analyze market intelligence.

Our approach has consistently proven to be reliable and effective in generating accurate market insights, identifying key industry trends, and uncovering emerging business opportunities.

Through both primary and secondary research, we capture and analyze critical company-level data such as manufacturing footprints, including technical centers, R&D facilities, sales offices, and headquarters.

Our expert panel further enhances our ability to estimate market size for specific brands based on validated field-level intelligence.

Our data mining techniques incorporate both parametric and non-parametric methods, allowing for structured data collection, sorting, processing, and cleaning.

Demand projections are derived from large-scale data sets analyzed through proprietary algorithms, culminating in robust and reliable market sizing.

Research Approach

The bottom-up approach builds market estimates by starting with the smallest addressable market units and systematically aggregating them to create comprehensive market size projections.

This method begins with specific, granular data points and builds upward to create the complete market landscape.

Customer Analysis → Segmental Analysis → Geographical Analysis

The top-down approach starts with the broadest possible market data and systematically narrows it down through a series of filters and assumptions to arrive at specific market segments or opportunities.

This method begins with the big picture and works downward to increasingly specific market slices.

TAM → SAM → SOM

Research Methods

Desk / Secondary Research

While analysing the market, we extensively study secondary sources, directories, and databases to identify and collect information useful for this technical, market-oriented, and commercial report. Secondary sources that we utilize are not only the public sources, but it is a combination of Open Source, Associations, Paid Databases, MG Repository & Knowledgebase, and others.

- Company websites, annual reports, financial reports, broker reports, and investor presentations

- National government documents, statistical databases and reports

- News articles, press releases and web-casts specific to the companies operating in the market, Magazines, reports, and others

- We gather information from commercial data sources for deriving company specific data such as segmental revenue, share for geography, product revenue, and others

- Internal and external proprietary databases (industry-specific), relevant patent, and regulatory databases

- Governing Bodies, Government Organizations

- Relevant Authorities, Country-specific Associations for Industries

We also employ the model mapping approach to estimate the product level market data through the players' product portfolio

Primary Research

Primary research/ interviews is vital in analyzing the market. Most of the cases involves paid primary interviews. Primary sources include primary interviews through e-mail interactions, telephonic interviews, surveys as well as face-to-face interviews with the different stakeholders across the value chain including several industry experts.

| Type of Respondents | Number of Primaries |

|---|---|

| Tier 2/3 Suppliers | ~20 |

| Tier 1 Suppliers | ~25 |

| End-users | ~25 |

| Industry Expert/ Panel/ Consultant | ~30 |

| Total | ~100 |

MG Knowledgebase

• Repository of industry blog, newsletter and case studies

• Online platform covering detailed market reports, and company profiles

Forecasting Factors and Models

Forecasting Factors

- Historical Trends – Past market patterns, cycles, and major events that shaped how markets behave over time. Understanding past trends helps predict future behavior.

- Industry Factors – Specific characteristics of the industry like structure, regulations, and innovation cycles that affect market dynamics.

- Macroeconomic Factors – Economic conditions like GDP growth, inflation, and employment rates that affect how much money people have to spend.

- Demographic Factors – Population characteristics like age, income, and location that determine who can buy your product.

- Technology Factors – How quickly people adopt new technology and how much technology infrastructure exists.

- Regulatory Factors – Government rules, laws, and policies that can help or restrict market growth.

- Competitive Factors – Analyzing competition structure such as degree of competition and bargaining power of buyers and suppliers.

Forecasting Models / Techniques

Multiple Regression Analysis

- Identify and quantify factors that drive market changes

- Statistical modeling to establish relationships between market drivers and outcomes

Time Series Analysis – Seasonal Patterns

- Understand regular cyclical patterns in market demand

- Advanced statistical techniques to separate trend, seasonal, and irregular components

Time Series Analysis – Trend Analysis

- Identify underlying market growth patterns and momentum

- Statistical analysis of historical data to project future trends

Expert Opinion – Expert Interviews

- Gather deep industry insights and contextual understanding

- In-depth interviews with key industry stakeholders

Multi-Scenario Development

- Prepare for uncertainty by modeling different possible futures

- Creating optimistic, pessimistic, and most likely scenarios

Time Series Analysis – Moving Averages

- Sophisticated forecasting for complex time series data

- Auto-regressive integrated moving average models with seasonal components

Econometric Models

- Apply economic theory to market forecasting

- Sophisticated economic models that account for market interactions

Expert Opinion – Delphi Method

- Harness collective wisdom of industry experts

- Structured, multi-round expert consultation process

Monte Carlo Simulation

- Quantify uncertainty and probability distributions

- Thousands of simulations with varying input parameters

Research Analysis

Our research framework is built upon the fundamental principle of validating market intelligence from both demand and supply perspectives. This dual-sided approach ensures comprehensive market understanding and reduces the risk of single-source bias.

Demand-Side Analysis: We understand end-user/application behavior, preferences, and market needs along with the penetration of the product for specific application.

Supply-Side Analysis: We estimate overall market revenue, analyze the segmental share along with industry capacity, competitive landscape, and market structure.

Validation & Evaluation

Data triangulation is a validation technique that uses multiple methods, sources, or perspectives to examine the same research question, thereby increasing the credibility and reliability of research findings. In market research, triangulation serves as a quality assurance mechanism that helps identify and minimize bias, validate assumptions, and ensure accuracy in market estimates.

- Data Source Triangulation – Using multiple data sources to examine the same phenomenon

- Methodological Triangulation – Using multiple research methods to study the same research question

- Investigator Triangulation – Using multiple researchers or analysts to examine the same data

- Theoretical Triangulation – Using multiple theoretical perspectives to interpret the same data

Custom Market Research Services

We will customise the research for you, in case the report listed above does not meet your requirements.

Get 10% Free Customisation